Lincoln Navigator: Front Drive Axle/Differential / Differential Ring Gear and Pinion. Removal and Installation

Special Tool(s) / General Equipment

|

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge |

|

205-001

(TOOL-4000-E)

Spreader, Differential Carrier |

|

205-005

(T53T-4621-C)

Installer, Drive Pinion Bearing Cone |

|

205-010

(T57L-4221-A2)

Installer, Differential Side Bearing |

|

205-024

(T67P-4616-A)

Installer, Drive Pinion Bearing Cup |

|

205-105

(T76P-4020-A3)

Adapter for 205-S127 |

|

205-109

(T76P-4020-A9)

Adapter for 205-S127 |

|

205-110

(T76P-4020-A10)

Gauge Block |

|

205-111

(T76P-4020-A11)

Handle |

|

205-129

(T79P-4020-A18)

Disc, Guage |

|

205-335

(T93P-4000-A)

Spreader, Differential Housing (Plate) TKIT-1993-FLM TKIT-1993-LM TKIT-1996-F/FM |

|

205-336

(T93P-4020-A)

Gauge Tube, Drive Pinion TKIT-1993-FLM TKIT-1993-LM TKIT-1996-F/FM |

|

205-368

(T96T-4000-A)

Adapter for Differential Housing Spreader TKIT-1998-LM (NavigatoR) TKIT-1996-F/FM TKIT-1996-FLM2 |

|

205-460 Protector, Drive Pinion Thread TKIT-1999A-F/LT TKIT-1999A-FM/FLM TKIT-1999A-LM |

|

205-D044

(D81T-4221-A)

Installer, Differential Carrier Bearing |

|

205-D061

(D83T-4205-C2)

Step Plate |

|

308-021

(T75L-4201-A)

Gauge, Clutch Housing |

| Three Leg Puller | |

| Hydraulic Press | |

| Punch | |

| Copper Hammer | |

| Bearing Separator | |

| Caliper Gauge | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Ultra Silicone Sealant TA-29 |

WSS-M4G323-A8 |

Removal

-

Remove the differential carrier.

Refer to: Differential Carrier (205-03 Front Drive Axle/Differential, Removal and Installation).

-

Remove the drive pinion flange and seal.

Refer to: Drive Pinion Flange and Seal (205-03 Front Drive Axle/Differential, Removal and Installation).

-

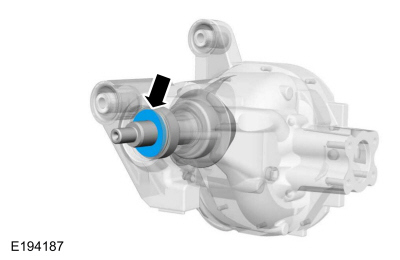

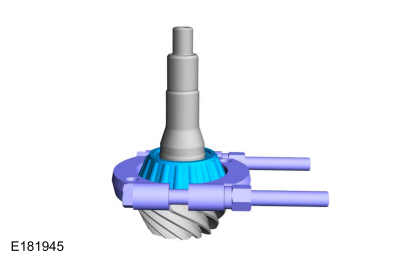

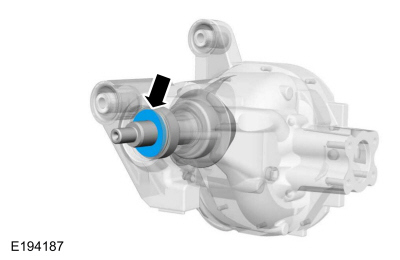

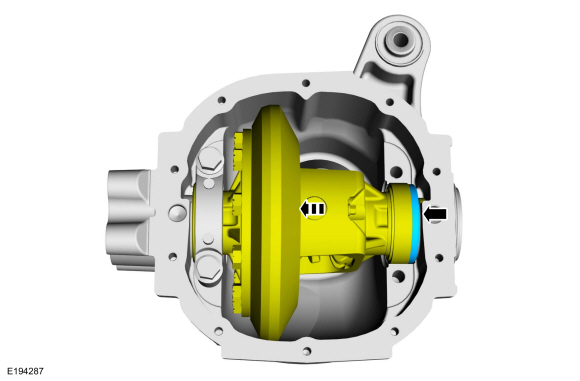

Remove the outer drive pinion oil slinger.

|

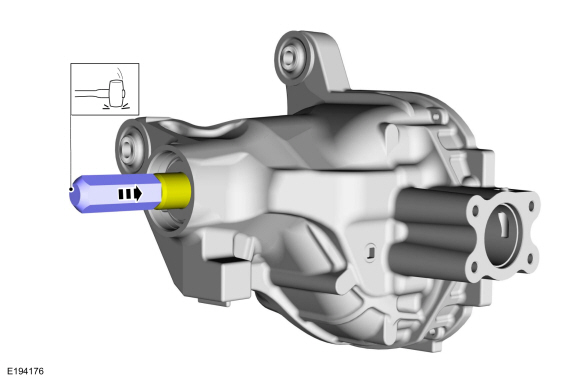

-

Using the special tool and a soft hammer, tap the drive pinion free of the drive pinion outer bearing.

Use Special Service Tool: 205-460 Protector, Drive Pinion Thread.

Use the General Equipment: Copper Hammer

|

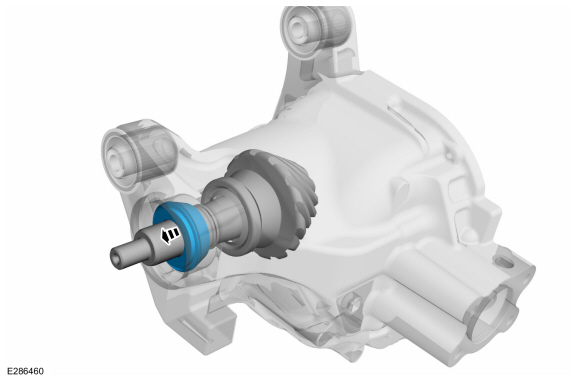

-

Remove the outer drive pinion bearing and the drive pinion gear.

