Lincoln Navigator: Rear End Sheet Metal Repairs / Inner Quarter Panel. Removal and Installation

Special Tool(s) /

General Equipment

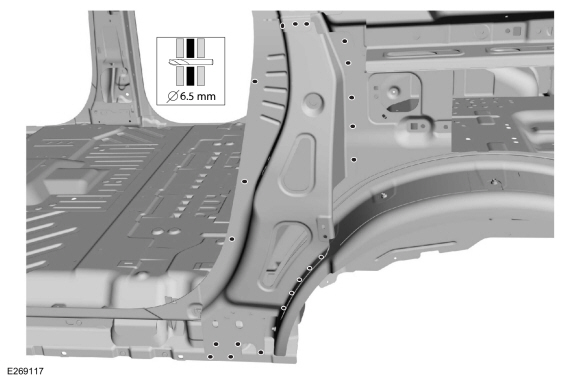

| 6.5 mm Drill Bit |

| Spherical Cutter |

| Polydrive Bit Socket |

| Rivet Gun |

| Self-Piercing Rivet (SPR) Remover/Installer |

| Belt Sander |

| Blind Rivet Gun |

| Air Body Saw |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

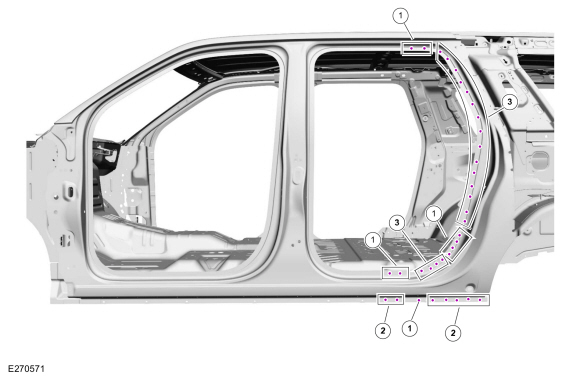

Removal

NOTE:

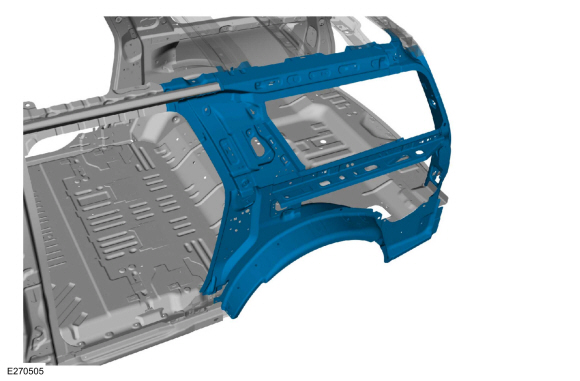

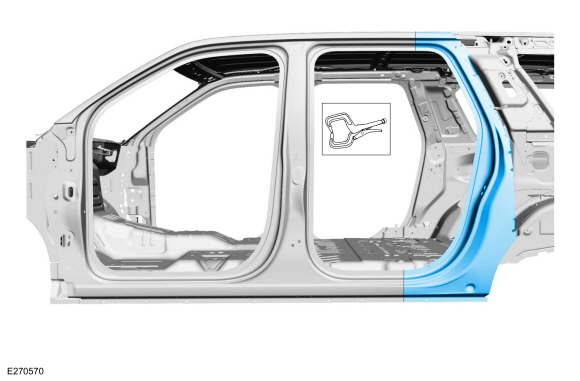

The inner quarter panel is provided in several parts

including body side panel, roof side rail reinforcement, C-pillar

reinforcement, wheelhouse panel, extension and water drain panel. The

following procedure assumes complete assembly replacement. Adjust to

meet repair needs.

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

LH side shown, RH side similar.

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

Remove the quarter panel.

Refer to: Quarter Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Remove the rear lamp mounting panel and water drain panel.

Refer to: Rear Lamp Mounting Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Water Drain Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Remove the wheel and tire on the affected side.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

Remove the subwoofer speaker.

Refer to: Subwoofer Speaker (415-00 Information and Entertainment

System - General Information - Vehicles With: SYNC 4, Removal and

Installation).

-

Position aside the carpeting, all modules and wiring harnesses.

