Lincoln Navigator: Fuel Charging and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS) / Turbocharger Oil Supply Tube RH. Removal and Installation

Materials

| Name | Specification |

|---|---|

| Motorcraft® Metal Brake Parts Cleaner PM-4-A, PM-4-B, APM-4-C |

- |

Removal

NOTICE: The turbocharger compressor vanes can be damaged by even the smallest particles. When removing any turbocharger or engine air intake system component, ensure that no debris enters the system. Failure to do so may result in damage to the turbocharger.

NOTICE: Special attention needs to be given to the sealing ports for the oil feed, the oil drain, and the coolant lines, on turbocharged engines. The sealing ports must be totally clean and free from O-ring residue, have no damage to the sealing surface and the lines to ensure that there are no leaks or repeat repairs.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

Remove the engine rear undershield.

-

Remove the right front fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Remove the charge air cooler intake pipe - right side.

Refer to: Charge Air Cooler (CAC) Intake Pipe (303-12 Intake Air Distribution and Filtering - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

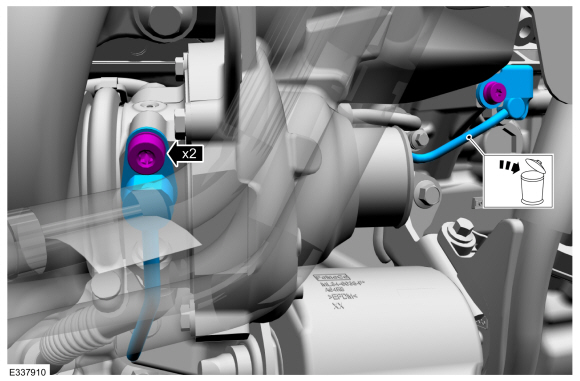

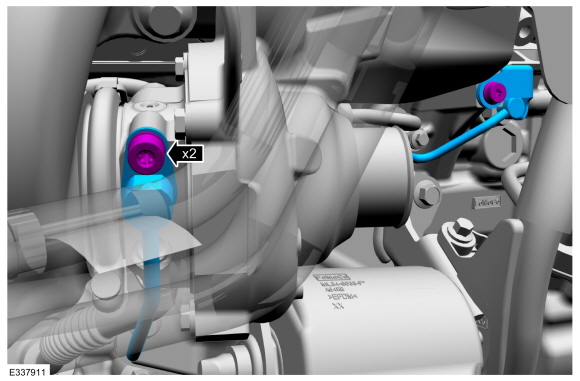

Remove the turbocharger oil supply tube bolts, then remove and discard the turbocharger oil supply tube.

|

-

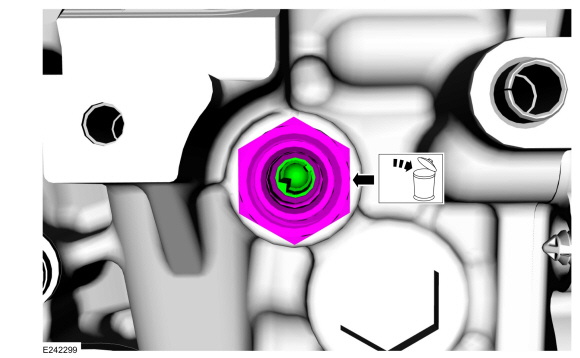

Remove and discard the turbocharger fitting and oil filter assembly from the engine block.

|

Installation

-

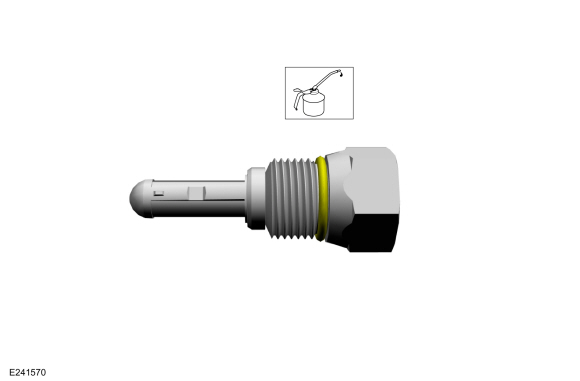

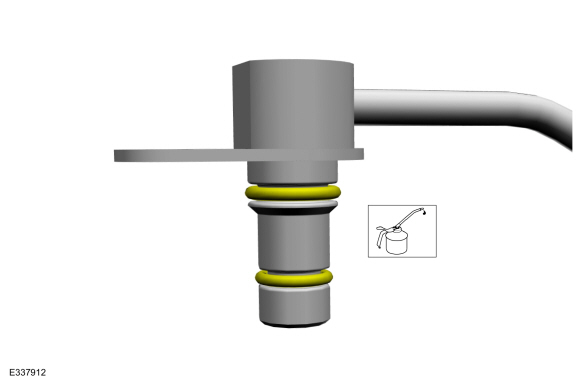

Lubricate the new turbocharger fitting and oil filter assembly O-ring seal with clean engine oil.