|

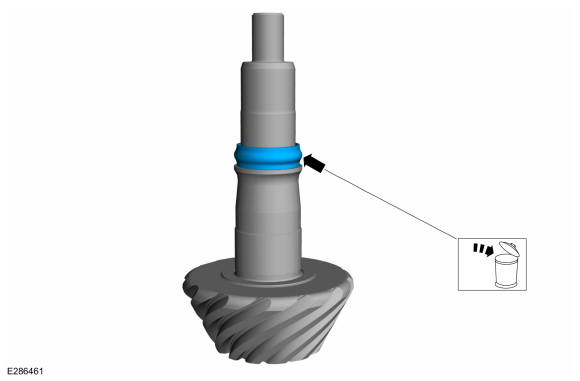

-

Remove and discard the drive pinion collapsible spacer.

|

-

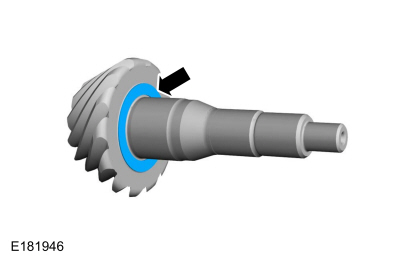

NOTE: This step is only necessary if the original component is to be reused.

Remove the inner drive pinion bearing.

Use the General Equipment: Bearing Separator

|

-

NOTE: This step is only necessary if the original component is to be reused.

Remove the inner drive pinion bearing adjustment shim.

|

-

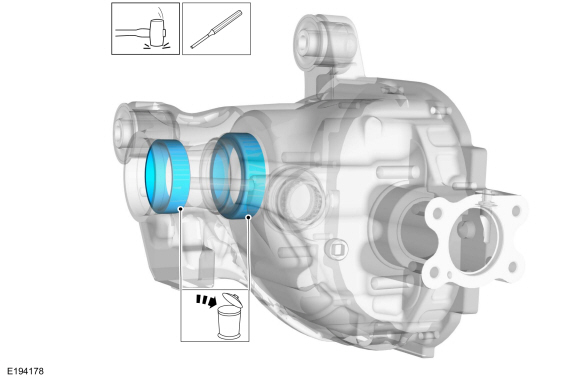

Using the general equipment, remove and discard the drive pinion inner and outer bearing cups.

Use the General Equipment: Copper Hammer

Use the General Equipment: Punch

|

-

If necessary.

Remove and discard the drive pinion oil baffle.

|

-

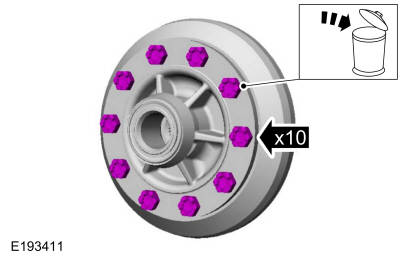

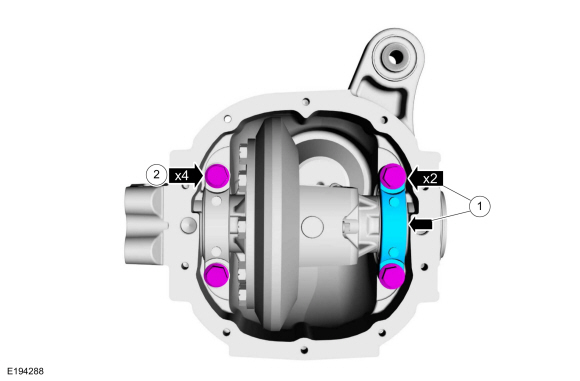

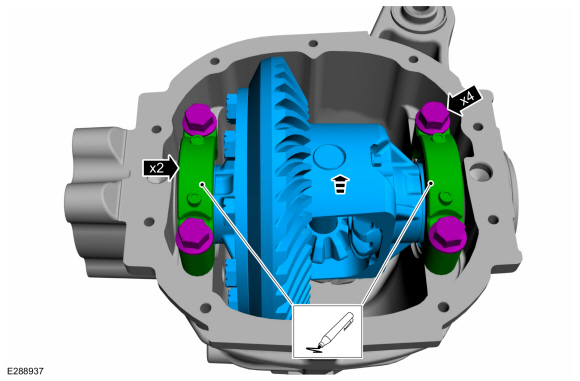

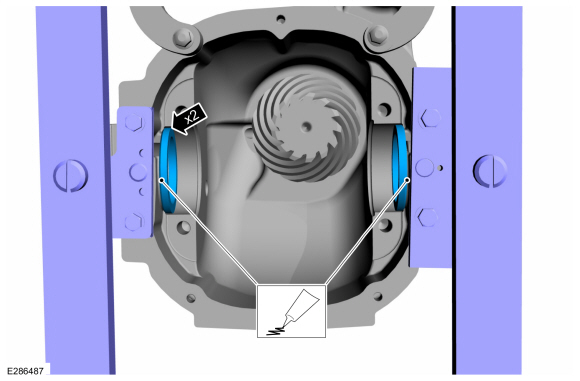

Remove and discard the differential ring gear bolts.

|

-

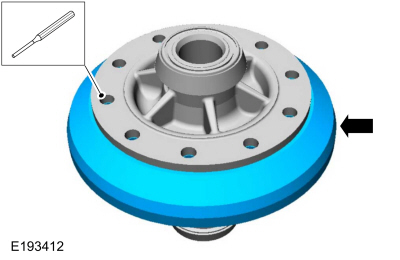

NOTICE: Care should be taken not to damage the differential ring gear bolt hole threads.

Using the general equipment, separate the ring gear from the differential case.

Use the General Equipment: Punch

Use the General Equipment: Copper Hammer

|

-

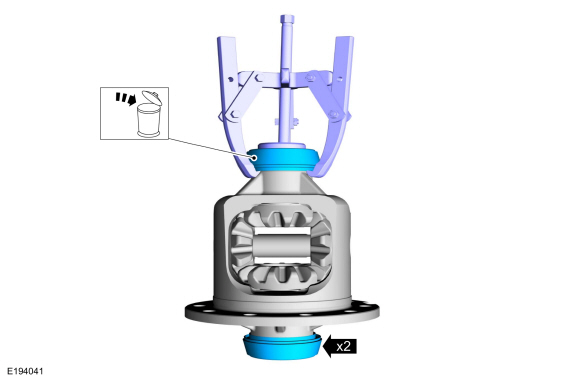

Using the general equipment and the special tool, remove and discard the differential bearings.

