Lincoln Navigator: Rear Drive Halfshafts / Rear Halfshaft. Removal and Installation

Removal

NOTICE: Never pick up or hold the halfshaft by only the inner or outer CV joint. Damage to the CV joint will occur.

NOTICE: Never use a hammer to remove or install the halfshafts. Damage to the CV joint may occur.

NOTICE: Never use the halfshaft assembly as a lever to position other components. Damage to the halfshaft or CV joint may occur.

NOTICE: Do not allow the boots to contact sharp edges or hot exhaust components. Damage to the halfshaft boots will occur.

NOTICE: Do not drop assembled halfshafts. The impact may cut the boots from the inside without evidence of external damage.

-

Remove the wheel knuckle.

Refer to: Wheel Knuckle (204-02 Rear Suspension, Removal and Installation).

-

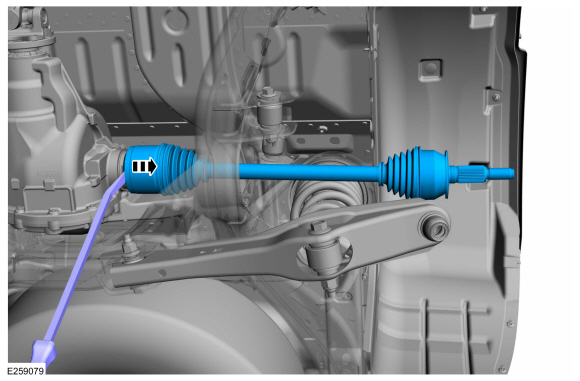

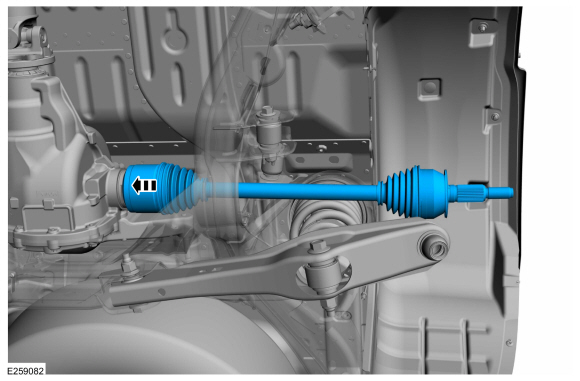

Using a pry bar, remove the halfshaft.

|

-

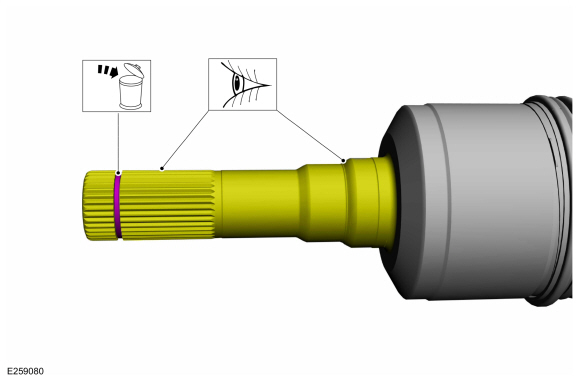

Inspect the inner halfshaft seal surface and splines for damage. Remove and discard the inner halfshaft circlip.

|

-

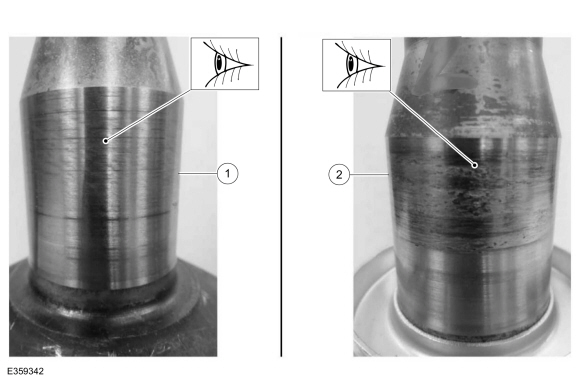

Inspect the inner CV housing.

-

Normal or acceptable wear.

-

Abnormal or excessive wear.

-

Normal or acceptable wear.

|

Installation

-

NOTE: The halfshaft seal has to be replaced whenever the halfshaft is removed.

Replace the halfshaft seal.

Refer to: Rear Halfshaft Seal (205-02 Rear Drive Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, Removal and Installation).

-

Install a new inner halfshaft circlip.

|

-

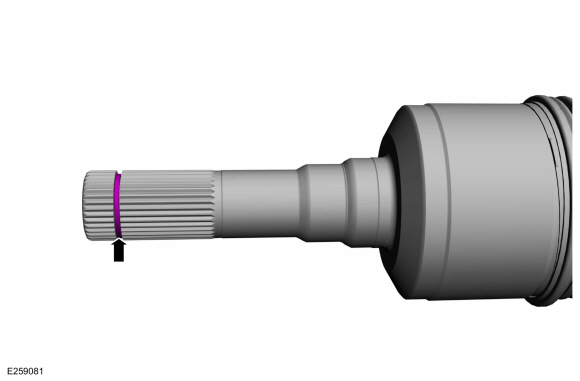

NOTICE: After insertion, pull the halfshaft inner end to make sure the circlip is locked.

NOTE: When seated correctly, the halfshaft retainer circlip can be felt as it snaps into the differential side gear groove.

Install the halfshaft until the halfshaft circlip is fully seated.

|

-

Install the wheel knuckle.

Refer to: Wheel Knuckle (204-02 Rear Suspension, Removal and Installation).

-

Check and top off the rear differential fluid.

Refer to: Differential Fluid Level Check (205-02 Rear Drive Axle/Differential - Vehicles With: Ford 9.75 Inch Ring Gear, General Procedures).

Outer Constant Velocity (CV) Joint Boot. Removal and Installation

Outer Constant Velocity (CV) Joint Boot. Removal and Installation

Special Tool(s) /

General Equipment

Flat Headed Screw Driver

Boot Clamp Pliers

Removal

Remove the inner CV joint boot...

Brake System

Brake System

..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Engine - Overview. Description and Operation

Overview The 3.5L Ecoboost is a turbocharged engine which may also be described with these terms: GTDI - Gasoline Turbocharged Direct Injection DI - Direct Injection GT - Gasoline Turbocharged Ti-VCT TC - Twin independent Variable Camshaft Timing Turbocharged V6 - 6 cylinder engine 24V - 4 valves per cylinder 4V - 4 valves per cylinde..

Lincoln Navigator 2018-2026 Workshop Manual: Specifications

Materials Name Specification Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM - Motorcraft® High Performance Engine RTV SiliconeTA-357 WSE-M4G323-A6 Motorcraft® Silicone Spray LubricantXL-6 ESR-M13P4-A Permatex® Trim and Weatherstrip Adhesive81850 - ..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Second Row Seat. Removal and Installation

- Front Seat. Removal and Installation

- Power Running Board (PRB). Diagnosis and Testing

- All Terrain Control Module (ATCM). Removal and Installation

- SYNC Module [APIM]. Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and