Lincoln Navigator: Engine - 3.5L EcoBoost (272kW/370PS) / Piston. Disassembly and Assembly of Subassemblies

DISASSEMBLY

-

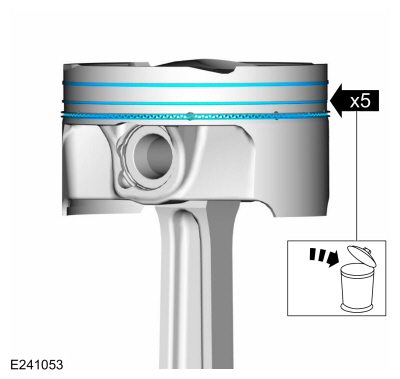

Remove the piston rings and discard.

|

-

-

Remove the piston pin retainers and discard.

-

Remove the piston pin.

-

Remove the piston pin retainers and discard.

|

-

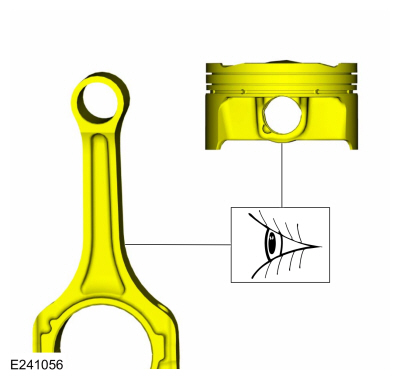

NOTE: If the piston and connecting rod are to be reinstalled, they must be assembled in the same orientation. Mark the piston orientation to the connecting rod for reassembly.

Remove the piston from the connecting rod.

|

-

Inspect the piston and connecting rod.

Refer to: Piston Inspection (303-00 Engine System - General Information, General Procedures).

|

ASSEMBLY

-

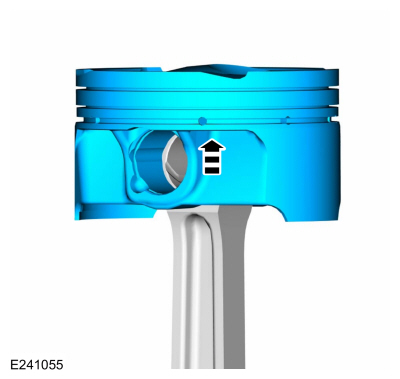

If the piston and/or connecting rod are being installed

new, the piston rod orientation marks and the arrow on the top of the

dome of the piston should be facing toward the front of the engine

block.

|

-

Install the piston to the connecting rod.

|

-

Lubricate with clean engine oil and install the piston pin.

Refer to: Specifications (303-01C) .

|

-

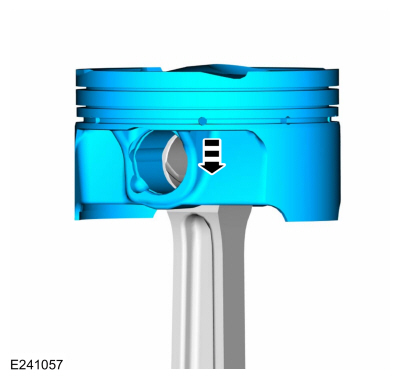

NOTE: The piston pin retaining clip gap orientation must be toward the top or dome of piston.

Install the piston pin retainers.