Use Special Service Tool: 205-D061 (D83T-4205-C2) Step Plate.

Use the General Equipment: Three Leg Puller

|

Installation

-

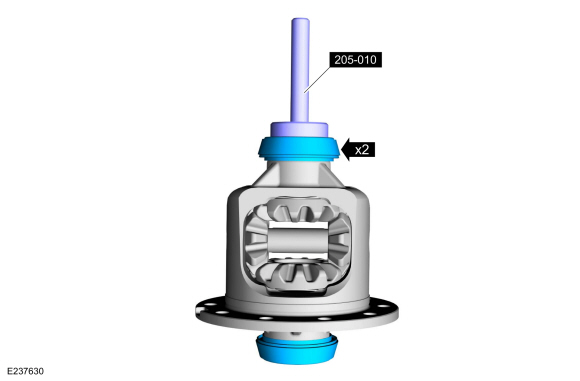

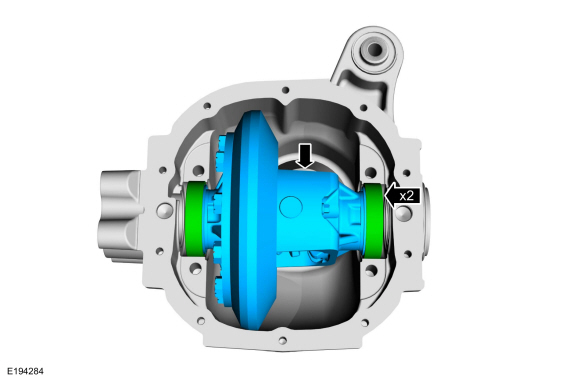

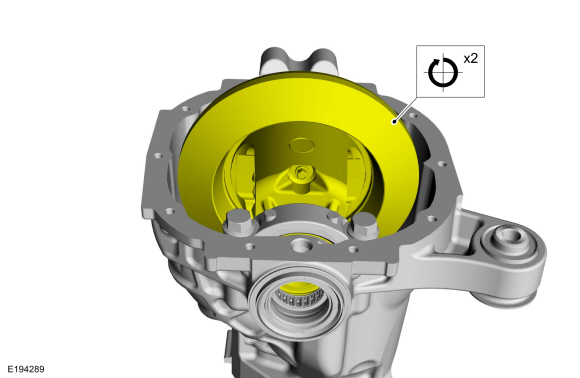

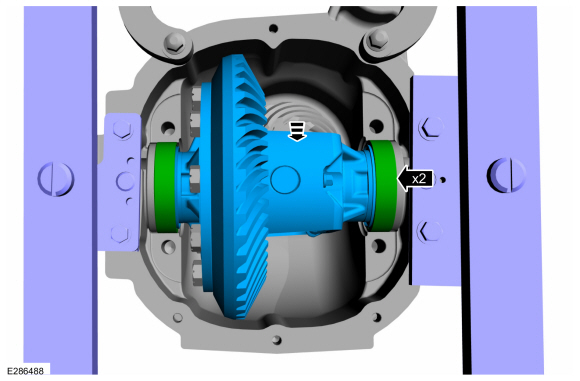

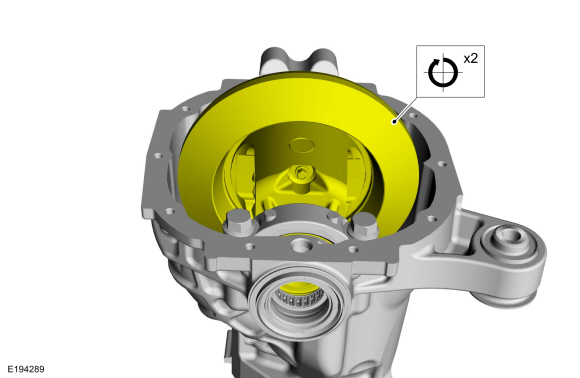

Using the special tools, install the new differential bearings.

Use Special Service Tool: 205-010 (T57L-4221-A2) Installer, Differential Side Bearing.

|

-

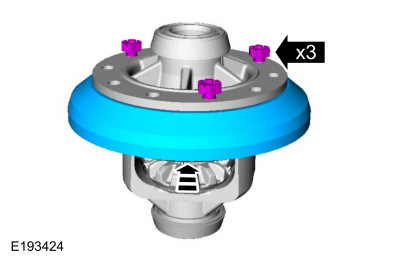

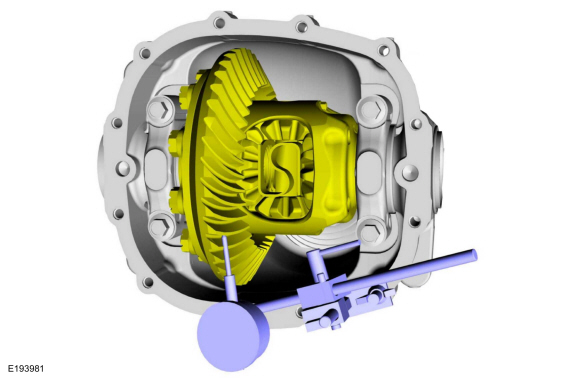

Install the ring gear onto the differential carrier.

Align the ring gear using 3 new bolts. Using the general equipment:

press the ring gear into place.

Use the General Equipment: Hydraulic Press

|

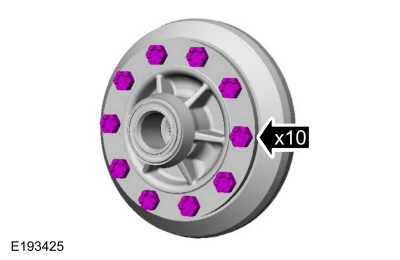

-

Install the remaining new ring gear bolts.

Torque: 94 lb.ft (128 Nm)

|

-

If removed.

Using the special tool, install the new drive pinion oil baffle.

