Lincoln Navigator: Driveshaft / Front Driveshaft. Removal and Installation

Special Tool(s) / General Equipment

| Crimping Tool |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Premium Long-Life Grease XG-1-E1 |

ESA-M1C75-B |

Removal

-

With the vehicle in NEUTRAL, position the vehicle on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

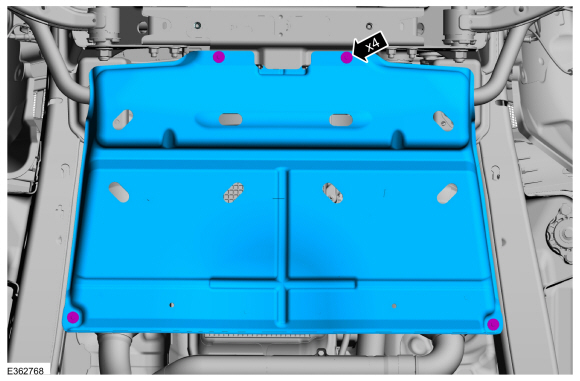

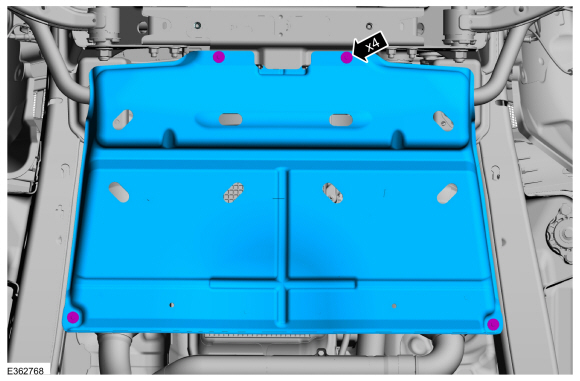

Remove the bolts and the transmission shield.

|

-

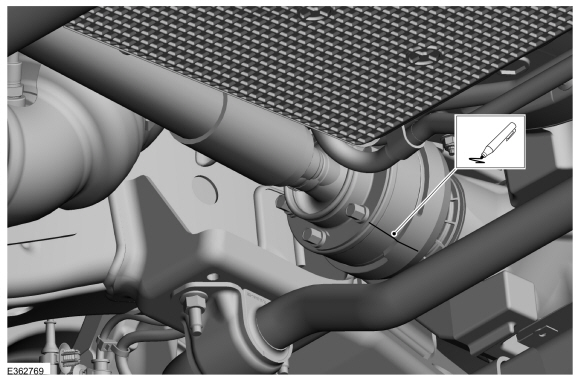

Index-mark the front driveshaft flange CV joint to the pinion flange cup.

|

-

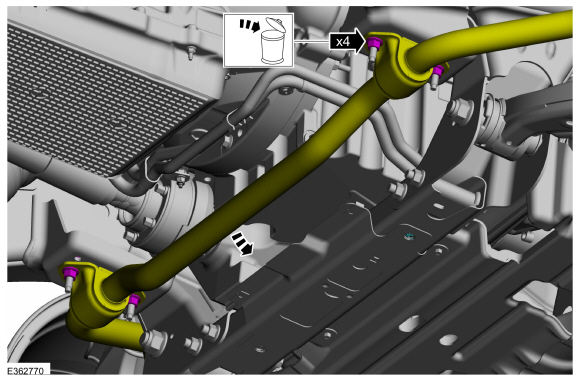

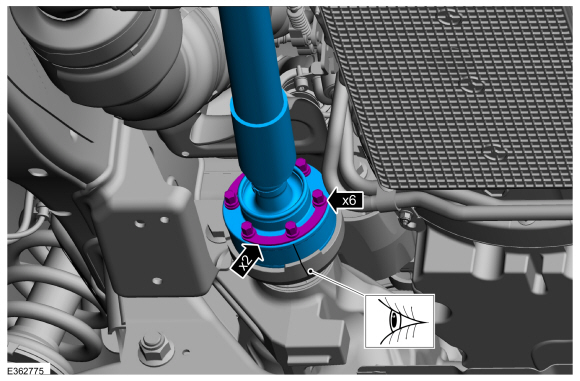

Remove and discard the stabilizer bar bracket nuts and allow the stabilizer bar to swing downward.

