Lincoln Navigator: Rear End Sheet Metal Repairs / Front Floor Panel. Removal and Installation

Special Tool(s) /

General Equipment

| 6.5 mm Drill Bit |

| Scraper for Straight Edges |

| Polydrive Bit Socket |

| Rivet Gun |

| Self-Piercing Rivet (SPR) Remover/Installer |

| Belt Sander |

| Hot Air Gun |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Removal

NOTICE:

Panel sectioning is prohibited within 50 mm of door hinge, door striker, restraints and suspension anchoring points.

NOTE:

Floor panel sectioning is permitted providing recommended

steps are followed. The following assumes full component replacement.

Adjust to meet repair needs.

NOTE:

Self-piercing rivet (SPR) fasteners may not be placed

directly over original self-piercing rivet (SPR) location. They must be

placed adjacent to original location matching original quantity.

NOTE:

Flow-Drill Screw (FDS) fasteners are not reused. Remove and discard.

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

Hood, roof and body side removed for clarity.

NOTE:

Standard wheelbase shown, long wheelbase similar.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

On Both Sides:

Remove the seats.

Refer to: Front Seat (501-10A Front Seats, Removal and Installation).

Refer to: Front Seat Track (501-10A Front Seats, Removal and Installation).

Refer to: Second Row Seat (501-10B Second Row Seats, Removal and Installation).

Refer to: Second Row Center Seat (501-10B Second Row Seats, Removal and Installation).

-

Remove the console.

Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

-

Remove the carpeting and position all wiring harnesses away from the working area.

