Lincoln Navigator: Fuel Charging and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS) / Turbocharger. Diagnosis and Testing

Pinpoint Tests

PINPOINT TEST A: BLUE SMOKE FROM EXHAUST

PINPOINT TEST A: BLUE SMOKE FROM EXHAUST

|

Possible Sources

- Oil leak

- Air cleaner

- Air intake

- Crankcase ventilation system

- Internal engine damage

- Turbocharger

|

| A1 CHECK THE EXHAUST |

-

Monitor the exhaust system.

Is blue smoke noticeable from the exhaust system?

| No |

INSPECT for external oil leaks. REFER to the Oil

Leak Inspection procedure in the 303-00 section for the engine being

diagnosed.

|

|

| A2 CHECK THE AIR CLEANER |

Is the air cleaner clogged?

| Yes |

REPLACE the air cleaner. Refer to the 303-12 section

for the engine being diagnosed. Check the system for normal operation.

|

|

| A3 CHECK THE AIR INTAKE PIPES AND HOSES |

-

Inspect the air intake pipes and hoses for loose connections or leaks.

Were any loose connections or leaks found from the air intake pipes or hoses?

| Yes |

REPAIR or REPLACE the intake air system. Refer to the 303-12 section for the procedure.

|

|

| A4 CHECK THE CRANKCASE VENTILATION SYSTEM |

-

Check the crankcase ventilation system for damage

and correct operation. REFER to the 303-08 Diagnosis and Testing

Crankcase Ventilation procedure for the engine being diagnosed.

Is the crankcase ventilation system damaged?

| Yes |

CLEAN, REPAIR or REPLACE the crankcase ventilation

components. Refer to the section 303-08 for the procedure.

|

|

| A5 CHECK THE AIR INTAKE PIPES AND HOSES FOR EXCESSIVE OIL |

|

NOTE:

It is normal for a small amount of combustion gas to

pass into the crankcase. This gas is scavenged into the air intake

system through the positive crankcase ventilation system, which

incorporates a crankcase vent oil separator. Some engine oil, in the

form of a vapor, is carried into the air intake system with the blow-by

gases (this engine oil also contributes to valve seat durability). This

means that oil will collect inside the air intake components and the

turbocharger. This is not an indication that the turbocharger oil seal

has failed. The turbocharger oil seal will generally not fail unless the

bearings fail first, which will cause the turbocharger to become noisy

or seize. Do not install a new turbocharger due to oil inside the

intake.

-

Inspect the inside of the air intake pipes and hoses for excessive oil.

Is excessive oil noticeable?

| No |

Diagnose internal engine damage. REFER to the 303-00

Diagnosis and Testing procedure for the engine being diagnosed. Follow

the pinpoint test to diagnose blue smoke.

|

|

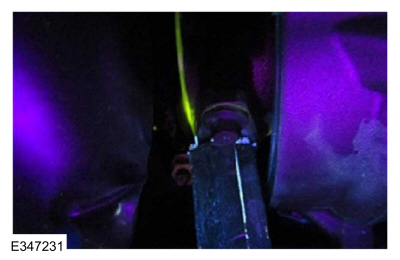

| A6 CHECK THE TURBOCHARGER |

-

Remove the air cleaner outlet pipe and CAC intake pipe. Refer to the section 303-12 for the procedure.

-

Inspect the compressor wheel for damage.

-

Check that the turbine shaft spins free.

-

Check for contact marks between the compressor wheel and the housing.

Is the turbocharger damaged?

| Yes |

INSTALL a new turbocharger. REFER to the Turbocharger Removal and Installation procedure in this section.

|

| No |

Diagnose internal engine damage. REFER to the 303-00

Diagnosis and Testing procedure for the engine being diagnosed. Follow

the pinpoint test to diagnose blue smoke.

|

|

PINPOINT TEST B: EXCESSIVE NOISE

PINPOINT TEST B: EXCESSIVE NOISE

|

Possible Sources

- Air intake system

- Engine

- Turbocharger

|

| B1 COMPARE CUSTOMER CONCERN TO A KNOWN GOOD VEHICLE |

-

Compare the customer concern to a known good

vehicle. Variations in vehicle options such as engine size, transmission

or tire size will sound different. Compare to a vehicle similarly

equipped. Compare the vehicle under similar driving conditions, like

road test route, APP and load.

