Lincoln Navigator: Rear End Sheet Metal Repairs / Quarter Panel. Removal and Installation

Special Tool(s) /

General Equipment

| 6.5 mm Drill Bit |

| Self-Piercing Rivet (SPR) Remover/Installer |

| Belt Sander |

| Blind Rivet Gun |

| Hot Air Gun |

| MIG/MAG Welding Equipment |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

Removal

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

Partial quarter panel replacement is possible and reasonable

depending on damage. The following procedure assumes full component

replacement. Removal and installation steps may be adjusted according to

damage as necessary.

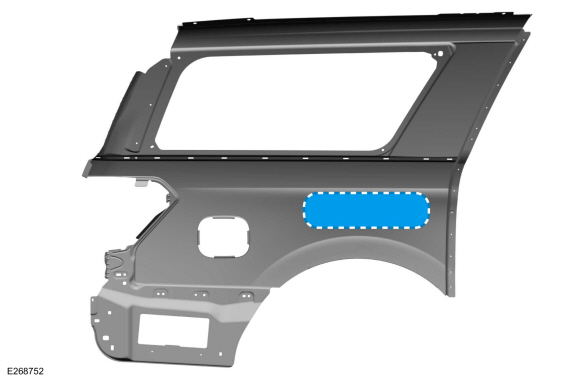

NOTE:

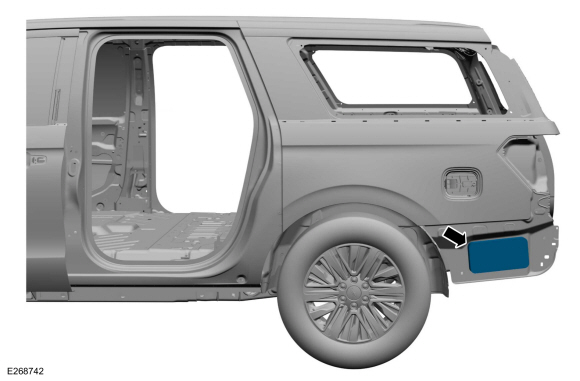

LH side shown, RH side similar.

NOTE:

Long wheelbase shown, short wheelbase similar.

-

Possible sectioning point.

-

Possible sectioning point.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the exterior trim and rear lamp.

Refer to: Rear Fender Splash Shield (501-08 Exterior Trim and Ornamentation, Removal and Installation).

Refer to: Rear Lamp Assembly (417-01 Exterior Lighting, Removal and Installation).

-

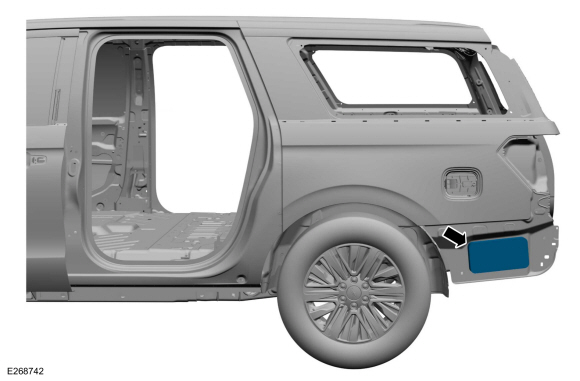

Remove the rear bumper cover.

Refer to: Rear Bumper Cover (501-19 Bumpers, Removal and Installation).

-

Remove the interior trim.

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: C-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel - Short Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel - Long Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the fuel fill door.

-

Remove the air vent.

-

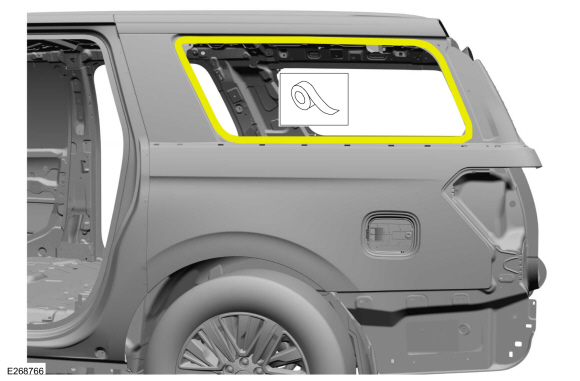

Remove the quarter glass.