-

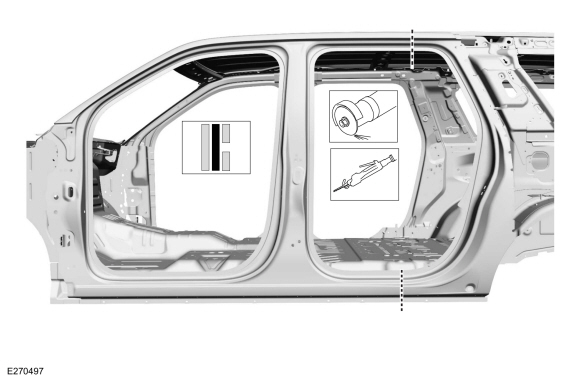

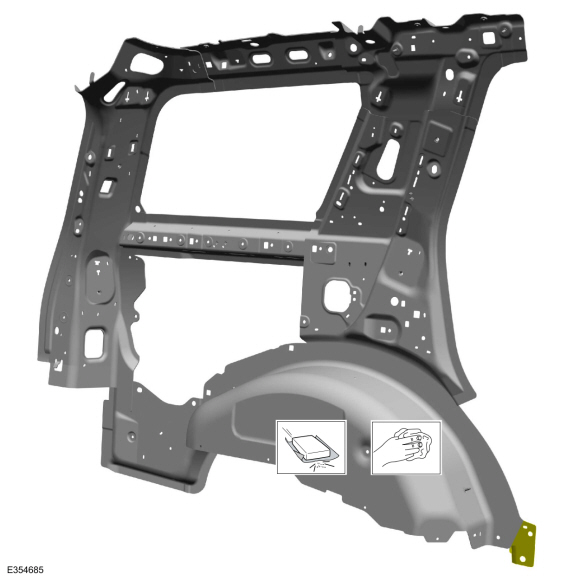

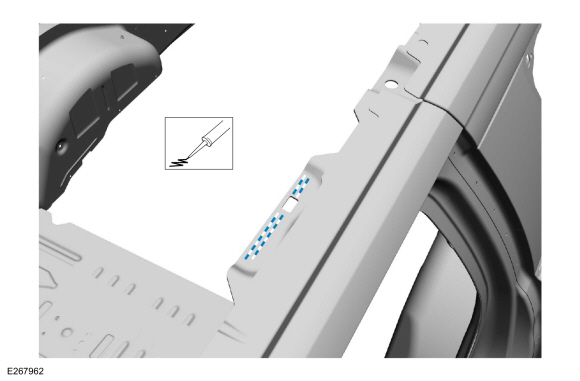

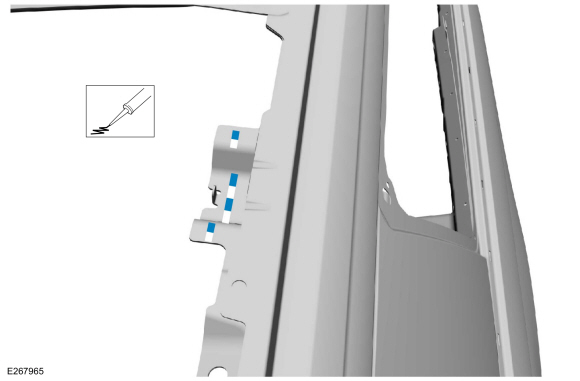

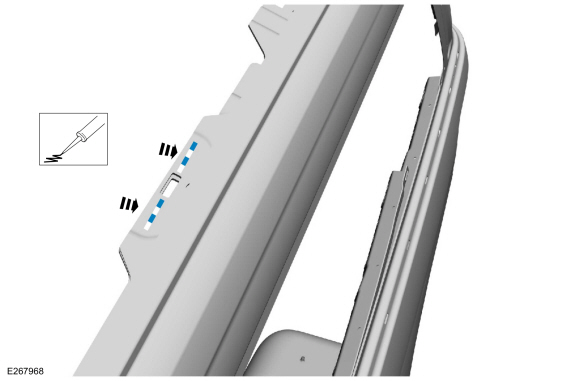

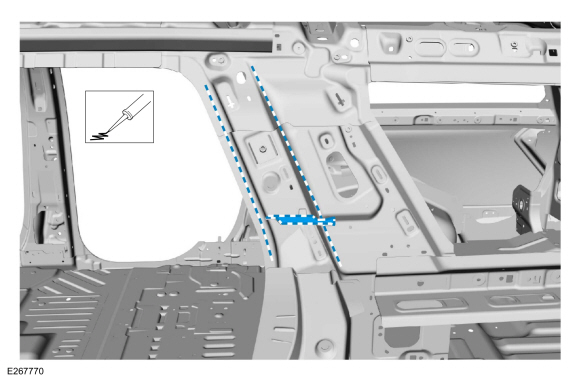

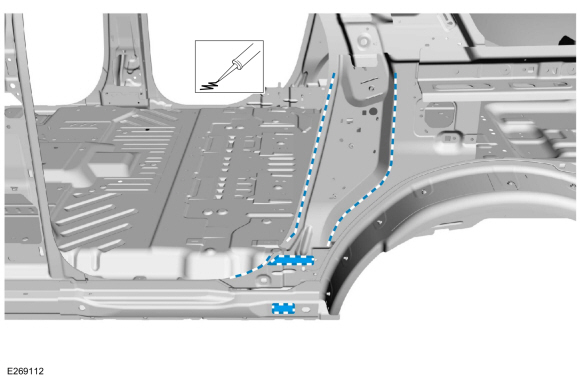

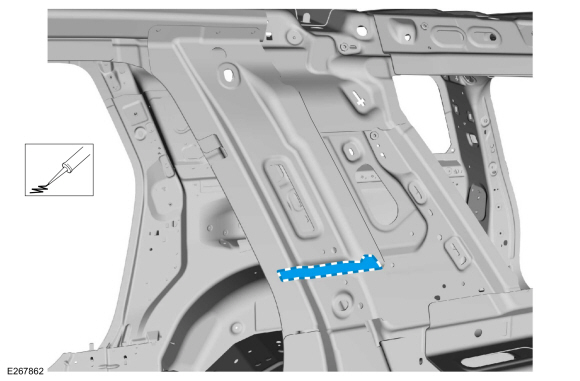

Carefully cut through outer layer only of the door opening panel.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

-

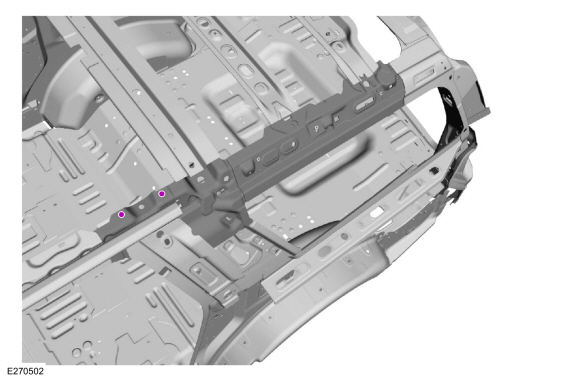

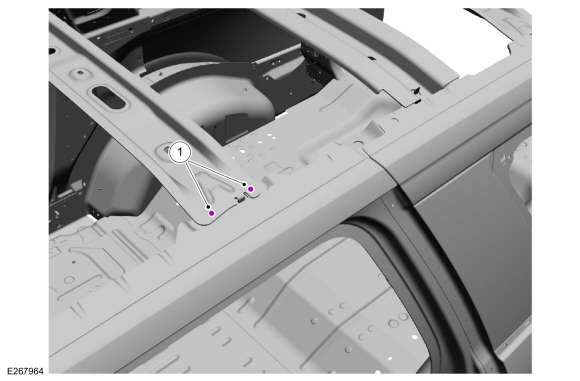

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Break the adhesive bond, grind the wheelhouse flange and remove the outer panel section.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

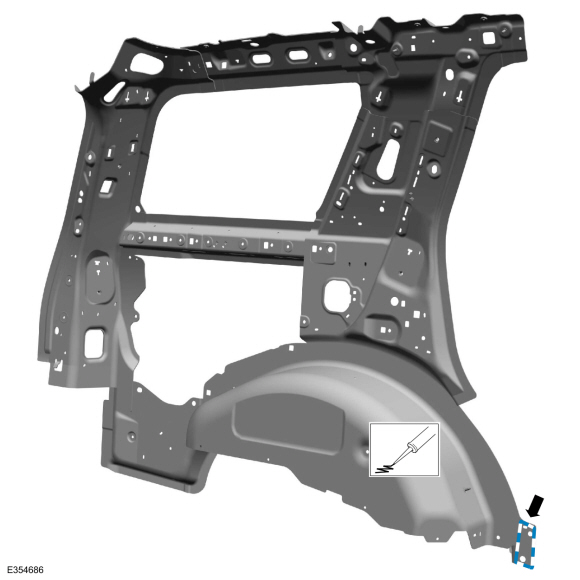

Remove and discard the FDS fasteners.

