Lincoln Navigator: Bumpers / Rear Bumper Cover. Removal and Installation

Special Tool(s) / General Equipment

| Interior Trim Remover |

Removal

NOTE: Removal steps in this procedure may contain installation details.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

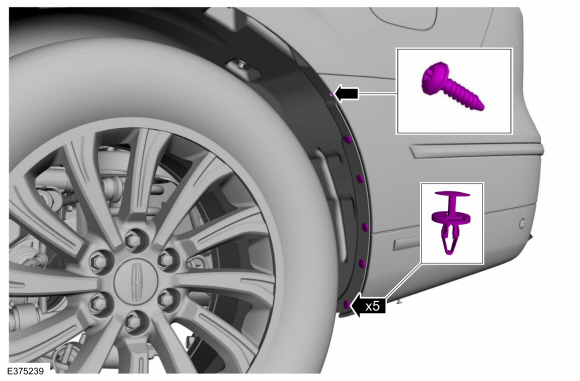

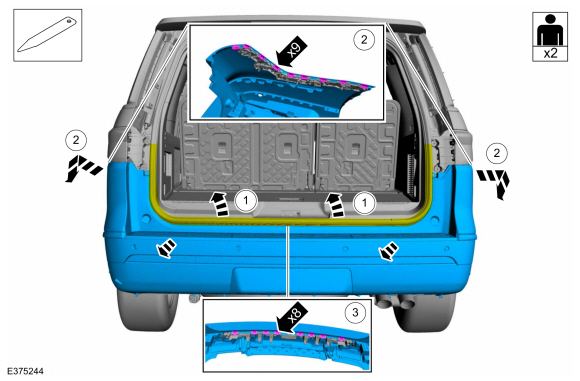

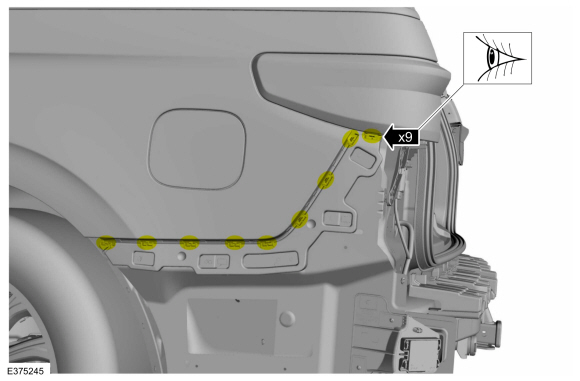

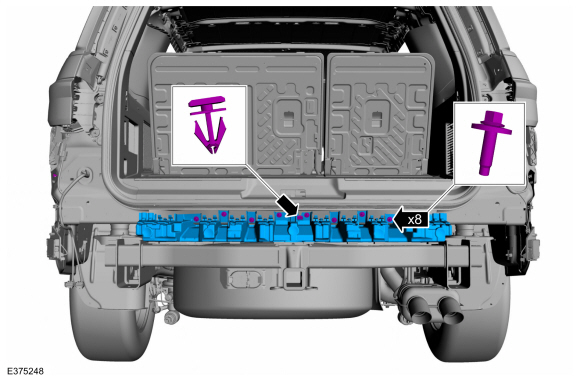

On both sides.

Remove the push pins and the screw.

Torque: 21 lb.in (2.4 Nm)

|

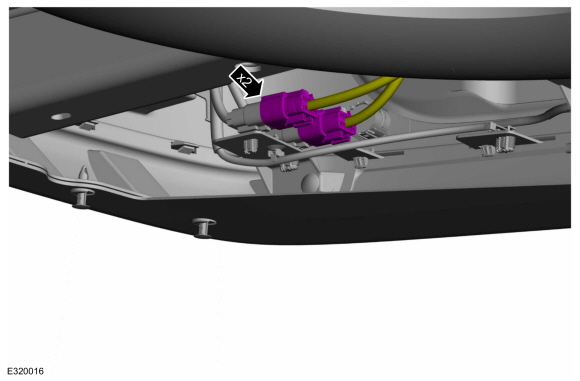

-

Disconnect the rear bumper cover electrical connectors.

|

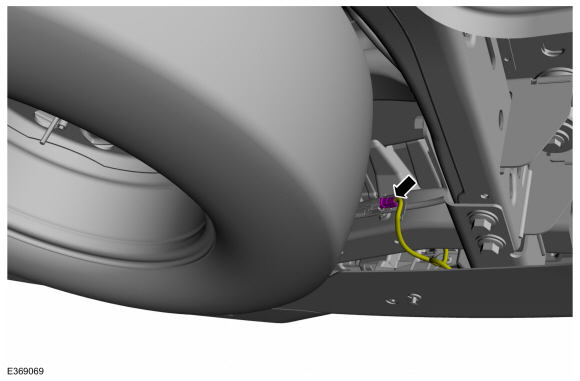

Vehicles With: Hands-Free Liftgate

-

Disconnect the rear bumper cover electrical connector.

|

All vehicles

-

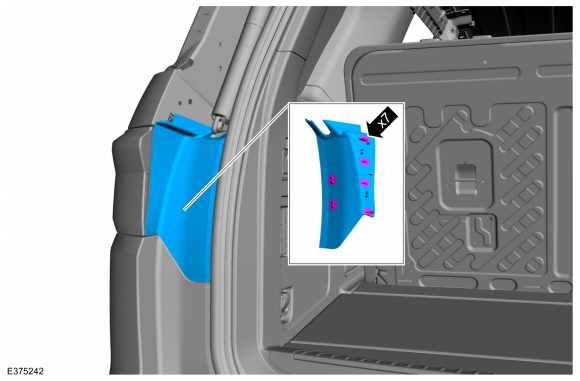

On both sides.

