Lincoln Navigator: Side Panel Sheet Metal Repairs / B-Pillar and Reinforcement. Removal and Installation

Special Tool(s) / General Equipment

| 6.5 mm Drill Bit | |

| Polydrive Bit Socket | |

| Self-Piercing Rivet (SPR) Remover/Installer | |

| Belt Sander | |

| Blind Rivet Gun | |

| Hot Air Gun | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

Removal

NOTICE: Body side sectioning is prohibited within 50 mm of door hinge, door striker and restraints anchoring points.

NOTE: LH side shown, RH side similar.

-

Verify the vehicle is dimensionally correct.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the side curtain air bag.

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Remove the front safety belt and safety belt height adjuster.

Refer to: Seatbelt Shoulder Height Adjuster (501-20A Seatbelt Systems, Removal and Installation).

-

Remove the rocker panel inner reinforcement.

Refer to: Rocker Panel Inner Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

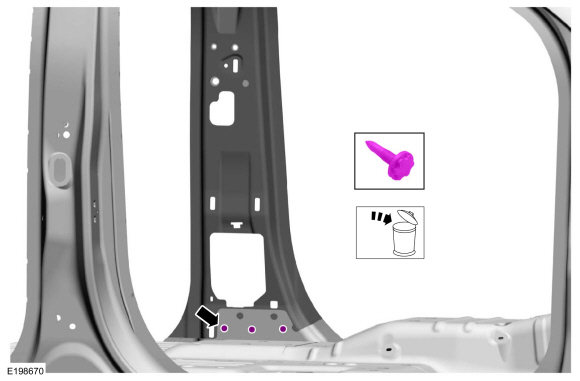

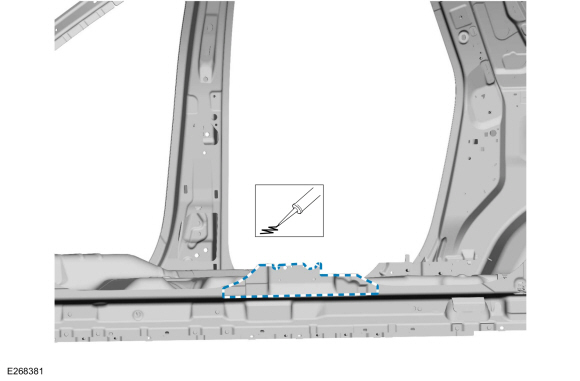

Remove the SPR fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

|

-

Remove and discard the FDS fasteners.

Use the General Equipment: Polydrive Bit Socket

|

-

NOTE: Aluminum body panels are highly receptive to heat transfer. With the extensive use of structural adhesives and non-structural sealers used in vehicle construction, the potential of heat transfer could impact adhesives and sealers in non-associated panels during the repair process. Many repairs areas that utilize structural adhesive may be separated after fastener removal by using a panel chisel along the joint/flange. Using heat not exceeding 425° F to loosen a bonded panel should only be done when all panels in the joint will be replaced and new adhesive applied.

Break the adhesive bond and remove the B-pillar.

Use the General Equipment: Hot Air Gun

|

Installation

NOTICE: Body side sectioning is prohibited within 50 mm of door hinge, door striker and restraints anchoring points.

NOTE: Do not install SPR fasteners directly in old SPR fastener location. SPR fasteners must be installed adjacent to the original location matching original quantity.

NOTE: Solid rivets or blind rivet fasteners may be used in place of SPR fasteners after enlarging existing holes to 6.5 mm.

NOTE: LH side shown, RH side similar.

