Lincoln Navigator: Information and Entertainment System - General Information - Vehicles With: SYNC 4 / Information and Entertainment System. Diagnosis and Testing

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Module | DTC | Description | Action |

|---|---|---|---|

| ACM | B116A:01 | Handset Microphone: General Electrical Failure | GO to Pinpoint Test V |

| ACM | B116A:12 | Handset Microphone: Circuit Short To Battery | GO to Pinpoint Test V |

| ACM | B116A:14 | Handset Microphone: Circuit Short To Ground Or Open | GO to Pinpoint Test V |

| ACM | B117A:01 | Backup Microphone: General Electrical Failure | GO to Pinpoint Test V |

| ACM | B117A:12 | Backup Microphone: Circuit Short To Battery | GO to Pinpoint Test V |

| ACM | B117A:14 | Backup Microphone: Circuit Short To Ground Or Open | GO to Pinpoint Test V |

| ACM | B13F5:01 | Microphone 3: General Electrical Failure | GO to Pinpoint Test V |

| ACM | B13F5:12 | Microphone 3: Circuit Short To Battery | GO to Pinpoint Test V |

| ACM | B13F5:14 | Microphone 3: Circuit Short To Ground Or Open | GO to Pinpoint Test V |

| ACM | B150C:01 | Automobile Audio Bus (A2B) Node 1: General Electrical Failure | GO to Pinpoint Test C |

| ACM | B150C:11 | Automobile Audio Bus (A2B) Node 1: Circuit Short To Ground | GO to Pinpoint Test C |

| ACM | B150C:12 | Automobile Audio Bus (A2B) Node 1: Circuit Short To Battery | GO to Pinpoint Test C |

| ACM | B150C:13 | Automobile Audio Bus (A2B) Node 1: Circuit Open | GO to Pinpoint Test C |

| ACM | B150C:55 | Automobile Audio Bus (A2B) Node 1: Not Configured | GO to Pinpoint Test C |

| ACM | B150C:87 | Automobile Audio Bus (A2B) Node 1: Missing Message | GO to Pinpoint Test C |

| ACM | B150C:8F | Automobile Audio Bus (A2B) Node 1: Erratic | GO to Pinpoint Test C |

| ACM | B150C:95 | Automobile Audio Bus (A2B) Node 1: Incorrect Assembly | GO to Pinpoint Test C |

| ACM | B1511:01 | Automobile Audio Bus (A2B) Master Node: General Electrical Failure | GO to Pinpoint Test C |

| ACM | B1511:11 | Automobile Audio Bus (A2B) Master Node: Circuit Short To Ground | GO to Pinpoint Test C |

| ACM | B1511:12 | Automobile Audio Bus (A2B) Master Node: Circuit Short To Battery | GO to Pinpoint Test C |

| ACM | B1511:13 | Automobile Audio Bus (A2B) Master Node: Circuit Open | GO to Pinpoint Test C |

| ACM | B1511:95 | Automobile Audio Bus (A2B) Master Node: Incorrect Assembly | GO to Pinpoint Test C |

| ACM | B1A56:11 | Antenna: Circuit Short To Ground | GO to Pinpoint Test A |

| ACM | B1A56:15 | Antenna: Circuit Short To Battery Or Open | GO to Pinpoint Test A |

| ACM | B1A89:11 | Satellite Antenna: Circuit Short To Ground | GO to Pinpoint Test B |

| ACM | B1A89:13 | Satellite Antenna: Circuit Open | GO to Pinpoint Test B |

| ACM | U0100:00 | Lost Communication With ECM/PCM 'A': No Sub Type Information | GO to Pinpoint Test Y |

| ACM | U0121:00 | Lost Communication With Anti-Lock Brake System (ABS) Control Module 'A': No Sub Type Information | GO to Pinpoint Test Z |

| ACM | U0140:00 | Lost Communication With Body Control Module: No Sub Type Information | GO to Pinpoint Test AA |

| ACM | U0155:00 | Lost Communication With Instrument Panel Cluster (IPC) Control Module: No Sub Type Information | GO to Pinpoint Test AD |

| ACM | U0198:00 | Lost Communication With Telematic Control Module 'A': No Sub Type Information | GO to Pinpoint Test AF |

| ACM | U0238:00 | Lost Communication With Digital Audio Control Module 'D': No Sub Type Information | GO to Pinpoint Test AI |

| ACM | U0249:00 | Lost Communication With Entertainment Control Module -Rear 'B': No Sub Type Information | GO to Pinpoint Test AJ |

| ACM | U0253:00 | Lost Communication With Accessory Protocol Interface Module: No Sub Type Information | GO to Pinpoint Test AK |

| ACM | U0256:00 | Lost Communication With Front Controls Interface Module 'A': No Sub Type Information | GO to Pinpoint Test AL |

| ACM | U201A:51 | Control Module Main Calibration Data: Not Programmed | GO to Pinpoint Test AQ |

| ACM | U201B:04 | Control Module Calibration Data #2: System Internal Failures | GO to Pinpoint Test AQ |

| ACM | U201B:51 | Control Module Calibration Data #2: Not Programmed | GO to Pinpoint Test AQ |

| ACM | U201B:55 | Control Module Calibration Data #2: Not Configured | GO to Pinpoint Test AQ |

| ACM | U2024:00 | Control Module Cal-Config Data: No Sub Type Information | GO to Pinpoint Test AQ |

| ACM | U2024:57 | Control Module Cal-Config Data: Invalid/Incompatible Software Component | GO to Pinpoint Test AQ |

| ACM | U2026:54 | Control Module Cal-Config Data #3: Missing Calibration | GO to Pinpoint Test AQ |

| ACM | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AQ |

| ACM | U2101:00 | Control Module Configuration Incompatible: No Sub Type Information | GO to Pinpoint Test AQ |

| ACM | U3000:41 | Control Module: General Checksum Failure | GO to Pinpoint Test AR |

| ACM | U3000:42 | Control Module: General Memory Failure | GO to Pinpoint Test AR |

| ACM | U3000:92 | Control Module: Performance Or Incorrect Operation | GO to Pinpoint Test AR |

| ACM | U3000:94 | Control Module: Unexpected Operation | GO to Pinpoint Test AR |

| ACM | U3000:96 | Control Module: Component Internal Failure | GO to Pinpoint Test AR |

| ACM | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AM |

| ACM | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AN |

| APIM | B108E:01 | Display: General Electrical Failure | GO to Pinpoint Test J |

| APIM | B108E:02 | Display: General Signal Failure | GO to Pinpoint Test J |

| APIM | B108E:4A | Display: Incorrect Component Installed | GO to Pinpoint Test J |

| APIM | B108E:4B | Display: Over Temperature | GO to Pinpoint Test J |

| APIM | B108E:87 | Display: Missing Message | GO to Pinpoint Test J |

| APIM | B119F:01 | GPS Antenna: General Electrical Failure | GO to Pinpoint Test S |

| APIM | B119F:13 | GPS Antenna: Circuit Open | GO to Pinpoint Test S |

| APIM | B1252:11 | USB Port: Circuit Short To Ground | GO to Pinpoint Test N |

| APIM | B1252:13 | USB Port: Circuit Open | GO to Pinpoint Test N |

| APIM | B14FD:11 | External Media Control Connectivity: Circuit Short To Ground | GO to Pinpoint Test N |

| APIM | B156D:54 | TCU Customer Connectivity Settings Synchronization With HMI: Missing Calibration | GO to Pinpoint Test AX |

| APIM | B156D:89 | TCU Customer Connectivity Settings Synchronization With HMI: Data Transfer Failure | GO to Pinpoint Test AX |

| APIM | B15EB:57 | Consumer Apps: Invalid/Incompatible Software Component | GO to Pinpoint Test AX |

| APIM | B1D79:11 | Microphone Input: Circuit Short To Ground | GO to Pinpoint Test L |