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

-

Remove the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

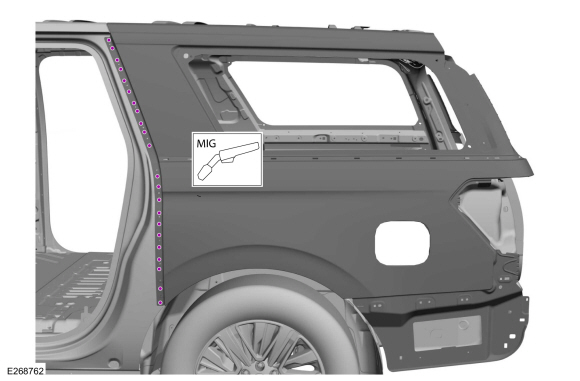

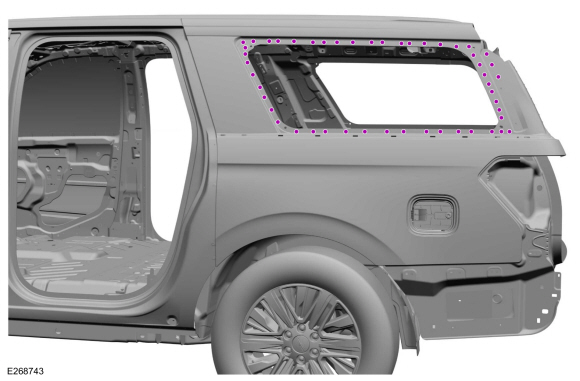

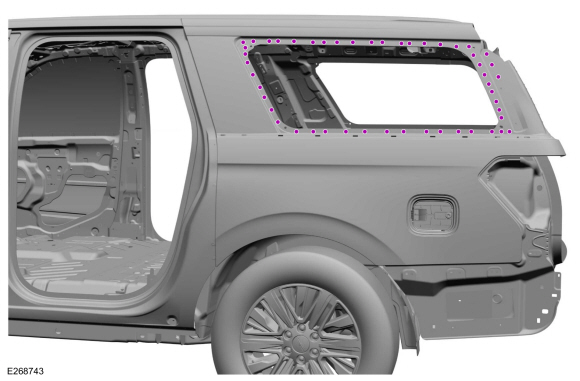

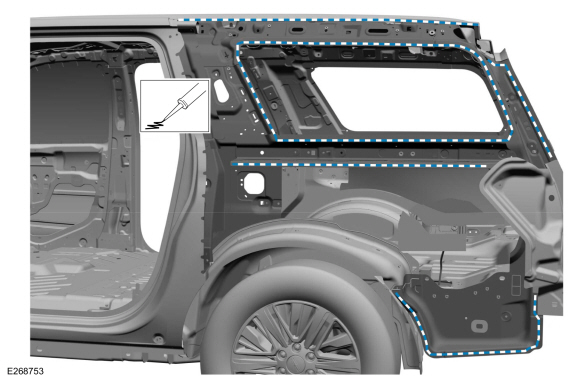

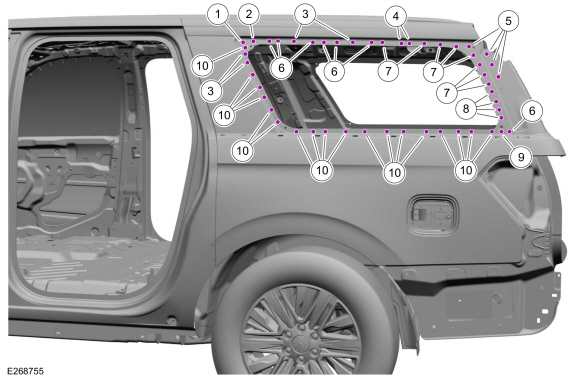

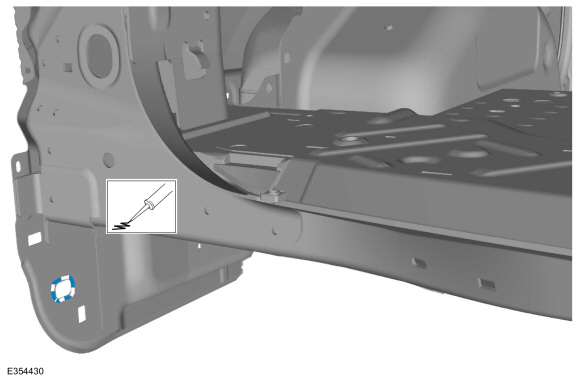

Remove the SPR fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Remove the SPR fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