|

-

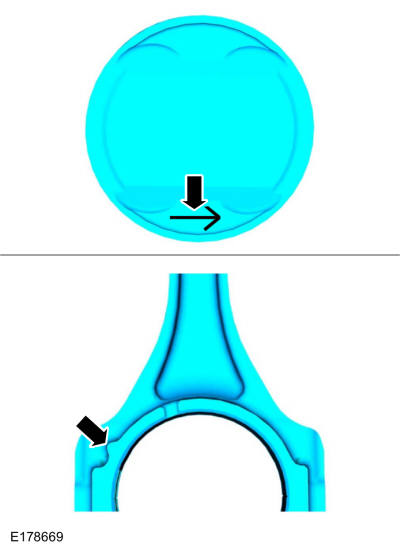

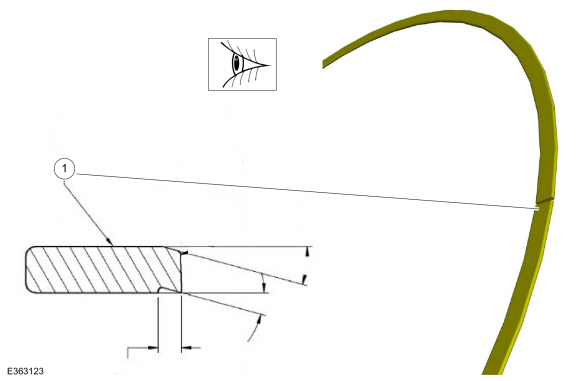

Inspect the lower compression ring to identify the

orientation. The top of the lower compression ring will be angled at the

top and notched on the bottom.

-

Top Side.

-

Top Side.

|

-

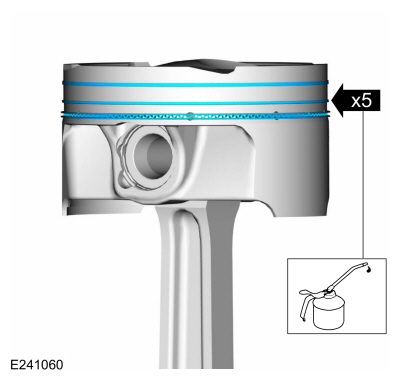

Lubricate with clean engine oil and install the piston rings.

Refer to: Specifications (303-01C) .

|

-

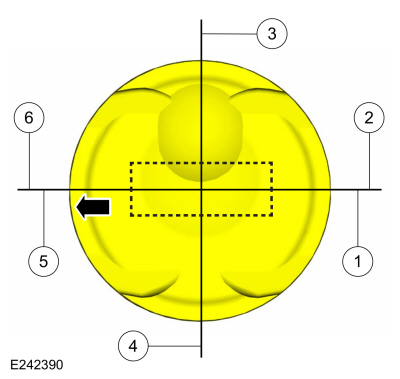

NOTE: The piston compression upper ring should be installed with the "O" mark on the ring face pointing up toward the top of the piston.

NOTE: The arrow on the top of the piston indicates the front of the engine.

-

Center line of the piston parallel to the wrist pin bore.

-

Upper compression ring gap location.

-

Upper oil control segment ring gap location.

-

Lower oil control segment ring gap location.

-

Lower compression ring gap location.

-

Spacer oil control ring gap location.

-

Center line of the piston parallel to the wrist pin bore.

|

Engine. Assembly

Engine. Assembly

Special Tool(s) /

General Equipment

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge

205-142

(T80T-4000-J)

Installer, Differential Bearing Cone

205-149

(T80T-4000-R)

Installer, Spindle Bearing

205-153

(T80T-4000-W)

Handle

303-102Installer, Crankshaft Pulley

303-1246Engine Spreader BarTKIT-2006UF-FLMTK..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Leakage Inspection. Diagnosis and Testing

Leak Check Test With the vehicle in NEUTRAL, position it on a hoist. REFER to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation). Inspect the gaskets and sealing areas for evidence of leakage. Trace the transmission fluid leak to the highest point. Clean the area of the suspected leak. Lower the vehi..

Lincoln Navigator 2018-2026 Workshop Manual: Windshield Washer Jets. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the cowl panel grille. Refer to: Cowl Panel Grille (501-02 Front End Body Panels, Removal and Installation). Disconnect the windshield washer fluid house coupler. NOTE: LH (left-hand) side shown, RH (right-hand) sid..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Transmission Fluid Level Check. General Procedures

- Brake Service Mode Activation and Deactivation. General Procedures

- SYNC Module [APIM]. Removal and Installation

- Body and Paint

- Liftgate Trim Panel. Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and