Lincoln Navigator: Rear End Sheet Metal Repairs / Rear Floor Panel. Removal and Installation

Special Tool(s) /

General Equipment

| 6.5 mm Drill Bit |

| Self-Piercing Rivet (SPR) Remover/Installer |

| Belt Sander |

| Blind Rivet Gun |

| Knife |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

Removal

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

Flow drill screws are not reused. Remove and discard.

NOTE:

Short wheelbase (SWB) shown, long wheelbase (LWB) similar.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Verify the vehicle is dimensionally correct.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the D-pillar trim.

Refer to: D-Pillar Trim Panel - Long Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel - Short Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the loadspace trim panels.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the subwoofer speaker.

Refer to: Subwoofer Speaker (415-00 Information and Entertainment

System - General Information - Vehicles With: SYNC 4, Removal and

Installation).

-

Remove the fuel tank filler pipe.

Refer to: Fuel Tank Filler Pipe (310-01 Fuel Tank and Lines - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Position aside the carpeting, all modules and wiring harnesses.

-

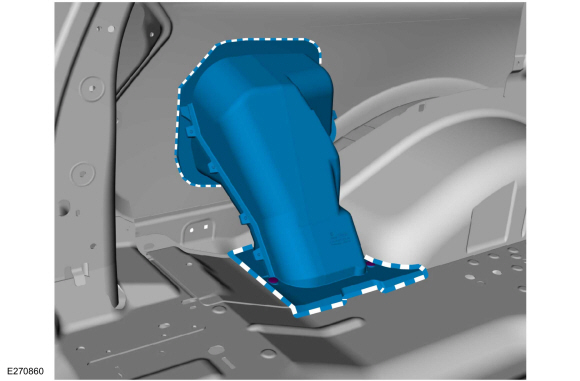

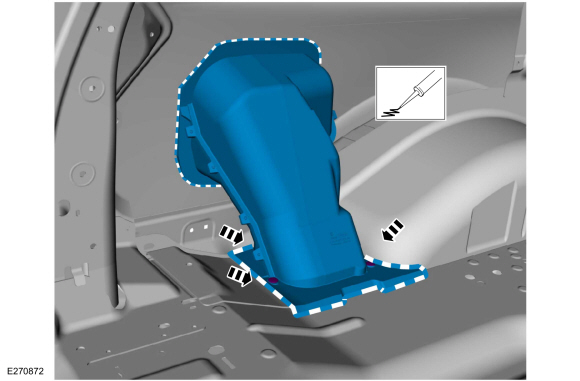

Cut the NVH foam attaching the fuel pipe housing and remove.