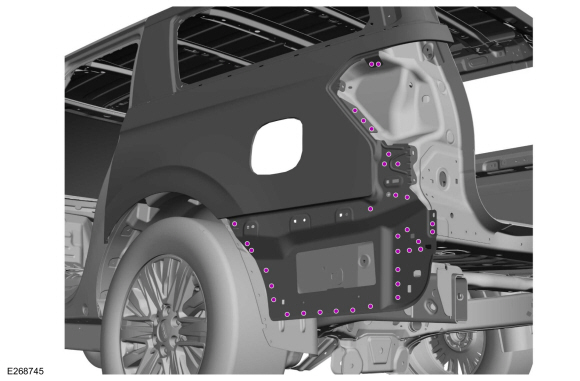

Remove the SPR fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Remove the SPR fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

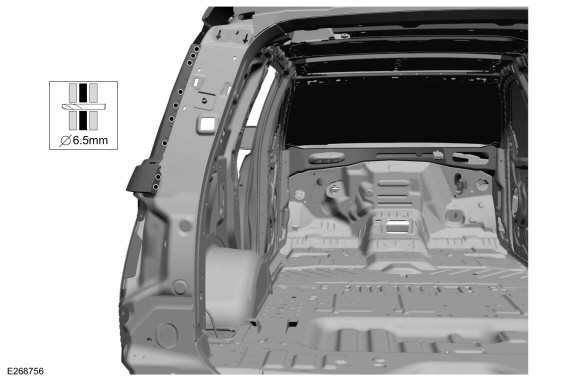

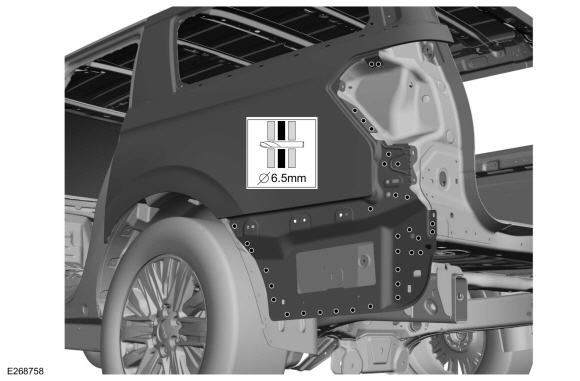

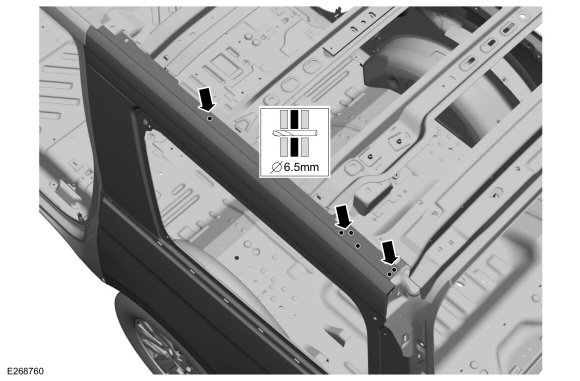

Remove the clinch joints.

Use the General Equipment: 6.5 mm Drill Bit

-

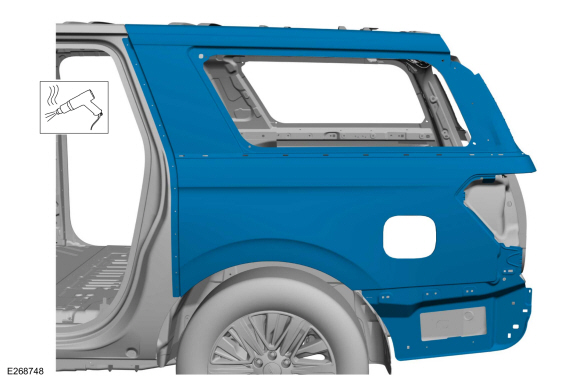

NOTE:

The use of heat may be required to soften adhesives and sealers.

