Refer to Wiring Diagrams Cell 44 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Horn - System Operation and Component Description (413-06 Horn, Description and Operation).

DTC Fault Trigger Conditions

| DTC |

Description |

Fault Trigger Condition |

| BCM B1C55:12 |

Horn Relay: Circuit Short To Battery |

A Continuous Memory Diagnostic Trouble Code (CMDTC) that sets when the

BCM detects a short to voltage on the horn relay control circuit. The

BCM disables the horn when this DTC is set.

|

| BCM B1C55:14 |

Horn Relay: Circuit Short To Ground Or Open |

This DTC sets when the BCM detects a short to ground or an open on the horn relay control circuit.

|

Possible Sources

- Fuse

- Wiring, terminals or connectors

- Clockspring

- Horn

- Horn switch

-

BCM

-

BJB

Visual Inspection and Pre-checks

- Verify the BJB fuse 15 (20A) is OK.

NOTICE:

Use the correct probe adapter(s) when making

measurements. Failure to use the correct probe adapter(s) may damage the

connector.

|

| A1 CHECK THE BCM (BODY CONTROL MODULE)

OUTPUT BY ACTIVATING THE BCM (BODY CONTROL MODULE)

HORN_RELAY PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view BCM Parameter Identifications (PIDs).

Does the horn sound when commanded ON?

|

| A2 CHECK FOR BCM (BODY CONTROL MODULE)

DTC (DIAGNOSTIC TROUBLE CODE)

B1C55:12, OR B1C55:14 |

-

Using a diagnostic scan tool, carry out the BCM self-test.

Is DTC B1C55:12 or B1C55:14 present?

| Yes |

For DTC B1C55:12, GO to A3

For DTC B1C55:14, GO to A5

|

|

| A3 CHECK THE HORN RELAY CONTROL CIRCUIT FOR A SHORT TO VOLTAGE |

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1035C-34

|

|

Ground

|

Is any voltage present?

|

| A4 ISOLATE THE HORN RELAY VOLTAGE SUPPLY CIRCUIT SHORT TO VOLTAGE |

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1035C-34

|

|

Ground

|

Is any voltage present?

| Yes |

REPAIR the circuit. TEST system for normal operation.

|

|

| A5 CHECK THE HORN RELAY CONTROL CIRCUIT FOR A SHORT TO GROUND |

-

Disconnect: negative battery cable.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280F-20

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| A6 ISOLATE THE HORN RELAY CONTROL CIRCUIT SHORT TO GROUND |

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280F-20

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| No |

REPAIR the circuit. TEST system for normal operation.

|

|

| A7 CHECK THE HORN RELAY CONTROL CIRCUIT FOR AN OPEN |

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1035C-34

|

|

C2280F-20

|

Is the resistance less than 3 ohms?

| No |

REPAIR the circuit. TEST system for normal operation.

|

|

| A8 CHECK THE BJB INTERNAL HORN RELAY CONTROL CIRCUIT FOR AN OPEN |

-

Connect negative battery cable.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280F-20

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| A9 CHECK THE HORN POWER SUPPLY CIRCUIT FOR AN OPEN |

-

Disconnect

LH Horn C131

.

-

Measure:

Left hand horn

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C131-2

|

|

C1035C-43

|

Is the resistance less than 3 ohms?

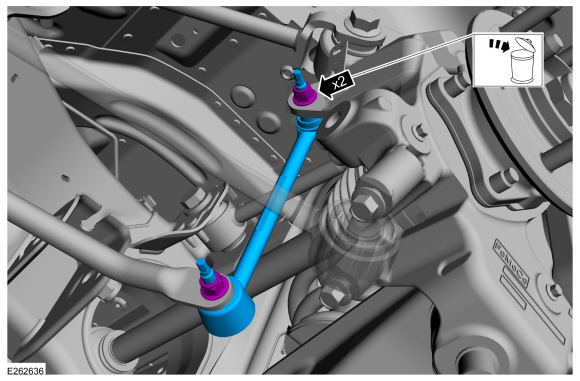

| Yes |

VERIFY BJB

BCMC Fuse 15 (20A) is OK. If not OK, use the wiring diagrams as a

guide to identify the cause of the circuit short. If OK, INSTALL a new

horn.

REFER to: Horn (413-06 Horn, Removal and Installation).

|

| No |

REPAIR the circuit. TEST the system for normal operation. If the horn is still inoperative, GO to A10

|

|

| A10 CHECK THE HORN GROUND CIRCUIT |

-

Measure:

Left hand horn

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C131-1

|

|

Ground

|

Is the resistance less than 3 ohms?

| Yes |

VERIFY BJB

Fuse 15 (20A) is OK. If not OK, use the wiring diagrams as a guide to

identify the cause of the circuit short. If OK, INSTALL a new horn.