| APIM | B1D79:12 | Microphone Input: Circuit Short To Battery | GO to Pinpoint Test L |

| APIM | B1D79:13 | Microphone Input: Circuit Open | GO to Pinpoint Test L |

| APIM | U0100:00 | Lost Communication With ECM/PCM 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0121:00 | Lost Communication With Anti-Lock Brake System (ABS) Control Module 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0121:55 | Lost Communication With Anti-Lock Brake System (ABS) Control Module 'A': Not Configured | GO to Pinpoint Test AX |

| APIM | U0122:00 | Lost Communication With Vehicle Dynamics Control Module: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0140:00 | Lost Communication With Body Control Module: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0151:00 | Lost Communication With Restraints Control Module: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0155:00 | Lost Communication With Instrument Panel Cluster (IPC) Control Module: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0159:00 | Lost Communication With Parking Assist Control Module 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0162:00 | Lost Communication With Navigation Display Module: No Sub Type Information | GO to Pinpoint Test J |

| APIM | U0162:94 | Lost Communication With Navigation Display Module: Unexpected Operation | GO to Pinpoint Test J |

| APIM | U0184:00 | Lost Communication With Radio: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0196:00 | Lost Communication With Entertainment Control Module-Rear 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0198:00 | Lost Communication With Telematic Control Module 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0208:00 | Lost Communication With 'Seat Control Module A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0209:00 | Lost Communication With 'Seat Control Module B': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U020C:00 | Lost Communication with Wireless Accessory Charging Module 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0212:00 | Lost Communication With Steering Column Control Module: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0214:00 | Lost Communication With Remote Function Actuation Module: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0232:00 | Lost Communication With Side Obstacle Detection Control Module 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0233:00 | Lost Communication With Side Obstacle Detection Control Module 'B': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0238:00 | Lost Communication With Digital Audio Control Module 'D': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U023B:00 | Lost Communication With Image Processing Module B: No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U024B:00 | Lost Communication with Seat Control Module 'G': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U024C:00 | Lost Communication with Seat Control Module 'H': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0256:00 | Lost Communication With Front Controls Interface Module 'A': No Sub Type Information | GO to Pinpoint Test AV |

| APIM | U0415:00 | Invalid Data Received from Anti-Lock Brake System (ABS) Control Module 'A': No Sub Type Information | GO to Pinpoint Test AW |

| APIM | U0415:94 | Invalid Data Received from Anti-Lock Brake System (ABS) Control Module 'A': Unexpected Operation | GO to Pinpoint Test AW |

| APIM | U0416:00 | Invalid Data Received From Vehicle Dynamics Control Module: No Sub Type Information | GO to Pinpoint Test AW |

| APIM | U0422:00 | Invalid Data Received From Body Control Module: No Sub Type Information | GO to Pinpoint Test AW |

| APIM | U0452:00 | Invalid Data Received From Restraints Control Module: No Sub Type Information | GO to Pinpoint Test AW |

| APIM | U1A00:87 | Private Communication Network: Missing Message | GO to Pinpoint Test B |

| APIM | U1A00:94 | Private Communication Network: Unexpected Operation | GO to Pinpoint Test B |

| APIM | U2017:45 | Control Module Software #2: Program Memory Failure | GO to Pinpoint Test AX |

| APIM | U2017:51 | Control Module Software #2: Not Programmed | GO to Pinpoint Test AX |

| APIM | U2017:52 | Control Module Software #2: Not Activated | GO to Pinpoint Test AX |

| APIM | U2017:54 | Control Module Software #2: Missing Calibration | GO to Pinpoint Test AX |

| APIM | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AX |

| APIM | U2101:00 | Control Module Configuration Incompatible: No Sub Type Information | GO to Pinpoint Test AX |

| APIM | U3000:04 | Control Module: System Internal Failures | GO to Pinpoint Test AY |

| APIM | U3000:05 | Control Module: System Programming Failures | GO to Pinpoint Test AY |

| APIM | U3000:09 | Control Module: Component Failures | GO to Pinpoint Test AY |

| APIM | U3000:41 | Control Module: General Checksum Failure | GO to Pinpoint Test AY |

| APIM | U3000:43 | Control Module: Special Memory Failure | GO to Pinpoint Test AY |

| APIM | U3000:57 | Control Module: Invalid/Incompatible Software Component | GO to Pinpoint Test AX |

| APIM | U3000:88 | Control Module: Bus Off | GO to Pinpoint Test AV |

| APIM | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AM |

| APIM | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AN |

| DSP | B128A:01 | Speaker #13: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B128A:11 | Speaker #13: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B128A:12 | Speaker #13: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B128A:13 | Speaker #13: Circuit Open | GO to Pinpoint Test G |

| DSP | B128B:01 | Speaker #14: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B128B:11 | Speaker #14: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B128B:12 | Speaker #14: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B128B:13 | Speaker #14: Circuit Open | GO to Pinpoint Test G |

| DSP | B128C:01 | Speaker #15: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B128C:11 | Speaker #15: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B128C:12 | Speaker #15: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B128C:13 | Speaker #15: Circuit Open | GO to Pinpoint Test G |

| DSP | B128D:01 | Speaker #16: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B128D:11 | Speaker #16: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B128D:12 | Speaker #16: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B128D:13 | Speaker #16: Circuit Open | GO to Pinpoint Test G |

| DSP | B128E:01 | Speaker #17: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B128E:11 | Speaker #17: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B128E:12 | Speaker #17: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B128E:13 | Speaker #17: Circuit Open | GO to Pinpoint Test G |

| DSP | B128F:01 | Speaker #18: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B128F:11 | Speaker #18: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B128F:12 | Speaker #18: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B128F:13 | Speaker #18: Circuit Open | GO to Pinpoint Test G |

| DSP | B1290:01 | Speaker #19: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1290:11 | Speaker #19: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1290:12 | Speaker #19: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1290:13 | Speaker #19: Circuit Open | GO to Pinpoint Test G |

| DSP | B1291:01 | Speaker #20: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1291:11 | Speaker #20: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1291:12 | Speaker #20: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1291:13 | Speaker #20: Circuit Open | GO to Pinpoint Test G |

| DSP | B13FB:11 | Audio Enable Line: Circuit Short To Ground | GO to Pinpoint Test C |

| DSP | B1A01:01 | Speaker #1: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A01:01 | Speaker #1: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A01:11 | Speaker #1: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A01:11 | Speaker #1: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A01:12 | Speaker #1: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A01:12 | Speaker #1: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A01:13 | Speaker #1: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A01:13 | Speaker #1: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A02:01 | Speaker #2: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A02:01 | Speaker #2: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A02:11 | Speaker #2: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A02:11 | Speaker #2: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A02:12 | Speaker #2: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A02:12 | Speaker #2: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A02:13 | Speaker #2: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A02:13 | Speaker #2: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A03:01 | Speaker #3: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A03:01 | Speaker #3: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A03:11 | Speaker #3: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A03:11 | Speaker #3: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A03:12 | Speaker #3: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A03:12 | Speaker #3: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A03:13 | Speaker #3: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A03:13 | Speaker #3: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A04:01 | Speaker #4: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A04:01 | Speaker #4: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A04:11 | Speaker #4: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A04:11 | Speaker #4: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A04:12 | Speaker #4: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A04:12 | Speaker #4: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A04:13 | Speaker #4: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A04:13 | Speaker #4: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A05:01 | Speaker #5: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A05:01 | Speaker #5: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A05:11 | Speaker #5: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A05:11 | Speaker #5: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A05:12 | Speaker #5: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A05:12 | Speaker #5: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A05:13 | Speaker #5: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A05:13 | Speaker #5: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A06:01 | Speaker #6: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A06:01 | Speaker #6: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A06:11 | Speaker #6: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A06:11 | Speaker #6: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A06:12 | Speaker #6: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A06:12 | Speaker #6: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A06:13 | Speaker #6: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A06:13 | Speaker #6: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A07:01 | Speaker #7: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A07:01 | Speaker #7: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A07:11 | Speaker #7: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A07:11 | Speaker #7: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A07:12 | Speaker #7: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A07:12 | Speaker #7: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A07:13 | Speaker #7: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A07:13 | Speaker #7: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A08:01 | Speaker #8: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A08:01 | Speaker #8: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A08:11 | Speaker #8: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A08:11 | Speaker #8: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A08:12 | Speaker #8: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A08:12 | Speaker #8: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A08:13 | Speaker #8: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A08:13 | Speaker #8: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A09:01 | Speaker #9: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A09:01 | Speaker #9: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A09:11 | Speaker #9: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A09:11 | Speaker #9: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A09:12 | Speaker #9: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A09:12 | Speaker #9: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A09:13 | Speaker #9: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A09:13 | Speaker #9: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A10:01 | Speaker #10: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A10:01 | Speaker #10: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A10:11 | Speaker #10: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A10:11 | Speaker #10: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A10:12 | Speaker #10: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A10:12 | Speaker #10: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A10:13 | Speaker #10: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A10:13 | Speaker #10: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A11:01 | Speaker #11: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A11:01 | Speaker #11: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A11:11 | Speaker #11: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A11:11 | Speaker #11: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A11:12 | Speaker #11: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A11:12 | Speaker #11: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A11:13 | Speaker #11: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A11:13 | Speaker #11: Circuit Open | GO to Pinpoint Test G |

