Lincoln Navigator: Automatic Transmission - 10-Speed Automatic Transmission – 10R80 / Shift Solenoids (SS). Removal and Installation

Materials

| Name |

Specification |

Motorcraft® MERCON® ULV Automatic Transmission Fluid

XT-12-QULV |

WSS-M2C949-A,

MERCON® ULV

|

Removal

NOTE:

If a new SS is installed, carry out the adaptive learning drive cycle procedure at the end of the repair.

All Solenoids

-

Remove the transmission fluid pan gasket and filter.

Refer to: Transmission Fluid Pan, Gasket and Filter (307-01 Automatic

Transmission - 10-Speed Automatic Transmission – 10R80, Removal and

Installation).

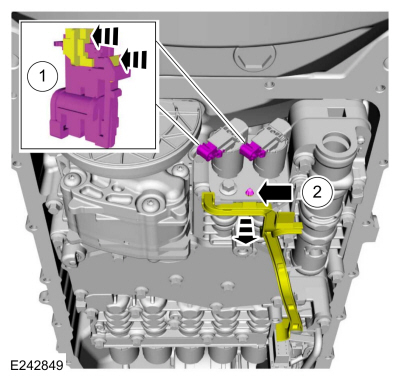

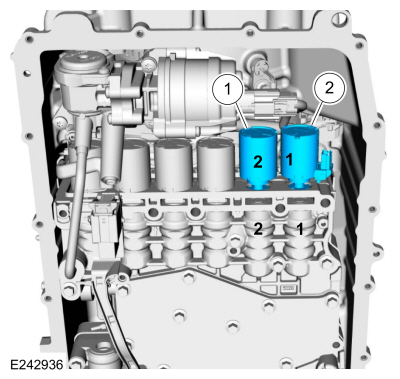

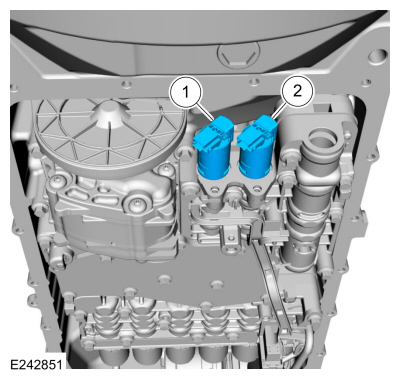

LPC (line pressure control) and TCC (torque converter clutch) Solenoids

-

-

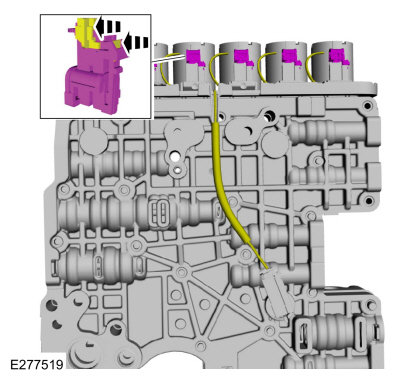

Slide the plastic lock to the unlock position.

While pressing the plastic tab, disconnect the electrical connector.

-

Disconnect the internal wiring harness retainer.

-

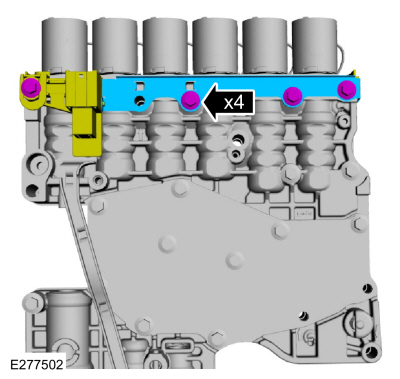

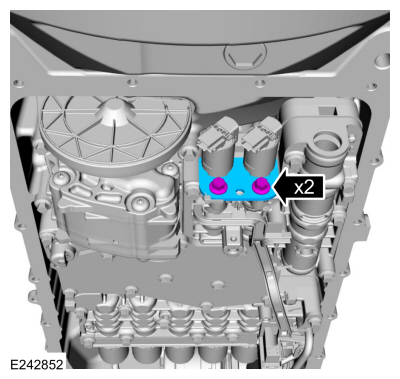

Remove and discard the bolts and remove the solenoid retaining plate.

