Lincoln Navigator: Rear Drive Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear / Rear Drive Axle and Differential. Diagnosis and Testing

Symptom Chart(s)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart - Differential

Symptom Chart - Differential

| Condition | Actions |

|---|---|

| Axle overheating | GO to Pinpoint Test A |

| Broken gear teeth on the ring gear or pinion | GO to Pinpoint Test B |

| Differential side gears/pinion gears are scored | GO to Pinpoint Test C |

| eLSD does not engage in snow, mud or on ice | GO to Pinpoint Test D |

| Gray or milky axle lubricant in low mileage vehicles | GO to Pinpoint Test E |

| Lubricant leaking from the pinion seal, axle shaft oil seals or support arm to the housing | GO to Pinpoint Test F |

Symptom Chart: NVH

Symptom Chart

| Condition | Actions |

|---|---|

| Rotational noise from center of axle including howl, whine, scraping, grinding, whistle, moan, or roar | GO to Pinpoint Test G |

| Driveline clunk — occurs as the vehicle starts to move forward following a stop | GO to Pinpoint Test H |

| Grinding, popping or chattering – noise from the rear axle when the vehicle is turning | GO to Pinpoint Test I |

| Grunting — normally associated with a shudder experienced during acceleration from a complete stop | GO to Pinpoint Test J |

| Rotational noise from outer ends of axle including howl, whine, grinding, moan, or roar that change in pitch when cornering | GO to Pinpoint Test K |

| Chuckle – heard at coast/ deceleration. Also described as knock | GO to Pinpoint Test L |

| Knock – noise occurs at various speeds. Not affected by acceleration or deceleration | GO to Pinpoint Test M |

| Scraping noise – a continuous low pitched noise starting at low speed | GO to Pinpoint Test N |

| Driveline shudder – occurs during acceleration from a slow speed or stop | GO to Pinpoint Test O |

Global Customer Symptom Code (GCSC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Symptom | Action |

|---|---|

| Start/Run/Move > Fluids > Axle > Consumption | GO to Pinpoint Test A |

| Start/Run/Move > Fluids > Axle > Consumption | GO to Pinpoint Test B |

| Start/Run/Move > Fluids > Axle > Consumption | GO to Pinpoint Test C |

| Start/Run/Move > Fluids > Axle > Visible Leak | GO to Pinpoint Test A |

| Start/Run/Move > Fluids > Axle > Visible Leak | GO to Pinpoint Test B |

| Start/Run/Move > Fluids > Axle > Visible Leak | GO to Pinpoint Test C |

| Start/Run/Move > Fluids > Axle > Visible Leak | GO to Pinpoint Test F |

| Start/Run/Move > Fluids > Axle > Contamination | GO to Pinpoint Test A |

| Start/Run/Move > Fluids > Axle > Contamination | GO to Pinpoint Test B |

| Start/Run/Move > Fluids > Axle > Contamination | GO to Pinpoint Test C |

| Start/Run/Move > Fluids > Axle > Contamination | GO to Pinpoint Test E |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test G |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test H |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test I |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test J |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test K |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test L |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test M |

| Start/Run/Move > Noise > Moving/Driving > Always | GO to Pinpoint Test N |

| Start/Run/Move > Vibration > Moving/Driving > Intermittent | GO to Pinpoint Test O |

Pinpoint Tests

PINPOINT TEST A: AXLE OVERHEATING

PINPOINT TEST A: AXLE OVERHEATING|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| A1 CHECK AXLE LUBRICANT LEVEL | ||||

Is the lubricant level low?

|

||||

| A2 CHECK AXLE CONDITION | ||||

Was damage found?

|

||||

| A3 INSPECT THE RING AND PINION GEAR | ||||

Does the ring and pinion have a wear pattern?

|

||||

| A4 INSPECT ALL THE AXLE GEARS FOR WEAR OR DAMAGE | ||||

Was wear or damage found?

|

||||

| A5 INSPECT THE RING GEAR FOR SCORING | ||||

Was a wear pattern found on the ring and pinion?