-

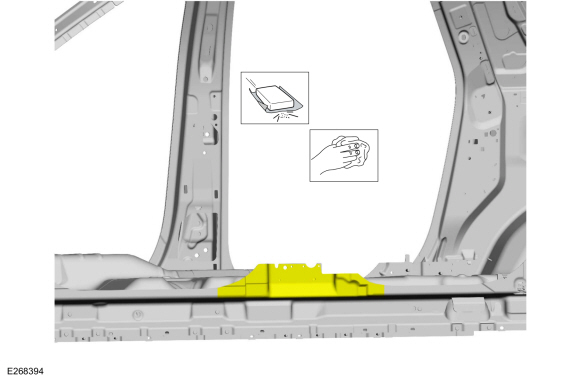

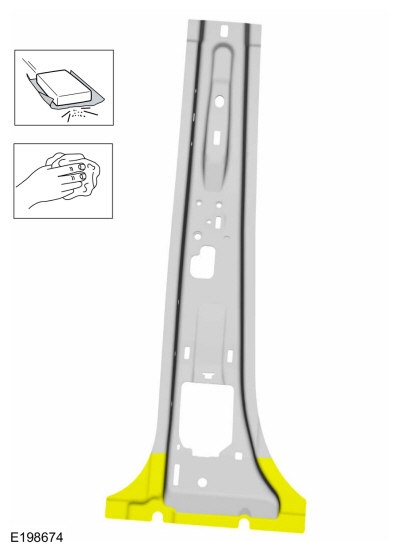

Sand using 80 grit sand paper to remove old adhesive and clean the B-pillar reinforcement lower mating surface.

|

-

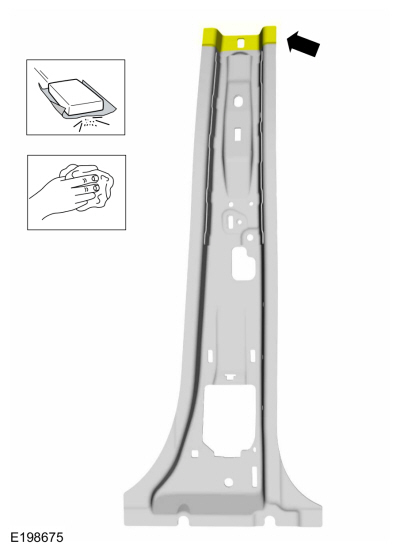

Sand using 80 grit sand paper to remove old adhesive and clean the B-pillar reinforcement upper mating surface.

|

-

Sand using 80 grit sand paper to remove e-coat and clean the B-pillar service panel lower mating surface.

|

-

Sand using 80 grit sand paper to remove e-coat and clean the B-pillar service panel upper mating surface.

|

-

Apply adhesive.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

Apply adhesive.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

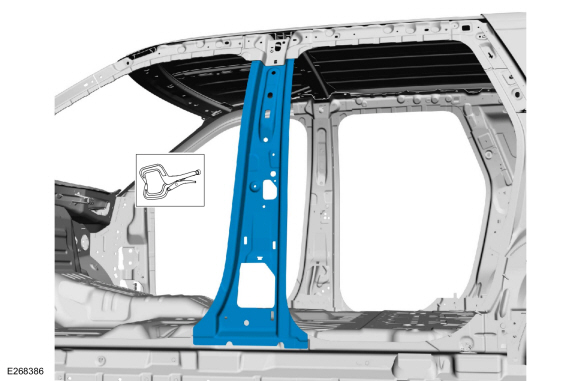

Install the B-pillar and clamp in position.

Use the General Equipment: Locking Pliers

|

-

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

|

-

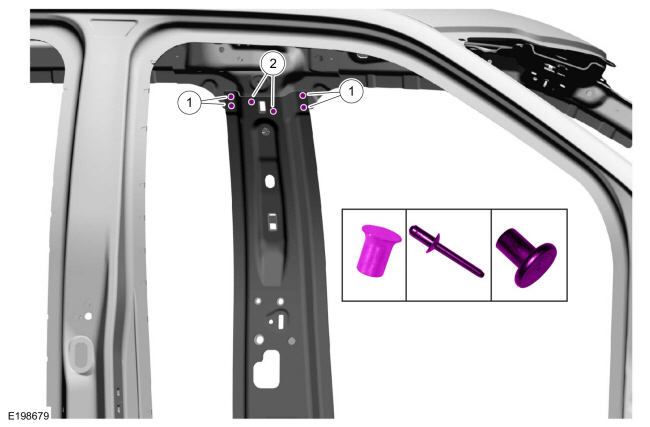

NOTE: Do not install SPR fasteners directly in old SPR fastener location. SPR fasteners must be installed adjacent to the original location matching original quantity.