Use the General Equipment: Polydrive Bit Socket

-

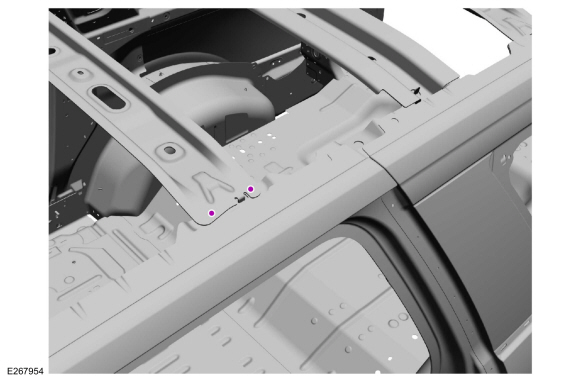

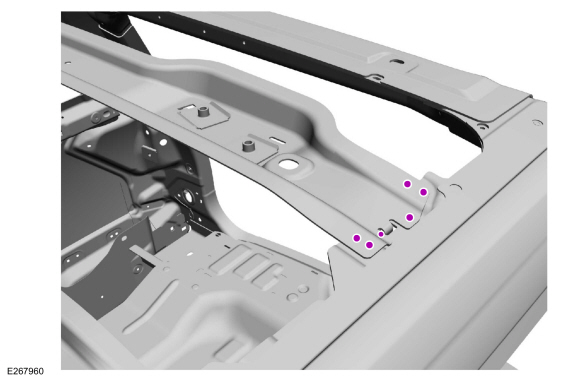

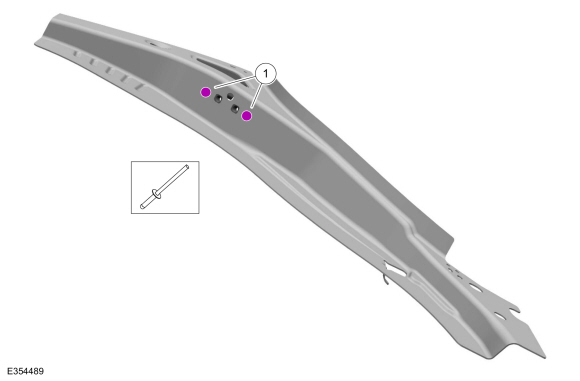

Remove the roof rail reinforcement fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

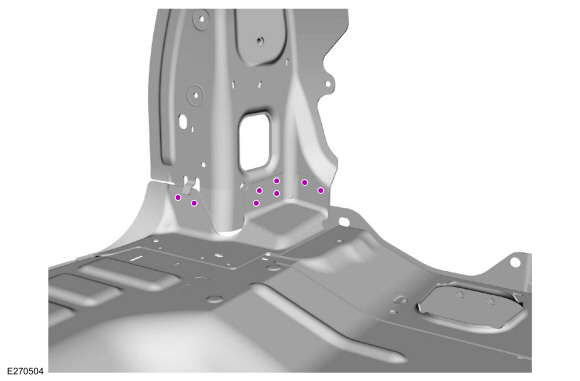

Remove roof bow the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

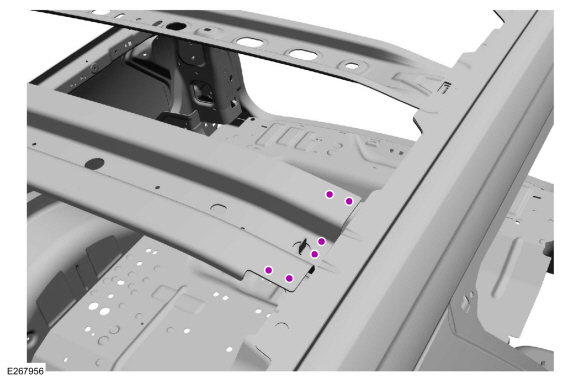

Remove the roof fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Remove the roof bow fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

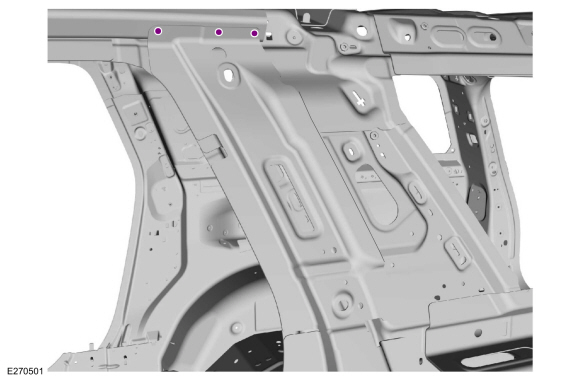

NOTE:

Vehicles with long wheelbase (LWB).