|

PINPOINT TEST B: BROKEN GEAR TEETH ON THE RING GEAR OR PINION

PINPOINT TEST B: BROKEN GEAR TEETH ON THE RING GEAR OR PINION|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Broken gear teeth on the ring or pinion gear can be the result of vehicle overloading, insufficient axle lubricant, contaminated axle lubricant or incorrect axle lubricant. Possible Sources

|

||||

| B1 INSPECT THE RING GEAR OR PINION GEARS FOR BROKEN GEAR TEETH | ||||

Was wear or damage found?

|

PINPOINT TEST C: DIFFERENTIAL SIDE GEARS/PINION GEARS ARE SCORED

PINPOINT TEST C: DIFFERENTIAL SIDE GEARS/PINION GEARS ARE SCORED|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Scoring on the pinion gear or side gears can be the result of insufficient axle lubricant, contaminated axle lubricant, or incorrect axle lubricant. Possible Sources

|

||||

| C1 CHECK AXLE LUBRICANT LEVEL AND CONDITION | ||||

Is the lubricant level low or contaminated?

|

||||

| C2 INSPECT THE DIFFERENTIAL SIDE GEARS/PINION GEARS FOR SCORING | ||||

Was wear or damage found?

|

| D1 CHECK THE ELSD (ELECTRONIC LIMITED-SLIP DIFFERENTIAL) DTC (DIAGNOSTIC TROUBLE CODE)S | ||||

Are there ant DTC s present?

|

PINPOINT TEST E: GRAY OR MILKY AXLE LUBRICANT IN LOW MILEAGE VEHICLE

PINPOINT TEST E: GRAY OR MILKY AXLE LUBRICANT IN LOW MILEAGE VEHICLE|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| E1 INSPECT AXLE HOUSING AND VENT | ||||

Was any damage or leaks found?

|

PINPOINT TEST F: LUBRICANT LEAKING FROM THE PINION SEAL, AXLE SHAFT OIL SEALS OR SUPPORT ARM TO THE HOUSING

PINPOINT TEST F: LUBRICANT LEAKING FROM THE PINION SEAL, AXLE SHAFT OIL SEALS OR SUPPORT ARM TO THE HOUSING|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| F1 INSPECT AXLE VENT | ||||

Was blockage found?

|

||||

| F2 INSPECT THE PINION SEAL AND DUST SLINGER | ||||

Was any damage found?

|

PINPOINT TEST G: ROTATIONAL NOISE FROM CENTER OF AXLE INCLUDING HOWL, WHINE, SCRAPING, GRINDING, WHISTLE, MOAN, OR ROAR

PINPOINT TEST G: ROTATIONAL NOISE FROM CENTER OF AXLE INCLUDING HOWL, WHINE, SCRAPING, GRINDING, WHISTLE, MOAN, OR ROAR|

Normal Operation and Fault Conditions All gearsets and roller bearings, including those found in the axle, generate some noise during normal operation. Some normal noises may be perceived as severe when the vehicle is raised on a hoist and the listener is closer to the axle. A worn ring and pinion gearset can produce a whine or whistle type of noise. The noise comes in at certain vehicle speed. The noise will peak and fade away usually within a 5-10 MPH (8-16 km/h) range. The noise may be present in one or more drive conditions: tip in / tip out / coast / cruise. Worn pinion bearings can produce a scraping noise. This noise will be a continuous low pitched noise starting at low speeds. Worn differential bearings can produce a growling or grinding noise that increases with speed and load. Gear tooth damage on the drive side of the ring or pinion can cause a knock noise. This noise can occur at various speeds and is not affected by acceleration or deceleration. Excessive backlash can cause a driveline clunk that occurs as the vehicle starts to move forward following a stop. Excessive backlash can also cause a chuckle or knock type of noise that will be heard during coast and deceleration. Excessive backlash is caused by ring and pinion gear wear. Gear tooth damage on the coast side of the ring or pinion can cause a chuckle or knock type of noise that will be heard during coast and deceleration. As the bearings or gears wear, metallic particles are shed and distributed into the axle fluid. This metallic contamination can cause the other components in the axle to fail. The ring and pinion gears, pinion bearings (included in -4209- kit), differential bearings (-4221-), and differential bearing cups (-4222-) should be replaced when repairing an axle for the noise concerns described in this diagnostic test. Possible Sources

|

||||

| G1 COMPARE TO LIKE UNIT | ||||

Is the noise in the subject vehicle similar to the noise from the comparable vehicle?

