Lincoln Navigator: Rear End Sheet Metal Repairs / Rear Crossmember. Removal and Installation

Special Tool(s) / General Equipment

| 6.5 mm Drill Bit | |

| Polydrive Bit Socket | |

| Rivet Gun | |

| Self-Piercing Rivet (SPR) Remover/Installer | |

| Belt Sander | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTICE: Panel sectioning is prohibited within 50 mm of door hinge, door striker, restraints and suspension anchoring points.

NOTE: Self-piercing rivet (SPR) fasteners may not be placed directly over original self-piercing rivet (SPR) location. They must be placed adjacent to original location matching original quantity.

NOTE: Aluminum body panels are highly receptive to heat transfer. With the extensive use of structural adhesives and non-structural sealers used in vehicle construction, the potential of heat transfer could impact adhesives and sealers in non-associated panels during the repair process. Many repairs areas that utilize structural adhesive may be separated after fastener removal by using a panel chisel along the joint/flange. Using heat not exceeding 425° F to loosen a bonded panel should only be done when all panels in the joint will be replaced and new adhesive applied.

NOTE: Flow-drill screw (FDS) fasteners are not reused. Remove and discard.

NOTE: Right-hand (RH) side shown, left-hand (LH) side similar.

NOTE: Standard wheelbase shown, long wheelbase similar.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If Necessary:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

On Both Sides: Remove the closeout panel only.

Refer to: Rear Lamp Mounting Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

On Both Sides:

Remove the floor panel reinforcement.