Remove the roof bow fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

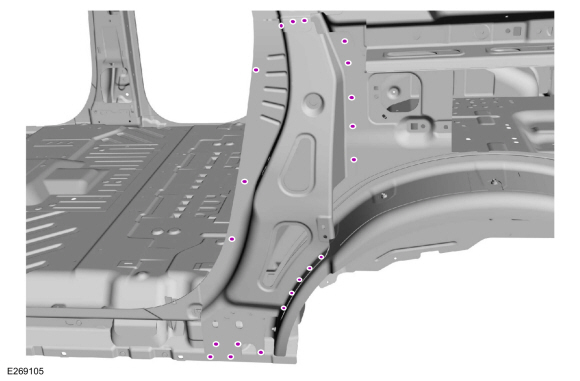

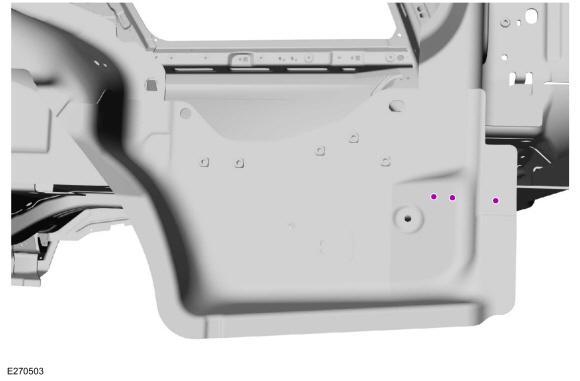

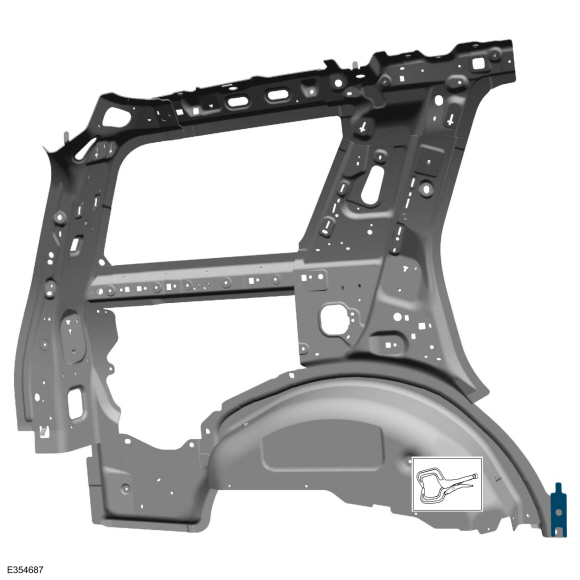

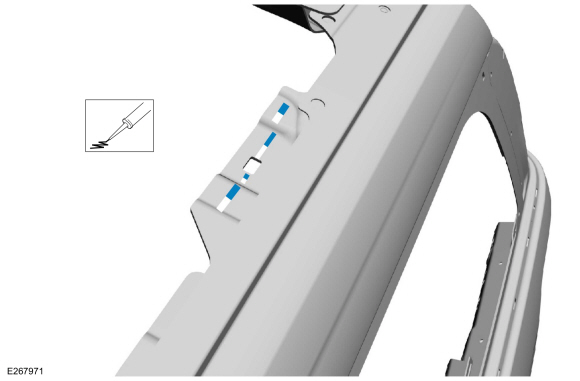

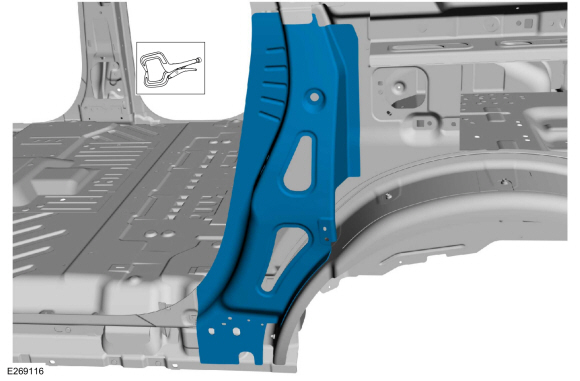

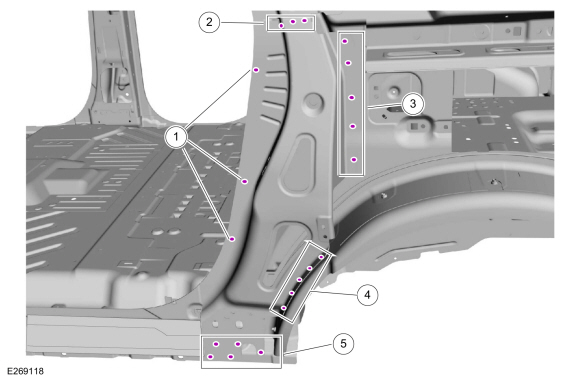

Remove the C-pillar lower reinforcement fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

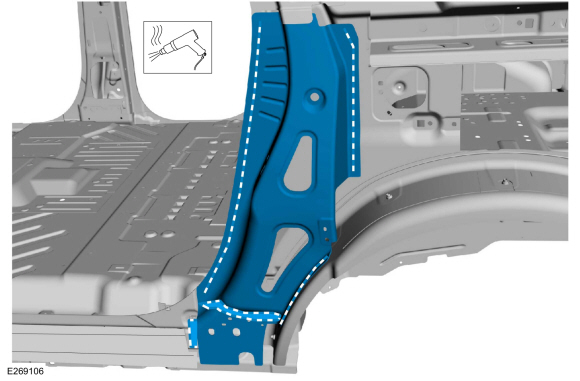

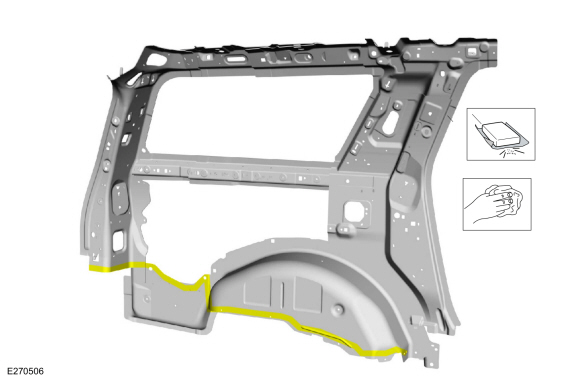

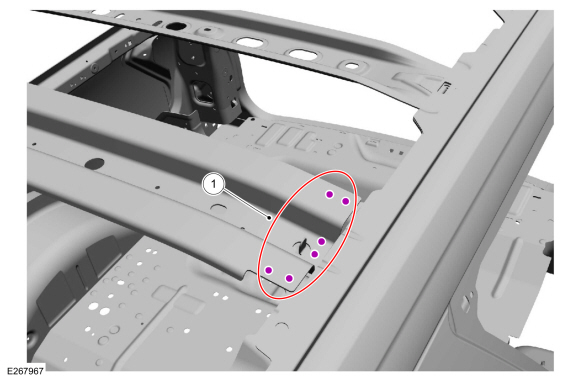

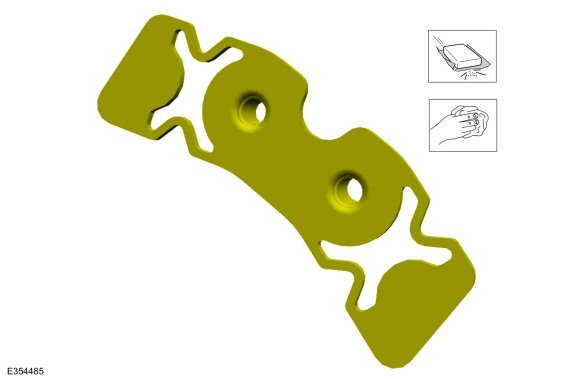

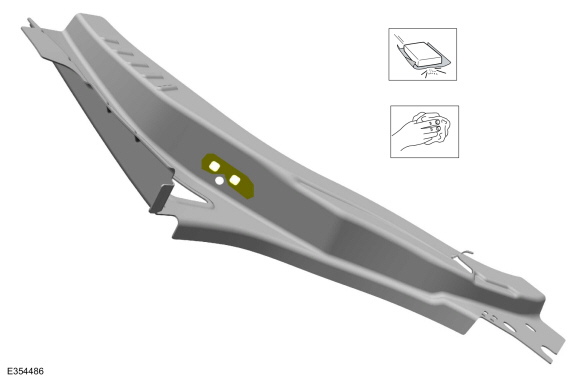

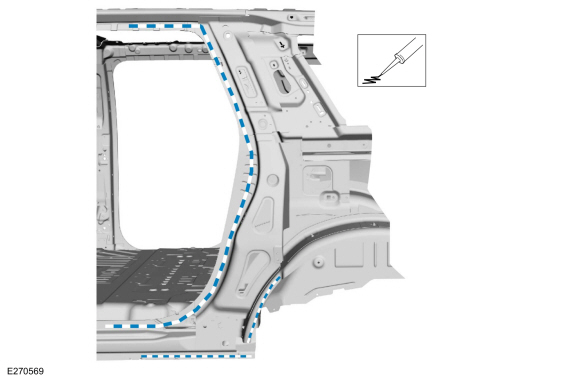

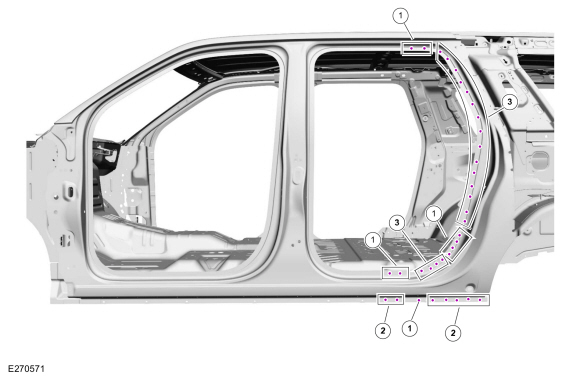

NOTE:

Long wheelbase (LWB) shown, standard wheelbase (SWB) similar.