|

PINPOINT TEST H: DRIVELINE CLUNK — OCCURS AS THE VEHICLE STARTS TO MOVE FORWARD FOLLOWING A STOP

PINPOINT TEST H: DRIVELINE CLUNK — OCCURS AS THE VEHICLE STARTS TO MOVE FORWARD FOLLOWING A STOP|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| H1 INSPECT PINION GEARS | ||||

Was any damage found?

|

PINPOINT TEST I: GRINDING, POPPING OR CHATTERING- NOISE FROM THE REAR AXLE WHEN THE VEHICLE IS TURNING

PINPOINT TEST I: GRINDING, POPPING OR CHATTERING- NOISE FROM THE REAR AXLE WHEN THE VEHICLE IS TURNING|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| I1 INSPECT THE DIFFERENTIAL CARRIER AND THE COMPONENTS OF THE DIFFERENTIAL CARRIER | ||||

Was any damage found?

|

PINPOINT TEST J: GRUNTING- NORMALLY ASSOCIATED WITH A SHUDDER EXPERIENCED DURING ACCELERATION FROM A COMPLETE STOP

PINPOINT TEST J: GRUNTING- NORMALLY ASSOCIATED WITH A SHUDDER EXPERIENCED DURING ACCELERATION FROM A COMPLETE STOP|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| J1 CHECK FOR LOOSE BOLTS | ||||

Are any bolts loose?

|

PINPOINT TEST K: ROTATIONAL NOISE FROM AXLE THAT CHANGES PITCH WHEN CORNERING

PINPOINT TEST K: ROTATIONAL NOISE FROM AXLE THAT CHANGES PITCH WHEN CORNERING|

Normal Operation and Fault Conditions All roller bearings, including those found in the rear axle, generate some noise during normal operation. Some normal noises may be perceived as severe when the vehicle is raised on a hoist and the listener is closer to the rear axle. Worn outer wheel bearings can produce a howl, whine, grinding, moan, or roar that change in pitch when cornering. Possible Sources

|

||||

| K1 COMPARE TO LIKE UNIT | ||||

Is the noise in the subject vehicle similar to the noise from the comparable vehicle?

|

PINPOINT TEST L: CHUCKLE – HEARD AT COAST/ DECELERATION ALSO DESCRIBED AS KNOCK

PINPOINT TEST L: CHUCKLE – HEARD AT COAST/ DECELERATION ALSO DESCRIBED AS KNOCK |

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| L1 INSPECT RING AND PINION CONTACT AND FOR DAMAGED TEETH ON RING AND PINION | ||||

Was any damage found?

|

PINPOINT TEST M: KNOCK – NOISE OCCURS AT VARIOUS SPEEDS (NOT AFFECTED BY ACCELERATION OR DECELERATION)

PINPOINT TEST M: KNOCK – NOISE OCCURS AT VARIOUS SPEEDS (NOT AFFECTED BY ACCELERATION OR DECELERATION)|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| M1 INSPECT FOR TOOTH DAMAGE ON RING AND PINION | ||||

Was any damage found?

|

PINPOINT TEST N: SCRAPING NOISE – A CONTINUOUS LOW PITCHED NOISE STARTING AT LOW SPEED

PINPOINT TEST N: SCRAPING NOISE – A CONTINUOUS LOW PITCHED NOISE STARTING AT LOW SPEED|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| N1 INSPECT PINION BEARINGS | ||||

Was wear or damage found?