Use Special Service Tool: 205-D044 (D81T-4221-A) Installer, Differential Carrier Bearing.

|

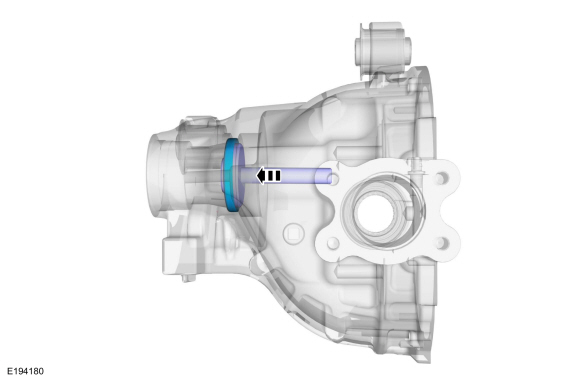

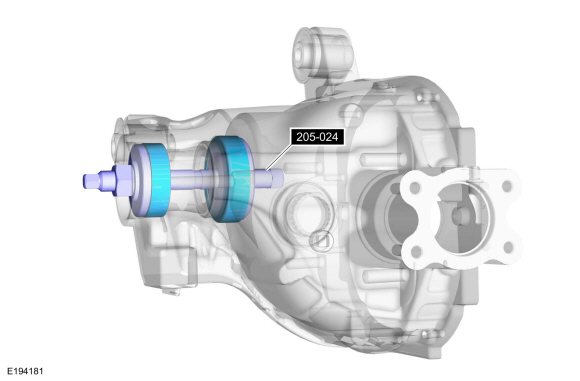

-

NOTE: Make sure the drive pinion bearing cups are seated correctly or damage to the components may occur.

Using the special tools, install the new drive pinion inner and outer bearing cups.

Use Special Service Tool: 205-024 (T67P-4616-A) Installer, Drive Pinion Bearing Cup.

|

-

NOTICE: Use the same drive pinion bearings and the drive pinion bearing adjustment shim from the drive pinion bearing adjustment shim selection procedure for final assembly or damage to the component may occur.

NOTE: Install new drive pinion bearings without any additional lubricant since the anti-rust oil provides adequate lubricant without upsetting the drive pinion bearing preload settings.

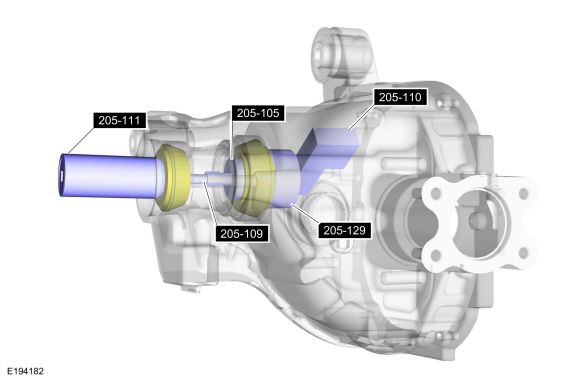

Assemble the special tools using the new inner and outer drive pinion bearings.

Use Special Service Tool: 205-105 (T76P-4020-A3) Adapter for 205-S127. , 205-109 (T76P-4020-A9) Adapter for 205-S127. , 205-110 (T76P-4020-A10) Gauge Block. , 205-111 (T76P-4020-A11) Handle. , 205-129 (T79P-4020-A18) Disc, Guage.

Torque: 19 lb.in (2.2 Nm)

|

-

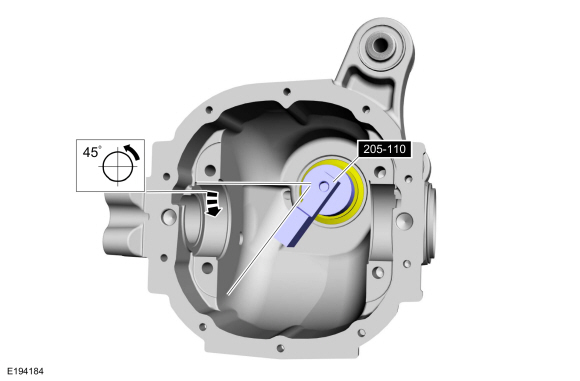

Rotate the special tools several half turns to ensure correct seating of the drive pinion bearings.

Use Special Service Tool: 205-110 (T76P-4020-A10) Gauge Block.

|

-

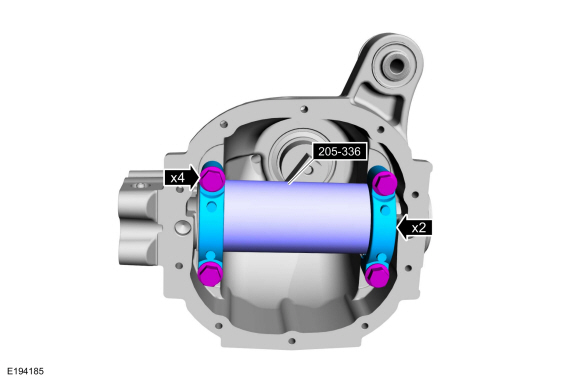

Install the special tool, the differential bearing caps and the differential bearing cap bolts.

Use Special Service Tool: 205-336 (T93P-4020-A) Gauge Tube, Drive Pinion.

Torque: 77 lb.ft (105 Nm)

|

-

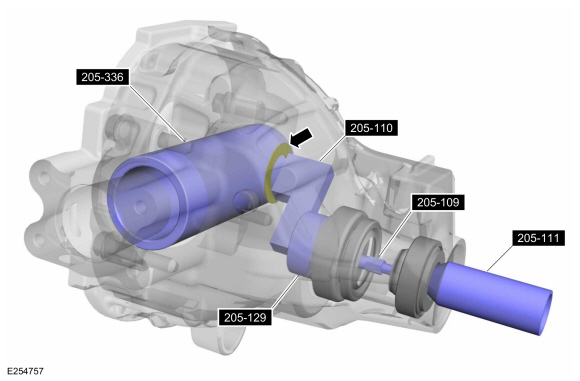

NOTE: Drive pinion bearing adjustment shims must be flat and clean.