NOTE:

Pay particular attention to location of NVH sealers and adhesives to aid in installation.

Break the adhesive bond and remove the outer quarter panel.

Use the General Equipment: Hot Air Gun

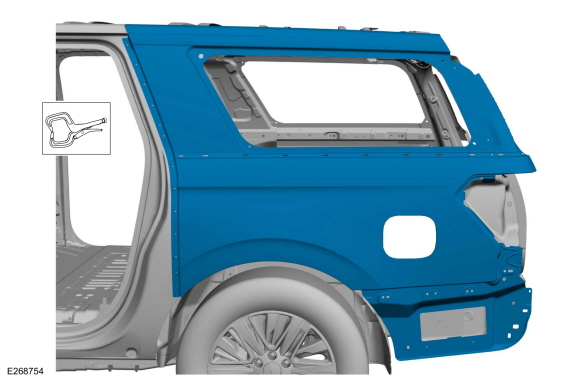

Installation

NOTE:

If sectioning, trim the replacement panel to fit repair area.

NOTE:

Do not install SPR fasteners directly in old SPR location. SPR

fasteners must be installed adjacent to the original location matching

original quantity.

NOTE:

Solid or blind rivet fasteners may be used in place of SPR

fasteners after enlarging existing holes to 6.5 mm. Solid of blind

rivet fasteners must equal original fasteners in both location and

quantity.

NOTE:

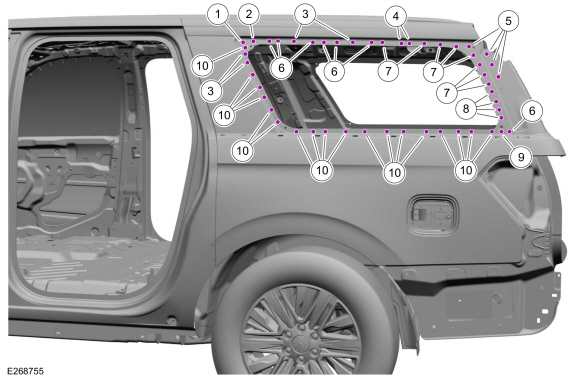

LH side shown, RH side similar.

NOTE:

Long wheelbase shown, short wheelbase similar.

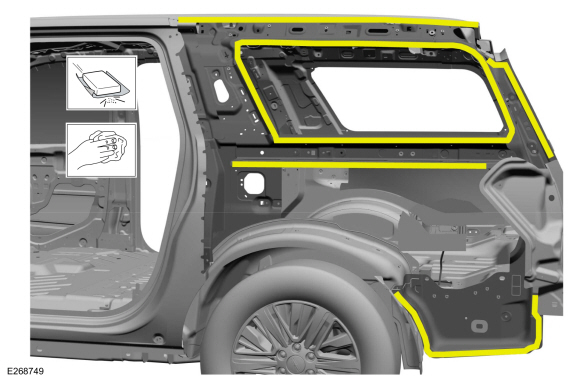

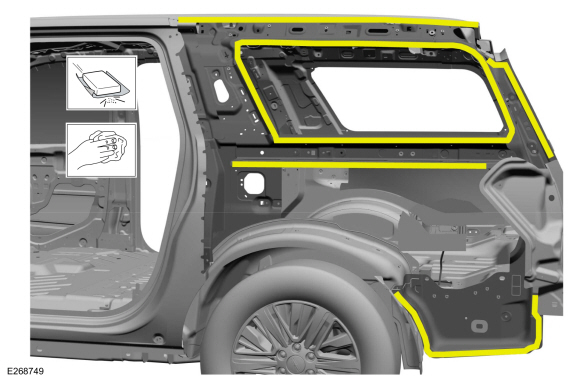

-

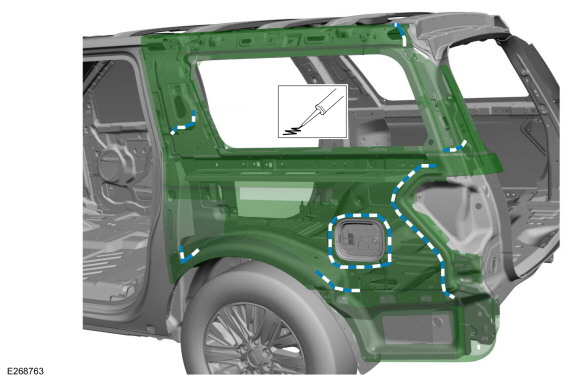

80-120 grit sandpaper.