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

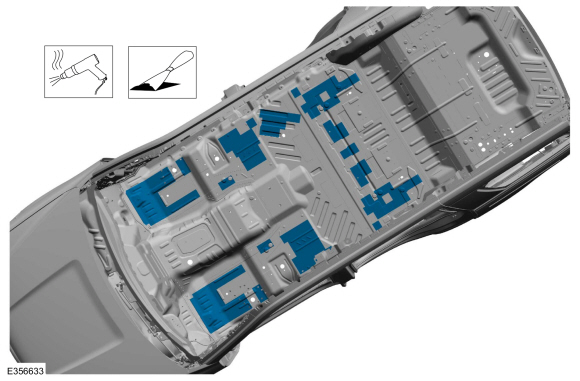

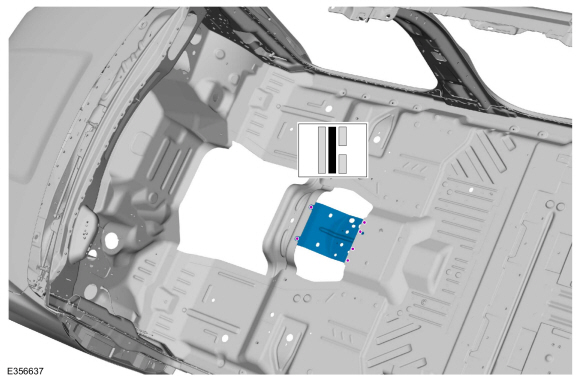

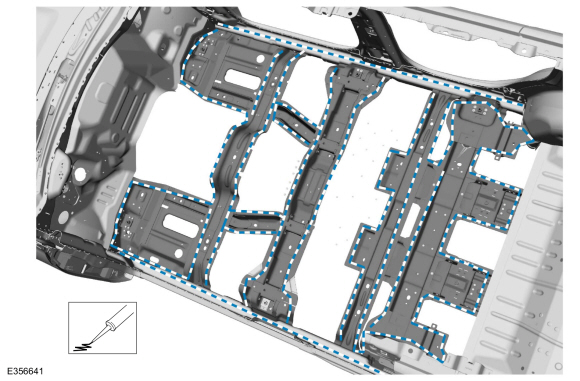

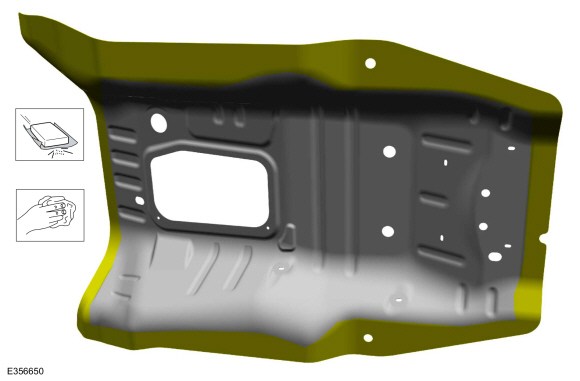

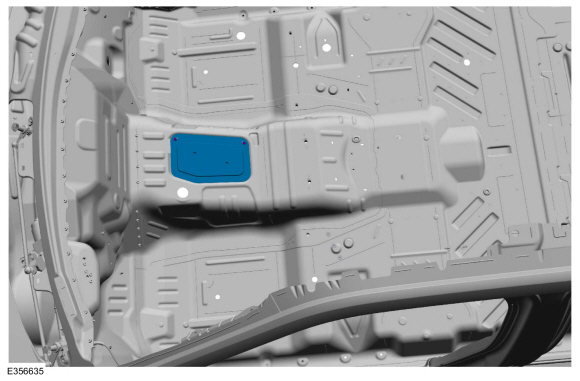

Remove the front floor panel NVH pads.