NOTE: A slight drag should be felt for correct drive pinion bearing adjustment shim selection. Do not attempt to force the drive pinion bearing adjustment shim between the gauge block and the gauge tube. This will minimize selection of a drive pinion bearing adjustment shim thicker than required, which results in a deep tooth contact in final assembly of integral axle assemblies.

Use a drive pinion bearing adjustment shim as a gauge for drive pinion bearing adjustment shim selection.

-

After the correct drive pinion bearing adjustment

shim thickness has been determined, remove all of the Adapters.

Use Special Service Tool: 205-111 (T76P-4020-A11) Handle. , 205-109 (T76P-4020-A9) Adapter for 205-S127. , 205-110 (T76P-4020-A10) Gauge Block. , 205-129 (T79P-4020-A18) Disc, Guage. , 205-336 (T93P-4020-A) Gauge Tube, Drive Pinion.

-

After the correct drive pinion bearing adjustment

shim thickness has been determined, remove all of the Adapters.

|

-

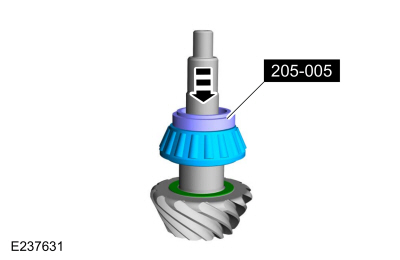

NOTE: The same drive pinion bearing from the previous steps must be used.

Install the drive pinion bearing and the selected drive pinion bearing adjustment shim until they are firmly seated on the drive pinion.

Use Special Service Tool: 205-005 (T53T-4621-C) Installer, Drive Pinion Bearing Cone.

Use the General Equipment: Hydraulic Press

|

-

Install the pinion gear.

|

-

Install the new drive pinion collapsible spacer.

|

-

Install the outer drive pinion bearing.

|

-

Install the outer drive pinion oil slinger.

|

-

Install the drive pinion flange and seal.

Refer to: Drive Pinion Flange and Seal (205-03 Front Drive Axle/Differential, Removal and Installation).

-

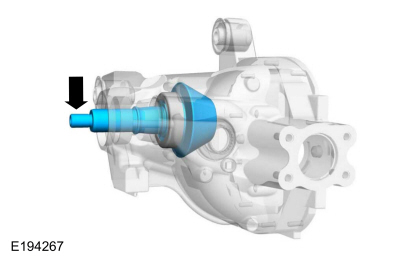

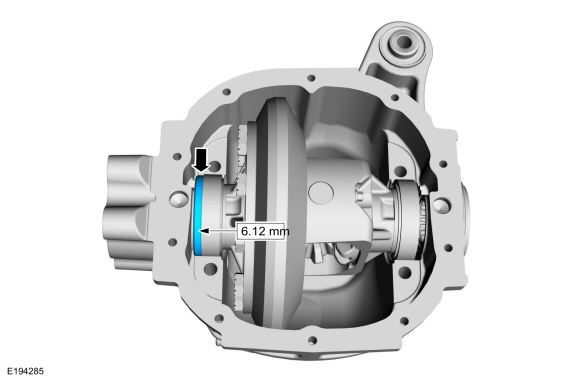

NOTICE: It is necessary to loosely install the bearing caps and bolts to hold the differential in place.

Install the differential carrier and the differential carrier bearing cups as a assembly.

|

-

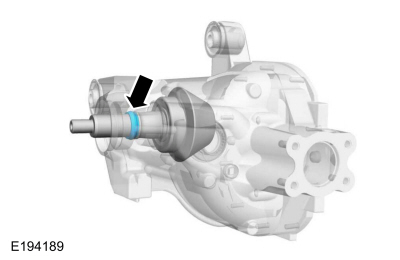

Install a 6.12 mm (0.241 in) differential bearing shim on the LH side of the differential bearing.

|

-

NOTE: Apply pressure toward the left side to make sure the left differential bearing cap is seated.

Install the left differential bearing cap and loosely install the differential bearing cap bolts.

|

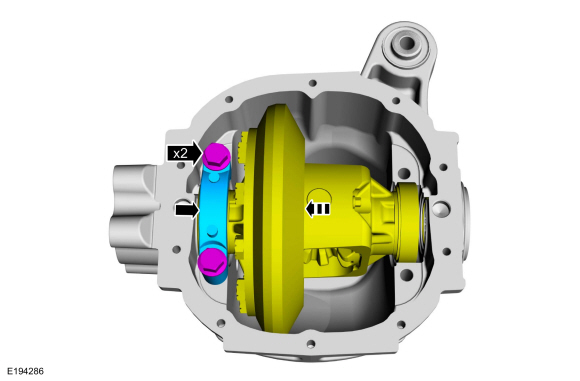

-

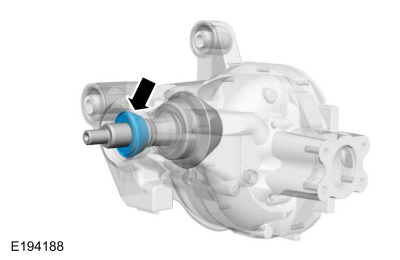

NOTE: Apply pressure toward the left side to make sure the left differential bearing cap is seated.

Install progressively thicker differential bearing shims on the right side until the thickest differential bearing shim can be inserted by hand.

|

-

-

Install the RH differential bearing cap and bolts.

-

Tighten the differential bearing cap bolts.

Torque: 77 lb.ft (105 Nm)

-

Install the RH differential bearing cap and bolts.

|

-

Rotate the differential carrier to make sure it turns freely.

|

-

Using the dial indicator, measure the differential ring gear backlash at 4 equally spaced points.

-

To correct for high or low backlash, increase the

thickness of one differential bearing shim and decrease the thickness of

the other differential bearing shim by the same amount. Refer to the

following tables when adjusting the backlash.

Refer to: Specifications (205-03 Front Drive Axle/Differential, Specifications).

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

-

To correct for high or low backlash, increase the

thickness of one differential bearing shim and decrease the thickness of

the other differential bearing shim by the same amount. Refer to the

following tables when adjusting the backlash.

|

-

NOTE: Mark the differential bearing caps Top or Bottom and LH or RH appropriately before removing them. Always install the differential bearing caps in their original positions or damage to the component may occur.