| DSP | B1A12:01 | Speaker #12: General Electrical Failure | GO to Pinpoint Test F |

| DSP | B1A12:01 | Speaker #12: General Electrical Failure | GO to Pinpoint Test G |

| DSP | B1A12:11 | Speaker #12: Circuit Short To Ground | GO to Pinpoint Test F |

| DSP | B1A12:11 | Speaker #12: Circuit Short To Ground | GO to Pinpoint Test G |

| DSP | B1A12:12 | Speaker #12: Circuit Short To Battery | GO to Pinpoint Test F |

| DSP | B1A12:12 | Speaker #12: Circuit Short To Battery | GO to Pinpoint Test G |

| DSP | B1A12:13 | Speaker #12: Circuit Open | GO to Pinpoint Test F |

| DSP | B1A12:13 | Speaker #12: Circuit Open | GO to Pinpoint Test G |

| DSP | U0100:00 | Lost Communication With ECM/PCM 'A': No Sub Type Information | GO to Pinpoint Test Y |

| DSP | U0140:00 | Lost Communication With Body Control Module: No Sub Type Information | GO to Pinpoint Test AA |

| DSP | U0155:00 | Lost Communication With Instrument Panel Cluster (IPC) Control Module: No Sub Type Information | GO to Pinpoint Test AD |

| DSP | U0184:00 | Lost Communication With Radio: No Sub Type Information | GO to Pinpoint Test AE |

| DSP | U0253:00 | Lost Communication With Accessory Protocol Interface Module: No Sub Type Information | GO to Pinpoint Test AK |

| DSP | U0256:00 | Lost Communication With Front Controls Interface Module 'A': No Sub Type Information | GO to Pinpoint Test AL |

| DSP | U0422:00 | Invalid Data Received From Body Control Module: No Sub Type Information | GO to Pinpoint Test AP |

| DSP | U0423:00 | Invalid Data Received from Instrument Panel Cluster Control Module: No Sub Type Information | GO to Pinpoint Test AP |

| DSP | U201A:51 | Control Module Main Calibration Data: Not Programmed | GO to Pinpoint Test AQ |

| DSP | U2024:41 | Control Module Cal-Config Data: General Checksum Failure | GO to Pinpoint Test AQ |

| DSP | U2024:48 | Control Module Cal-Config Data: Supervision Software Failure | GO to Pinpoint Test AQ |

| DSP | U2024:51 | Control Module Cal-Config Data: Not Programmed | GO to Pinpoint Test AQ |

| DSP | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AQ |

| DSP | U2101:00 | Control Module Configuration Incompatible: No Sub Type Information | GO to Pinpoint Test AQ |

| DSP | U3000:41 | Control Module: General Checksum Failure | GO to Pinpoint Test AR |

| DSP | U3000:42 | Control Module: General Memory Failure | GO to Pinpoint Test AR |

| DSP | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AM |

| DSP | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AN |

| FCIM | B10B8:63 | Push Buttons: Circuit/Component Protection Time-Out | GO to Pinpoint Test AR |

| FCIM | U0100:00 | Lost Communication With ECM/PCM 'A': No Sub Type Information | GO to Pinpoint Test Y |

| FCIM | U0140:00 | Lost Communication With Body Control Module: No Sub Type Information | GO to Pinpoint Test AA |

| FCIM | U0151:00 | Lost Communication With Restraints Control Module: No Sub Type Information | GO to Pinpoint Test AC |

| FCIM | U0155:00 | Lost Communication With Instrument Panel Cluster (IPC) Control Module: No Sub Type Information | GO to Pinpoint Test AD |

| FCIM | U0253:00 | Lost Communication With Accessory Protocol Interface Module: No Sub Type Information | GO to Pinpoint Test AK |

| FCIM | U0401:00 | Invalid Data Received from ECM/PCM A: No Sub Type Information | GO to Pinpoint Test AP |

| FCIM | U0401:82 | Invalid Data Received from ECM/PCM A: Alive/Sequence Counter Incorrect/Not Updated | GO to Pinpoint Test AP |

| FCIM | U0422:68 | Invalid Data Received From Body Control Module: Event Information | GO to Pinpoint Test AP |

| FCIM | U0422:81 | Invalid Data Received From Body Control Module: Invalid Serial Data Received | GO to Pinpoint Test AP |

| FCIM | U1000:00 | Solid State Driver Protection Active -Driver Disabled: No Sub Type Information | GO to Pinpoint Test AS |

| FCIM | U2024:51 | Control Module Cal-Config Data: Not Programmed | GO to Pinpoint Test AQ |

| FCIM | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AQ |

| FCIM | U3000:41 | Control Module: General Checksum Failure | GO to Pinpoint Test AR |

| FCIM | U3000:49 | Control Module: Internal Electronic Failure | GO to Pinpoint Test AR |

| FCIM | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AM |

| FCIM | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AN |

| RACM | U0100:00 | Lost Communication With ECM/PCM 'A': No Sub Type Information | GO to Pinpoint Test Y |

| RACM | U0140:00 | Lost Communication With Body Control Module: No Sub Type Information | GO to Pinpoint Test AA |

| RACM | U0155:00 | Lost Communication With Instrument Panel Cluster (IPC) Control Module: No Sub Type Information | GO to Pinpoint Test AD |

| RACM | U0162:00 | Lost Communication With Navigation Display Module: No Sub Type Information | GO to Pinpoint Test AR |

| RACM | U0184:00 | Lost Communication With Radio: No Sub Type Information | GO to Pinpoint Test AE |

| RACM | U0198:00 | Lost Communication With Telematic Control Module 'A': No Sub Type Information | GO to Pinpoint Test AG |

| RACM | U0211:00 | Lost Communication With 'Seat Control Module D': No Sub Type Information | GO to Pinpoint Test AH |

| RACM | U0238:00 | Lost Communication With Digital Audio Control Module 'D': No Sub Type Information | GO to Pinpoint Test AI |

| RACM | U0253:00 | Lost Communication With Accessory Protocol Interface Module: No Sub Type Information | GO to Pinpoint Test AK |

| RACM | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AQ |

| RACM | U2101:00 | Control Module Configuration Incompatible: No Sub Type Information | GO to Pinpoint Test AQ |

| RACM | U3000:41 | Control Module: General Checksum Failure | GO to Pinpoint Test AR |

| RACM | U3000:42 | Control Module: General Memory Failure | GO to Pinpoint Test AR |

| RACM | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AM |

| RACM | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AN |

| SCCM | B137F:11 | Steering Wheel Left Switch Pack: Circuit Short To Ground | GO to Pinpoint Test I |