Use the General Equipment: Hot Air Gun

Use the General Equipment: Scraper for Straight Edges

-

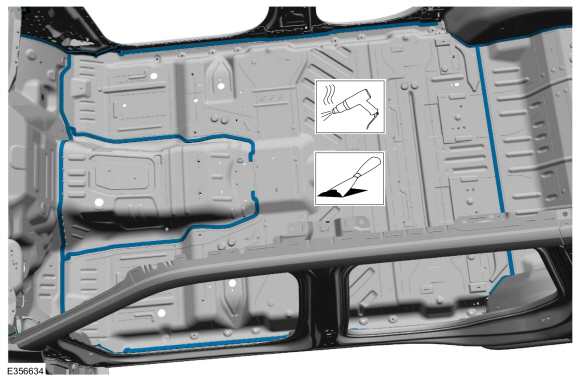

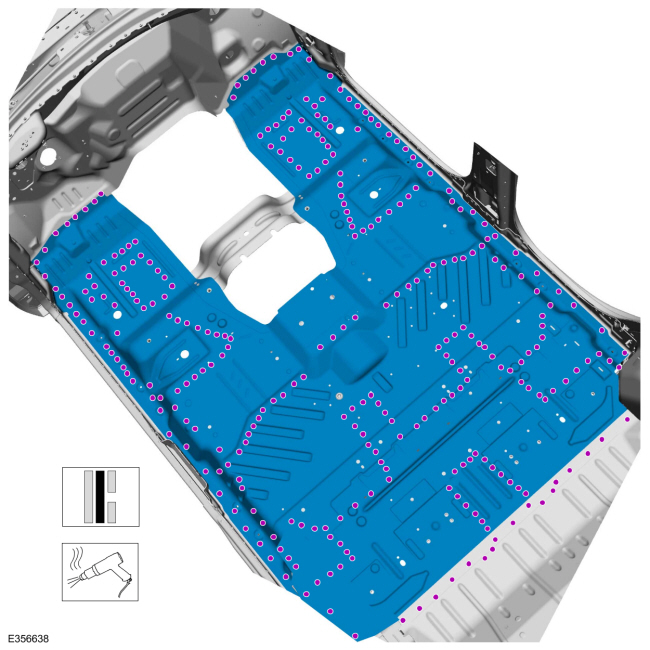

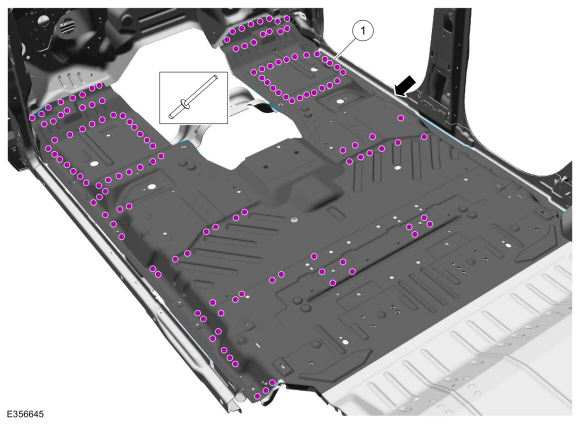

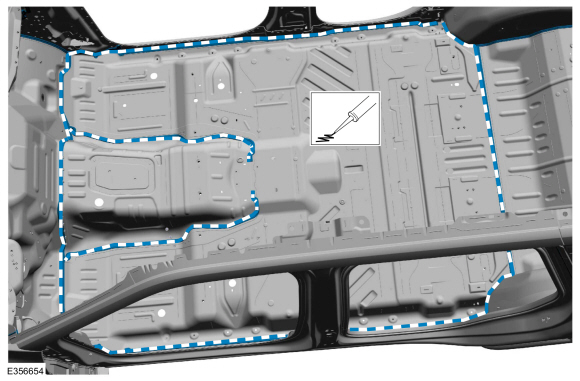

Entire Perimeter:

Remove the front floor panel seam sealer.

Use the General Equipment: Hot Air Gun

Use the General Equipment: Scraper for Straight Edges

-

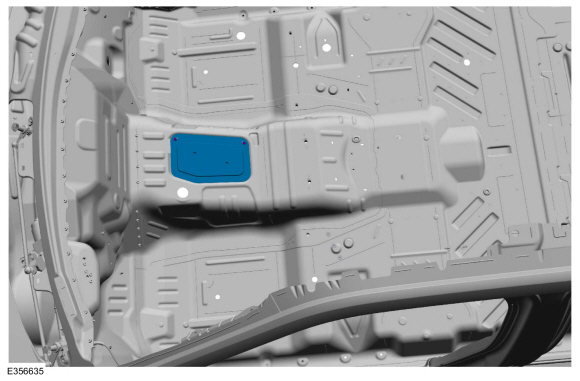

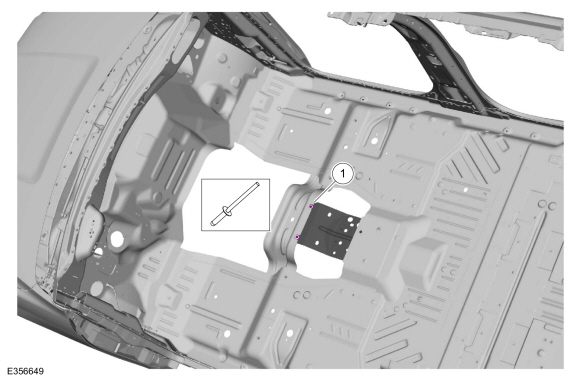

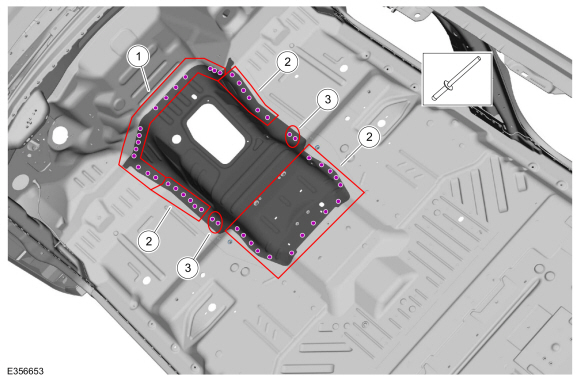

Remove the pushpin fasteners, break the adhesive bond and remove the plate.