Refer to: Rear Floor Panel Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

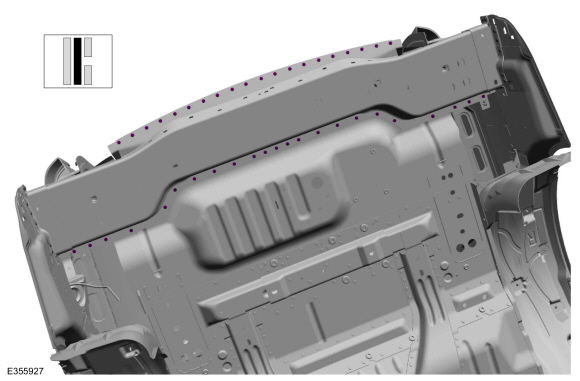

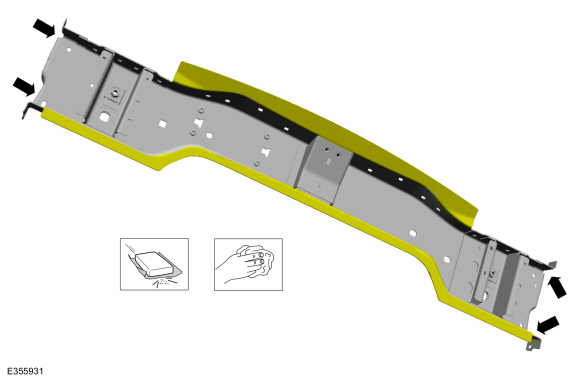

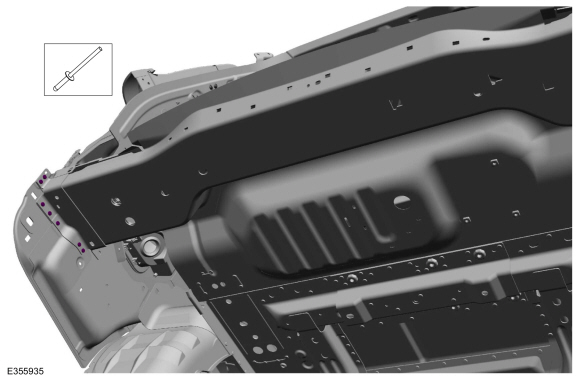

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

|

-

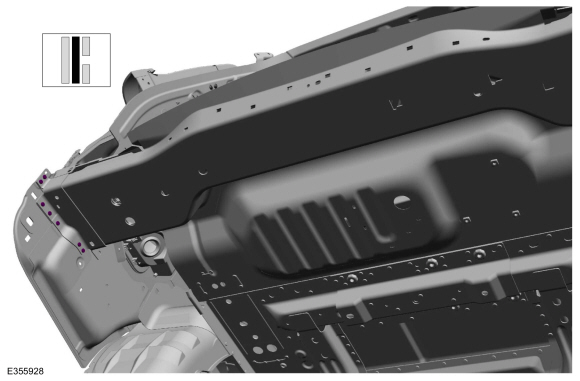

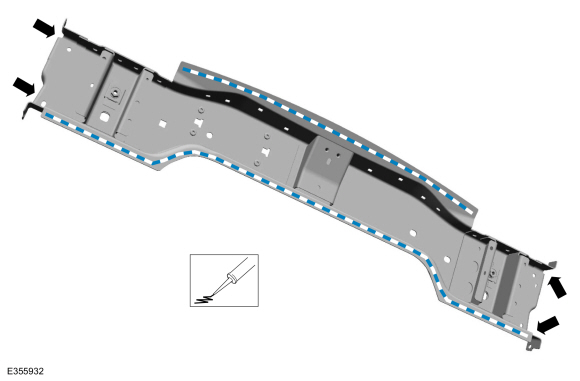

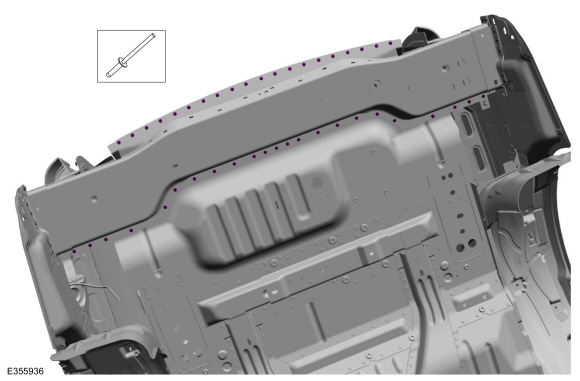

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

|

-

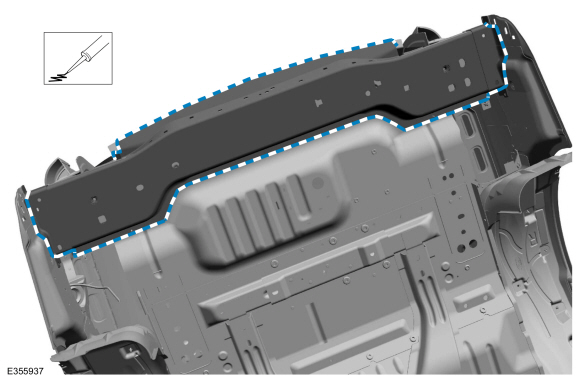

Break the adhesive bond and remove the rear crossmember.

|

Installation

NOTICE: Panel sectioning is prohibited within 50 mm of door hinge, door striker, restraints and suspension anchoring points.

NOTE: Self-piercing rivet (SPR) fasteners may not be placed directly over original self-piercing rivet (SPR) location. They must be placed adjacent to original location matching original quantity.

NOTE: Aluminum body panels are highly receptive to heat transfer. With the extensive use of structural adhesives and non-structural sealers used in vehicle construction, the potential of heat transfer could impact adhesives and sealers in non-associated panels during the repair process. Many repairs areas that utilize structural adhesive may be separated after fastener removal by using a panel chisel along the joint/flange. Using heat not exceeding 425° F to loosen a bonded panel should only be done when all panels in the joint will be replaced and new adhesive applied.

NOTE: Right-hand (RH) side shown, left-hand (LH) side similar.

NOTE: Standard wheelbase shown, long wheelbase similar.

-

80-120 Grit Sand Paper:

Sand to remove old adhesive, paint, e-coat and clean.

|

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

|

-

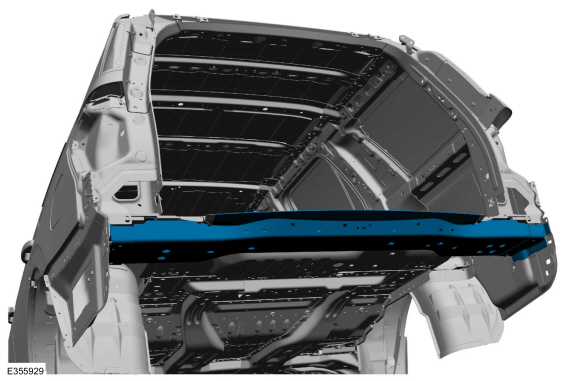

Apply adhesive.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

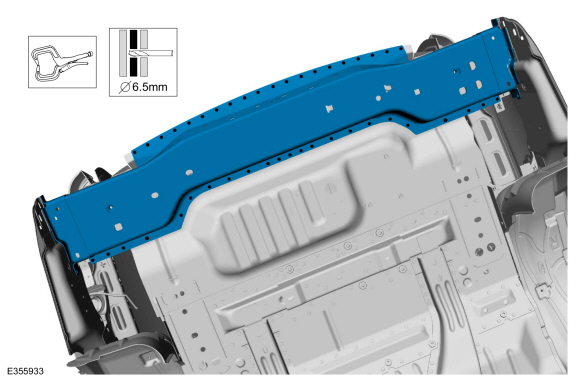

Install, properly position and clamp the rear crossmember, drill for fasteners.

