Lincoln Navigator: Front Drive Axle/Differential / Drive Pinion Flange and Seal. Removal and Installation

Special Tool(s) / General Equipment

|

205-002

(TOOL-4858-E)

Installer, Drive Pinion Flange |

|

205-126

(T78P-4851-A)

Holding Fixture, Drive Pinion Flange |

|

205-208

(T83T-4676-A)

Installer, Drive Pinion Oil Seal TKIT-1983-F TKIT-1983-FLM TKIT-1983-FX |

|

303-144

(T79T-6316-A)

Remover, Crankshaft Harmonic Balancer |

| Flat Headed Screw Driver | |

Materials

| Name | Specification |

|---|---|

| Motorcraft® SAE 75W-85 Premium Synthetic Hypoid Gear Lubricant XY-75W85-QL |

WSS-M2C942-A |

Removal

-

Remove the front brake pads.

Refer to: Brake Pads (206-03 Front Disc Brake, Removal and Installation).

-

Remove the front driveshaft.

Refer to: Front Driveshaft (205-01 Driveshaft, Removal and Installation).

-

NOTE: Rotational torque of the drive pinion flange must be measured and recorded using a Nm (lb-in) torque wrench for correct pinion bearing preload when reassembled. This will be the torque-to-turn measurement.

-

Using a dial type torque wrench, measure and record the rotational torque of the drive pinion.

-

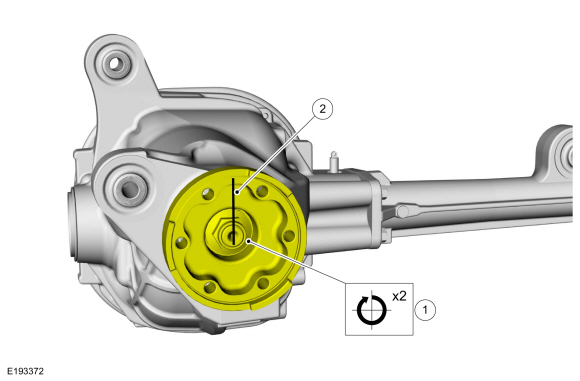

Index-mark the pinion flange and the drive pinion stem.

-

Using a dial type torque wrench, measure and record the rotational torque of the drive pinion.

|

-

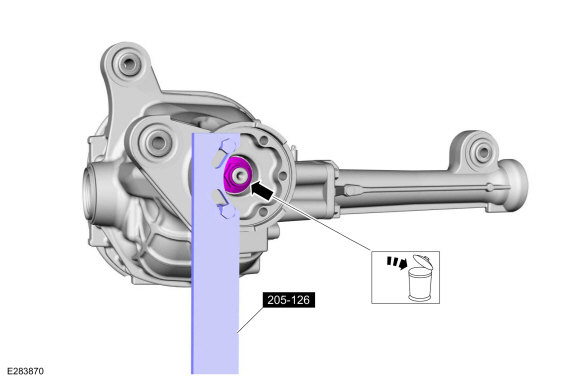

Using the special tool, remove and discard the pinion nut.

Use Special Service Tool: 205-126 (T78P-4851-A) Holding Fixture, Drive Pinion Flange.

|

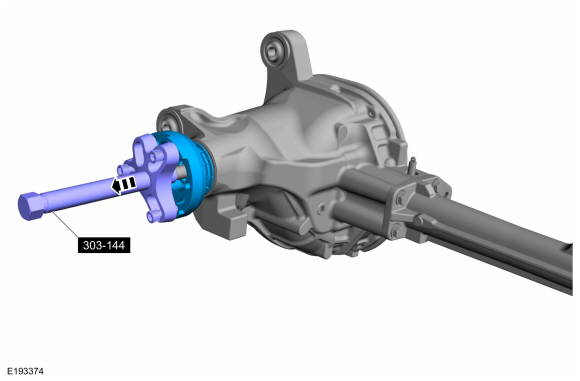

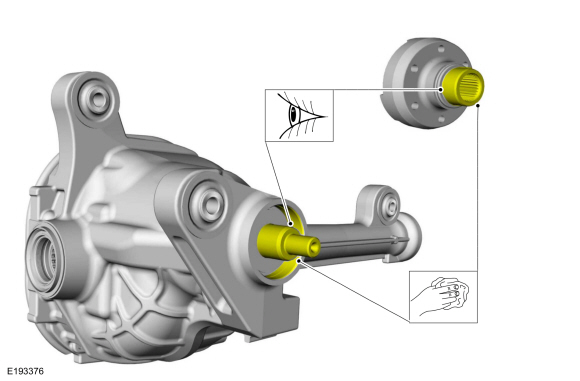

-

Using the special tool, remove the pinion flange.

Use Special Service Tool: 303-144 (T79T-6316-A) Remover, Crankshaft Harmonic Balancer.

|

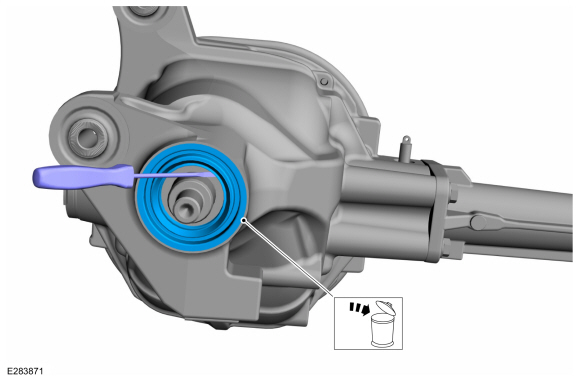

-

Using the general equipment, remove and discard the drive pinion seal.