Sand to remove old adhesive and sealer and clean.

-

80-120 grit sandpaper.

Sand to remove e-coat at mating surfaces only and clean.

-

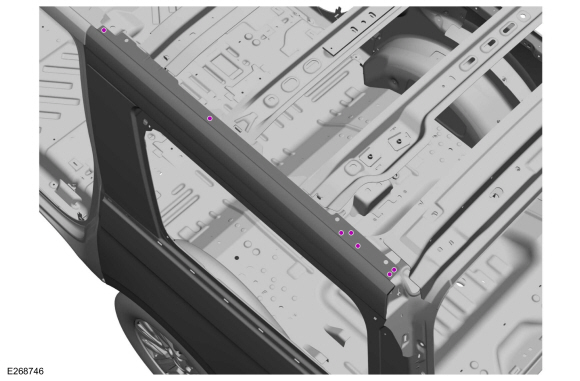

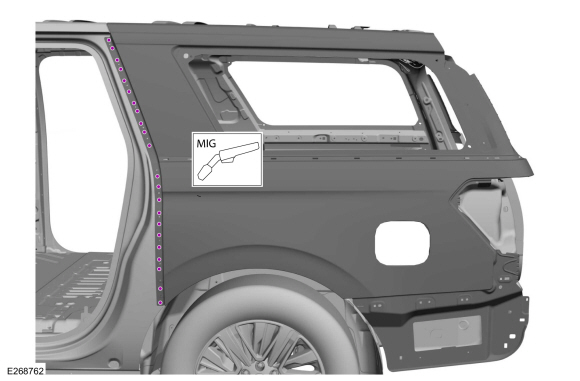

Drill plug weld holes.

Use the General Equipment: 6.5 mm Drill Bit

-

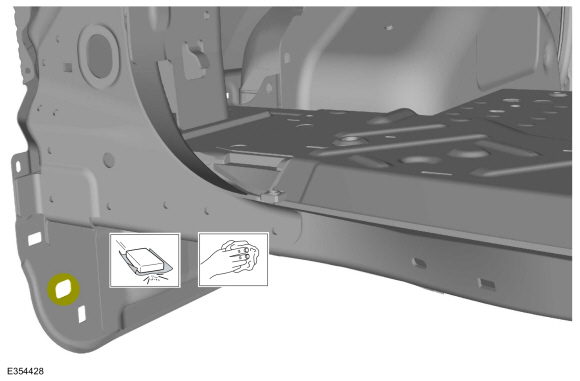

Install a locally obtained butyl NVH patch.

-

NOTE:

Do not apply adhesive in areas to be welded.

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

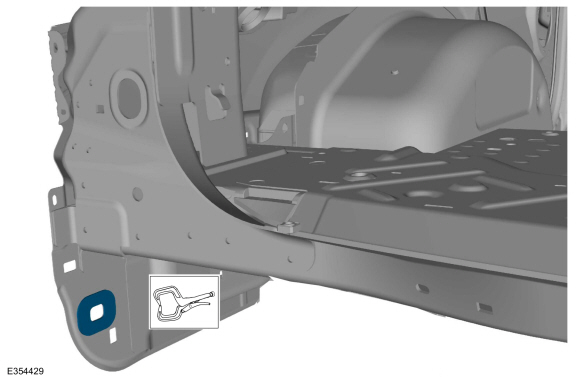

Install, properly position and clamp the outer quarter panel.

Use the General Equipment: Locking Pliers

-

Install aluminum MIG plug welds.

Refer to: Welding Precautions (501-25 Body Repairs - General Information, General Procedures).