-

Remove the solenoid(s) from the main control valve body.

-

LPC solenoid (7G383)

-

TCC solenoid (7G136)

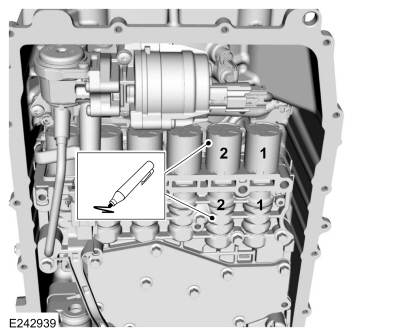

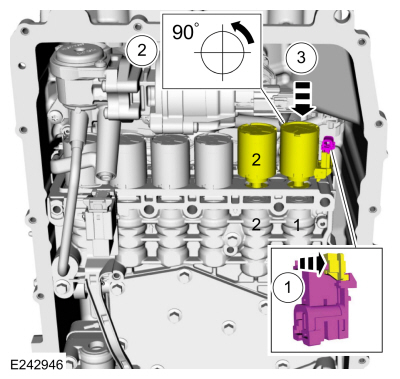

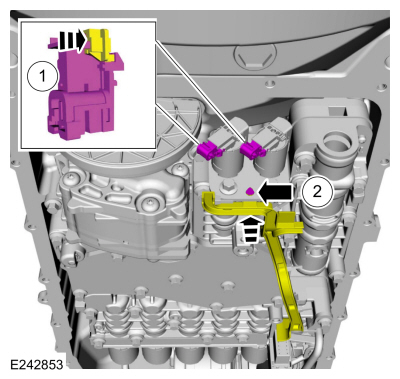

Solenoids D and E

-

Remove the bolts and the shift solenoid retaining plate.

-

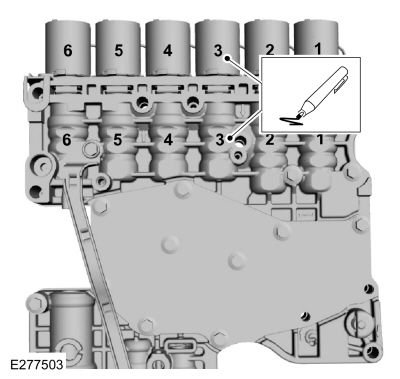

If replacing more then one solenoid, number the

solenoids and number the main control valve body solenoid ports to

correspond to the solenoid.

-

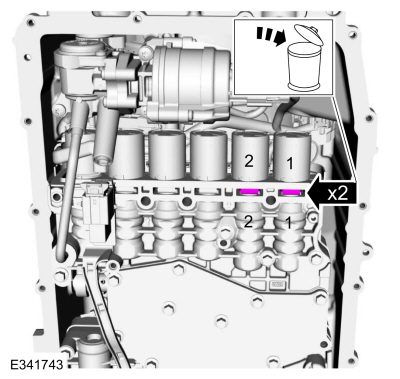

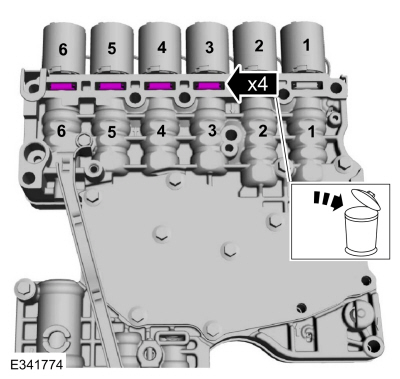

Remove and discard the shift solenoid retainer(s).

-

-

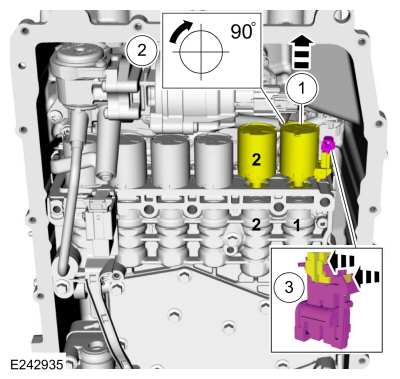

Slide the solenoid(s) out of the main control valve body bore.