Use the General Equipment: Knife

-

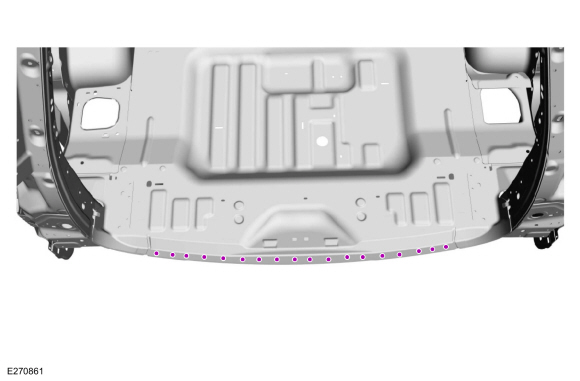

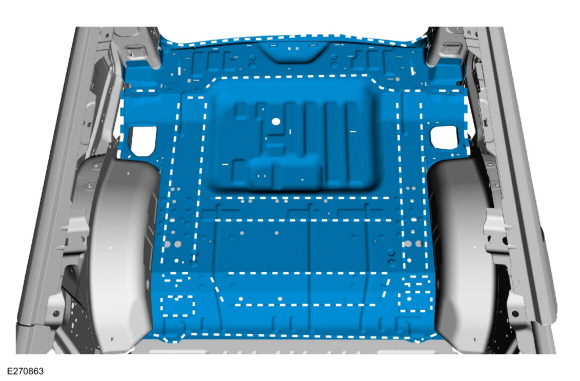

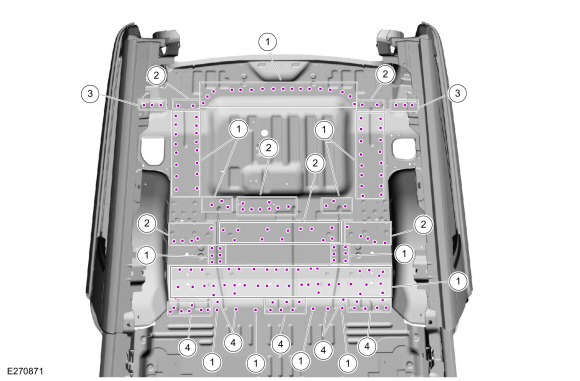

Remove the rivet fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

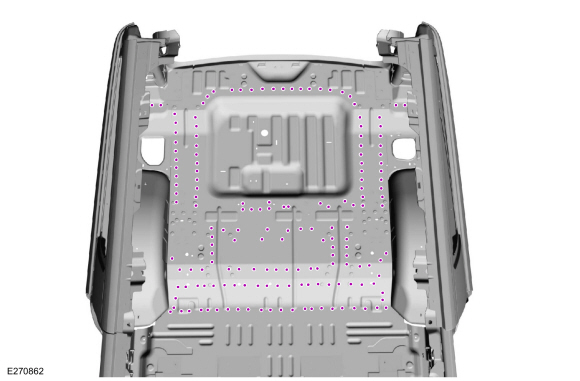

Remove the rivet fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

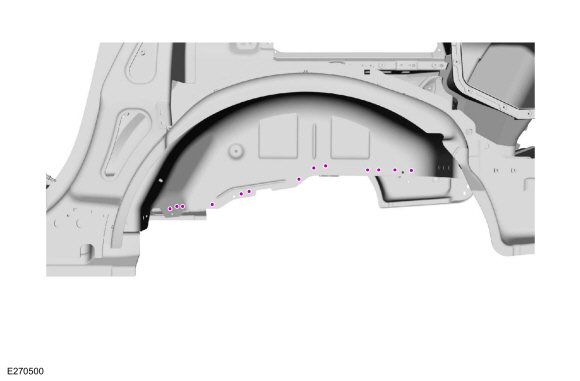

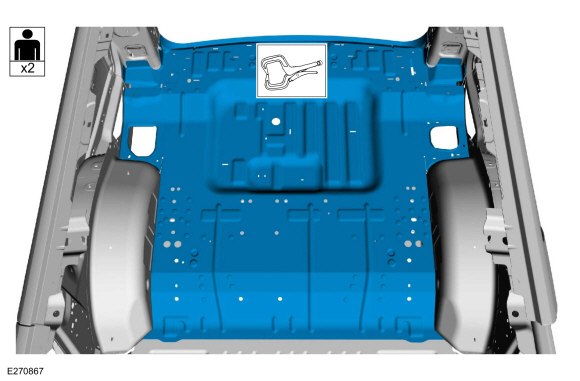

On Both Sides:

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Break the adhesive bond and remove the rear floor panel.