Use the General Equipment: Locking Pliers

Use the General Equipment: 6.5 mm Drill Bit

|

-

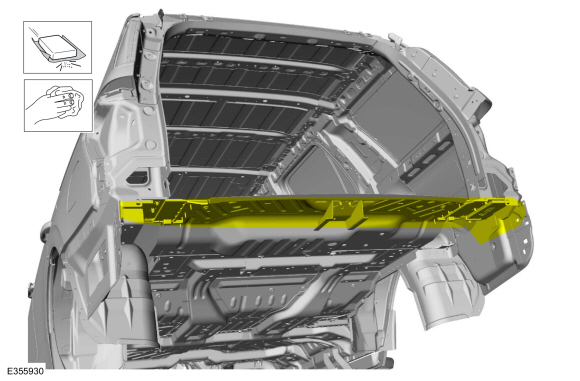

On Both Sides:

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

|

-

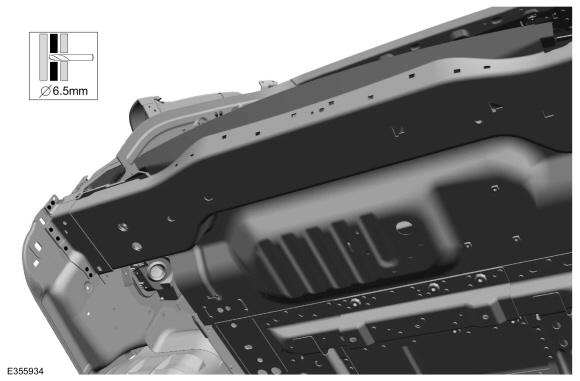

On Both Sides:

Install the fasteners.

Use the General Equipment: Rivet GunItem SPR Number SPR Code Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel Pro- Spot ® Mandrel Blind Rivet Solid rivet Rivnut® 1 - - - - W702512-S900C - -

|

-

Install the fasteners.

Use the General Equipment: Rivet GunItem SPR Number SPR Code Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel Pro- Spot ® Mandrel Blind Rivet Solid rivet Rivnut® 1 - - - - W702512-S900C - -

|

-

Seam Sealing:

All seams must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

|

-

Refinish the repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

On Both Sides: Install the closeout panel.

Refer to: Rear Lamp Mounting Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

On Both Sides:

Install the rear floor panel reinforcement.

Refer to: Rear Floor Panel Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Rear Floor Panel. Removal and Installation

Rear Floor Panel. Removal and Installation

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Blind Rivet Gun

Knife

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, 3M™ 08308, LORD Fuso..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Voice Microphone. Removal and Installation

Removal Vehicles equipped with dual voice microphones Lower the headliner. Refer to: Headliner - Lowering (501-05 Interior Trim and Ornamentation, Removal and Installation). Disconnect the electrical connector. Release the tabs and remove the voice microphones. Vehicl..

Lincoln Navigator 2018-2026 Workshop Manual: Climate Control System - System Operation and Component Description. Description and Operation

System Operation System Diagram E371291 *.sttxt { visibility: hidden; } *.stcallout { visibility: visible; } 1 GWM 2 Cabin heater coolant pump 3 Externally Controlled Variable Dsiplacement Compressor (EVDC) ..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Transmission Fluid Level Check. General Procedures

- Rear Bumper. Removal and Installation

- Remote Function Actuator (RFA) Module. Removal and Installation

- Liftgate Trim Panel. Removal and Installation

- SYNC Module [APIM]. Removal and Installation

Front Driveshaft. Removal and Installation

Special Tool(s) / General Equipment

Crimping ToolMaterials

Name Specification Motorcraft® Premium Long-Life GreaseXG-1-E1 ESA-M1C75-B

Removal

With the vehicle in NEUTRAL, position the vehicle on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

Remove the bolts and the transmission shield.