REFER to: Horn (413-06 Horn, Removal and Installation).

|

| No |

REPAIR the circuit. TEST system for normal operation.

|

|

| A11 CHECK THE HORN SWITCH INPUT TO THE BCM (BODY CONTROL MODULE)

|

-

While pressing the horn, measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280B-18

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| A12 ISOLATE THE HORN SWITCH |

-

Remove the driver airbag.

REFER to: Driver Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Momentarily connect a fused jumper wire:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C217-1

|

|

C217-2

|

Does the horn sound?

| Yes |

REMOVE the fused jumper wire. INSTALL a new driver airbag (includes horn switch).

REFER to: Driver Airbag (501-20B Supplemental Restraint System, Removal and Installation).

|

| No |

REMOVE the fused jumper wire. GO to A13

|

|

| A13 CHECK THE HORN SWITCH SIGNAL CIRCUIT |

-

Momentarily connect a fused jumper wire:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218A-9

|

|

Ground

|

Does the horn sound?

| Yes |

REMOVE the fused jumper wire. GO to A14

|

| No |

REMOVE the fused jumper wire. REPAIR the open circuit.

|

|

| A14 CHECK THE HORN SWITCH GROUND FROM THE HORN SWITCH |

-

Measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C217-2

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| A15 CHECK THE HORN SWITCH GROUND WHILE BYPASSING THE SCCM (STEERING COLUMN CONTROL MODULE)

|

-

Disconnect Clockspring C218B.

-

Connect a fused jumper wire:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C226A-8

|

|

C218B-4

|

-

Measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C217-2

|

|

Ground

|

Is the resistance less than 3 ohms?

| Yes |

REMOVE the fused jumper wire. CHECK OASIS for any applicable TSB , GSB , SSM , or FSA

. If a service article exists for this concern, DISCONTINUE this test

and FOLLOW the service article instructions. If no service articles

address this concern, INSTALL a new SCCM

REFER to: Steering Column Control Module (SCCM) (211-05 Steering

Wheel and Column Electrical Components, Removal and Installation).

|

| No |

REMOVE the fused jumper wire. GO to A16

|

|

| A16 CHECK THE SCCM (STEERING COLUMN CONTROL MODULE)

HORN GROUND CIRCUIT FOR AN OPEN |

-

Measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C226A-8

|

|

Ground

|

Is the resistance less than 3 ohms?

| Yes |

INSTALL a new steering wheel (includes steering wheel wiring harness).

REFER to: Steering Wheel (211-04 Steering Column, Removal and Installation).

|

|

| A17 CHECK HORN OPERATION WITH STEERING WHEEL HARNESS ISOLATED |

-

Momentarily connect a fused jumper wire:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

Clockspring C218B, pin 5, component side

|

|

Ground

|

Does the horn sound?

| Yes |

REMOVE the fused jumper wire. INSTALL a new steering wheel (includes steering wheel wiring harness).

REFER to: Steering Wheel (211-04 Steering Column, Removal and Installation).

|

| No |

REMOVE the fused jumper wire. CHECK OASIS for any applicable TSB , GSB , SSM , or FSA

. If a service article exists for this concern, DISCONTINUE this test

and FOLLOW the service article instructions. If no service articles

address this concern, INSTALL a new SCCM .

REFER to: Steering Column

Control Module (SCCM) (211-05 Steering Wheel and Column Electrical

Components, Removal and Installation).

|

|

| A18 CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION |

-

Disconnect and inspect the BCM connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Reconnect the BCM connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes |

CHECK OASIS for any applicable service articles: TSB , GSB , SSM , or FSA

. If a service article exists for this concern, DISCONTINUE this test

and FOLLOW the service article instructions. If no service articles

address this concern, INSTALL a new BCM

REFER to: Body Control Module (BCM) (419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No |

The system is operating correctly at this time. The

concern may have been caused by module connections. ADDRESS the root

cause of any connector or pin issues.

|

|

PINPOINT TEST A: THE HORN IS INOPERATIVE

PINPOINT TEST A: THE HORN IS INOPERATIVE

PINPOINT TEST B: THE HORN IS ALWAYS ON

PINPOINT TEST B: THE HORN IS ALWAYS ON Horn. Removal and Installation

Horn. Removal and Installation