Note NVH foam locations when removing panel.

Break the adhesive bond and remove the C-pillar lower reinforcement.

-

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

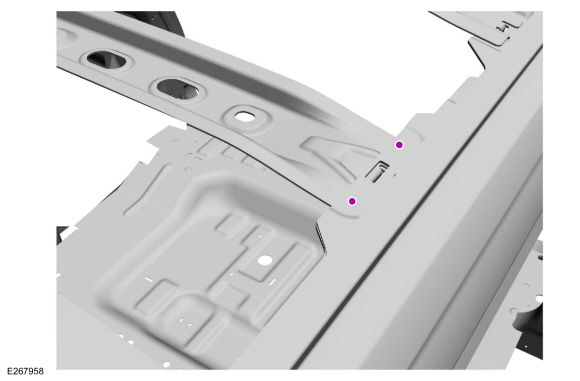

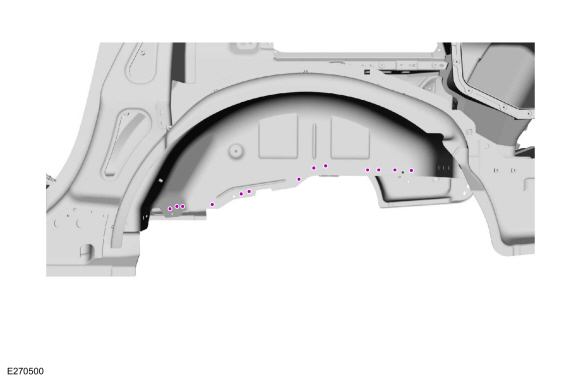

Remove the inner wheelhouse flange fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Remove the inner wheelhouse flange fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

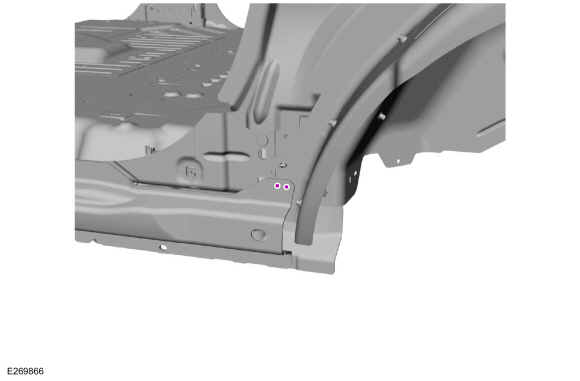

Remove the fasteners at the D-pillar corner.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Break the adhesive and NVH foam bond and remove the inner quarter panel assembly.

Installation

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

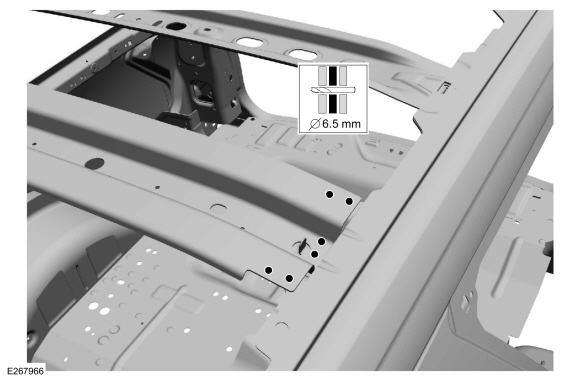

NOTE:

