Lincoln Navigator: Engine - 3.5L EcoBoost (272kW/370PS) / Rocker Arm. Removal and Installation

Special Tool(s) / General Equipment

|

303-1633 Remover, Roller Rocker Follower TKIT-2014D-ROW3 TKIT-2014D-FL_ROW |

|

303-1633-01 Remover, Roller Rocker Follower |

Removal

NOTE: This procedure should be used when removing and replacing the clipped roller finger follower or hydraulic lash adjuster and the camshafts are not removed.

LH side rocker arm

-

Remove the LH valve cover.

Refer to: Valve Cover LH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

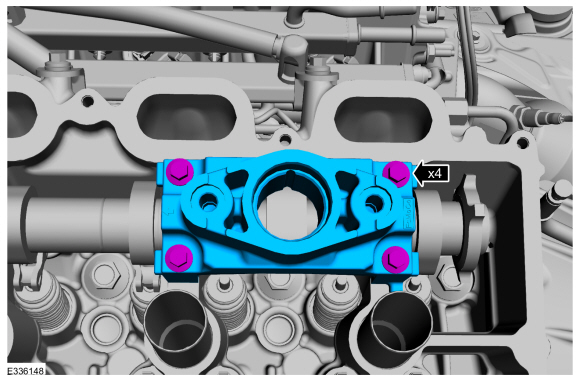

NOTE: This step only necessary if the pedestal cap needs to be removed to access the clipped roller finger followers.

Remove the bolts and the pedestal cap.

|

-

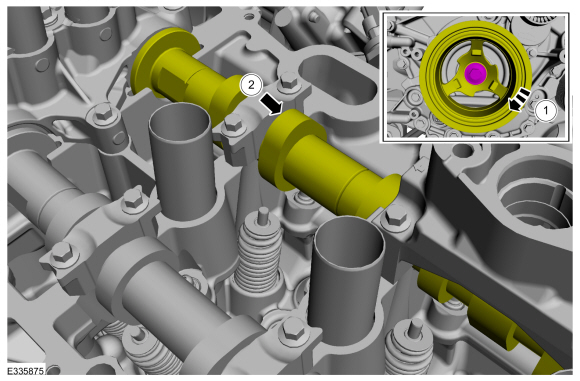

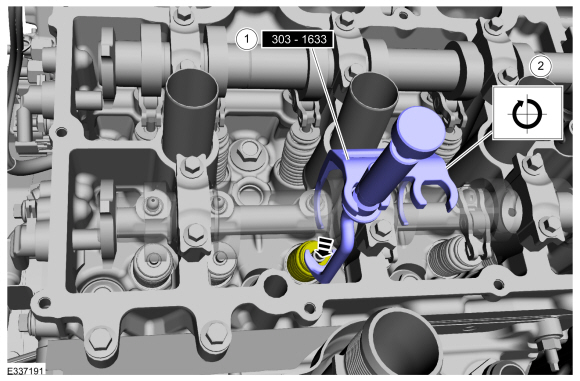

Rotate the crankshaft pulley bolt clockwise to

position the camshaft lobe upward for the clipped roller finger follower

to be removed.

|

-

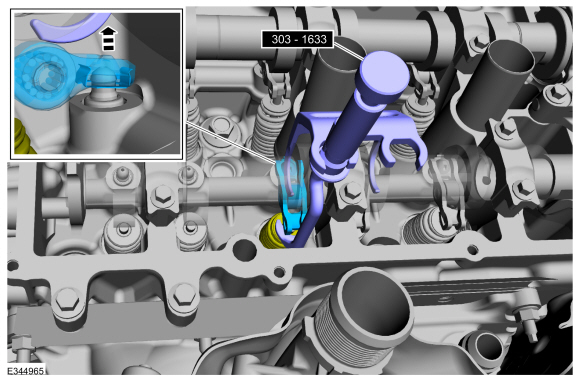

Remove the clipped roller finger follower. Repeat

steps for any other clipped roller finger follower that needs to be

removed.

|

RH side rocker arm

-

Remove the valve cover.