|

PINPOINT TEST O: DRIVELINE SHUDDER- OCCURS DURING ACCELERATION FROM A SLOW SPEED OR STOP

PINPOINT TEST O: DRIVELINE SHUDDER- OCCURS DURING ACCELERATION FROM A SLOW SPEED OR STOP|

Normal Operation and Fault Conditions

REFER to: Rear Drive Axle and Differential (205-02 Rear Drive

Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Description

and Operation). Possible Sources

|

||||

| O1 CHECK THE AXLE MOUNTS AND THE REAR SUSPENSION FOR DAMAGE OR WEAR | ||||

Was wear or damage found?

|

||||

| O2 CHECK THE REAR AXLE FOR LOOSE BOLTS | ||||

Were any bolts loose?

|

||||

| O3 CHECK FOR CORRECT DRIVELINE ANGLES | ||||

Are the driveline angles correct?

|

Axle Fluid Analysis

The appearance of milky or gray axle fluid in early mileage axles is a result of white marking compound used at the assembly plant to verify gear mesh contact pattern. The marking compound within the fluid will darken some over time. The milky fluid appearance will diminish and cause no harm and does not require a fluid change.

Analysis of Leakage

Clean up the leaking area enough to identify the exact source.

A plugged Rear axle housing vent can cause excessive pinion seal lip wear due to internal pressure buildup.

Verify the differential lubricant level is at the correct level.

REFER

to: Differential Fluid Level Check (205-02 Rear Drive Axle/Differential

- Vehicles With: Ford 9.75 Inch Ring Gear, General Procedures).

Axle Vent

A plugged vent will cause excessive seal lip wear due to internal pressure buildup. If a leak occurs, check the vent. If the vent cannot be cleared, install a new vent.

Drive Pinion Seal

Leaks at the drive pinion seal originate from the following causes:

- Damaged seal

- Worn seal journal surface

A new drive pinion flange must be installed if any of these conditions exist.

- Any damage to the seal bore (dings, dents, gouges or other imperfections) distorts the seal casing and allows leakage past the outer edge of the drive pinion seal.

- The drive pinion seal can be torn, cut or gouged if it is not installed correctly. The spring that holds the drive pinion seal against the pinion flange may be knocked out and allow fluid to pass the lip.

- Metal chips trapped at the sealing lip can cause oil leaks. These can cause a wear groove on the drive pinion flange and result in pinion seal wear.

- When a seal leak occurs, install a new drive pinion seal and check the vent to make sure it is clean and free of foreign material.