| SCCM | B137F:13 | Steering Wheel Left Switch Pack: Circuit Open | GO to Pinpoint Test I |

| SCCM | B137F:96 | Steering Wheel Left Switch Pack: Component Internal Failure | GO to Pinpoint Test I |

| SCCM | B137F:9E | Steering Wheel Left Switch Pack: Stuck On | GO to Pinpoint Test I |

| SCCM | B1380:11 | Steering Wheel Right Switch Pack: Circuit Short To Ground | GO to Pinpoint Test I |

| SCCM | B1380:13 | Steering Wheel Right Switch Pack: Circuit Open | GO to Pinpoint Test I |

| SCCM | B1380:96 | Steering Wheel Right Switch Pack: Component Internal Failure | GO to Pinpoint Test I |

| SCCM | B1380:9E | Steering Wheel Right Switch Pack: Stuck On | GO to Pinpoint Test I |

| TCU | B116C:04 | External SIM Cable/SIM Card: System Internal Failures | GO to Pinpoint Test AR |

| TCU | B116C:57 | External SIM Cable/SIM Card: Invalid/Incompatible Software Component | GO to Pinpoint Test AR |

| TCU | B1246:11 | GSM (Group System for Mobile) Antenna: Circuit Short To Ground | GO to Pinpoint Test T |

| TCU | B1246:13 | GSM (Group System for Mobile) Antenna: Circuit Open | GO to Pinpoint Test T |

| TCU | B1D55:11 | Antenna #2: Circuit Short To Ground | GO to Pinpoint Test U |

| TCU | B1D55:13 | Antenna #2: Circuit Open | GO to Pinpoint Test U |

| TCU | C006A:00 | Multi-axis Acceleration Sensor: No Sub Type Information | GO to Pinpoint Test AR |

| TCU | U0001:09 | High Speed CAN Communication Bus: Component Failures | GO to Pinpoint Test AO |

| TCU | U0100:00 | Lost Communication With ECM/PCM 'A': No Sub Type Information | GO to Pinpoint Test Y |

| TCU | U0140:00 | Lost Communication With Body Control Module: No Sub Type Information | GO to Pinpoint Test AA |

| TCU | U0146:09 | Lost Communication With Serial Data Gateway 'A': Component Failures | GO to Pinpoint Test AB |

| TCU | U0422:00 | Invalid Data Received From Body Control Module: No Sub Type Information | GO to Pinpoint Test AP |

| TCU | U0554:00 | Invalid Data Received From Accessory Protocol Interface Module: No Sub Type Information | GO to Pinpoint Test AP |

| TCU | U1A01:09 | Communication Link: Component Failures | GO to Pinpoint Test AQ |

| TCU | U1A01:93 | Communication Link: No Operation | GO to Pinpoint Test AR |

| TCU | U1A4B:52 | Control Module Processor B: Not Activated | GO to Pinpoint Test AR |

| TCU | U2100:00 | Initial Configuration Not Complete: No Sub Type Information | GO to Pinpoint Test AQ |

| TCU | U2101:00 | Control Module Configuration Incompatible: No Sub Type Information | GO to Pinpoint Test AQ |

| TCU | U2101:56 | Control Module Configuration Incompatible: Invalid/Incompatible Configuration | GO to Pinpoint Test AQ |

| TCU | U2200:00 | Control Module Configuration Memory Corrupt: No Sub Type Information | GO to Pinpoint Test AR |

| TCU | U3000:04 | Control Module: System Internal Failures | GO to Pinpoint Test AT |

| TCU | U3000:09 | Control Module: Component Failures | GO to Pinpoint Test AR |

| TCU | U3000:43 | Control Module: Special Memory Failure | GO to Pinpoint Test AR |

| TCU | U3000:49 | Control Module: Internal Electronic Failure | GO to Pinpoint Test AR |

| TCU | U3000:57 | Control Module: Invalid/Incompatible Software Component | GO to Pinpoint Test AU |

| TCU | U3000:96 | Control Module: Component Internal Failure | GO to Pinpoint Test AR |

| TCU | U3003:16 | Battery Voltage: Circuit Voltage Below Threshold | GO to Pinpoint Test AM |

| TCU | U3003:17 | Battery Voltage: Circuit Voltage Above Threshold | GO to Pinpoint Test AN |

Symptom Charts

Symptom Chart: Radio

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

|---|---|

| A module does not respond to the diagnostic scan tool |

REFER to: Controller Area Network (CAN) Module Communications Network (418-00A Controller Area Network (CAN) Module Communications Network, Diagnosis and Testing). |

| The AM radio is inoperative | GO to Pinpoint Test A |

| The FM radio is inoperative | GO to Pinpoint Test A |

| Poor AM reception | GO to Pinpoint Test A |

| Poor FM reception | GO to Pinpoint Test A |

| Continuous seek or scan in AM / FM mode | GO to Pinpoint Test A |

| The DAB feature is inoperative | GO to Pinpoint Test A |

| Poor satellite radio reception | GO to Pinpoint Test B |

| SIRIUS™ on-demand streaming content does not play or is not available | GO to Pinpoint Test B |

| SIRIUS™ content pausing repeatedly | GO to Pinpoint Test B |

| Poor sound quality or no sound while in satellite radio mode - all other functions operate correctly | GO to Pinpoint Test B |

| The satellite radio is inoperative or does not operate correctly | GO to Pinpoint Test B |

| The audio system does not operate correctly from the FCIM | GO to Pinpoint Test H |

| The audio system does not operate correctly from the RACM | CARRY OUT the RACM self-test. DIAGNOSE the DTC present. |

| One or more audio steering wheel control button is inoperative | GO to Pinpoint Test I |

| The speed compensated volume is inoperative | GO to Pinpoint Test E |

| Unable to change the audio source | GO to Pinpoint Test C |

| The touchscreen displays Audio System Off at regular intervals | GO to Pinpoint Test C |

Symptom Chart: Speakers and Sound Quality - 14 Speaker System

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

|---|---|

| No sound from all speakers | GO to Pinpoint Test C |

| The left speakers are inoperative when using Bluetooth and USB hub SYNC features | GO to Pinpoint Test K |

| The right speakers are inoperative when using Bluetooth and USB hub SYNC features | GO to Pinpoint Test K |

| Poor sound quality or distorted sound from one or more speakers (not all speakers) | GO to Pinpoint Test D |

| The instrument panel center speaker is inoperative | GO to Pinpoint Test F |

| The left front door tweeter speaker is inoperative | GO to Pinpoint Test F |

| The right front door tweeter speaker is inoperative | GO to Pinpoint Test F |

| The left front door midrange speaker is inoperative | GO to Pinpoint Test F |

| The right front door midrange speaker is inoperative | GO to Pinpoint Test F |

| The left front door woofer speaker is inoperative | GO to Pinpoint Test F |

| The right front door woofer speaker is inoperative | GO to Pinpoint Test F |

| The left rear door tweeter speaker is inoperative | GO to Pinpoint Test F |

| The right rear door tweeter speaker is inoperative | GO to Pinpoint Test F |

| The left rear door woofer speaker is inoperative | GO to Pinpoint Test F |

| The right rear door woofer speaker is inoperative | GO to Pinpoint Test F |

| The subwoofer speaker is inoperative | GO to Pinpoint Test F |

Symptom Chart: Speakers and Sound Quality - 28 Speaker System

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

|---|---|

| No sound from all speakers | GO to Pinpoint Test C |

| The left speakers are inoperative when using Bluetooth and USB hub SYNC features | GO to Pinpoint Test K |

| The right speakers are inoperative when using Bluetooth and USB hub SYNC features | GO to Pinpoint Test K |

| Poor sound quality or distorted sound from one or more speakers (not all speakers) | GO to Pinpoint Test D |