|

-

-

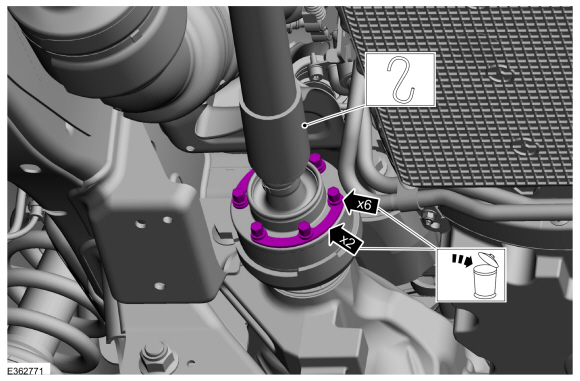

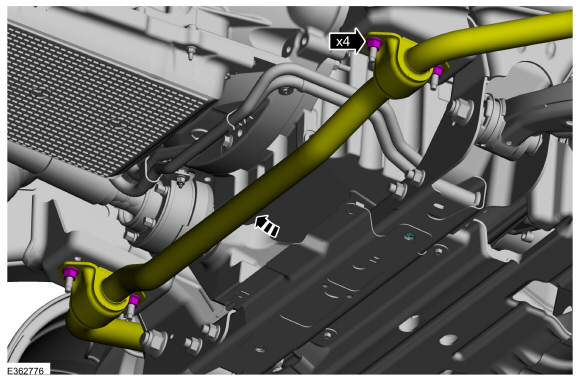

Remove and discard the front driveshaft CV joint-to-pinion flange cup bolts and retaining straps.

-

Support the front driveshaft.

-

Remove and discard the front driveshaft CV joint-to-pinion flange cup bolts and retaining straps.

|

-

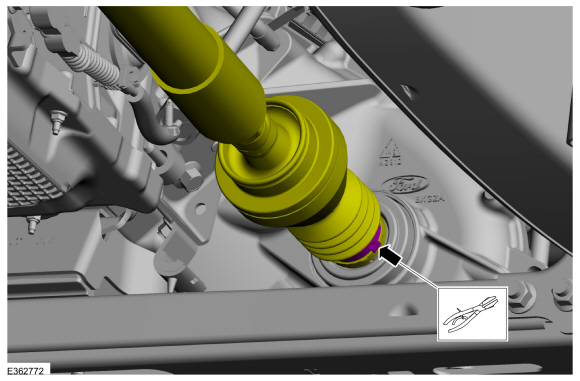

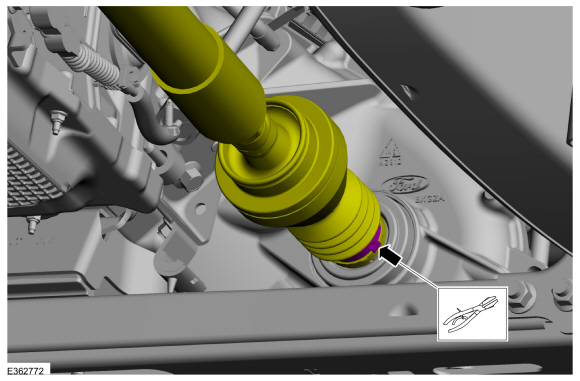

Remove the front driveshaft slip yoke boot clamp at transfer case end.

Use the General Equipment: Crimping Tool

|

-

NOTE: Care should be taken not to damage the driveshaft splines.

-

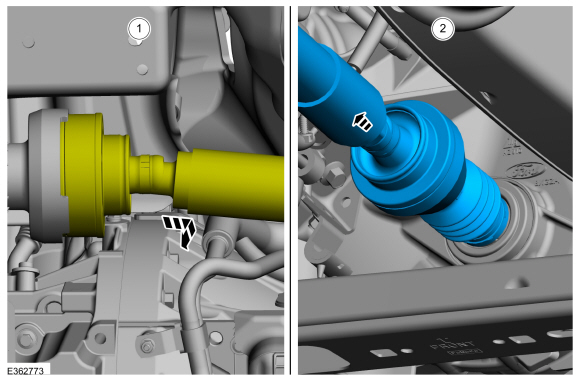

Remove the front driveshaft from pinion flange and allow it to move rearward.