Use the General Equipment: Flat Headed Screw Driver

|

-

Clean and inspect the pinion flange mating surfaces and pinion seal surface.

|

Installation

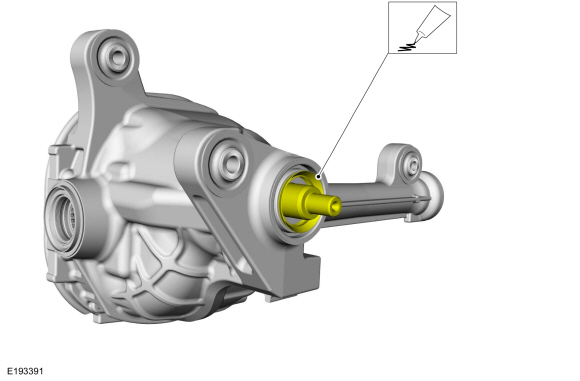

-

Using the special tool, install the new pinion seal.

Use Special Service Tool: 205-208 (T83T-4676-A) Installer, Drive Pinion Oil Seal.

|

-

Lubricate the pinion seal and pinion splines.

Material: Motorcraft® SAE 75W-85 Premium Synthetic Hypoid Gear Lubricant / XY-75W85-QL (WSS-M2C942-A)

|

-

NOTE: Make sure drive pinion flange and drive pinion stem are phased correctly using previously applied mark.

-

Align the index marks made during removal.

-

Using the special tool, install the pinion flange.

Use Special Service Tool: 205-002 (TOOL-4858-E) Installer, Drive Pinion Flange.

-

Align the index marks made during removal.

|

-

NOTICE: Do not loosen the pinion nut to reduce drive pinion bearing preload. Install a new drive pinion collapsible spacer and pinion nut if drive pinion bearing preload reduction is necessary. If a new collapsible spacer must be installed for pinion bearing preload reduction, install the nut supplied with the new spacer or damage to the component may occur.

NOTE: Tighten the pinion nut, rotating the pinion occasionally to make sure the drive pinion bearings are seating correctly. Take frequent drive pinion bearing preload readings by rotating the drive pinion gear with a Nm (lb-in) torque wrench. The final reading must be 0.56 Nm (5 lb-in) more than the initial reading taken during removal.

NOTE: When installing the drive pinion flange and pinion nut with no differential carrier installed, the drag torque (torque to turn) should be 1.8 to 3.3 Nm (16-29 in-lbs).

Using the special tool, install the new pinion nut.

Use Special Service Tool: 205-126 (T78P-4851-A) Holding Fixture, Drive Pinion Flange.

|

-

Check the front differential fluid level.

Refer to: Differential Fluid Level Check (205-03 Front Drive Axle/Differential, General Procedures).

-

Install the front driveshaft.

Refer to: Front Driveshaft (205-01 Driveshaft, Removal and Installation).

-

Install the front brake pads.

Refer to: Brake Pads (206-03 Front Disc Brake, Removal and Installation).

Differential Carrier. Disassembly and Assembly

Differential Carrier. Disassembly and Assembly

Special Tool(s) /

General Equipment

205-386

(T97T-4205-D)

Gauge, Differential (Traction Lock)TKIT-1998-LM (NavigatoR)TKIT-1997-F/FLM/LT

Hydraulic Press

Punch

Copper Hammer

Bearing Separator

Materials

Name

Specification

Motorcraft® SAE 75W-85 Premium Synthetic Hypoid Gear LubricantXY-75W85-QL

WSS-M2C942-A

D..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Windshield Wiper Pivot Arm. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Raise the windshield wiper pivot arms into the SERVICE-UP position. NOTE: During installation, it is necessary to fully release the windshield wiper pivot arm latch and hold while installing the pivot arm onto the wiper linkage assembly. ..

Lincoln Navigator 2018-2026 Workshop Manual: Charging System - 3.5L EcoBoost (272kW/370PS) - Overview. Description and Operation

Overview The generator is driven by the FEAD belt. When the engine is started, the generator begins to generate AC voltage which is internally converted to DC voltage. The DC voltage level is controlled by the voltage regulator (located on the rear of the generator) and is supplied to the battery. The PCM controls the voltage regulation setpoint and communicates this information t..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Rear Bumper. Removal and Installation

- Rear View Mirrors - System Operation and Component Description. Description and Operation

- SYNC Module [APIM]. Removal and Installation

- Liftgate Trim Panel. Removal and Installation

- Transmission Fluid Drain and Refill. General Procedures

Rear Drive Axle and Differential. Diagnosis and Testing

Symptom Chart(s)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart - Differential

Symptom Chart - Differential

Condition Actions Axle overheating GO to Pinpoint Test A Broken gear teeth on the ring gear or pinion GO to Pi