-

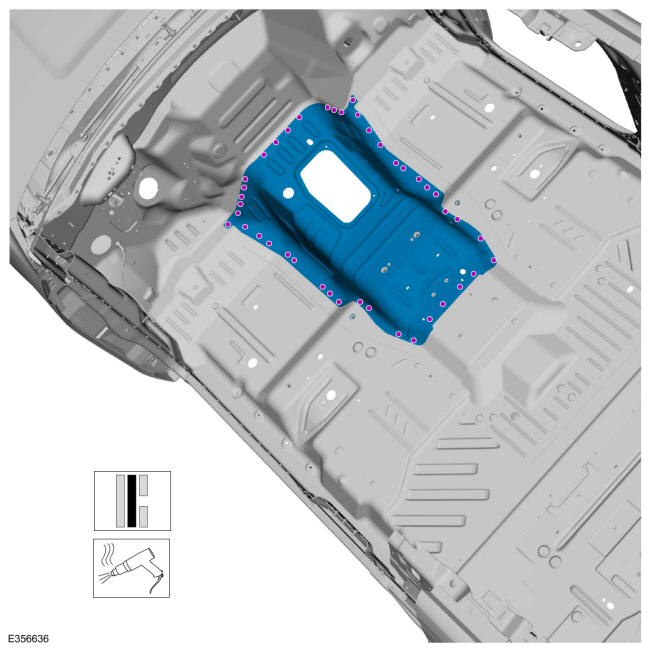

Remove the fasteners, break the adhesive bond and remove the transmission tunnel.

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

Use the General Equipment: Hot Air Gun

-

Remove the fasteners, break the adhesive bond and remove the transmission tunnel brace.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

-

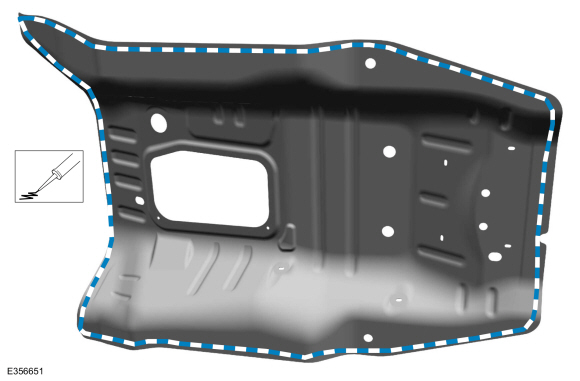

Entire Perimeter:

Remove the fasteners, break the adhesive bond and remove the front floor panel.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

Use the General Equipment: Hot Air Gun

Installation

NOTICE:

Panel sectioning is prohibited within 50 mm of door hinge, door striker, restraints and suspension anchoring points.

NOTE:

Floor panel sectioning is permitted providing recommended

steps are followed. The following assumes full component replacement.

Adjust to meet repair needs.

NOTE:

Self-piercing rivet (SPR) fasteners may not be placed

directly over original self-piercing rivet (SPR) location. They must be

placed adjacent to original location matching original quantity.

NOTE:

Flow-Drill Screw (FDS) fasteners are not reused. Remove and discard.

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

Hood, roof and body side removed for clarity.

NOTE:

Standard wheelbase shown, long wheelbase similar.

-

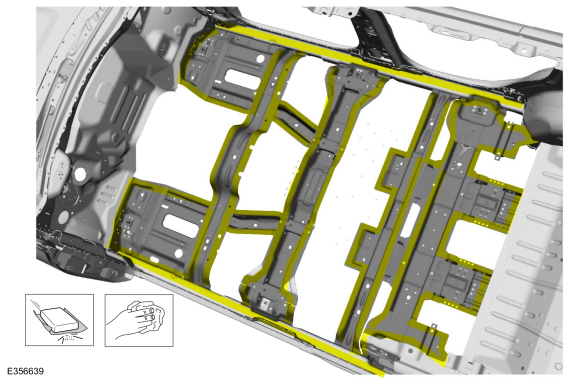

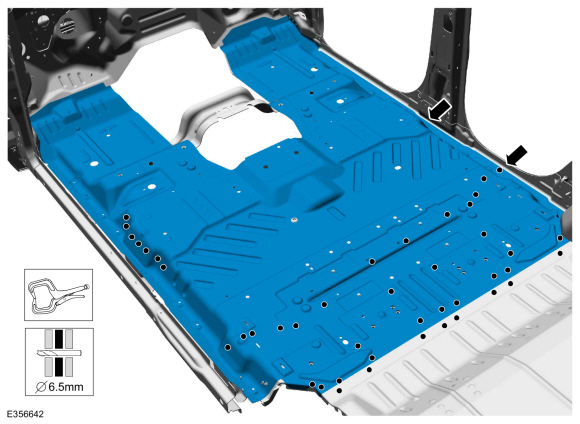

80-120 Grit Sand Paper:

Sand to remove old adhesive, paint and clean.

