Lincoln Navigator: Roof Sheet Metal Repairs / Roof Front Frame. Removal and Installation

Special Tool(s) / General Equipment

| 6.5 mm Drill Bit | |

| Self-Piercing Rivet (SPR) Remover/Installer | |

| Belt Sander | |

| Blind Rivet Gun | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

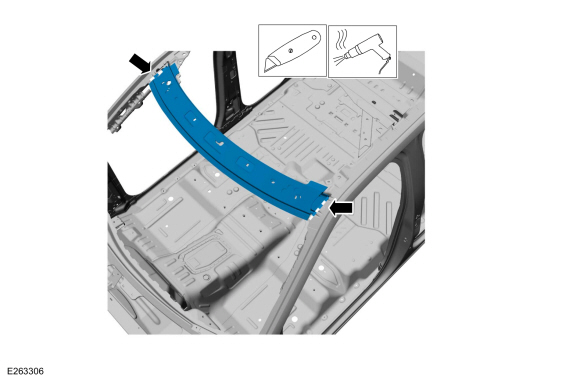

Removal

NOTE: Aluminum body panels are highly receptive to heat transfer. With the extensive use of structural adhesives and non-structural sealers used in vehicle construction, the potential of heat transfer could impact adhesives and sealers in non-associated panels during the repair process. Many repairs areas that utilize structural adhesive may be separated after fastener removal by using a panel chisel along the joint/flange. Using heat not exceeding 425° F to loosen a bonded panel should only be done when all panels in the joint will be replaced and new adhesive applied.

-

Remove the roof outer panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

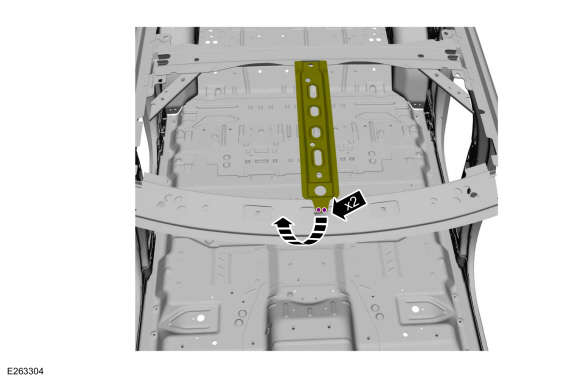

NOTE: Vehicles without roof opening panel.

Remove the center reinforcement SPR fasteners and position aside.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

|

-

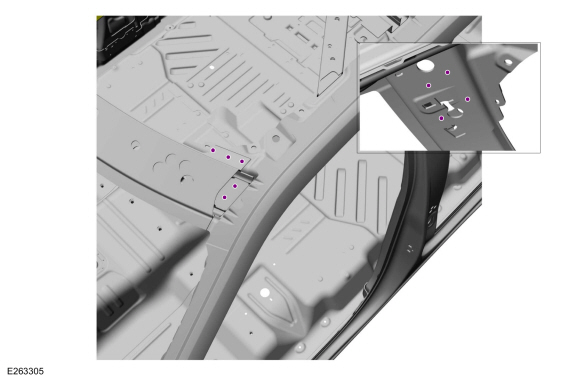

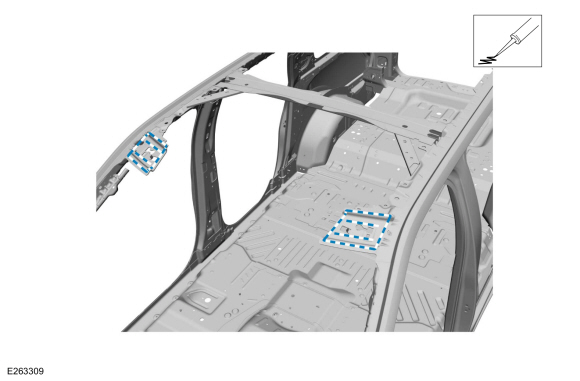

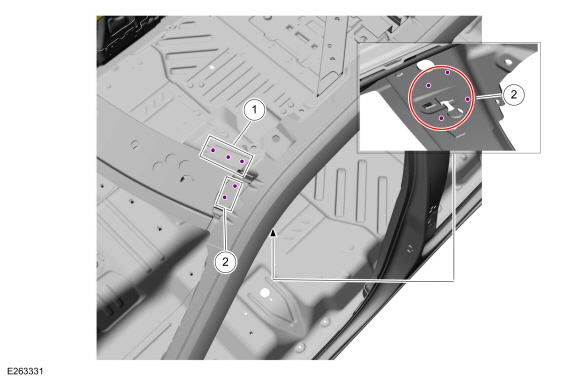

Remove the SPR fasteners (both sides).

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

|

-

Break the adhesive bond and remove the roof front frame.

|

Installation

-

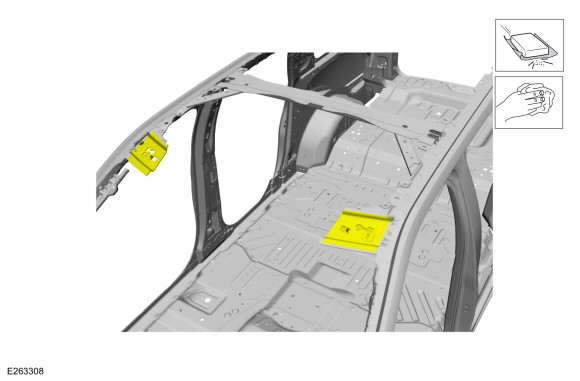

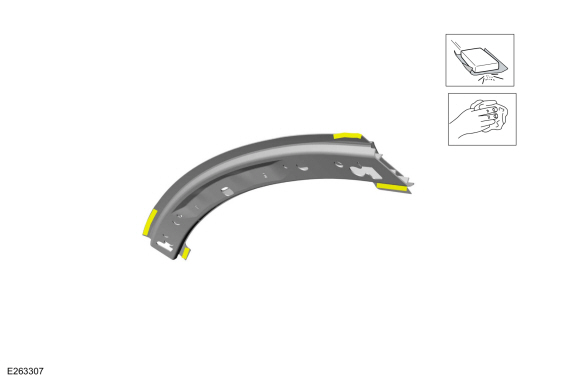

Sand gussets using 80 grit sandpaper to remove all remaining adhesive and clean.