-

Rotate the solenoid(s) in a clockwise direction.

-

Slide the plastic lock to the unlock position.

While pressing the plastic tab, disconnect the electrical connector.

-

Remove the solenoid(s) from the main control valve body.

-

SSE (7J136)

-

SSD (7J136)

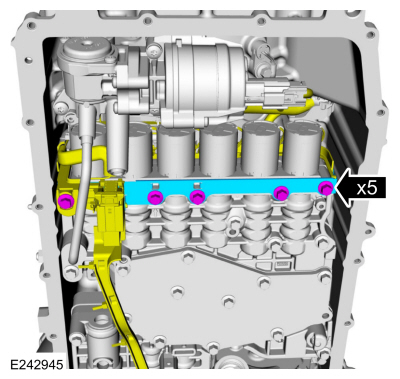

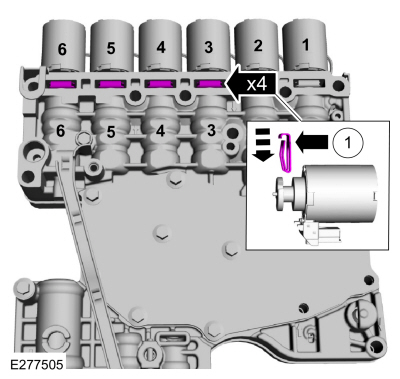

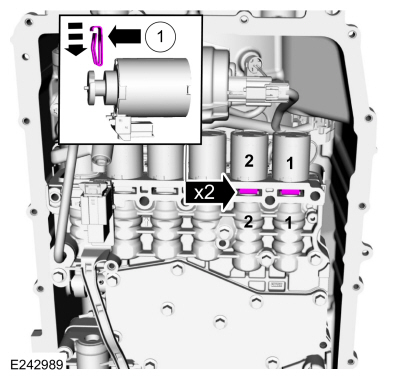

Solenoids A, B, C, and F

-

Remove the main control valve body.

Refer to: Main Control Valve Body (307-01 Automatic Transmission -

10-Speed Automatic Transmission – 10R80, Removal and Installation).

-

Remove the bolts and the shift solenoid retaining plate.

-

If replacing more then one solenoid, number the

solenoids and number the main control valve body solenoid ports to

correspond to the solenoid.

-

Remove and discard the shift solenoid retainer(s).

-

Slide the plastic lock to the unlock position. While

pressing the plastic tab, disconnect the electrical connector(s).

-

Remove the solenoid(s) from the main control valve body.

-

SSA (7J136)

-

SSF (7J136)

-

SSC (7J136)

-

SSB (7J136)

Installation

Solenoids A, B, C, and F

-

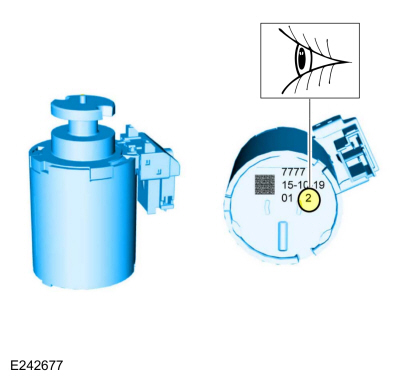

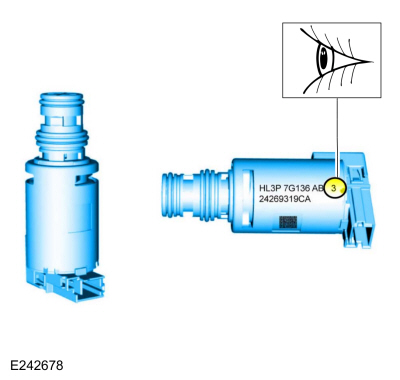

NOTICE:

Solenoids are calibrated from the factory and

are not all the same. To replace a solenoid, match the band number with

the original solenoid or harsh shifts or damage to the transmission can

occur.