-

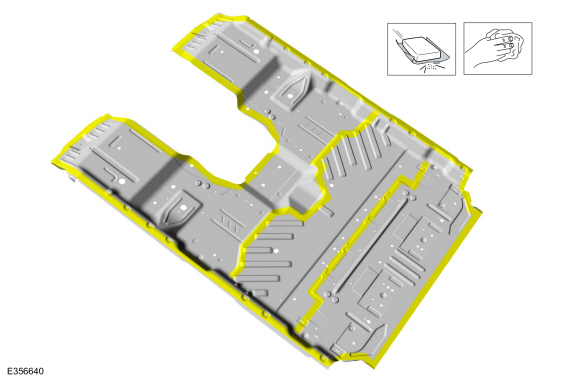

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

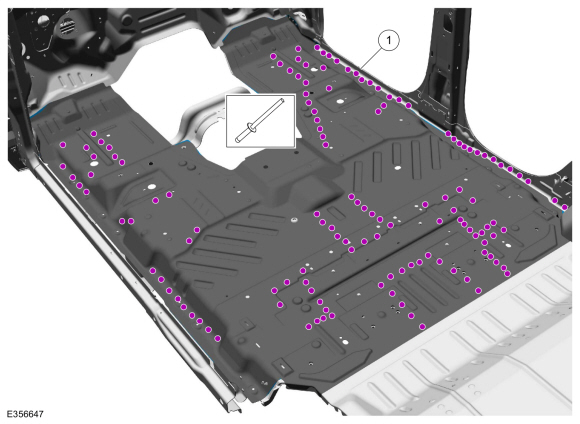

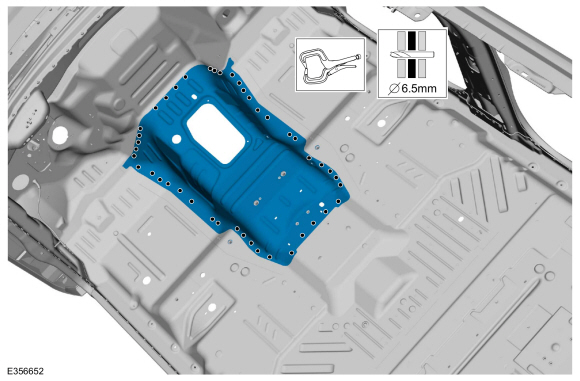

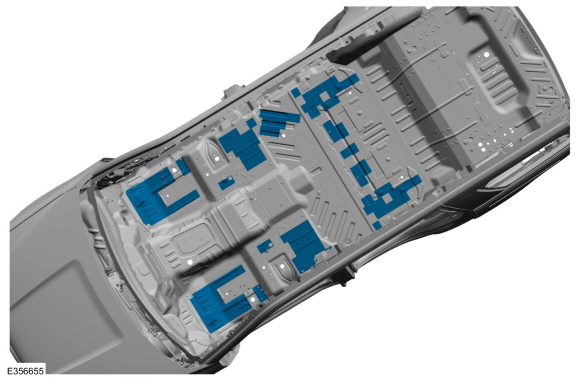

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

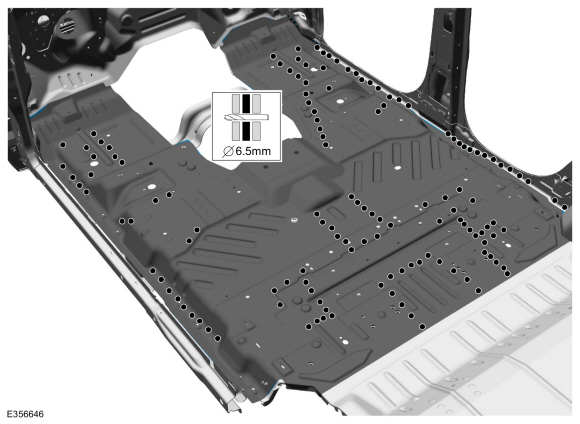

Install, properly position and clamp the front floor panel. Drill for fasteners.