NOTE: Solid rivets or blind rivet fasteners may be used in place of SPR fasteners after enlarging existing holes to 6.5 mm.

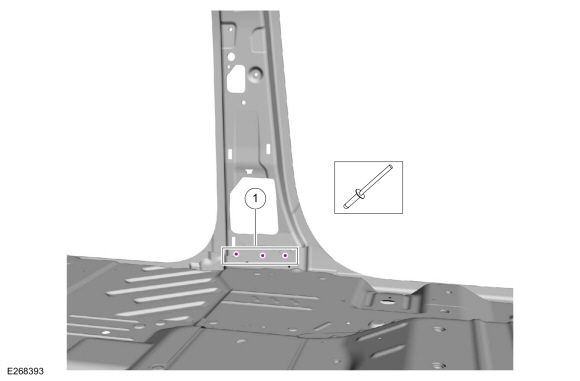

Install fasteners.Item SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 W717186-S900 EN DG11-200/H SA-0400/SA-0401 - W790376-S900 - 2 - - - - W708777-S900C - -

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Blind Rivet Gun

|

-

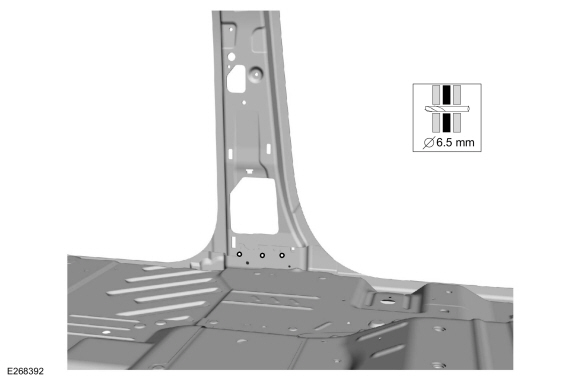

Drill 6.5 mm holes for blind rivet installation.

Use the General Equipment: 6.5 mm Drill Bit

|

-

NOTE: Do not install SPR fasteners directly in old SPR fastener location. SPR fasteners must be installed adjacent to the original location matching original quantity.

NOTE: Solid rivets or blind rivet fasteners may be used in place of SPR fasteners after enlarging existing holes to 6.5 mm.

Install fasteners.Item SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 - - - - W708777-S900C - -

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

Use the General Equipment: Blind Rivet Gun

|

-

Refinish using a Ford approved paint system and typical refinishing techniques.

-

Install the rocker panel reinforcement.

Refer to: Rocker Panel Inner Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Install the side curtain air bag.

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Install the front safety belt and safety belt height adjuster.

Refer to: Seatbelt Shoulder Height Adjuster (501-20A Seatbelt Systems, Removal and Installation).

B-Pillar Outer Panel. Removal and Installation

B-Pillar Outer Panel. Removal and Installation

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Spherical Cutter

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Blind Rivet Gun

Air Body Saw

MIG/MAG Welding Equipment

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Exhaust System. Description and Operation

Overview NOTICE: Do not use leaded fuel in a vehicle equipped with a catalytic converter. In a vehicle that is continually misfueled, the lead in the fuel will be deposited in the catalytic converter and completely blanket the catalyst. Lead reacts with platinum to "poison" the catalyst. Continuous use of leaded fuel can destroy the catalyst and render the catalytic converter usel..

Lincoln Navigator 2018-2026 Workshop Manual: Power Running Board (PRB) Motor. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: The power running board motor and drive bracket are serviced as an assembly. With the vehicle in NEUTRAL, position it on a hoist. Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation). NOTE: LH side shown, RH side similar..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Head Up Display (HUD) Module Calibration. General Procedures

- Rear View Mirrors - System Operation and Component Description. Description and Operation

- Rear Bumper. Removal and Installation

- Front Bumper Cover. Removal and Installation

- Body and Paint

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and