Use the General Equipment: MIG/MAG Welding Equipment

|

|

-

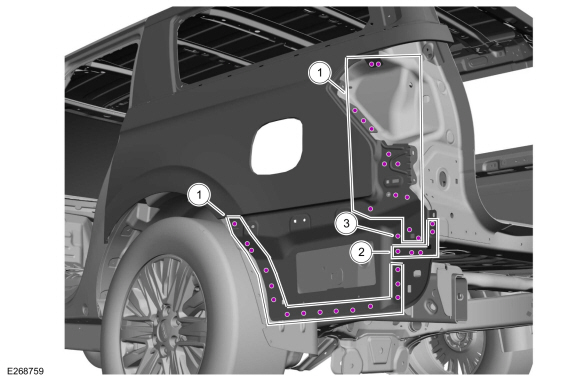

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

W717188-S900

|

PW

|

DG10-200/H

|

SA-0400/SA-0402

|

W708777-S900C

|

W790377-S900

|

-

|

|

2

|

W718958-S900

|

SP

|

DP10-200/H

|

SA-0400/SA-0402

|

W702554-S900C

|

W790377-S900

|

-

|

|

3

|

W712218-S900

|

DB

|

DZ09-025/H

|

SA-0400/SA-0401

|

W702512-S900C

|

W790376-S900

|

-

|

|

4

|

W717529-S900

|

QZ

|

DG10-200/H

|

SA-0400/SA-0402

|

W708777-S900C

|

W790377-S900

|

-

|

|

5

|

W713404-S900

|

FC

|

DZ09-025/H

|

SA-0400/SA-0401

|

W702512-S900C

|

W790376-S900

|

-

|

|

6

|

W717752-S900

|

RB

|

DP10-200/H

|

SA-0400/SA-0402

|

W708777-S900C

|

W790377-S900

|

-

|

|

7

|

W717184-S900

|

QA

|

DP10-200/H

|

SA-0400/SA-0402

|

W708777-S900C

|

W790377-S900

|

-

|

|

8

|

W708713-S900

|

AS

|

DZ09-025/H

|

SA-0400/SA-0401

|

W702512-S900C

|

W790376-S900

|

-

|

|

9

|

W708717-S900

|

AW

|

DP11-200/H

|

SA-0400/SA-0402

|

W707638-S900C

|

W790377-S900

|

-

|

|

10

|

W718595-S900

|

SU

|

DP07-140/H

|

SA-0400/SA-0401

|

W702512-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Blind Rivet Gun

|

|

-

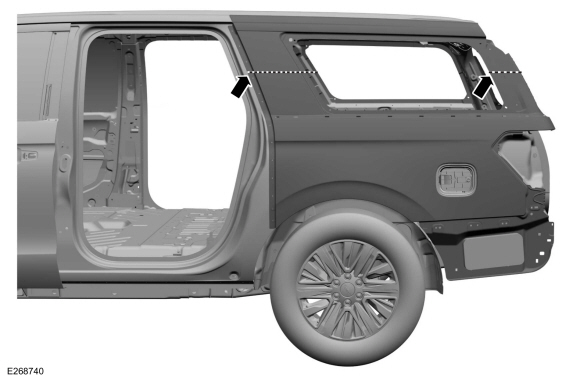

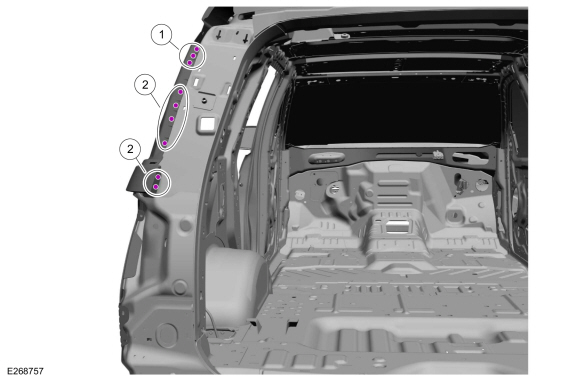

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702554-S900C

|

-

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Install, properly position and clamp the reinforcement.

Use the General Equipment: Locking Pliers

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W707638-S900C

|

-

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

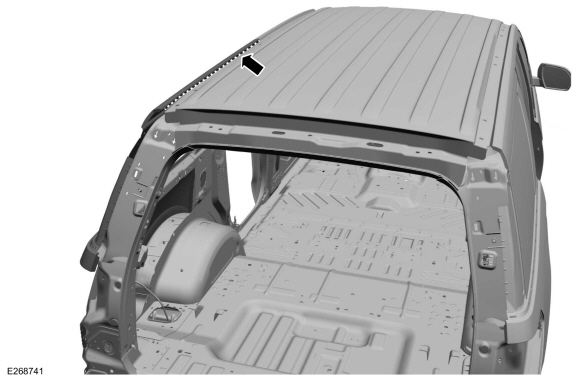

Install the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

If sectioning:

Completely seam weld all sectioning joints using a MIG welder set up for aluminum welding.