Installation

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

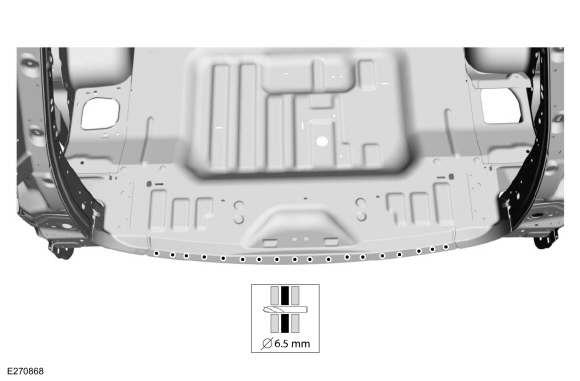

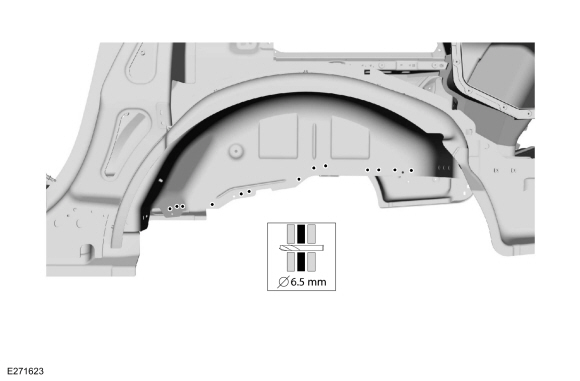

Blind or solid rivet fasteners may be used in place of SPR fasteners

after enlarging holes to 6.5 mm and must equal original quantity.

-

Use a hammer and dolly dedicated to aluminum repair to repair any damage to the flange mating surfaces.

Refer to: Special Repair Considerations for Aluminum Repairs (501-25

Body Repairs - General Information, Description and Operation).

-

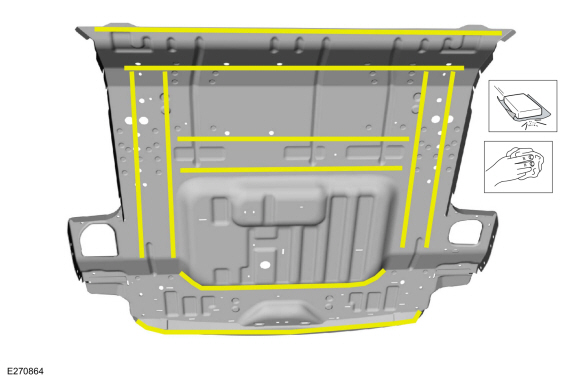

80-120 Grit Sand Paper:

Sand and clean the replacement floor panel mating surfaces.

-

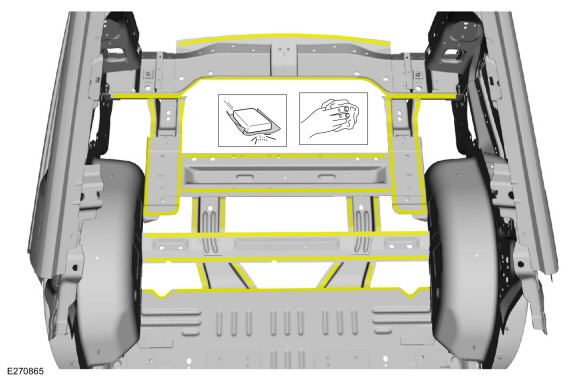

80-120 Grit Sand Paper:

Sand and clean the underbody mating surfaces.

-

Apply adhesive to the mating surfaces, and NVH foam to D-pillar corners as noted during removal.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

With the aid of an assistant, position and install the floor panel.