| The instrument panel center speaker is inoperative | GO to Pinpoint Test G |

| The left front door tweeter speaker is inoperative | GO to Pinpoint Test G |

| The right front door tweeter speaker is inoperative | GO to Pinpoint Test G |

| The left front door midrange speaker is inoperative | GO to Pinpoint Test G |

| The right front door midrange speaker is inoperative | GO to Pinpoint Test G |

| The left front door woofer speaker is inoperative | GO to Pinpoint Test G |

| The right front door woofer speaker is inoperative | GO to Pinpoint Test G |

| The left rear door tweeter speaker is inoperative | GO to Pinpoint Test G |

| The right rear door tweeter speaker is inoperative | GO to Pinpoint Test G |

| The left rear door midrange speaker is inoperative | GO to Pinpoint Test G |

| The right rear door midrange speaker is inoperative | GO to Pinpoint Test G |

| The left rear door woofer speaker is inoperative | GO to Pinpoint Test G |

| The right rear door woofer speaker is inoperative | GO to Pinpoint Test G |

| The left D-pillar speaker is inoperative | GO to Pinpoint Test G |

| The right D-pillar speaker is inoperative | GO to Pinpoint Test G |

| The left front overhead speaker is inoperative | GO to Pinpoint Test G |

| The right front overhead speaker is inoperative | GO to Pinpoint Test G |

| The left rear overhead speaker is inoperative | GO to Pinpoint Test G |

| The right rear overhead speaker is inoperative | GO to Pinpoint Test G |

| The subwoofer speaker is inoperative | GO to Pinpoint Test G |

Symptom Chart: Display Unit

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

|---|---|

| The display unit is blank or black | GO to Pinpoint Test J |

| The display unit is not responsive to touch | GO to Pinpoint Test J |

| The display unit is slow to respond to touch | GO to Pinpoint Test J |

| The image on the display unit is incorrect, the image color is incorrect, or the image is distorted, flickering, or unclear | GO to Pinpoint Test J |

| The image on the display unit is locked or frozen | GO to Pinpoint Test J |

Symptom Chart: SYNC Features/Media/Phone/Connectivity

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

|---|---|

| The SYNC system does not operate correctly from the FCIM | GO to Pinpoint Test H |

| One or more steering wheel SYNC control button is inoperative | GO to Pinpoint Test I |

| The left speakers are inoperative when using Bluetooth and media hub SYNC features | GO to Pinpoint Test K |

| The right speakers are inoperative when using Bluetooth and media hub SYNC features | GO to Pinpoint Test K |

| The SYNC system audible prompts are inoperative or do not operate correctly | GO to Pinpoint Test K |

| During a phone call, no incoming audio is heard in the vehicle | GO to Pinpoint Test K |

| Poor sound quality, distorted, or no sound while in SYNC mode | GO to Pinpoint Test K |

| Voice commands are inoperative or outgoing audio is not transmitted during a phone call | GO to Pinpoint Test L |

| The SYNC system does not respond to the wake word | GO to Pinpoint Test M |

| Unable to pair Bluetooth device or a Bluetooth functionality is inoperative | GO to Pinpoint Test O |

| A USB device is not recognized by the SYNC system or audio files on a USB device are not found using the SYNC system from one or both USB ports | GO to Pinpoint Test N |

| The 911 Assist or Emergency Assistance Not Operational message displays | GO to Pinpoint Test P |

| Android Auto™ or Apple CarPlay™ is inoperative | GO to Pinpoint Test Q |

| SYNC AppLink is inoperative or does not operate correctly - vehicles equipped with a touchscreen display | GO to Pinpoint Test R |

| Lincoln Way is inoperative or does not operate correctly | GO to Pinpoint Test T |

| The vehicle Wi-Fi hotspot feature is inoperative, experiencing poor data speed or cannot stream any data | GO to Pinpoint Test U |

| Automatic system updates do not occur or are delayed |

REFER to: Module Configuration (418-01B Module Configuration - Vehicles With: Over-the-Air (OTA) Programming, Diagnosis and Testing). |

Symptom Chart: Navigation/Compass

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

|---|---|

| The compass is inoperative or does not operate correctly | GO to Pinpoint Test S |

| Navigation is inoperative or does not operate correctly | GO to Pinpoint Test S |

| Traffic announcement is inoperative (vehicles equipped with a DAB radio) | GO to Pinpoint Test B |

Symptom Chart: Family Entertainment System

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Actions |

|---|---|

| Video does not display on the passenger seat display screen | GO to Pinpoint Test W |

| The family entertainment system is inoperative | GO to Pinpoint Test X |

Pinpoint Tests

PINPOINT TEST A: POOR AM (AMPLITUDE MODULATION)

- FM (FREQUENCY MODULATION)

RECEPTION

PINPOINT TEST A: POOR AM (AMPLITUDE MODULATION)

- FM (FREQUENCY MODULATION)

RECEPTION|

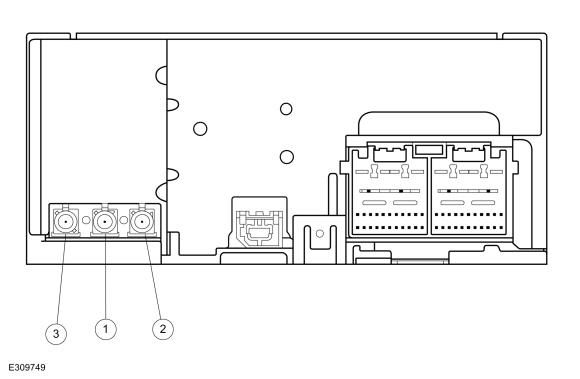

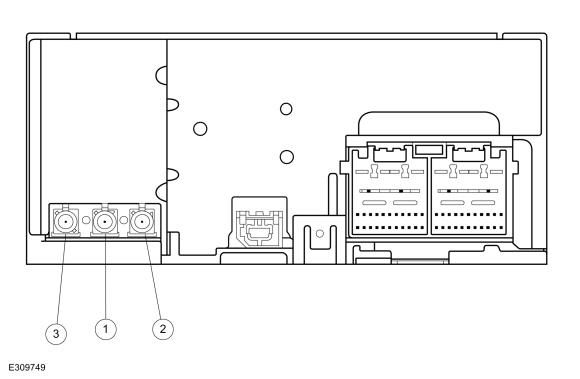

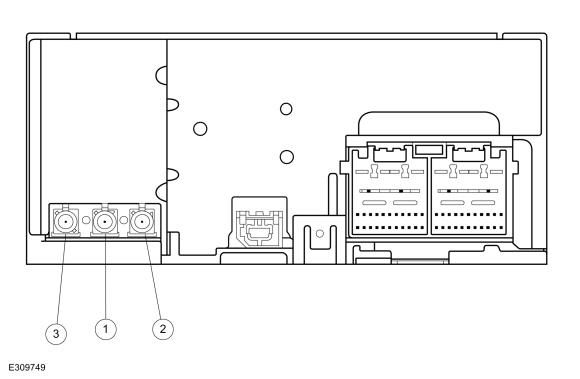

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - Component Location

(415-00 Information and Entertainment System - General Information -

Vehicles With: SYNC 4, Description and Operation). ACM Coaxial Cable Connections

DTC Fault Trigger Conditions

Possible Sources

NOTE: Prior to carrying out diagnostics, it may be beneficial to determine the cause using the Antenna Tool Kit (refer to the Rotunda catalog for the latest part number) or equivalent tool. |

|||||||||||||||||||||

| A1 CHECK THE AUDIO SYSTEM RECEPTION WITH THE ENGINE RUNNING AND WITH THE ENGINE OFF | |||||||||||||||||||||

Does the poor reception only occur with the engine running?

|

|||||||||||||||||||||

| A2 CHECK THE GENERATOR | |||||||||||||||||||||

Is the reception OK?

|

|||||||||||||||||||||

| A3 CHECK THE IGNITION CIRCUITS | |||||||||||||||||||||

Are the ignition components OK?

|

|||||||||||||||||||||

| A4 CHECK FOR ACM (AUDIO FRONT CONTROL MODULE) ANTENNA VOLTAGE OUTPUT | |||||||||||||||||||||

|

NOTE: The AM / FM 1 antenna cable is also known as the audio unit antenna cable.