Refer to: Specifications (303-01 Engine - 3.5L EcoBoost (BM)) .

|

-

-

NOTICE: Do not use any brushes, damage to sealing area will result in leaks and possible internal turbo bearing damage.

Use brake cleaner on a lint free rag to remove the O-ring residue out of the turbocharger fitting to engine block O-ring bore. Inspect the area for deep scratches and gouges. Install new components if necessary.

Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

-

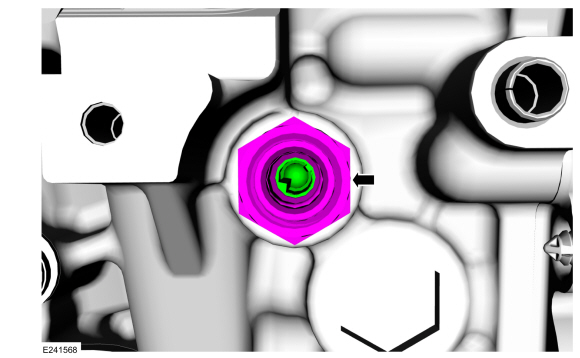

Install and tighten the new turbocharger fitting, oil filter assembly.

Torque: 24 lb.ft (32 Nm)

-

|

-

Lubricate the new turbocharger oil supply tube O-ring seals with clean engine oil.

Refer to: Specifications (303-01 Engine - 3.5L EcoBoost (BM)) .

|

-

-

NOTICE: Do not use any brushes, damage to sealing area will result in leaks and possible internal turbo bearing damage.

Use brake cleaner on a lint free rag to remove the O-ring residue out of the turbocharger and the engine oil filter adapter O-ring bores. Inspect the area for deep scratches and gouges. Install new components if necessary.

-

Install the oil supply tube and the bolts, by

simultaneously fully seating the oil supply tube into the turbocharger

bore hole and the engine oil filter adapter bore hole flush to 2.5 mm

off the mounting surface prior to tightening the bolts, then tighten the

bolts in the following 2 stages.

Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

Torque:

Stage 1: Tighten to : 89 lb.in (10 Nm)

Stage 2: Tighten an additional : 30°

-

|

-

Install the charge air cooler intake pipe - right side.

Refer to: Charge Air Cooler (CAC) Intake Pipe (303-12 Intake Air Distribution and Filtering - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the right fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Install the engine rear undershield.

-

Check and top off the engine oil level as needed.

Refer to: Specifications (303-01 Engine - 3.5L EcoBoost (BM)) .

Turbocharger Oil Supply Tube LH. Removal and Installation

Turbocharger Oil Supply Tube LH. Removal and Installation

Materials

Name

Specification

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C

-

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Turbocharger RH. Removal and Installation

Turbocharger RH. Removal and Installation

Materials

Name

Specification

Motorcraft® High Temperature Nickel Anti-Seize LubricantXL-2

-

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C

-

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Other information:

Lincoln Navigator 2018-2025 Workshop Manual: Driver Status Monitor Camera Module [CMR]. Removal and Installation

Removal NOTE: If installing a new module, it is necessary to upload the module configuration information to the diagnostic scan tool prior to removing the module. This information must be downloaded into the new module after installation...

Lincoln Navigator 2018-2025 Workshop Manual: Transmission Support Insulator. Removal and Installation

Removal With the vehicle in NEUTRAL, position it on a hoist. Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation). Remove the transmission support crossmember. Refer to: Transmission Support Crossmember (502-02 Full Frame and Body Mounting, Removal and Installation)...

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2025)

- Windshield Washer Pump. Removal and Installation

- SYNC Module [APIM]. Removal and Installation

- Body and Paint

- All Terrain Control Module (ATCM). Removal and Installation

- Front Seat. Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and