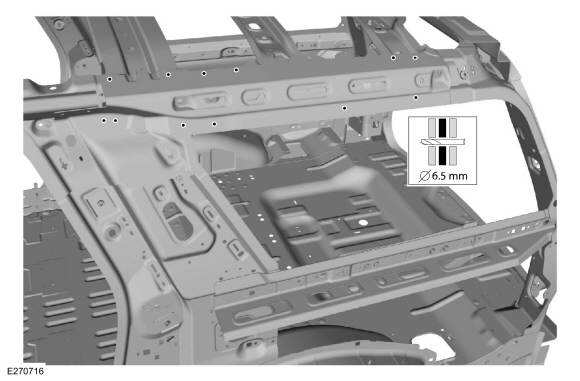

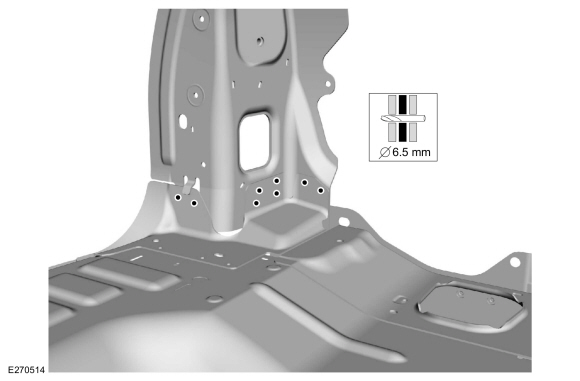

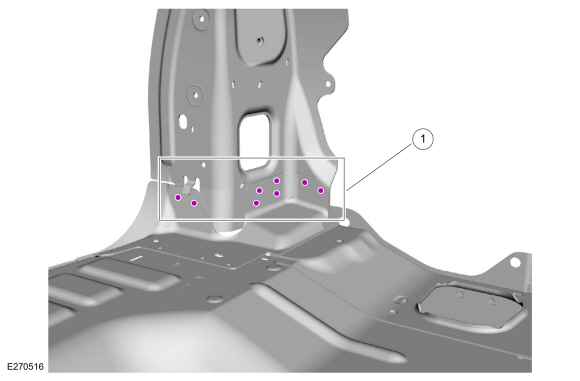

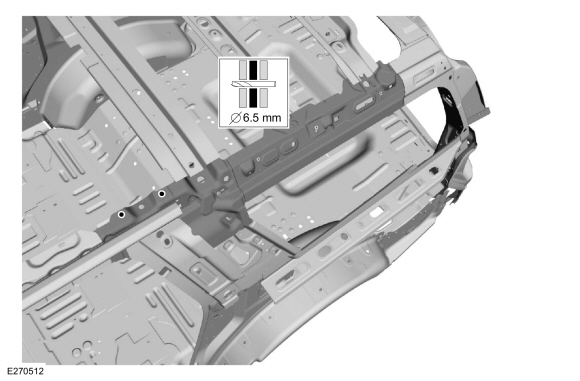

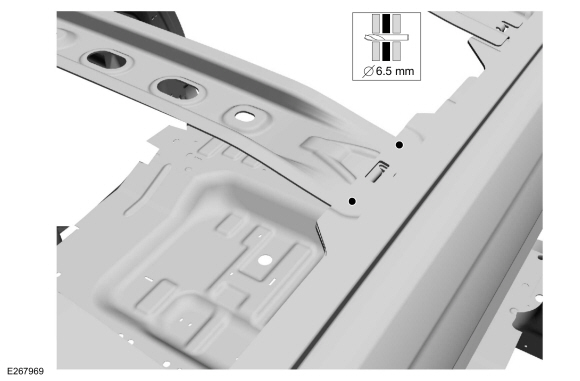

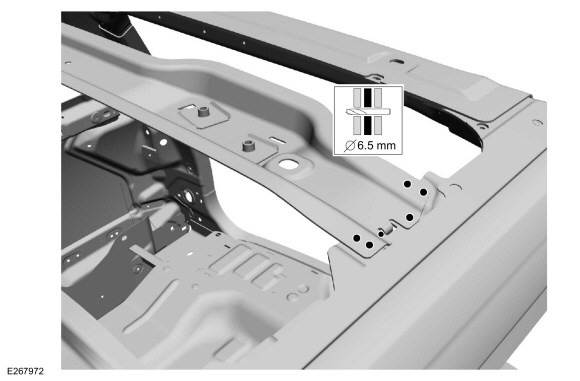

Blind or solid rivet fasteners may be used in place of SPR fasteners

after enlarging holes to 6.5 mm and must equal original quantity.

-

Use a hammer and dolly dedicated to aluminum repair to

repair any damage to the body side flange to roof mating surfaces.

Refer to: Special Repair Considerations for Aluminum Repairs (501-25

Body Repairs - General Information, Description and Operation).

-

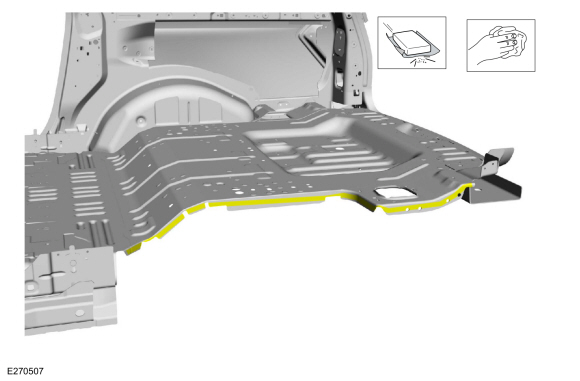

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

80-120 Grit Sand Paper:

Sand to remove old adhesive, paint and clean..

-

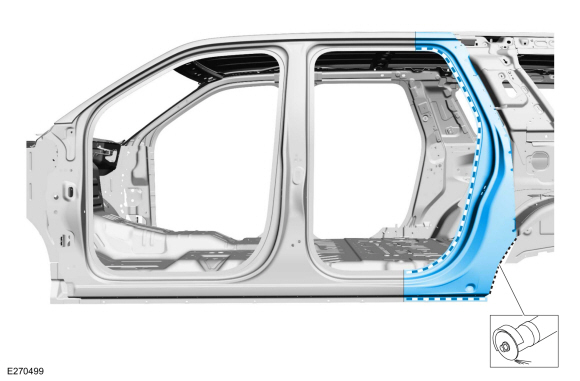

Apply adhesive and NVH foam.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install sub-assemblies as required prior to installing inner panel assembly.

Refer to: Water Drain Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Rear Lamp Mounting Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Rear Wheelhouse (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

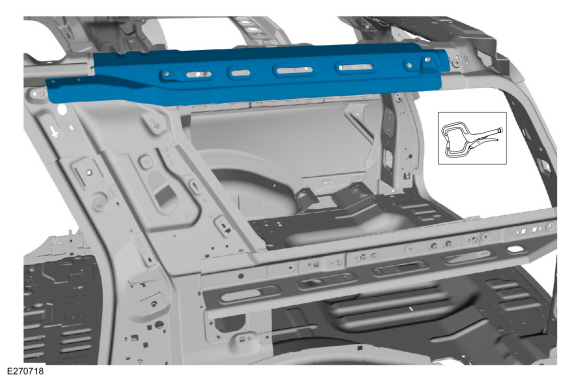

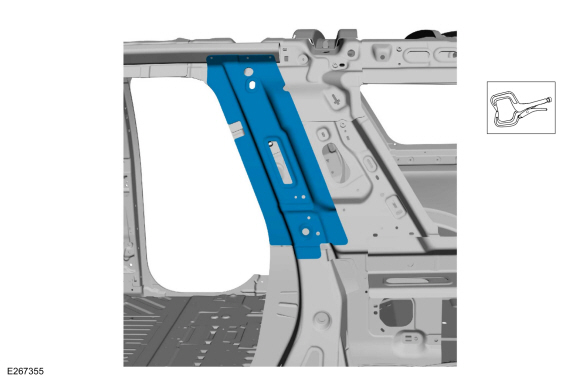

Install, properly position and clamp the reinforcement.

Use the General Equipment: Locking Pliers

-

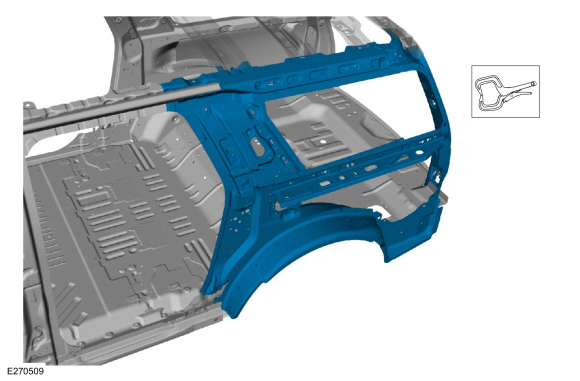

Install and clamp the inner quarter panel assembly.

-

Install and clamp roof rail reinforcement.