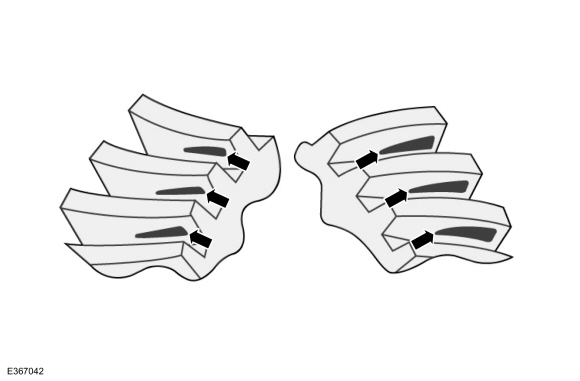

Contact Pattern

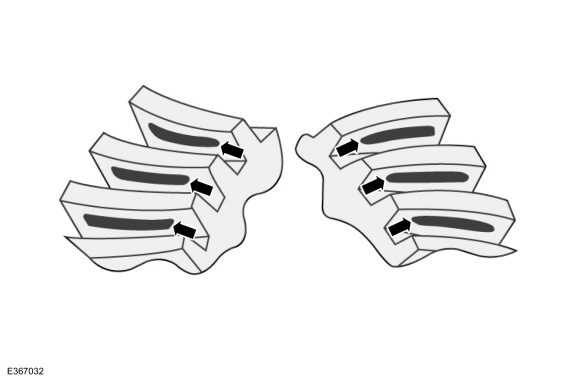

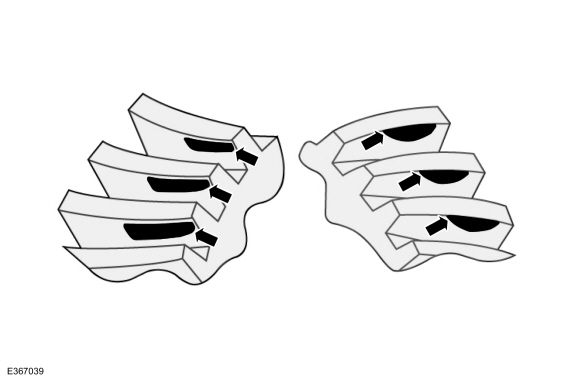

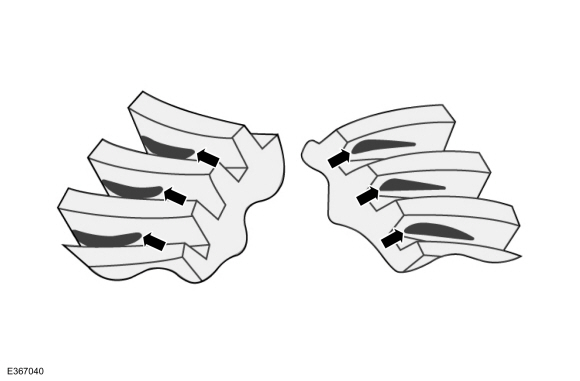

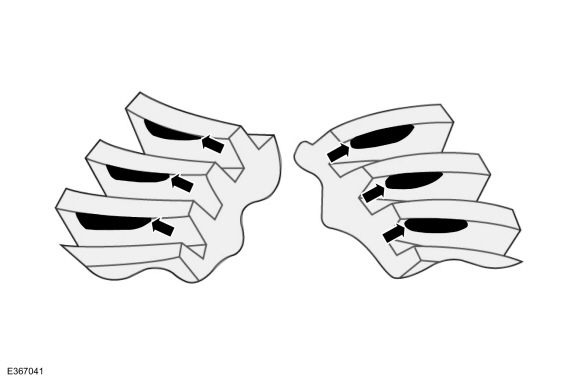

In general, desirable ring gear tooth patterns must have the following characteristics:

- Drive pattern on the drive side ring gear well centered on the tooth. There should be some clearance between the pattern and the top of the tooth.

- Coast pattern on the coast side ring gear well centered on the tooth, but may be slightly toward the toe. There should be some clearance between the pattern and the top of the tooth.

Acceptable ring gear tooth patterns for all axles.

Correct backlash with a thicker pinion position shim required.

Correct backlash with a thinner pinion position shim required.

Pinion position correct. Decrease backlash.

Pinion position correct. Increase backlash.

Rear Drive Axle and Differential - Vehicles With: Electronic Limited-Slip Differential. Diagnosis and Testing

Rear Drive Axle and Differential - Vehicles With: Electronic Limited-Slip Differential. Diagnosis and Testing

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Piston Selection. General Procedures

Check Refer to specifications for piston selection. Refer to: Specifications (303-01) . NOTE: The cylinder bore must be within the specifications for taper and out-of-round before fitting a piston. Measure the cylinder bore in 2 directions...

Lincoln Navigator 2018-2026 Workshop Manual: Turbocharger Coolant Supply Tube RH. Removal and Installation

Materials Name Specification Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C - Removal NOTICE: The turbocharger compressor vanes can be damaged by even the smallest particles. When removing any turbocharger or engine air intake system component, ensure that no debris enters the system...

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- All Terrain Control Module (ATCM). Removal and Installation

- SYNC Module [APIM]. Removal and Installation

- Transmission Fluid Drain and Refill. General Procedures

- Identification Codes. Description and Operation

- Rear View Mirrors - System Operation and Component Description. Description and Operation

Diagnostic Methods. Description and Operation

This document provides critical diagnostic knowledge required for successful repair outcomes. It identifies technical competencies expected by users of this manual.

Ford Diagnostic Assumptions

Ford diagnostics assume the vehicle concern described by the test title is currently present. Exceptions to this rule are noted in each test. Do not replace modules or other components as directed by a diagnostic if the concern is not present at the time of testing.