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||

| A5 CHECK FOR VOLTAGE TO THE ANTENNA AMPLIFIER | |||||||||||||||||||||

Is the voltage approximately 10 volts?

|

|||||||||||||||||||||

| A6 CHECK THE AM (AMPLITUDE MODULATION) / FM (FREQUENCY MODULATION) ANTENNA AMPLIFIER | |||||||||||||||||||||

Is the reception OK?

|

|||||||||||||||||||||

| A7 CHECK FOR CORRECT ACM (AUDIO FRONT CONTROL MODULE) OPERATION | |||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST B: SATELLITE RADIO/SIRIUS™ STREAMING CONTENT/TRAFFIC ANNOUNCEMENT CONCERN

PINPOINT TEST B: SATELLITE RADIO/SIRIUS™ STREAMING CONTENT/TRAFFIC ANNOUNCEMENT CONCERN|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - Component Location

(415-00 Information and Entertainment System - General Information -

Vehicles With: SYNC 4, Description and Operation). When a satellite radio subscription is active, the ESN of the satellite radio receiver built into the ACM associates with the VIN . ACM Coaxial Cable Connections

DTC Fault Trigger Conditions

Possible Sources

NOTE: Prior to carrying out diagnostics, it may be beneficial to determine the cause using the Antenna Tool Kit (refer to the Rotunda catalog for the latest part number) or equivalent tool. NOTE: Carrying out a Master Reset of the SYNC system prior to diagnostics may resolve some satellite radio/traffic announcement concerns. |

|||||||||||||||||||||||||||

| B1 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) U1A00:87 | |||||||||||||||||||||||||||

Is DTC U1A00:87 or U1A00:94 present?

|

|||||||||||||||||||||||||||

| B2 CHECK FOR PROMOTIONAL CHANNEL 1 | |||||||||||||||||||||||||||

Does the satellite radio system receive channel 1 with normal sound quality?

|

|||||||||||||||||||||||||||

| B3 VERIFY AN ACTIVE SUBSCRIPTION | |||||||||||||||||||||||||||

Does the display indicate the subscription has expired?

|

|||||||||||||||||||||||||||

| B4 CHECK THE VEHICLE SERVICE HISTORY FOR ACM (AUDIO FRONT CONTROL MODULE) REPLACEMENT | |||||||||||||||||||||||||||

Does the vehicle service history indicate the ACM was recently replaced?

|

|||||||||||||||||||||||||||

| B5 VERIFY THE VIN (VEHICLE IDENTIFICATION NUMBER) AND THE ESN (ELECTRONIC SERIAL NUMBER) ON FILE MATCHES THE VIN (VEHICLE IDENTIFICATION NUMBER) AND THE ESN (ELECTRONIC SERIAL NUMBER) FROM THE VEHICLE | |||||||||||||||||||||||||||

Does the VIN and the ESN on the SIRIUS customer file match the ESN and VIN retrieved from the vehicle?

|

|||||||||||||||||||||||||||

| B6 CHECK THE CONNECTIVITY SETTINGS USING THE TOUCHSCREEN DISPLAY UNIT | |||||||||||||||||||||||||||

Are the Vehicle Connectivity and the SiriusXM with 360L settings enabled?

|

|||||||||||||||||||||||||||

| B7 CHECK FOR GWM (GATEWAY MODULE A) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||

Are any GWM Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||||||||||||||||

| B8 CHECK THE CELLULAR SIGNAL STRENGTH | |||||||||||||||||||||||||||

Does the display indicate a good cellular strength signal of at least 2 bars?

|

|||||||||||||||||||||||||||

| B9 VERIFY THE VIN (VEHICLE IDENTIFICATION NUMBER) AND THE ESN (ELECTRONIC SERIAL NUMBER) ON FILE MATCHES THE VIN (VEHICLE IDENTIFICATION NUMBER) AND THE ESN (ELECTRONIC SERIAL NUMBER) FROM THE VEHICLE | |||||||||||||||||||||||||||

Does the satellite radio system receive multiple channels with normal sound quality?

|

|||||||||||||||||||||||||||

| B10 CHECK FOR CORRECT ACM (AUDIO FRONT CONTROL MODULE) OUTPUT VOLTAGE TO THE SATELLITE RADIO ANTENNA CABLE | |||||||||||||||||||||||||||

Is the voltage between 4.7 and 5.8 volts?

|

|||||||||||||||||||||||||||

| B11 CHECK FOR VOLTAGE TO THE GPS (GLOBAL POSITIONING SYSTEM) /SATELLITE RADIO ANTENNA | |||||||||||||||||||||||||||

Is the voltage between 4.7 and 5.8 volts?

|

|||||||||||||||||||||||||||

| B12 ISOLATE THE GPS (GLOBAL POSITIONING SYSTEM) /SATELLITE RADIO ANTENNA SPLITTER CABLE | |||||||||||||||||||||||||||

Does the system in question operate correctly?

|

|||||||||||||||||||||||||||

| B13 CHECK THE ANTENNA BASE AND MOUNTING SURFACE | |||||||||||||||||||||||||||

Is antenna base and mounting free of corrosion?

|

|||||||||||||||||||||||||||

| B14 VERIFY THE COMPASS OPERATES CORRECTLY | |||||||||||||||||||||||||||

Does the compass operate correctly?

|

|||||||||||||||||||||||||||

| B15 ISOLATE THE GPS (GLOBAL POSITIONING SYSTEM) /SATELLITE RADIO ANTENNA | |||||||||||||||||||||||||||

Does the system in question operate correctly?

|

|||||||||||||||||||||||||||

| B16 CHECK THE SERIAL DATA CIRCUITS FOR A SHORT TO GROUND | |||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| B17 CHECK THE SERIAL DATA CIRCUITS FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||

| B18 CHECK THE SERIAL DATA CIRCUITS FOR A SHORT TOGETHER | |||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||||||||

| B19 CHECK THE SERIAL DATA CIRCUITS FOR AN OPEN | |||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||||||||||||||||

| B20 CHECK FOR CORRECT ACM (AUDIO FRONT CONTROL MODULE) OPERATION | |||||||||||||||||||||||||||

Is the concern still present?

|

|||||||||||||||||||||||||||

| B21 CHECK FOR CORRECT APIM (SYNC MODULE) OPERATION | |||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST C: NO SOUND FROM ALL SPEAKERS

PINPOINT TEST C: NO SOUND FROM ALL SPEAKERS|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). A short to ground or voltage in the circuitry to one of the speakers may cause multiple speakers to lose sound due to the built-in overload protection feature of the ACM . In this case, a speaker fault DTC sets. DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||||||||||||||||||||||||||||||||||

| C1 VERIFY THE ACM (AUDIO FRONT CONTROL MODULE) PASSES THE NETWORK TEST | |||||||||||||||||||||||||||||||||||||||||||||

Does the ACM pass the network test?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C2 VERIFY THE APIM (SYNC MODULE) PASSES THE NETWORK TEST | |||||||||||||||||||||||||||||||||||||||||||||

Does the APIM pass the network test?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C3 VERIFY THE DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) PASSES THE NETWORK TEST | |||||||||||||||||||||||||||||||||||||||||||||

Does the DSP pass the network test?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C4 CHECK FOR APIM (SYNC MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||||||||||||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C5 CHECK FOR ACM (AUDIO FRONT CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||||||||||||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C6 CHECK FOR DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) SPEAKER-RELATED DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||||||||||||||||||||

Are any speaker-related Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C7 CHECK THE DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) ENABLE CIRCUIT FOR CORRECT VOLTAGE | |||||||||||||||||||||||||||||||||||||||||||||