Use the General Equipment: Locking Pliers

-

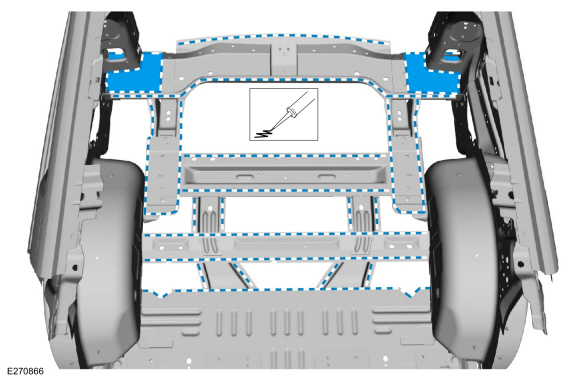

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

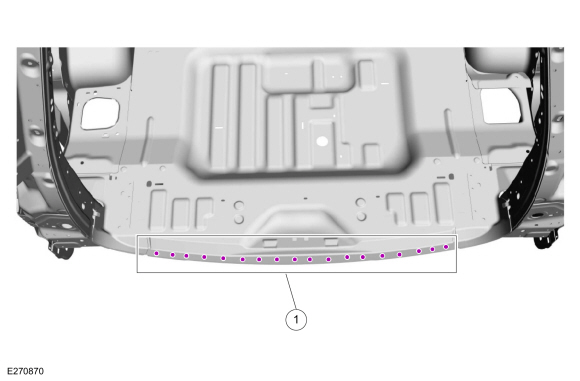

Install blind rivet fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

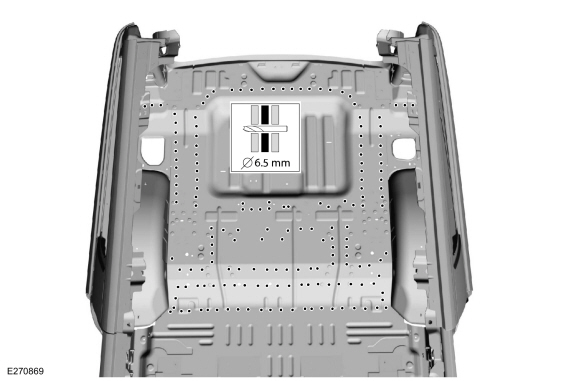

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install blind rivet fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W708778-S900C

|

-

|

-

|

|

4

|

-

|

-

|

-

|

-

|

W707638-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

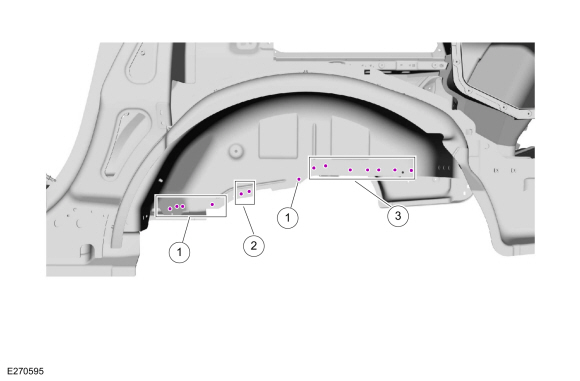

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install rivet fasteners on both sides.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W707638-S900C

|

W790377-S900

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W708777-S900C

|

W790377-S900

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W702512-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Metal finish the repair using typical aluminum metal finishing techniques and a fiber-based body filler.

Refer to: Special Repair Considerations for Aluminum Repairs (501-25

Body Repairs - General Information, Description and Operation).

-

Seam Sealing:

All areas must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair area using a Ford approved paint system and typical refinishing techniques.

-

Apply flexible foam to fuel pipe housing flanges, install push clips and clamp in position.

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install the fuel tank filler pipe.

Refer to: Fuel Tank Filler Pipe (310-01 Fuel Tank and Lines - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the subwoofer speaker.

Refer to: Subwoofer Speaker (415-00 Information and Entertainment

System - General Information - Vehicles With: SYNC 4, Removal and

Installation).

-

Reposition all modules, wiring harnesses and the carpeting to original locations.

-

Install the D-pillar trim.

Refer to: D-Pillar Trim Panel - Long Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel - Short Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Install the loadspace trim panels.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Polydrive Bit Socket

Rivet Gun

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, 3M™ 08308, ..

Other information:

Removal

Remove the transmission fluid pan, gasket and filter.

Refer to: Transmission Fluid Pan, Gasket and Filter (307-01 Automatic

Transmission - 10-Speed Automatic Transmission – 10R80, Removal and

Installation).

Slide the plastic lock to the unlock position. While

pressing the plastic tab, disconnect the electrical connector.

..

Symptom Chart

E Clutch

For E clutch operation, REFER to: E Clutch (307-01 Automatic Transmission - 10-Speed Automatic Transmission – 10R80, Description and Operation).

E Clutch

Condition

Possible Sources

Action

E clutch does not apply

SSE mechanically stuck OFF

INSTALL a new sole..

Rear Floor Panel Crossmember. Removal and Installation

Rear Floor Panel Crossmember. Removal and Installation