Remove the differential cap bolts, differential caps and the carrier assembly.

|

-

-

Measure the thickness of the selected right and left bearing shims.

Use the General Equipment: Caliper Gauge

-

To establish differential bearing preload, increase

both the left and right differential bearing shim thickness by 0.203 mm

(0.008 in).

-

Measure the thickness of the selected right and left bearing shims.

|

-

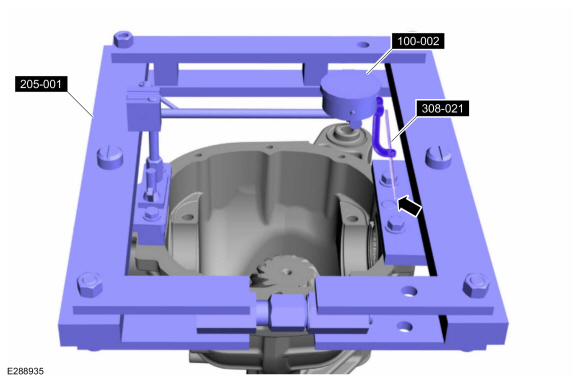

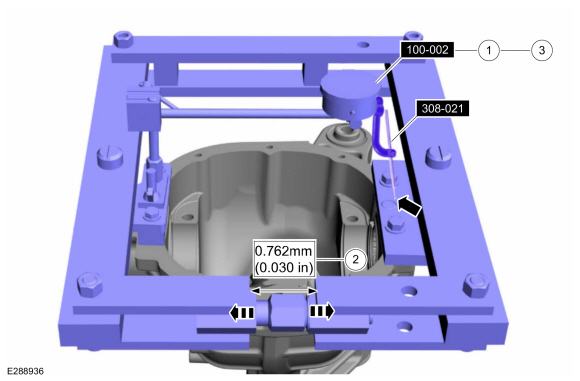

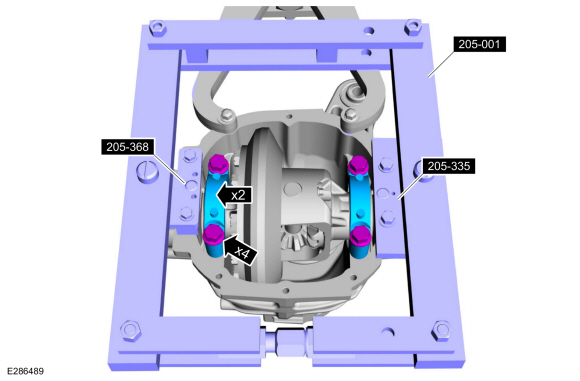

Install the Dial Indicator Gauge with Holding Fixture, Clutch Housing Gauge and Differential Carrier Spreader.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge. , 308-021 (T75L-4201-A) Gauge, Clutch Housing. , 205-001 (TOOL-4000-E) Spreader, Differential Carrier.

|

-

NOTICE: Overspreading may damage the component. Do not spread the differential housing more then 0.762 mm (0.030 in).

NOTE: Tighten and loosen the differential carrier spreader screw to normalize the housing spreader adapters prior to taking the final Dial Indicator reading.

Spread the differential housing to the specification.

-

Adjust the Dial Indicator Gauge with Holding Fixture and Clutch Housing Gauge to zero.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge. , 308-021 (T75L-4201-A) Gauge, Clutch Housing.

-

Tighten the screw until spreading the differential housing to the specification.

-

Remove the Dial Indicator Gauge with Holding Fixture and Clutch Housing Gauge.

-

Adjust the Dial Indicator Gauge with Holding Fixture and Clutch Housing Gauge to zero.

|

-

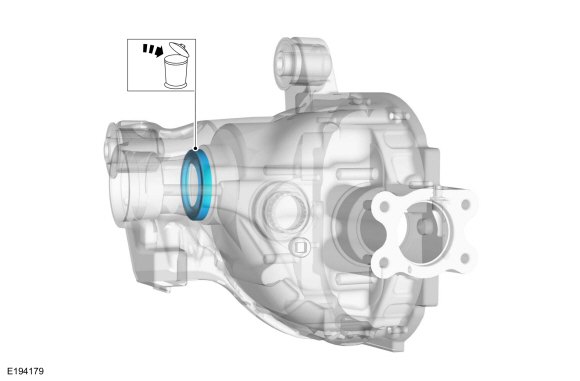

NOTICE: To avoid galling the case, insert shims with a light coating of grease before installing the differential assembly. If not carried out in this order, the aluminum housing may be damaged.

Place the differential bearing shims in the differential housing.

|

-

Install the differential carrier.

-

Position the differential bearing cups on the differential bearings.

-

Lower the differential carrier in place between the differential bearing shims.

-

Position the differential bearing cups on the differential bearings.

|

-

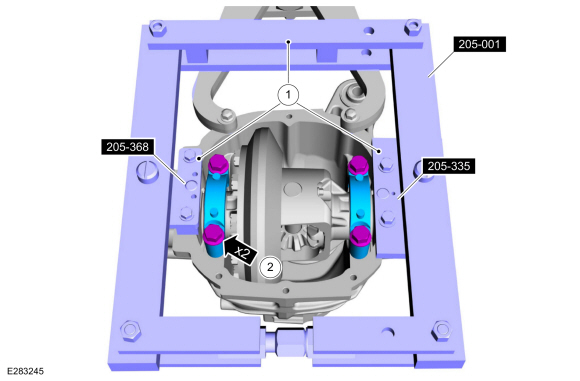

NOTICE: The fixture mounting bolts must have the minimum of 12.7 mm (0.500 In) of thread engagement in the carrier or damage to the component may occur.

NOTE: Always install the differential bearing caps in their original positions or damage to the component may occur.

NOTE: Hand-tighten the differential bearing cap bolts prior to releasing the carrier spreader.

-

With the differential housing spread to 0.762 mm

(0.030 in) maximum. Install the differential caps and bolts in their

original locations and positions.

Use Special Service Tool: 205-001 (TOOL-4000-E) Spreader, Differential Carrier. , 205-368 (T96T-4000-A) Adapter for Differential Housing Spreader. , 205-335 (T93P-4000-A) Spreader, Differential Housing (Plate).