Refer to: Valve Cover RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

Refer to: Valve Cover RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

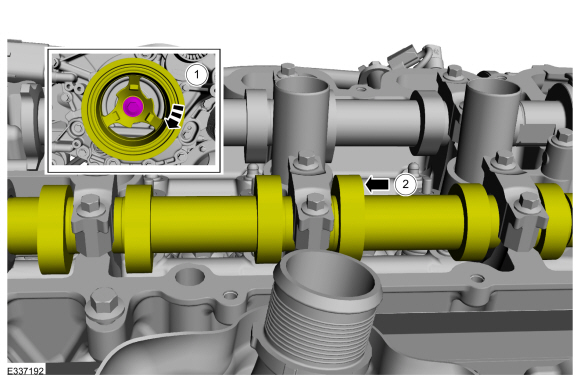

Rotate the crankshaft pulley bolt clockwise to

position the camshaft lobe upward for the clipped roller finger follower

to be removed.

|

-

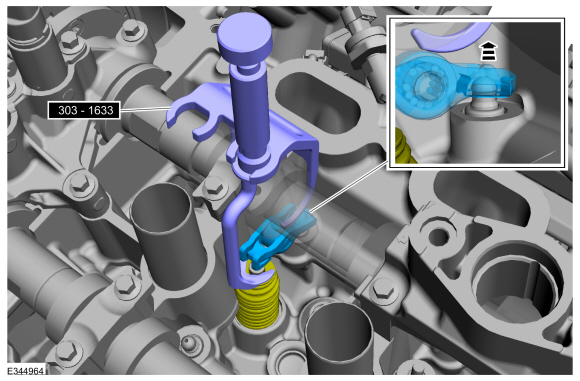

-

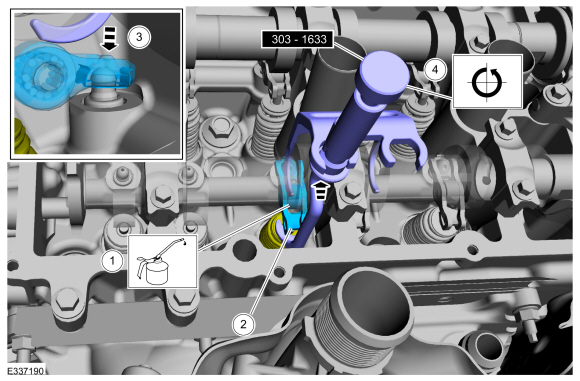

Install Special Service Tool: 303-1633 Remover, Roller Rocker Follower. , 303-1633-01 Remover, Roller Rocker Follower.

-

Turn the knob on the special tool clockwise to depress the valve and spring.

-

|

-

Remove the clipped roller finger follower. Repeat

steps for any other clipped roller finger follower that needs to be

removed.

|

Installation

LH side rocker arm

-

-

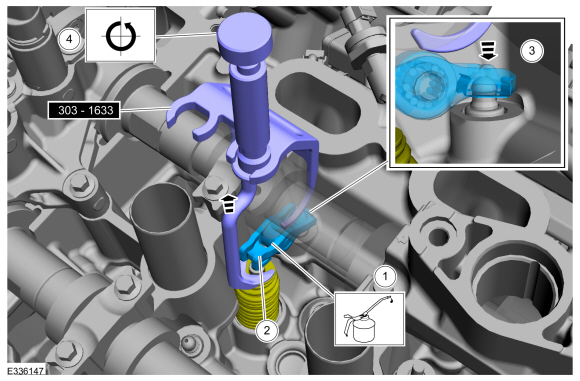

Lubricate the clipped roller finger follower with clean engine oil.

Refer to: Specifications (303-01C) .

-

Install the clipped roller finger follower.

-

Assemble the clipped roller finger follower spring clip onto the hydraulic lash adjuster.

