Lincoln Navigator: Automatic Transmission - 10-Speed Automatic Transmission – 10R80 / Leakage Inspection. Diagnosis and Testing

Lincoln Navigator 2018-2026 Workshop Manual / Automatic Transmission / Automatic Transmission - 10-Speed Automatic Transmission – 10R80 / Leakage Inspection. Diagnosis and Testing

Leak Check Test

-

With the vehicle in NEUTRAL, position it on a hoist.

REFER to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

Inspect the gaskets and sealing areas for evidence of leakage.

-

Trace the transmission fluid leak to the highest point.

-

Clean the area of the suspected leak.

-

Lower the vehicle.

-

Remove the transmission fluid fill plug or fluid level indicator.

-

Add leak detection dye to the transmission fluid. Use 1 fl oz

(30 ml) of dye solution for every 4 qt (3.8 L) of transmission fluid.

-

With the transmission fluid at normal operating temperature,

road test the vehicle for at least 1 mile with at least 1 application of

the TCC .

-

With the vehicle in NEUTRAL, position it on a hoist.

REFER to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

If the source of the leak is obvious, repair as required.

-

After the repair, clean the affected area.

Leakage From Torque Converter Housing

-

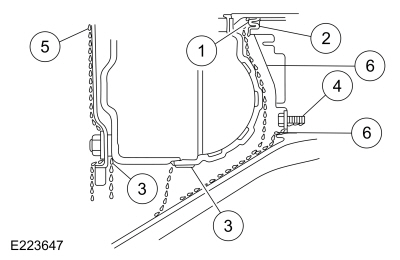

Leaks from the torque converter housing can originate from

several locations. The paths which the transmission fluid takes to reach

the bottom of the torque converter housing is shown in the

illustration. The following 6 steps correspond with the numbers in the

illustration.

-

Transmission fluid leaking by the converter hub seal lip

will tend to move along the drive hub and onto the back of the torque

converter. Except in the case of a total seal failure, transmission

fluid leakage by the lip of the seal will be deposited on the inside of

the torque converter housing only, near the outside diameter of the

housing.

-

Transmission fluid leakage by the outside diameter of the

torque converter impeller hub seal and the case will follow the same

path that leaks by the inside diameter of the converter hub seal follow.

-

Transmission fluid leakage from the converter cover weld or

the converter-to-flexplate stud weld will appear at the outside diameter

of the torque converter on the back face of the flexplate and in the

converter housing only near the flexplate. If a converter-to-flexplate

lug, lug weld or converter cover weld leak is suspected, remove the

converter and pressure check.

-

Transmission fluid leakage from the bolts inside the

converter housing will flow down the back of the torque converter

housing. Leakage may be from loose or missing bolts.

-

Engine oil leaks from the rear main oil seal.

-

Transmission fluid leak from front support cover and seal assembly.

-

Transmission fluid leaking by the converter hub seal lip

will tend to move along the drive hub and onto the back of the torque

converter. Except in the case of a total seal failure, transmission

fluid leakage by the lip of the seal will be deposited on the inside of

the torque converter housing only, near the outside diameter of the

housing.

-

Remove the torque converter.

-

Using a black light, observe the torque converter housing.

Inspect for evidence of dye from the pump bolts, front support cover and

seal assembly, and torque converter hub seal. Repair as required.

-

If the source of the leak is not evident, continue with this procedure to leak test the torque converter.

-

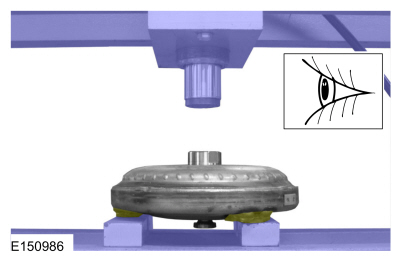

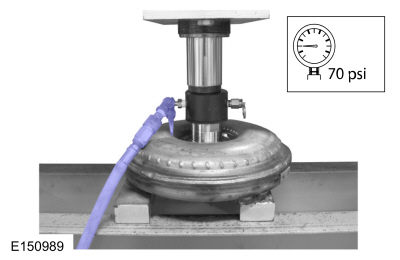

Place the torque converter in an arbor press. Support the torque converter on the mounting pads.