Use the General Equipment: Locking Pliers

Use the General Equipment: 6.5 mm Drill Bit

-

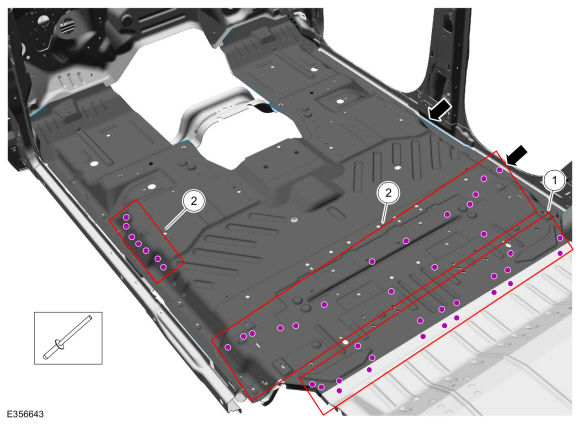

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro- Spot ® Mandrel

|

Blind Rivet

|

Solid

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W707638-S900C

|

-

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702554-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

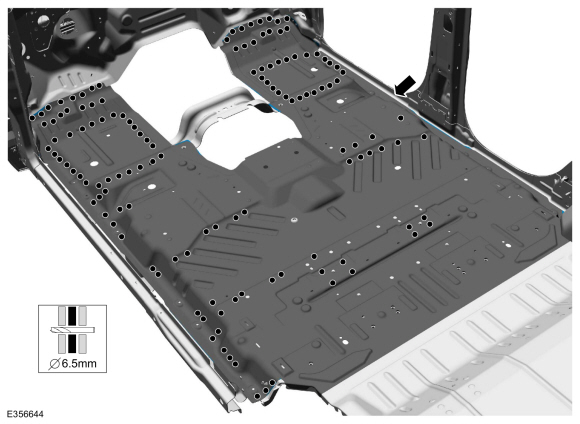

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro- Spot ® Mandrel

|

Blind Rivet

|

Solid

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro- Spot ® Mandrel

|

Blind Rivet

|

Solid

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

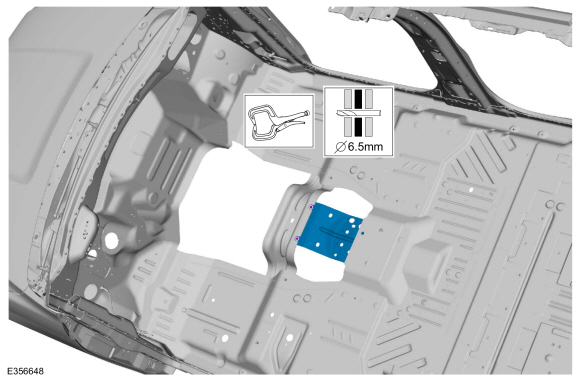

Install, properly position, clamp and drill the transmission tunnel brace.

Use the General Equipment: Locking Pliers

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro- Spot ® Mandrel

|

Blind Rivet

|

Solid

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

80-120 Grit Sand Paper:

Sand to remove e-coat and clean.

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Install, properly position, clamp and drill the transmission tunnel.

Use the General Equipment: Locking Pliers

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro- Spot ® Mandrel

|

Blind Rivet

|

Solid

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W707638-S900C

|

-

|

-

|

-

Install the plate and push-pin fasteners.

-

Seam Sealing:

All seams must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Install locally obtained NVH mastic pads.

-

Refinish the repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition all wiring harnesses to original location. Install the carpet.

-

Install the console.

Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

-

On Both Sides:

Install the seats.

Refer to: Second Row Center Seat (501-10B Second Row Seats, Removal and Installation).

Refer to: Second Row Seat (501-10B Second Row Seats, Removal and Installation).

Refer to: Front Seat Track (501-10A Front Seats, Removal and Installation).

Refer to: Front Seat (501-10A Front Seats, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Polydrive Bit Socket

Rivet Gun

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Hot Air Gun

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerT..

Other information:

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Scraper for Straight Edges

Grinder

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Blind Rivet Gun

Hot Air Gun

Knife

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

..

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTE:

LH shown, RH similar.

Remove the upper B-pillar trim panel.

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Remove the bolt and position front seatbelt retractor and pretensioner D-ring aside.

Torque:

..

Front Floor Panel Crossmember. Removal and Installation

Front Floor Panel Crossmember. Removal and Installation