If new solenoids are needed, identify the solenoid band number.

-

Install the solenoid(s) in the main control valve body in the correct port(s) as marked during removal.

-

SSA (7J136)

-

SSF (7J136)

-

SSC (7J136)

-

SSB (7J136)

-

Connect the electrical connectors and slide the plastic lock to the locked position.

-

Install the new shift solenoid retainer(s) with the flat side towards the solenoids.

-

Retainer flat side

-

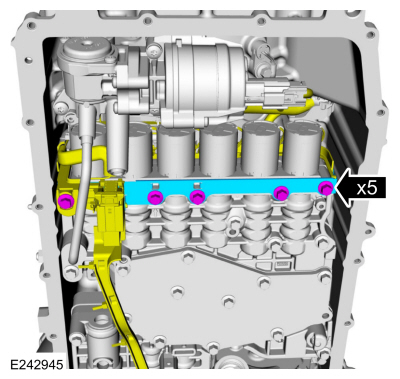

Install and the shift solenoid retaining plate and the bolts.

Torque:

106 lb.in (12 Nm)

-

Install the main control valve body.

Refer to: Main Control Valve Body (307-01 Automatic Transmission -

10-Speed Automatic Transmission – 10R80, Removal and Installation).

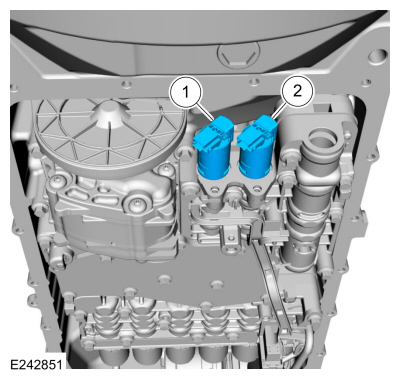

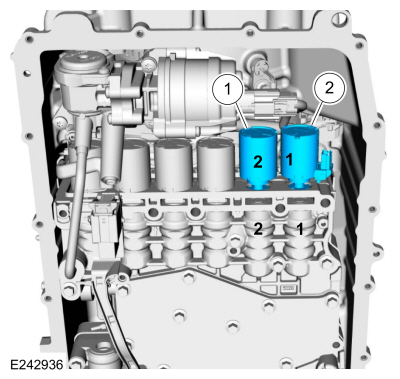

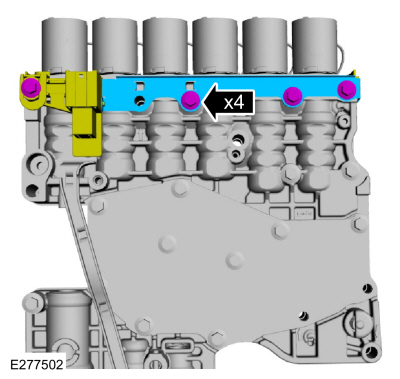

Solenoids D and E

-

NOTICE:

Solenoids are calibrated from the factory and

are not all the same. To replace a solenoid, match the band number with

the original solenoid or harsh shifts or damage to the transmission can

occur.

If new solenoids are needed, identify the solenoid band number.

-

Install the solenoid(s) in the main control valve body in the correct port(s) as marked during removal.

-

SSE (7J136)

-

SSD (7J136)

-

-

Connect the electrical connectors and slide the plastic lock to the locked position.

-

Rotate the solenoid(s) in a counter-clockwise direction.

-

Slide the solenoid(s) into the main control valve body bore.

-

Install new shift solenoid retainer(s) with the flat side towards the solenoids.

-

Retainer flat side

-

Install and the shift solenoid retaining plate and the bolts.