-

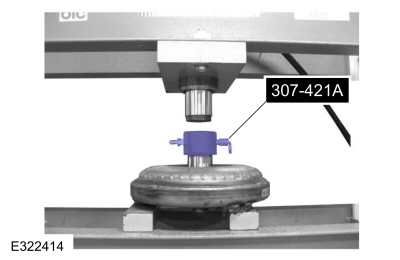

Install the torque converter leak tester (307-421A) into the torque converter hub.

-

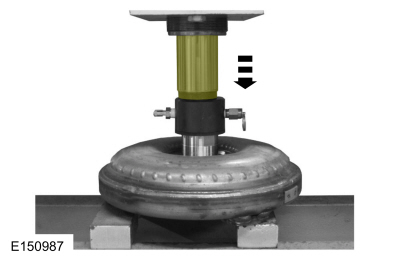

Secure the press. Apply enough force from the press to seal the

torque converter leak tester (307-421A) into the torque converter hub.

-

Connect a compressed air supply to the torque converter leak tester (307-421A).

-

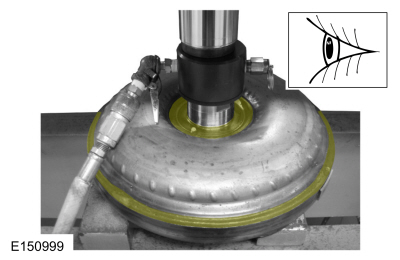

Apply air pressure to the torque converter and inspect for leaks

at the torque converter hub welds and seams. Use a soap bubble solution

around those areas to aid in diagnosis. If any leaks are present,

install a new torque converter.

-

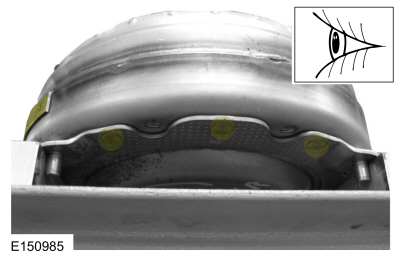

Inspect for leaks at the stud or mounting pad and balance weight

welds. Use a soap bubble solution around those areas to aid in

diagnosis. If any leaks are present, install a new torque converter.

-

After leaks are repaired, clean the remaining transmission fluid dye from serviced areas.

Road Testing Vehicle. Diagnosis and Testing

Road Testing Vehicle. Diagnosis and Testing

Shift Point Road Test

NOTE:

Always drive the vehicle in a safe manner according to driving conditions and obey all traffic laws.

Upshift Gear Sequence

At times the 10-speed transmission may skip gears when the vehicle starts from a complete stop...

Parameter Identification (PID) Chart. Diagnosis and Testing

Parameter Identification (PID) Chart. Diagnosis and Testing

Diagnostic PID Chart

PID Acronym

PID Name

Description

APP

Accelerator Pedal Position

Accelerator pedal position percentage

APP1_[APP_D]

Accelerator Pedal Position D

Accelerator pedal position sensor 1 percentage

AT_NEU_DRV_STA

Auto Trans Neutral Drive..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Fuel Charging and Controls - Component Location. Description and Operation

3.5L EcoBoost Item Description 1 Throttle body 2 High-pressure fuel pump 3 Port injection fuel rail assembly 4 Port injection fuel injector 5 Direct injection fuel injector 6 Direct injection fuel rail Fuel Pump Driver Module Item Description 1 Side frame mounted..

Lincoln Navigator 2018-2026 Workshop Manual: Air Cleaner Outlet Pipe RH. Removal and Installation

Removal NOTICE: The turbocharger compressor vanes can be damaged by even the smallest particles. When removing any turbocharger or engine air intake system component, ensure that no debris enters the system. Failure to do so may result in damage to the turbocharger. NOTE: Removal steps in this procedure may contain installation details. With the vehicle in NEU..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Second Row Seat. Removal and Installation

- Front Bumper Cover. Removal and Installation

- Rear Bumper. Removal and Installation

- Brake Service Mode Activation and Deactivation. General Procedures

- Transmission Fluid Level Check. General Procedures

Front Stabilizer Bar Link. Removal and Installation

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

NOTE: Removal steps in this procedure may contain installation details.

With the vehicle in NEUTRAL, position it on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

NOTICE: Do not use power tools to remove or install the stabilizer bar

Copyright © 2026 www.linavigator4.com