-

NOTE: Finger tighten the differential bearing cap bolts prior to releasing the carrier spreader.

Install the differential bearing caps and the differential bearing cap bolts in their original locations and positions.

-

With the differential housing spread to 0.762 mm

(0.030 in) maximum. Install the differential caps and bolts in their

original locations and positions.

|

-

-

Loosen and Remove the special tools.

Use Special Service Tool: 205-001 (TOOL-4000-E) Spreader, Differential Carrier. , 205-368 (T96T-4000-A) Adapter for Differential Housing Spreader. , 205-335 (T93P-4000-A) Spreader, Differential Housing (Plate).

-

Tighten the differential bearing cap bolts.

Torque: 77 lb.ft (105 Nm)

-

Loosen and Remove the special tools.

|

-

Rotate the differential carrier to make sure it turns freely.

|

-

Install the Dial Indicator Gauge with Holding Fixture at

the 12 o'clock position and recheck the ring gear backlash.

Use Special Service Tool: 100-002 (TOOL-4201-C) Holding Fixture with Dial Indicator Gauge.

|

-

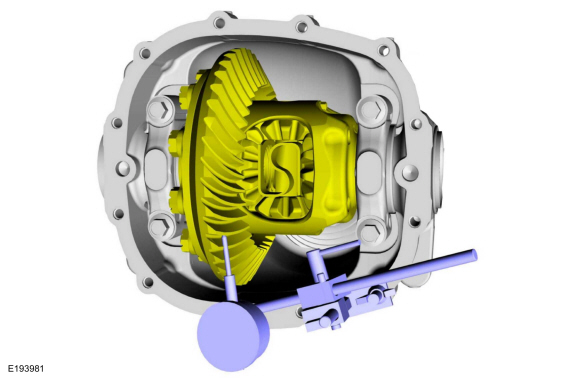

Apply marking compound and rotate the differential assembly 5 complete revolutions.

-

Verify an acceptable pattern check.

Refer to: Front Drive Axle (205-03 Front Drive Axle/Differential, Diagnosis and Testing).

-

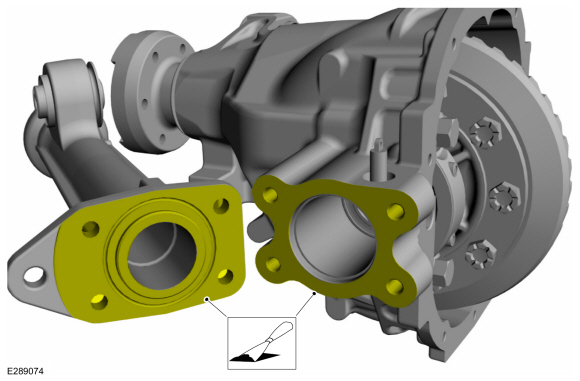

NOTE: Make sure that the mating surface and the bore is free of corrosion and foreign material, avoid particles getting into the bore. Particles might stick on the vent valve assembly and cause damage to vent valve.

Clean the mating surface of the axle and the axle tube.

|

-

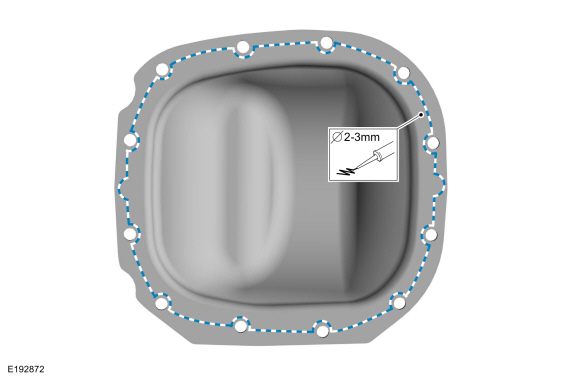

Apply a new continuous bead of sealant to the differential housing as shown.

Material: Motorcraft® Ultra Silicone Sealant / TA-29 (WSS-M4G323-A8)

|

-

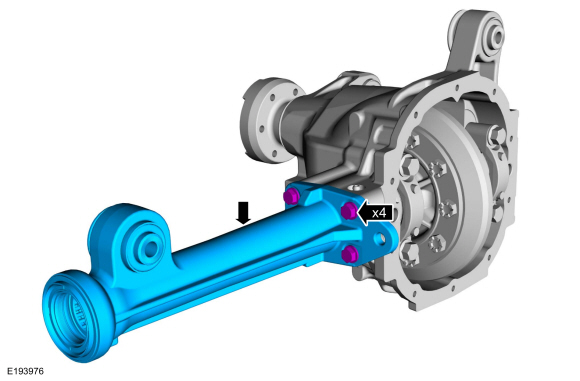

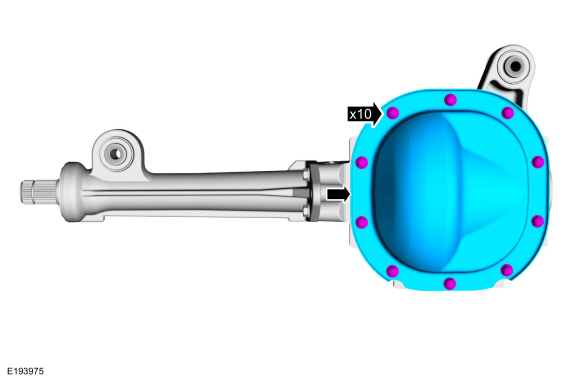

Install the axle tube and the axle tube bolts.