-

Turn the knob on the special tool counterclockwise to raise the valve and spring.

Remove Special Service Tool: 303-1633 Remover, Roller Rocker Follower. , 303-1633-01 Remover, Roller Rocker Follower.

-

Repeat steps for any remaining clipped roller finger follower removed.

-

Lubricate the clipped roller finger follower with clean engine oil.

|

-

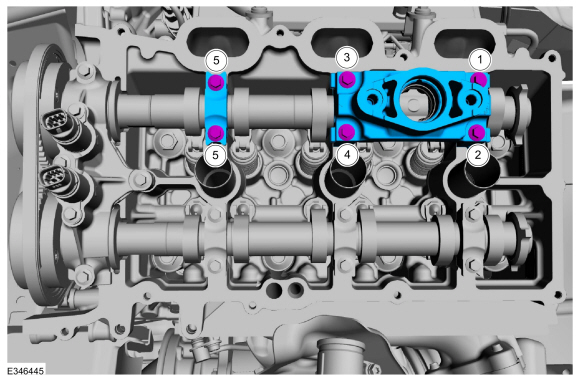

NOTE: This step only necessary if the pedestal cap was removed.

-

If removed, install the pedestal cap and the bolts.

Torque:

Stage 1: 1 thru 4: 71 lb.in (8 Nm)

Stage 2: 1 thru 4: 11°

Stage 3: Loosen 1 and 2: Loosen: turn(s)

Stage 4: 1 and 2: 71 lb.in (8 Nm)

Stage 5: 1 and 2: 11°

Stage 6: Loosen 5 and 6: Loosen: turn(s)

Stage 7: 5 and 6: 71 lb.in (8 Nm)

Stage 8: 5 and 6: 11°

Stage 9: Loosen 3 and 4: Loosen: turn(s)

Stage 10: 3 and 4: 71 lb.in (8 Nm)

Stage 11: 3 and 4: 11°

-

If removed, install the pedestal cap and the bolts.

|

-

Install the LH valve cover.

Refer to: Valve Cover LH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

RH side rocker arm

-

-

Lubricate the clipped roller finger follower with clean engine oil.

Refer to: Specifications (303-01C) .

-

Install the clipped roller finger follower.

-

Assemble the clipped roller finger follower spring clip onto the hydraulic lash adjuster.

-

Turn the knob on the special tool counterclockwise to raise the valve and spring.

Remove Special Service Tool: 303-1633 Remover, Roller Rocker Follower. , 303-1633-01 Remover, Roller Rocker Follower.

-

Repeat steps for any remaining clipped roller finger follower removed.

-

Lubricate the clipped roller finger follower with clean engine oil.

|

-

Install the RH valve cover.

Refer to: Valve Cover RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

Refer to: Valve Cover RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

Oil Pump. Removal and Installation

Oil Pump. Removal and Installation

Special Tool(s) /

General Equipment

303-1655Tool, Camshaft Holding

Vehicle/Axle Stands

Materials

Name

Specification

Motorcraft® High Performance Engine RTV SiliconeTA-357

WSE-M4G323-A6

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Timing Chain. Removal and Installation

Timing Chain. Removal and Installation

Special Tool(s) /

General Equipment

303-1655Tool, Camshaft Holding

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Steering Wheel. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: High series heated steering wheel shown, all others similar. NOTE: Make sure the wheels are in the straight ahead position. Remove the driver airbag...

Lincoln Navigator 2018-2026 Workshop Manual: Perimeter Anti-Theft Alarm. Diagnosis and Testing

DTC Chart: BCM Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). DTC Description Action B109F:01 Intrusion Sensor Module: General Electrical Failur..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Transmission Fluid Drain and Refill. General Procedures

- Liftgate Trim Panel. Removal and Installation

- Identification Codes. Description and Operation

- Power Running Board (PRB). Diagnosis and Testing

- Second Row Seat. Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and