Is the noise excessively different from the comparison vehicle?

| No |

The sound is a normal characteristic of the vehicle.

|

|

| B2 LOCATE THE SOURCE OF THE NOISE |

-

Using the Chassis/Ear, Engine/Ear, and VCMM

accelerometers along with the scan tool, locate the source of the noise.

REFER to the Engine Noise Identification and Location procedure in the

303-00 section.

Is the noise located near the turbocharger?

| No |

The turbocharger is not the source of the noise.

Diagnose an engine noise. REFER to the 303-00 Diagnosis and Testing

procedure for the engine being diagnosed. Follow the pinpoint test to

diagnose engine noise.

|

|

| B3 CHECK THE AIR INTAKE SYSTEM |

-

Check the air intake system, air cleaner and CAC

components, ducts, pipes and hoses. Check that all components are

installed correctly and tight. Check that all components are aligned

correctly. Check for damage that could cause an air-intake leak

resulting in a noise from the turbocharger(s). For additional

information, refer to the 303-12 Intake Air Distribution and Filtering

section for the engine being diagnosed.

Does the air intake system have any leaks?

| Yes |

Repair as necessary. For additional information,

refer to the 303-12 Intake Air Distribution and Filtering section for

the engine being diagnosed.

|

| No |

GO to Pinpoint Test C Check the turbocharger(s) for damage that could result in a noise.

|

|

PINPOINT TEST C: LOSS OF POWER

PINPOINT TEST C: LOSS OF POWER

|

Possible Sources

- Air cleaner

- Air intake

- Exhaust restricted

- Turbocharger

- Internal engine damage

|

| C1 CHECK FOR PCM (POWERTRAIN CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS) |

-

Carry out the PCM

KOEO and KOER self-tests.

Are any Diagnostic Trouble Codes (DTCs) present?

| Yes |

REFER to the Master DTC Chart to diagnose the DTC present.

|

|

| C2 CHECK THE AIR CLEANER |

Is the air cleaner clogged?

| Yes |

REPLACE the air cleaner. Refer to the section 303-12

for the procedure. Check the system for normal operation.

|

|

| C3 CHECK THE AIR INTAKE SYSTEM |

-

Check the air intake system, air cleaner and CAC

components, ducts, pipes and hoses. Check that all components are

installed correctly and tight. Check that all components are aligned

correctly. Check for damage that could cause an air-intake leak

resulting in a noise from the turbocharger(s). For additional

information, refer to the 303-12 Intake Air Distribution and Filtering

section for the engine being diagnosed.

Does the air intake system have any leaks?

| Yes |

Repair as necessary. Refer to the 303-12 Intake Air

Distribution and Filtering section for the engine being diagnosed.

|

|

| C4 CHECK THE EXHAUST SYSTEM |

-

Check the exhaust system for restrictions or damage.

Refer to the 309-00 Exhaust System section for the engine being

diagnosed.

Is the exhaust system restricted or damaged?

| Yes |

REPAIR as necessary. Refer to the 309-00 Exhaust System section for the engine being diagnosed.

|

|

| C5 CHECK THE WASTEGATE |

-

Check the wastegate for damage. Check to be sure the wastegate linkage moves freely.

Is the wastegate, wastegate actuator or linkage damaged?

| Yes |

REPAIR as necessary. Refer to the 303-04 Turbocharger section for the engine being diagnosed.

|

|

| C6 CHECK THE TURBOCHARGER |

-

Remove the air cleaner outlet pipe and CAC intake pipe. Refer to the section 303-12 for the procedure.