Torque: 54 lb.ft (73 Nm)

|

-

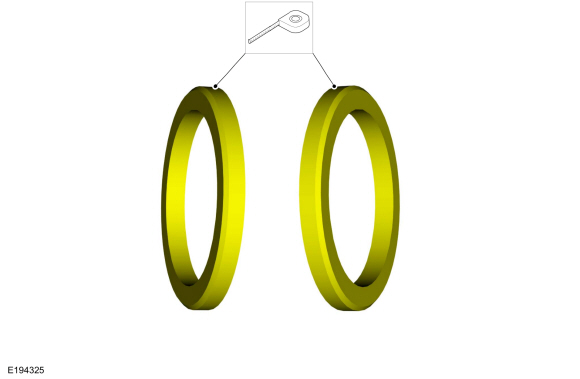

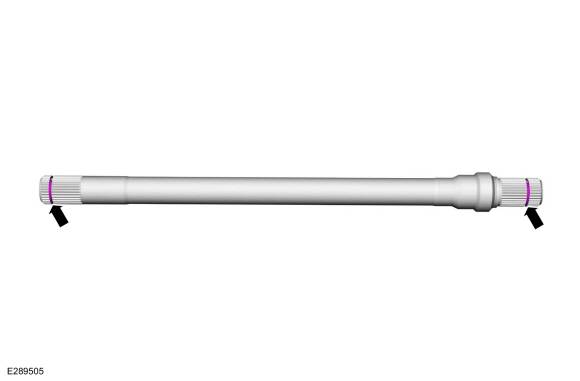

Install the new inner and outer circlips.

|

-

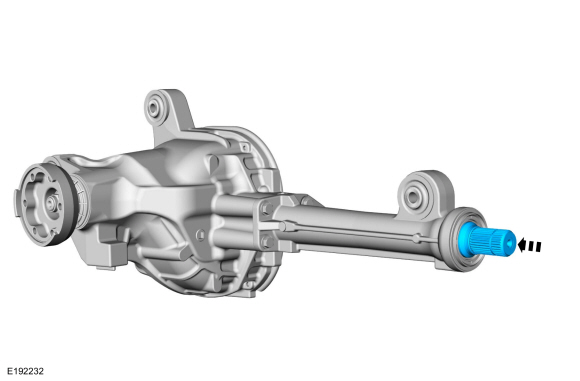

NOTE: The axle shaft is not fully seated until the circlip is engaged with the differential side gear.

Install the axle shaft.

|

-

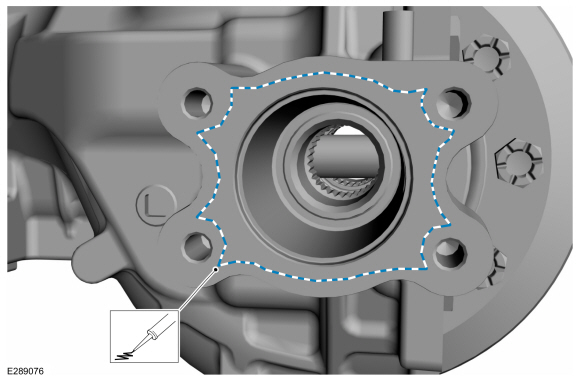

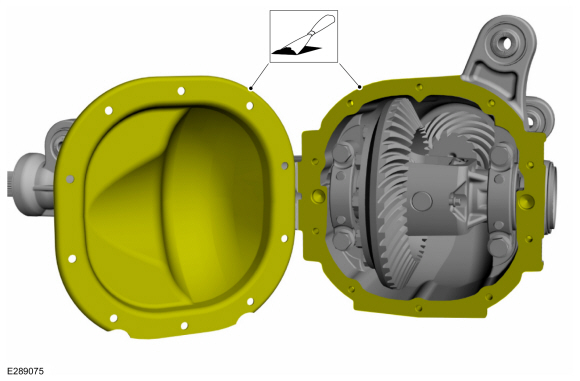

NOTE: Remove all of the silicone gasket and make sure the surfaces are free of oil before applying the new silicone gasket.

Clean the gasket mating surface of the axle and the differential housing cover.

|

-

NOTE: The differential housing cover must be installed within 15 minutes of application of the silicone, or new sealant must be applied. If possible, allow one hour before filling with lubricant to make sure the silicone sealant has correctly cured.

Apply a new continuous bead of sealant to the differential housing cover as shown.

Material: Motorcraft® Ultra Silicone Sealant / TA-29 (WSS-M4G323-A8)

|

-

Install the differential cover and differential cover bolts.

Torque: 24 lb.ft (32 Nm)

|

-

Install the front axle assembly.

Refer to: Axle Assembly (205-03 Front Drive Axle/Differential, Removal and Installation).

Differential Housing Cover. Removal and Installation

Differential Housing Cover. Removal and Installation

Materials

Name

Specification

Motorcraft® Ultra Silicone SealantTA-29

WSS-M4G323-A8

Removal

With the vehicle in NEUTRAL, position it on a hoist...

Drive Pinion Flange and Seal. Removal and Installation

Drive Pinion Flange and Seal. Removal and Installation

Special Tool(s) /

General Equipment

205-002

(TOOL-4858-E)

Installer, Drive Pinion Flange

205-126

(T78P-4851-A)

Holding Fixture, Drive Pinion Flange

205-208

(T83T-4676-A)

Installer, Drive Pinion Oil SealTKIT-1983-FTKIT-1983-FLMTKIT-1983-FX

303-144

(T79T-6316-A)

Remover, Crankshaft Harmonic Balancer

Flat Headed Screw Driver

M..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Evaporative Emission Canister Vent Solenoid. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the EVAP canister. Refer to: Evaporative Emission Canister (303-13 Evaporative Emissions - 3.5L EcoBoost (272kW/370PS), Removal and Installation). Installation To install, reverse the removal procedure. ..

Lincoln Navigator 2018-2026 Workshop Manual: Information and Entertainment System - Component Location. Description and Operation

NOTE: The available speaker configurations are shown first. The remaining hidden audio and SYNC system components and various cable routings follow the speaker configurations. NOTE: Some vehicles may not be equipped with all the optional components shown. 14 Speaker System Item Description 1 Instrument panel center speaker (counted as 3 speake..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Head Up Display (HUD) Module Calibration. General Procedures

- Rear View Mirrors - System Operation and Component Description. Description and Operation

- Body and Paint

- Telematics Control Unit (TCU) Module. Removal and Installation

- All Terrain Control Module (ATCM). Removal and Installation

Front Stabilizer Bar Link. Removal and Installation

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

NOTE: Removal steps in this procedure may contain installation details.

With the vehicle in NEUTRAL, position it on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

NOTICE: Do not use power tools to remove or install the stabilizer bar