Torque:

106 lb.in (12 Nm)

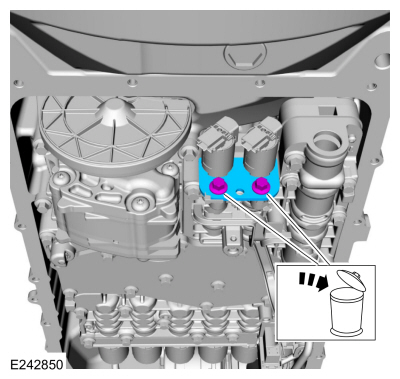

LPC (line pressure control) and TCC (torque converter clutch) Solenoids

-

NOTICE:

Solenoids are calibrated from the factory and

are not all the same. To replace a solenoid, match the replacement

solenoid type (normally high/normally low) and the band number with the

original solenoid or harsh shifts or damage to the transmission can

occur.

If new solenoids are needed, identify which type

(normally high/normally low) of solenoid it is and the solenoid band

number.

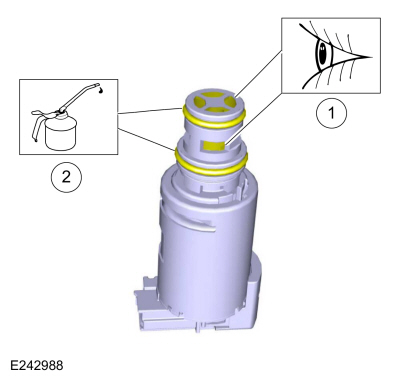

-

-

Inspect the solenoid screens for debris that may restrict fluid flow.

-

Lubricate the solenoid O-ring seals.

Material: Motorcraft® MERCON® ULV Automatic Transmission Fluid

/ XT-12-QULV

(WSS-M2C949-A, )

(MERCON® ULV)

-

Install the solenoid(s) in the main control valve body.

-

LPC solenoid (7G383)

-

TCC solenoid (7G136)

-

Install the solenoid retaining plate and the new bolts.

Torque:

80 lb.in (9 Nm)

-

-

Connect the electrical connectors and slide the plastic lock to the locked position.

-

Connect the internal wiring harness retainer.

All Solenoids

-

Install the transmission fluid pan gasket and filter.

Refer to: Transmission Fluid Pan, Gasket and Filter (307-01 Automatic

Transmission - 10-Speed Automatic Transmission – 10R80, Removal and

Installation).

-

If a new SS was installed, carry out the adaptive learning drive cycle procedure.

Refer to: Adaptive Learning Drive Cycle (307-01 Automatic Transmission -

10-Speed Automatic Transmission – 10R80, General Procedures).

Special Tool(s) /

General Equipment

307-549Installer, Shift Shaft Fluid SealTKIT-2005D1-F1

Removal

With the vehicle in NEUTRAL, position it on a hoist...

Special Tool(s) /

General Equipment

307-346

(T97T-7902-A)

Retainer, Torque ConverterTKIT-1998-LM (NavigatoR)TKIT-1997-F/FLM/LT

Transmission Jack

Materials

Name

Specification

Motorcraft® Multi-Purpose Grease SprayXL-5-A

ESB-M1C93-B

Motorcraft® MERCON® ULV Automatic Transmission FluidXT-12-QULV

WSS-M2C949-A, MERCON® ULV

..

Other information:

Adjustment

NOTE:

If the flash video link does not load or is

incompatible with your browser, a .wmv version of the video can be

accessed at:

http://www.fordservicecontent.com/Ford_Content/videos/FusionHeadlampAdj2.wmv

Click on the link above to view video.

Click here to view a video version of this procedure.

All headlamp types

NOTE:

..

Overview

The

EEC system provides optimum control of the engine through the enhanced

capability of the powertrain control module (PCM). The EEC system also

has an on board diagnostic (OBD) monitoring system with features and

functions to meet federal regulations on exhaust emissions. The EEC

system has two major divisions: hardware and software. The hardware

includes the PCM, sensors,..

Selector Shaft Seal. Removal and Installation

Selector Shaft Seal. Removal and Installation Transmission. Removal and Installation

Transmission. Removal and Installation 205-123

(T78P-1177-A)

205-123

(T78P-1177-A)

308-047

(T77F-1102-A)

308-047

(T77F-1102-A)