-

Pull and remove the front driveshaft from transfer case.

-

Remove the front driveshaft from pinion flange and allow it to move rearward.

|

Installation

-

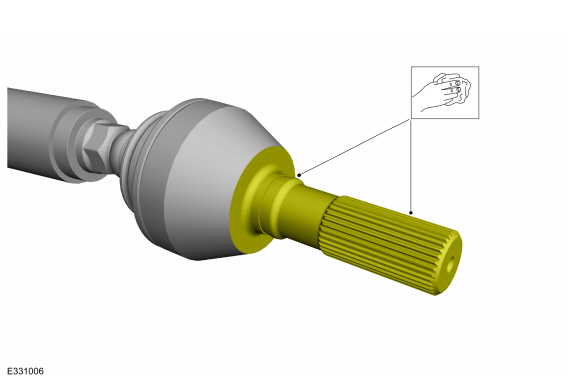

Clean and inspect the boot. If required replace the boot.

-

NOTE: Make sure that the mating faces are clean and free of foreign material.

Clean the debris or contamination of the splines.

|

-

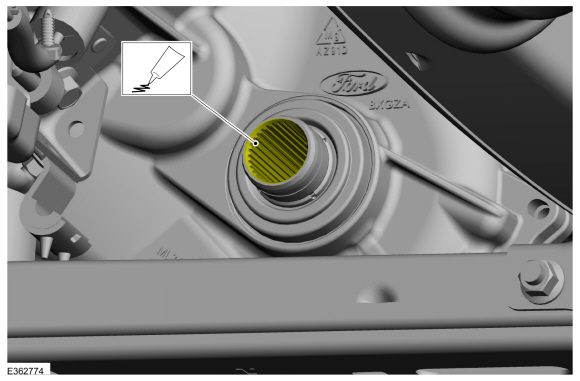

Lubricate the transfer case plug-on yoke splines with grease.

Material: Motorcraft® Premium Long-Life Grease / XG-1-E1 (ESA-M1C75-B)

|

-

Insert the front driveshaft into the transfer case plug-on yoke and secure the boot clamp.

Use the General Equipment: Crimping Tool

|

-

NOTE: Make sure that new components are installed.

-

Align the index-mark on the driveshaft and pinon flange.

-

Fit the driveshaft into the drive pinion flange.

-

Install the new front driveshaft CV joint-to-pinion flange cup retaining straps and bolts.

Torque: 41 lb.ft (55 Nm)

-

Align the index-mark on the driveshaft and pinon flange.

|

-

NOTE: Make sure that new nuts are installed.

Swing the stabilizer bar upward and install the new stabilizer bar bracket nuts.

Torque: 46 lb.ft (63 Nm)

|

-

Install the transmission shield and the bolts.

Torque: 71 lb.in (8 Nm)

|

Driveshaft Runout and Balancing. General Procedures

Driveshaft Runout and Balancing. General Procedures

Special Tool(s) /

General Equipment

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge

Inspection

NOTE:

Driveline vibration exhibits a higher frequency and lower

amplitude then high-speed shake...

Rear Driveshaft. Removal and Installation

Rear Driveshaft. Removal and Installation

Special Tool(s) /

General Equipment

Flat Headed Screw Driver

Tire Lever

Removal

All vehicles

With the vehicle in NEUTRAL, position it on a hoist...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Locks, Latches and Entry Systems. Diagnosis and Testing

DTC Chart: BCM Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). DTC Description Action B10AB:00 Remote Keyless Entry Synchronization: No Sub Type ..

Lincoln Navigator 2018-2026 Workshop Manual: Transmission Case. Assembly

Special Tool(s) / General Equipment 204-594Forcing screw 307-549Installer, Shift Shaft Fluid SealTKIT-2005D1-F1 307-648Remover/Installer, Rear BearingTKIT-2009C-FTKIT-2009C-ROW 307-738Installer, R2 Bearing 307-739Installer, R3 Bearing 307-740Installer, Dog Bone 307-745Installer, Park Sleeve Roll Pin ..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Vehicle Dynamics Control Module (VDM). Removal and Installation

- Identification Codes. Description and Operation

- Telematics Control Unit (TCU) Module. Removal and Installation

- SYNC Module [APIM]. Removal and Installation

- All Terrain Control Module (ATCM). Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and