|

-

Sand the roof front frame using 80 grit sandpaper to remove e-coat and clean.

|

-

Apply adhesive to the gussets.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

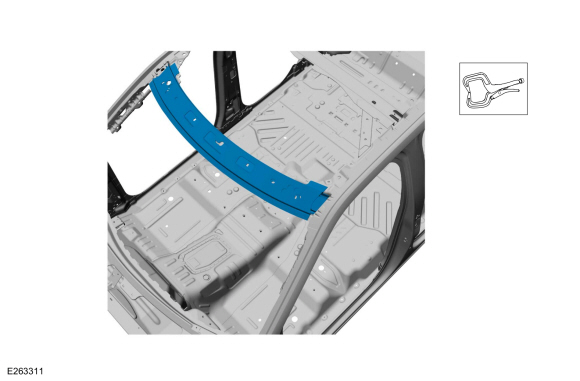

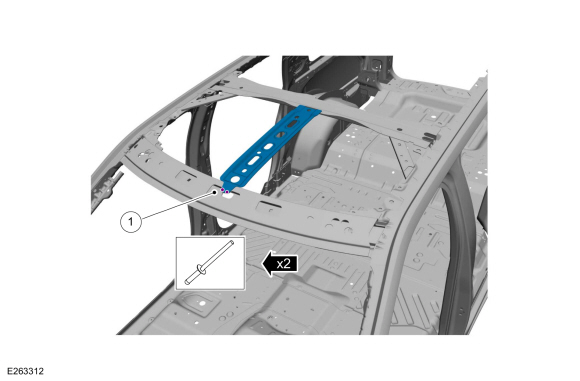

Install and clamp the roof frame.

Use the General Equipment: Locking Pliers

|

-

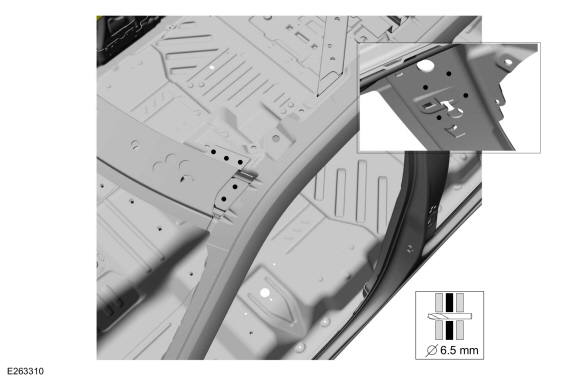

Drill blind fastener holes as indicated (both sides).

Use the General Equipment: 6.5 mm Drill Bit

|

-

NOTE: SPR fasteners may not be placed directly over original SPR location. They must be placed adjacent to original location matching original quantity.

NOTE: Solid or blind rivets may be used in place of SPR fasteners in the original SPR location after enlarging hole to 6.5 mm.

Install fasteners (both sides).Item SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 W717337-S900 PX DG11-200/H SA-0400/SA-0402 - W790377-S900 - 2 - - - - W708777-S900C - -

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

Use the General Equipment: Blind Rivet Gun

|

-

NOTE: Vehicles without roof opening panel.

NOTE: Blind rivets may be used in place of SPR fasteners in the original SPR location after enlarging hole to 6.5 mm.

Reposition the center reinforcement and install fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/InstallerItem SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 - - - - W702512-S900C - -

Use the General Equipment: Blind Rivet Gun

|

-

Sand and prime the repair area using a Ford approved paint system.

-

Sealing work: All areas must be sealed to production level.

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the roof outer panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Roof Panel. Removal and Installation

Roof Panel. Removal and Installation

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Grinder

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Knife

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Roof Ditch Sealer3M™ 08307, LORD Fusor® 129

..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Transfer Case - Vehicles With: 1-Speed Torque On Demand Transfer Case. Disassembly and Assembly

Special Tool(s) / General Equipment 205-153 (T80T-4000-W) Handle 205-293 (T89P-4850-A) Installer, Differential Oil SealTKIT-1989-FTKIT-1989-FMTKIT-1989-LMTKIT-1989-FLM 205-504Installer, Halfshaft Pilot BearingTKIT-2002N-F/FMTKIT-2002N-FLMTKIT-2002N-LM 308-250 (T96T-7127-B) Installer, Output Shaft Oil SealTKIT-1996-F/FMTKIT-1996-FLM2 ..

Lincoln Navigator 2018-2026 Workshop Manual: Driver Status Monitor Camera. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the steering column shrouds. Refer to: Steering Column Shrouds (501-05 Interior Trim and Ornamentation, Removal and Installation). NOTE: Typical application shown. Remove the driver status monitor camera. Detach the wire harness from the retaine..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Brake Service Mode Activation and Deactivation. General Procedures

- Front Bumper Cover. Removal and Installation

- Vehicle Dynamics Control Module (VDM). Removal and Installation

- SYNC Module [APIM]. Removal and Installation

- Rear Bumper. Removal and Installation

Rear Camber Adjustment. General Procedures

Special Tool(s) / General Equipment

Wheel Alignment SystemActivation

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

Using alignment equipment and the manufacturer's instructions, measure the rear camber.Use the General Equipment: Wheel Alignment System