-

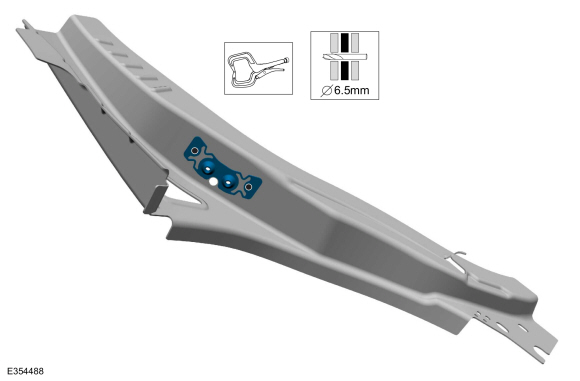

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

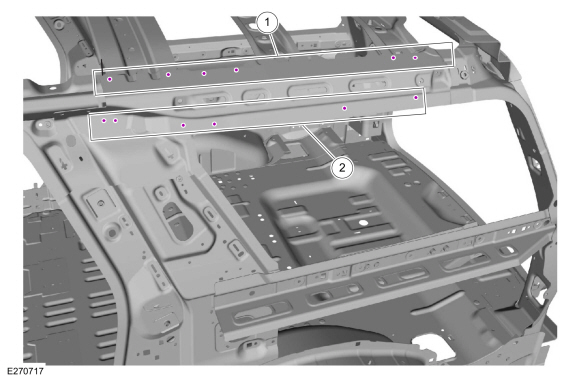

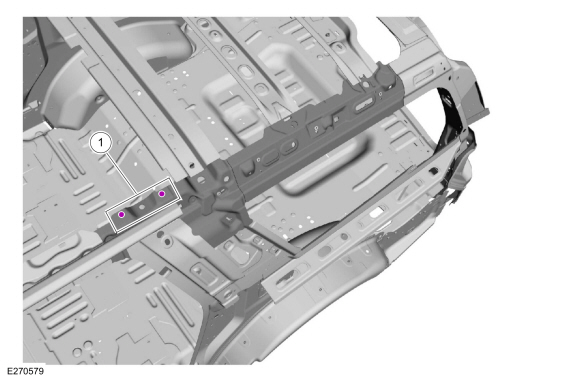

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

W790377-S900

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702554-S900C

|

W790377-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W707638-S900C

|

W790377-S900

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W708777-S900C

|

W790377-S900

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W702512-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

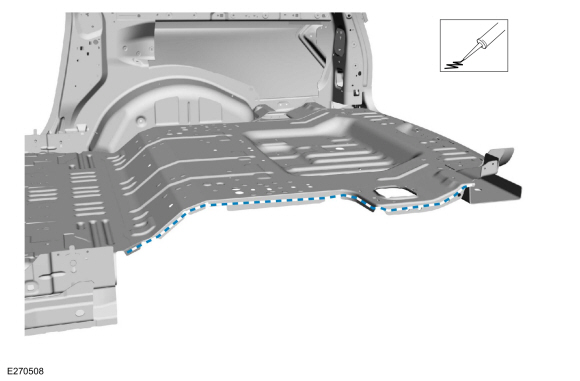

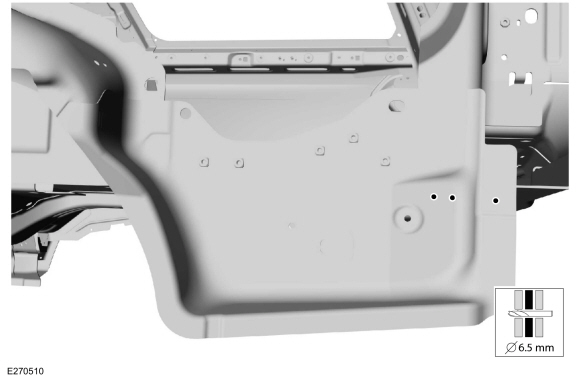

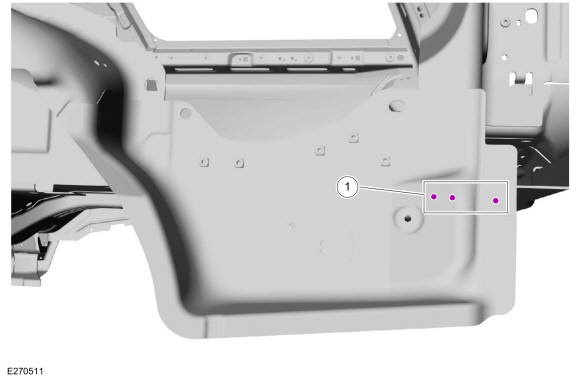

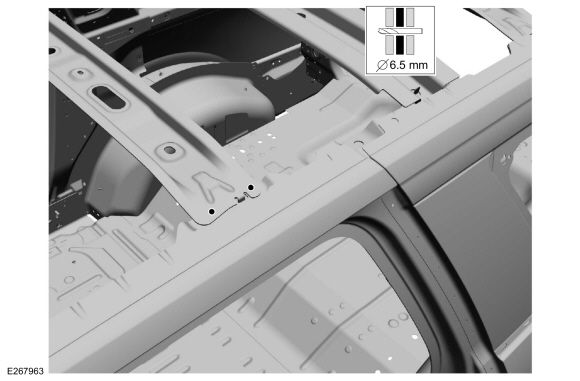

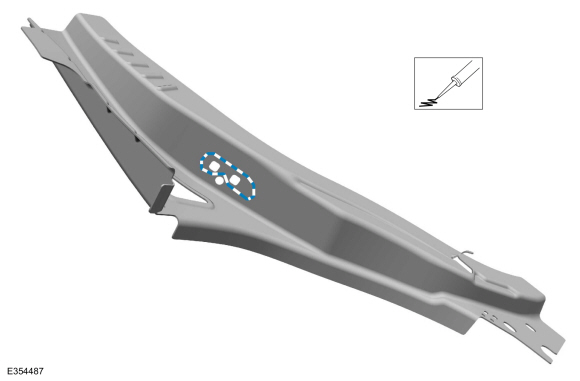

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

W790377-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

W790377-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

Blind or solid rivet fasteners may be used in place of SPR fasteners

after enlarging holes to 6.5 mm and must equal original quantity.

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Rivet Gun

-

NOTE:

Vehicles with long wheelbase (LWB).

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

NOTE:

Vehicles with long wheelbase (LWB).

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

NOTE:

Vehicles with long wheelbase (LWB).

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

W790376-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Apply adhesive and NVH foam.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install, properly position and clamp the C-pillar reinforcement.