Is the voltage between 3.5 and 7 volts?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C8 CHECK THE DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) ENABLE CIRCUIT FOR A SHORT TO GROUND | |||||||||||||||||||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C9 CHECK THE DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) ENABLE CIRCUIT FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C10 CHECK THE DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) ENABLE CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C11 CHECK THE ACM (AUDIO FRONT CONTROL MODULE) CONFIGURATION | |||||||||||||||||||||||||||||||||||||||||||||

Is sound heard from all of the speakers?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C12 CHECK THE DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) CONFIGURATION | |||||||||||||||||||||||||||||||||||||||||||||

Is sound heard from all of the speakers?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C13 CHECK THE REAR AUTOMOBILE AUDIO BUS (A2B) CABLE | |||||||||||||||||||||||||||||||||||||||||||||

Is sound heard from all of the speakers?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C14 CHECK THE CENTER AUTOMOBILE AUDIO BUS (A2B) CABLE | |||||||||||||||||||||||||||||||||||||||||||||

Is sound heard from all of the speakers?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C15 CHECK THE FRONT AUTOMOBILE AUDIO BUS (A2B) CABLE | |||||||||||||||||||||||||||||||||||||||||||||

Is sound heard from all of the speakers?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C16 CHECK FOR CORRECT DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) OPERATION | |||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

|||||||||||||||||||||||||||||||||||||||||||||

| C17 CHECK FOR CORRECT ACM (AUDIO FRONT CONTROL MODULE) OPERATION | |||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST D: POOR SOUND QUALITY OR DISTORTED SOUND FROM ONE OR MORE SPEAKERS (NOT ALL SPEAKERS)

PINPOINT TEST D: POOR SOUND QUALITY OR DISTORTED SOUND FROM ONE OR MORE SPEAKERS (NOT ALL SPEAKERS)|

Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| D1 ISOLATE THE ZONE | ||||

Does applying pressure to a trim panel reduce or eliminate the noise?

|

||||

| D2 REMOVE AND INSPECT BEHIND/UNDERNEATH THE SUSPECT TRIM PANEL | ||||

Is the source of the noise located?

|

||||

| D3 CHECK THE SUSPECT SPEAKER FOR WATER INTRUSION | ||||

Are any watermarks present on the speaker?

|

||||

| D4 ISOLATE THE SUSPECT SPEAKER TO VERIFY NOISE | ||||

Is the noise still present in the suspect speaker?

|

PINPOINT TEST E: THE SPEED COMPENSATED VOLUME IS INOPERATIVE

PINPOINT TEST E: THE SPEED COMPENSATED VOLUME IS INOPERATIVE|

Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). Possible Sources

|

||||

| E1 CHECK THE SPEED COMPENSATED VOLUME SETTING | ||||

|

NOTE: Refer to the Owner Literature to access the speed compensated volume settings.

Does the volume remain constant with the speed compensated volume turned off, and increase and decrease with vehicle speed with the speed compensated volume set to maximum?

|

||||

| E2 CHECK FOR COMMUNICATION DIAGNOSTIC TROUBLE CODES (DTCS) | ||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||

| E3 CARRY OUT PMI (PROGRAMMABLE MODULE INSTALLATION) FOR THE SUSPECT MODULE | ||||

Does the speed compensated volume feature operate?

|

||||

| E4 CHECK FOR CORRECT DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) OPERATION | ||||

Is the concern still present?

|

PINPOINT TEST F: ONE OR MORE SPEAKER IS INOPERATIVE - DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE)

CONTROLLED 14 SPEAKER SYSTEM

PINPOINT TEST F: ONE OR MORE SPEAKER IS INOPERATIVE - DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE)

CONTROLLED 14 SPEAKER SYSTEM|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - Component Location

(415-00 Information and Entertainment System - General Information -

Vehicles With: SYNC 4, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

NOTE: The rear door woofer speaker and corresponding door tweeter speaker share the same circuitry. If a concern exists with both speakers, retest the system with the tweeter speaker disconnected to determine if the tweeter speaker is the cause of the concern. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F1 CHECK FOR ACM (AUDIO FRONT CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F2 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR A SHORT TO GROUND | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NOTE: For a rear door tweeter speaker concern, make sure the corresponding door woofer speaker is disconnected.

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F3 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F4 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR A SHORT TOGETHER | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F5 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F6 CHECK THE AUDIO SIGNAL TO THE SUSPECT SPEAKER | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NOTE: For a rear door tweeter speaker concern, make sure the corresponding door woofer speaker is connected.

Is a fluctuating AC voltage present?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F7 CHECK FOR CORRECT DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) OPERATION | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST G: ONE OR MORE SPEAKER IS INOPERATIVE - DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE)

CONTROLLED 28 SPEAKER SYSTEM

PINPOINT TEST G: ONE OR MORE SPEAKER IS INOPERATIVE - DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE)

CONTROLLED 28 SPEAKER SYSTEM|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - Component Location

(415-00 Information and Entertainment System - General Information -

Vehicles With: SYNC 4, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

NOTE: The rear door speaker and corresponding door tweeter speaker share the same circuitry. If a concern exists with both speakers, retest the system with the tweeter speaker disconnected to determine if the tweeter speaker is the cause of the concern. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G1 CHECK FOR ACM (AUDIO FRONT CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR A SHORT TO GROUND | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NOTE: For a rear door tweeter speaker concern, make sure the corresponding door woofer speaker is disconnected.

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G3 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G4 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR A SHORT TOGETHER | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G5 CHECK THE AUDIO CIRCUITS TO THE SPEAKER FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G6 CHECK THE AUDIO SIGNAL TO THE SUSPECT SPEAKER | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is a fluctuating AC voltage present?

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G7 CHECK FOR CORRECT DSP (AUDIO DIGITAL SIGNAL PROCESSING MODULE) OPERATION | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST H: THE AUDIO/SYNC SYSTEM DOES NOT OPERATE CORRECTLY FROM FCIM (FRONT CONTROLS INTERFACE MODULE)

PINPOINT TEST H: THE AUDIO/SYNC SYSTEM DOES NOT OPERATE CORRECTLY FROM FCIM (FRONT CONTROLS INTERFACE MODULE)

|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). Possible Sources

|

||||

| H1 VERIFY THE ACM (AUDIO FRONT CONTROL MODULE) , THE APIM (SYNC MODULE) AND THE FCIM (FRONT CONTROLS INTERFACE MODULE) PASS THE NETWORK TEST | ||||

Does the ACM , the APIM and the FCIM pass the network test?

|

||||

| H2 CHECK FOR ACM (AUDIO FRONT CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||

| H3 CHECK FOR APIM (SYNC MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||

| H4 CHECK FOR FCIM (FRONT CONTROLS INTERFACE MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||

| H5 CHECK FOR CORRECT FCIM (FRONT CONTROLS INTERFACE MODULE) OPERATION | ||||

Is the concern still present?

|

PINPOINT TEST I: ONE OR MORE AUDIO/SYNC STEERING WHEEL CONTROL BUTTON IS INOPERATIVE

PINPOINT TEST I: ONE OR MORE AUDIO/SYNC STEERING WHEEL CONTROL BUTTON IS INOPERATIVE|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||||||||||||||||||||

| I1 CHECK FOR SCCM (STEERING COLUMN CONTROL MODULE) COMMUNICATION | ||||||||||||||||||||||||||||||||||

Does the SCCM pass the network test?

|

||||||||||||||||||||||||||||||||||

| I2 CHECK FOR VOLTAGE TO THE STEERING WHEEL SWITCH | ||||||||||||||||||||||||||||||||||

Are the voltages approximately 5 volts?

|

||||||||||||||||||||||||||||||||||

| I3 CHECK THE STEERING WHEEL HARNESS | ||||||||||||||||||||||||||||||||||

Are the voltages approximately 5 volts?