Release the clips and remove the rear lamp cover assembly.

|

-

Remove the screws.

Torque: 53 lb.in (6 Nm)

|

-

NOTE: This step requires the aid of another technician.

Remove the rear bumper cover.

-

Position the luggage compartment weatherstrip aside.

-

Release the sides of the rear bumper cover from the side brackets.

-

Using a non-marring tool, release the center of the rear bumper cover from the rear bracket.

Use the General Equipment: Interior Trim Remover

-

Position the luggage compartment weatherstrip aside.

|

-

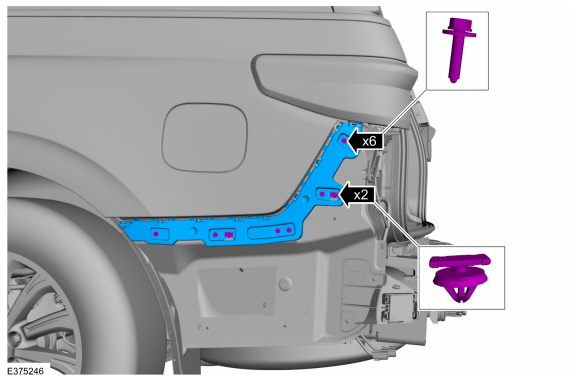

On both sides.

Inspect the side bracket for damage.

|

-

If required, on both sides.

Remove the screws, the trim-pins and the damaged side bracket.

Torque: 13 lb.in (1.5 Nm)

|

-

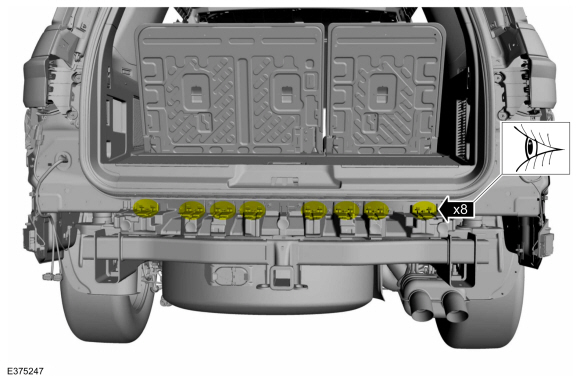

Inspect the rear bracket for damage.

|

-

If required.

Remove the screws, the trim-pin and the rear bracket.

Torque: 53 lb.in (6 Nm)

|

Installation

-

To install, reverse the removal procedure.

Vehicles With: Rear Parking Aid

-

If replacing the rear bumper cover.

Check the alignment of the rear parking aid sensors.

Refer to: Azimuth System Check (413-13A Parking Aid, General Procedures).

Refer to: Elevation System Check (413-13A Parking Aid, General Procedures).

-

If any sensor fails the check, diagnose the sensor fault.

Refer to: Parking Aid (413-13A Parking Aid, Diagnosis and Testing).

Vehicles With: Active Park Assist

-

If replacing the rear bumper cover.

Check the alignment of the rear active park assist sensors.

Refer to: Azimuth System Check (413-13C Parking Aid - Vehicles With: Active Park Assist, General Procedures).

-

If any sensor fails the check, diagnose the sensor fault.

Refer to: Parking Aid (413-13C Parking Aid - Vehicles With: Active Park Assist, Diagnosis and Testing).

Rear Bumper. Removal and Installation

Rear Bumper. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the rear bumper cover.

Refer to: Rear Bumper Cover (501-19 Bumpers, Removal and Installation)...

Front Bumper Cover. Disassembly and Assembly

Front Bumper Cover. Disassembly and Assembly

Special Tool(s) /

General Equipment

Electric Drill

DISASSEMBLY

NOTE:

Disassembly steps in this procedure may contain assembly details...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Subwoofer Speaker. Removal and Installation

Removal Remove the LH loadspace trim panel. Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation). Remove the subwoofer speaker. Disconnect the electrical connector...

Lincoln Navigator 2018-2026 Workshop Manual: E Clutch. Diagnosis and Testing

Symptom Chart E Clutch For E clutch operation, REFER to: E Clutch (307-01 Automatic Transmission - 10-Speed Automatic Transmission – 10R80, Description and Operation). E Clutch Condition Possible Sources Action E clutch does not apply SSE mechanically stuck OFF INSTALL a new sole..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Second Row Seat. Removal and Installation

- Liftgate Trim Panel. Removal and Installation

- Brake Service Mode Activation and Deactivation. General Procedures

- Vehicle Dynamics Control Module (VDM). Removal and Installation

- Head Up Display (HUD) Module Calibration. General Procedures

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and