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

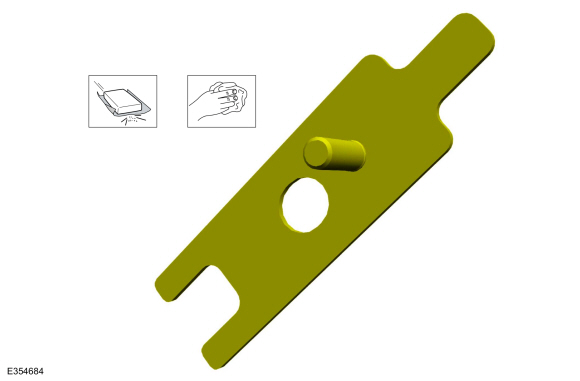

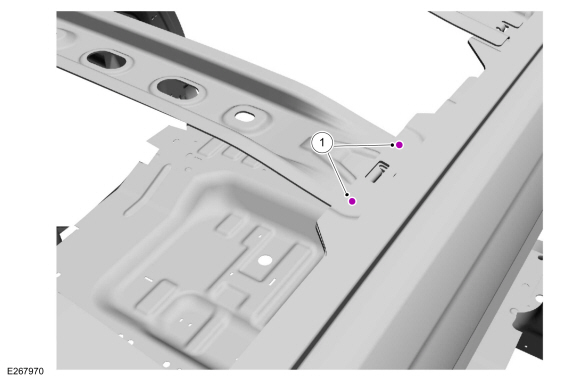

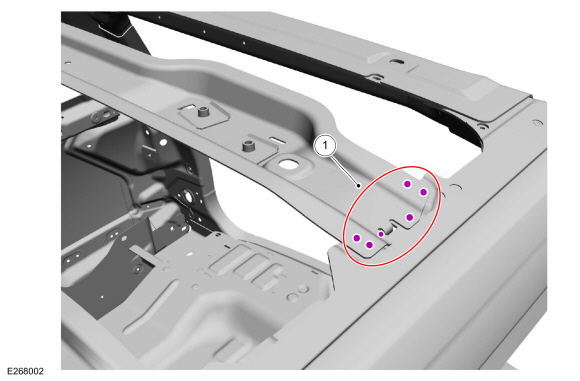

Install, properly position, clamp and drill the striker reinforcement.

Use the General Equipment: Locking Pliers

Use the General Equipment: 6.5 mm Drill Bit

-

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

Apply adhesive and NVH foam as indicated to the C-pillar mating surface.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install, properly position and clamp the C-pillar reinforcement.

Use the General Equipment: Locking Pliers

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

Blind or solid rivet fasteners may be used in place of SPR fasteners

after enlarging holes to 6.5 mm and must equal original quantity.

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702554-S900C

|

-

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

4

|

W7122218-S900

|

DB

|

DZ09-025/H

|

SA-0400/SA-0401

|

-

|

W790376-S900

|

-

|

|

5

|

W708717-S900

|

AW

|

DP11-200/H

|

SA-0400/SA-0402

|

-

|

W790377-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

-

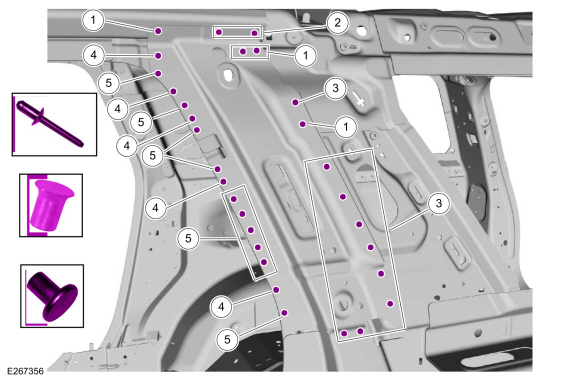

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

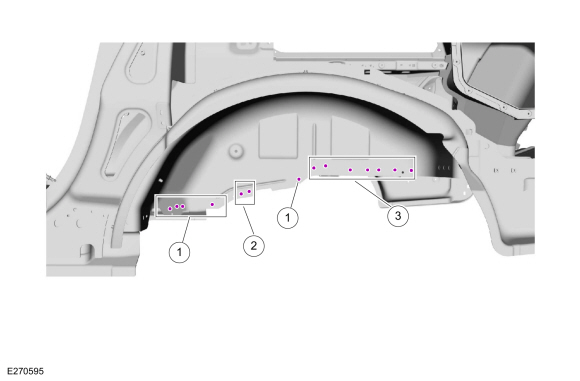

NOTE:

Blind or solid rivet fasteners may be used in place of SPR fasteners

after enlarging holes to 6.5 mm and must equal original quantity.

NOTE:

SPR

fasteners may not be placed directly over original location. They must

equal original quantity and be placed adjacent to original location.

NOTE:

Long wheelbase (LWB) shown, short wheelbase (SWB) similar.

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

W712218-S900

|

DB

|

DZ09-025/H

|

SA-0400/SA-0401

|

W702512-S900C

|

W790376-S900

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

4

|

-

|

-

|

|

-

|

W707638-S900C

|

-

|

-

|

|

5

|

-

|

-

|

-

|

-

|

W08777-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

-

Apply NVH foam as indicated.

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Install, properly position and clamp the outer panel section.

-

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

Blind or solid rivet fasteners may be used in place of SPR fasteners

after enlarging holes to 6.5 mm and must equal original quantity.

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

W708713-S900

|

AS

|

DZ09-025/H

|

SA-0400/SA-0401

|

-

|

W790376-S900

|

-

|

|

2

|

W717184-S900

|

QA

|

DP10-200/H

|

SA-0400/SA-0402

|

-

|

W790377-S900

|

-

|

|

3

|

W717186-S900

|

EN

|

DP11-200/H

|

SA-0400/SA-0402

|

-

|

W790377-S900

|

-

|

Use the General Equipment: Blind Rivet Gun

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

|

|

-

Metal finish the repair using typical aluminum metal finishing techniques and a fiber-based body filler.

Refer to: Special Repair Considerations for Aluminum Repairs (501-25

Body Repairs - General Information, Description and Operation).

-

Seam Sealing:

All areas must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair area using a Ford approved paint system and typical refinishing techniques.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the side curtain airbag.

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Install the subwoofer speaker.

Refer to: Subwoofer Speaker (415-00 Information and Entertainment

System - General Information - Vehicles With: SYNC 4, Removal and

Installation).

-

Install the quarter panel.

Refer to: Quarter Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Install the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

Reposition all modules, wiring harnesses and the carpeting to original location.

-

Install the wheel and tire on the affected side.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

Install and align the liftgate.

Refer to: Liftgate (501-03 Body Closures, Removal and Installation).

Refer to: Liftgate Alignment (501-03 Body Closures, General Procedures).

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Blind Rivet Gun

Hot Air Gun

MIG/MAG Welding Equipment

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

S..

Other information:

Cleaning

WARNING:

Do not bleach or re-dye the seatbelt webbing, as the webbing

may weaken. Failure to follow this instruction may increase the risk of

serious personal injury or death in a crash.

Refer to the owner's literature for information on

seatbelt care and the recommended cleaning solution to use. Follow the

manufacturer's instructions provided with th..

Activation

NOTE:

The following steps should be used when the engine will crank but not start.

NOTE:

If the vehicle has a discharged battery, an external power

source is required. If the battery discharges while in Stay in Neutral

Mode, the Park Lock Pawl Solenoid will release and transmission will

return to Park. Do not tow the vehicle in this mode.

Apply the..

Quarter Panel. Removal and Installation

Quarter Panel. Removal and Installation 205-1016

205-1016 205-153

(T80T-4000-W)

205-153

(T80T-4000-W)

205-D061

(D83T-4205-C2)

205-D061

(D83T-4205-C2)