|

||||||||||||||||||||||||||||||||||

| I4 CHECK THE CLOCKSPRING FOR AN OPEN | ||||||||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||||||||||||||

| I5 CHECK FOR CORRECT SCCM (STEERING COLUMN CONTROL MODULE) OPERATION | ||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST J: THE DISPLAY UNIT IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY

PINPOINT TEST J: THE DISPLAY UNIT IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY|

NOTE: The display unit calibrates after each ignition cycle. Touching the display during an ignition cycle may cause the touchscreen to be inoperative. Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

NOTE: Prior to carrying out diagnostics, it may be beneficial to determine the cause using the Circuit Tester and LVDS Adapter Kit 420-912 (Rotunda part number NUD420-912) or equivalent tool. |

||||||||||||||||||||||||

COMPLETE THE FDRS GUIDED ROUTINE COMPLETE THE FDRS GUIDED ROUTINE |

||||||||||||||||||||||||

|

PINPOINT TEST K: SOUND FROM THE SYNC SYSTEM (MUSIC/AUDIBLE PROMPTS) IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY

PINPOINT TEST K: SOUND FROM THE SYNC SYSTEM (MUSIC/AUDIBLE PROMPTS) IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). Possible Sources

|

||||||||||||||||||||||||||||||||||||||||

| K1 CHECK THE OPERATION OF THE SPEAKERS USING THE AM (AMPLITUDE MODULATION) / FM (FREQUENCY MODULATION) MODE | ||||||||||||||||||||||||||||||||||||||||

Do all of the speakers operate?

|

||||||||||||||||||||||||||||||||||||||||

| K2 CHECK THE STEERING WHEEL SWITCH PARAMETER IDENTIFICATIONS (PIDS) | ||||||||||||||||||||||||||||||||||||||||

Do the Parameter Identifications (PIDs) correspond correctly?

|

||||||||||||||||||||||||||||||||||||||||

| K3 CHECK THE APIM (SYNC MODULE) OUTPUT CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| K4 CHECK THE APIM (SYNC MODULE) OUTPUT CIRCUITS FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

||||||||||||||||||||||||||||||||||||||||

| K5 CHECK THE APIM (SYNC MODULE) OUTPUT CIRCUITS FOR A SHORT TOGETHER | ||||||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| K6 CHECK THE APIM (SYNC MODULE) OUTPUT CIRCUITS FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| K7 CHECK FOR AN AC (ALTERNATING CURRENT) VOLTAGE SIGNAL FROM THE APIM (SYNC MODULE) OUTPUT CIRCUITS | ||||||||||||||||||||||||||||||||||||||||

Is a fluctuating AC voltage present?

|

||||||||||||||||||||||||||||||||||||||||

| K8 CHECK FOR CORRECT APIM (SYNC MODULE) OPERATION | ||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||||||||||||||

| K9 CHECK FOR CORRECT ACM (AUDIO FRONT CONTROL MODULE) OPERATION | ||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST L: VOICE COMMANDS ARE INOPERATIVE OR OUTGOING AUDIO IS NOT TRANSMITTED DURING A PHONE CALL

PINPOINT TEST L: VOICE COMMANDS ARE INOPERATIVE OR OUTGOING AUDIO IS NOT TRANSMITTED DURING A PHONE CALL|

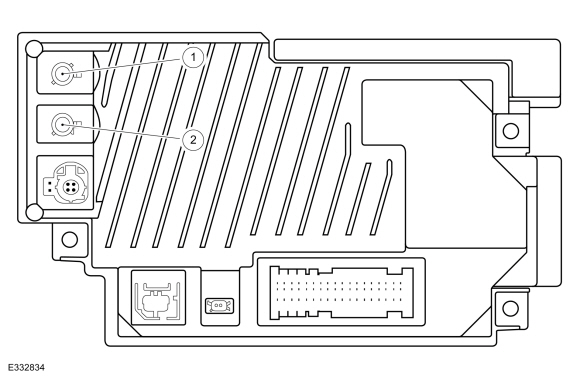

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - Component Location

(415-00 Information and Entertainment System - General Information -

Vehicles With: SYNC 4, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||

COMPLETE THE FDRS GUIDED ROUTINE COMPLETE THE FDRS GUIDED ROUTINE |

||||||||||||

|

PINPOINT TEST M: THE SYNC SYSTEM DOES NOT RESPOND TO THE WAKE WORD

PINPOINT TEST M: THE SYNC SYSTEM DOES NOT RESPOND TO THE WAKE WORD|

Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). Possible Sources

NOTE: The Wake Word used by the vehicle owner needs to be provided in advance of this test. |

||||

| M1 CHECK THE OPERATION OF THE STEERING WHEEL VOICE BUTTON | ||||

Does the SYNC system acknowledge the voice button press?

|

||||

| M2 CHECK THE OPERATION OF THE MICROPHONE | ||||

Does the radio change to FM?

|

||||

| M3 CHECK THE WAKE WORD SETTINGS | ||||

Is the Listen for Wake Word setting enabled?

|

||||

| M4 CHECK THE PREFERRED WAKE WORD | ||||

Does the Preferred Wake Word match the wake word provided by the vehicle owner?

|

PINPOINT TEST N: A USB (UNIVERSAL SERIAL BUS)

INPUT CONCERN

PINPOINT TEST N: A USB (UNIVERSAL SERIAL BUS)

INPUT CONCERN|

Refer to Wiring Diagrams Cell 134 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - Component Location

(415-00 Information and Entertainment System - General Information -

Vehicles With: SYNC 4, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||

COMPLETE THE FDRS GUIDED ROUTINE COMPLETE THE FDRS GUIDED ROUTINE |

||||||||||||

|

PINPOINT TEST O: UNABLE TO PAIR BLUETOOTH DEVICE OR A BLUETOOTH FUNCTIONALITY IS INOPERATIVE

PINPOINT TEST O: UNABLE TO PAIR BLUETOOTH DEVICE OR A BLUETOOTH FUNCTIONALITY IS INOPERATIVE|

Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). Possible Sources

|

COMPLETE THE FDRS GUIDED ROUTINE COMPLETE THE FDRS GUIDED ROUTINE |

|

PINPOINT TEST P: THE 911 ASSIST OR EMERGENCY ASSISTANCE NOT OPERATIONAL MESSAGE DISPLAYS

PINPOINT TEST P: THE 911 ASSIST OR EMERGENCY ASSISTANCE NOT OPERATIONAL MESSAGE DISPLAYS|

Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). If a fault message appears indicating the 911 Assist or emergency assistance is not operational, the concern may be caused due to modules not communicating or incorrect APIM programming procedures. Possible Sources

|

||||

| P1 VERIFY THE 911 ASSIST OR EMERGENCY ASSISTANCE FEATURE IS ENABLED | ||||

Is the 911 Assist or emergency assistance setting enabled?

|

||||

| P2 CHECK FOR CONTINUOUS MEMORY DIAGNOSTIC TROUBLE CODES (CMDTCS) | ||||

Are any Continuous Memory Diagnostic Trouble Codes (CMDTCs) present?

|

||||

| P3 CHECK THE VEHICLE SERVICE HISTORY | ||||

Is any recent service action noted with the RCM or the APIM noted?

|

||||

| P4 CHECK FOR CORRECT APIM (SYNC MODULE) OPERATION | ||||

Is the concern still present?

|

PINPOINT TEST Q: ANDROID AUTO™ OR APPLE CARPLAY™ CONCERN

PINPOINT TEST Q: ANDROID AUTO™ OR APPLE CARPLAY™ CONCERN|

Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and

Component Description (415-00 Information and Entertainment System -

General Information - Vehicles With: SYNC 4, Description and Operation). Possible Sources

|

COMPLETE THE FDRS GUIDED ROUTINE COMPLETE THE FDRS GUIDED ROUTINE |

|

PINPOINT TEST R: SYNC APPLINK CONCERN

PINPOINT TEST R: SYNC APPLINK CONCERN|

Normal Operation and Fault Conditions

REFER to: Information and Entertainment System - System Operation and