Refer to: Welding Precautions (501-25 Body Repairs - General Information, General Procedures).

Use the General Equipment: MIG/MAG Welding Equipment

-

If sectioning:

Metal finish all welds as required and complete with typical metal finishing techniques and materials.

Refer to: Special Repair Considerations for Aluminum Repairs (501-25

Body Repairs - General Information, Description and Operation).

-

Apply NVH sealer in areas noted during removal.

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

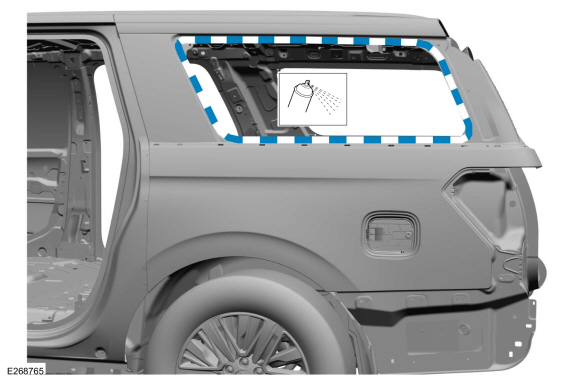

Seam sealing:

All seams must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Sand to remove e-coat and clean.

-

Apply a Ford approved, epoxy-based primer and allow to dry.

-

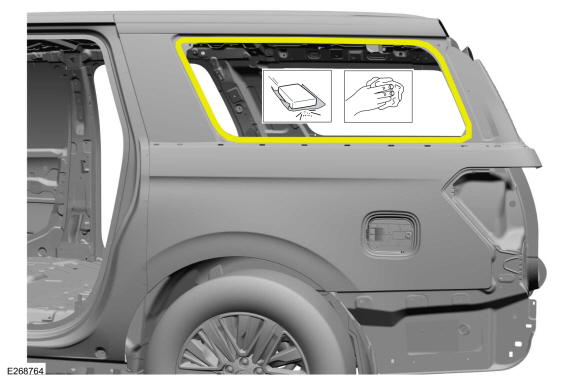

Mask off the glass opening channel.

-

Refinish the entire repair using a Ford approved paint system and typical refinishing techniques.

-

Remove the masking tape from the glass opening channel.

-

Install the quarter glass.

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

-

Install the fuel fill door.

-

Install the air vent.

-

Install the rear fender splash shield and rear lamp.

Refer to: Rear Fender Splash Shield (501-08 Exterior Trim and Ornamentation, Removal and Installation).

Refer to: Rear Lamp Assembly (417-01 Exterior Lighting, Removal and Installation).

-

Install the rear bumper cover.

Refer to: Rear Bumper Cover (501-19 Bumpers, Removal and Installation).

-

Install the interior trim.

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: C-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel - Short Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel - Long Wheelbase (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Polydrive Bit Socket

Rivet Gun

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, 3M™ 08308, ..

Other information:

Special Tool(s) /

General Equipment

Boot Clamp Pliers

Materials

Name

Specification

Motorcraft® Premium Long-Life GreaseXG-1-E1

ESA-M1C75-B

Removal

Remove the tie-rod end.

Refer to: Tie Rod End (211-02 Power Steering, Removal and Installation).

NOTE:

Count and record the number of turns required to

remo..

Overview

Power E-Z Entry Seats

While the rear passenger door is open, pressing and releasing the LH or RH

rear seat control switch (located at the back of the rear door

opening) causes the corresponding rear seat to pitch and slide forward

for access to the third row seating.

Power-Folding Seats

Pressing and releasing the rear seat control switch (located in the rear cargo ..

Rear Crossmember. Removal and Installation

Rear Crossmember. Removal and Installation 205-123

(T78P-1177-A)

205-123

(T78P-1177-A)

308-047

(T77F-1102-A)

308-047

(T77F-1102-A)