-

Inspect the compressor wheel for damage.

-

Check that the turbine shaft spins free.

-

Check for contact marks between the compressor wheel and the housing.

Is the turbocharger damaged?

| Yes |

INSTALL a new turbocharger. REFER to the Turbocharger Removal and Installation procedure in this section.

|

| No |

Diagnose internal engine damage. REFER to the 303-00

Diagnosis and Testing procedure for the engine being diagnosed. Follow

the pinpoint test to diagnose loss of power, poor idling, runs rough.

|

|

PINPOINT TEST D: EXTERNAL OIL LEAKS

PINPOINT TEST D: EXTERNAL OIL LEAKS

|

Possible Sources

- Oil supply tube

- Oil return tube

- Gaskets

- Turbocharger

NOTE:

It is very unlikely for the turbocharger to leak engine

oil externally. The moving parts of a turbocharger that require oil are

contained in a housing with no external sealing surfaces. Pressurized

engine oil is supplied to the turbocharger from the engine through an

oil supply tube and drains back to the engine sump through an

unpressurized return tube. The most likely source of an external oil

leak would be from the oil supply or oil return tubes or the gaskets and

seals.

|

| D1 CHECK THE OIL SUPPLY TUBE |

-

Perform an oil leak inspection. REFER to the Oil

Leak Inspection procedure in the 303-00 section for the engine being

diagnosed. Visually inspect the oil supply tube for traces of oil. Check

the engine and the turbocharger ends. Check for oil running down from

other areas of the tube or the engine to locate the source of the leak.

Check the oil supply tube gaskets and seals.

-

Movement of the vehicle, under hood components or

gravity can cause oil leaks to appear in different areas from the source

of the oil leak. Follow the trace of the oil leak to the source.

Is the oil supply tube leaking oil?

| Yes |

INSTALL a new turbocharger oil supply tube. REFER to

the Turbocharger Oil Supply Tube Removal and Installation procedure in

this section.

|

|

| D2 CHECK THE OIL RETURN TUBE |

-

Visually inspect the oil return tube for traces of

oil. Check the engine and the turbocharger ends. Check for oil running

down from other areas of the tube or the engine to locate the source of

the leak. Check the oil return tube gaskets and seals.

Is the oil return tube leaking oil?

| Yes |

INSTALL a new turbocharger oil return tube. REFER to

the Turbocharger Oil Return Tube Removal and Installation procedure in

this section.

|

| No |

CARRY OUT an oil leak inspection. REFER to the Oil

Leak Inspection procedure in the 303-00 section for the engine being

diagnosed. Check for an engine oil leak.

|

|

Turbocharger 3.5L EcoBoost/PowerBoost LH

Item

Description

1

Turbocharger LH

2

Turbocharger coolant return tube LH

3

Wastegate control actuator LH

4

Turbocharger coolant supply tube LH

5

Turbocharger oil supply tube LH

6

Turbocharger oil return tube LH

Turbocharger 3...

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Other information:

Removal

NOTE:

Removal steps in this procedure may contain installation steps.

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

Disconnect the battery ground cable...

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

NOTE:

Network communication or missing message Diagnostic Trouble

Codes (DTCs) may result from intermittent concerns, such as damaged

wiring or low battery..

PINPOINT TEST A: BLUE SMOKE FROM EXHAUST

PINPOINT TEST A: BLUE SMOKE FROM EXHAUST

PINPOINT TEST B: EXCESSIVE NOISE

PINPOINT TEST B: EXCESSIVE NOISE

PINPOINT TEST C: LOSS OF POWER

PINPOINT TEST C: LOSS OF POWER

PINPOINT TEST D: EXTERNAL OIL LEAKS

PINPOINT TEST D: EXTERNAL OIL LEAKS Turbocharger - Component Location. Description and Operation

Turbocharger - Component Location. Description and Operation Turbocharger Controls. Diagnosis and Testing

Turbocharger Controls. Diagnosis and Testing