Lincoln Navigator: Front End Sheet Metal Repairs / Cowl Panel. Removal and Installation

Special Tool(s) /

General Equipment

| 6.5 mm Drill Bit |

| Polydrive Bit Socket |

| Rivet Gun |

| Self-Piercing Rivet (SPR) Remover/Installer |

| Belt Sander |

| Hot Air Gun |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Removal

NOTE:

The cowl panel is available as a top panel, inner panel and

side panels. The following assumes full component replacement of the top

and inner panels. Adjust to meet repair needs.

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and new adhesive applied.

NOTE:

Flow drill screw (FDS) fasteners are not to be reused. Remove and discard.

NOTE:

Adequately protect all adjacent areas against cutting and grinding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

On Both Sides:

Remove the fender.

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

-

Remove the hood, cowl panel grille and cowl panel.

Refer to: Hood (501-02 Front End Body Panels, Removal and Installation).

Refer to: Cowl Panel Grille (501-02 Front End Body Panels, Removal and Installation).

Refer to: Cowl Panel (501-02 Front End Body Panels, Removal and Installation).

-

Remove the windshield wiper motor and associated linkage.

Refer to: Rear Window Wiper Pivot Arm (501-16 Wipers and Washers, Removal and Installation).

Refer to: Wiper Linkage Assembly (501-16 Wipers and Washers, Removal and Installation).

Refer to: Windshield Wiper Motor (501-16 Wipers and Washers, Removal and Installation).

-

Remove the windshield glass.

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the instrument panel and console.

Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

Refer to: Instrument Panel Upper Section (501-12 Instrument Panel and Console, Removal and Installation).

Refer to: Instrument Panel (501-12 Instrument Panel and Console, Removal and Installation).

-

Position the carpet, electrical modules and wiring harnesses away from the working area.

-

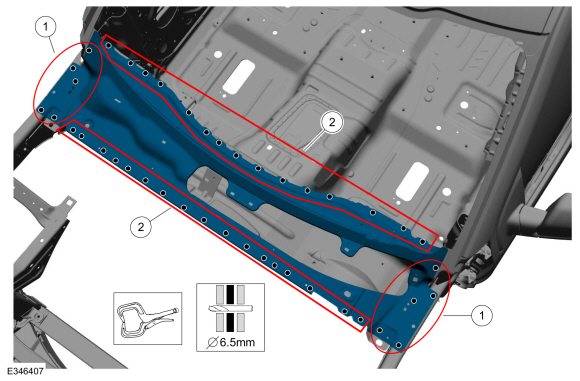

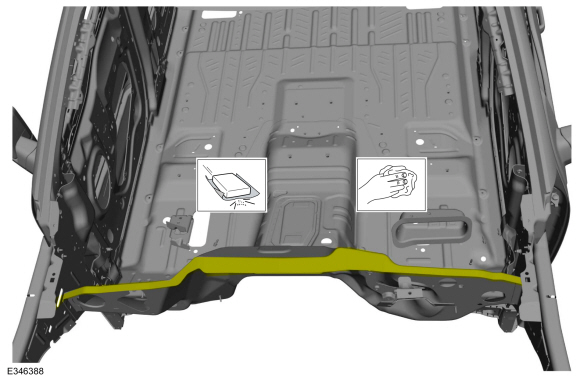

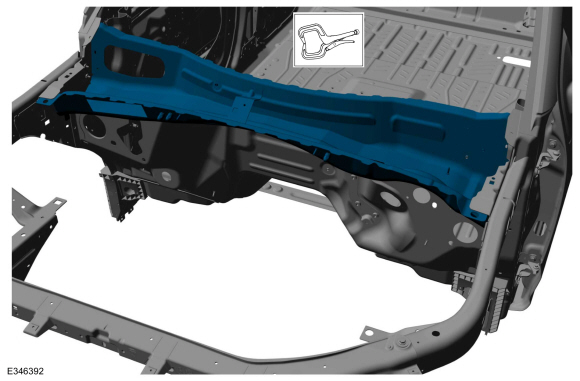

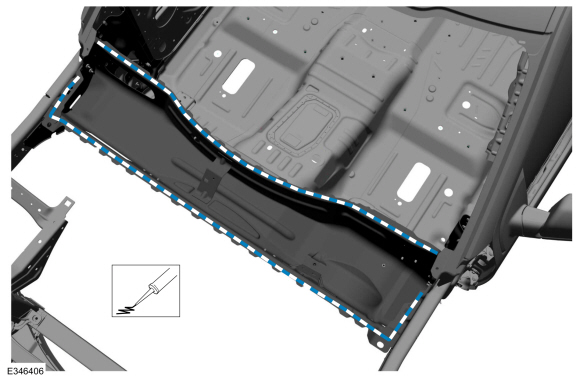

NOTE:

Pay particular attention to the location of adhesives or sealers to aid in installation.

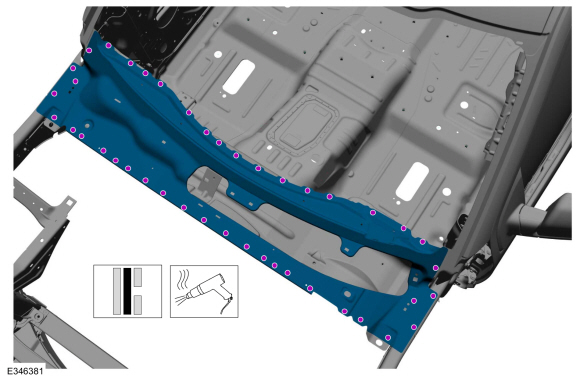

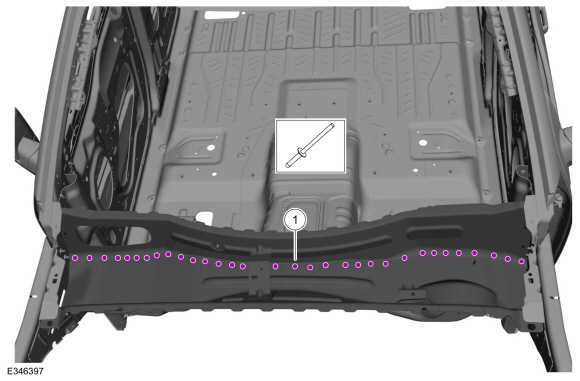

Remove the fasteners and the cowl top.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

Use the General Equipment: Hot Air Gun

-

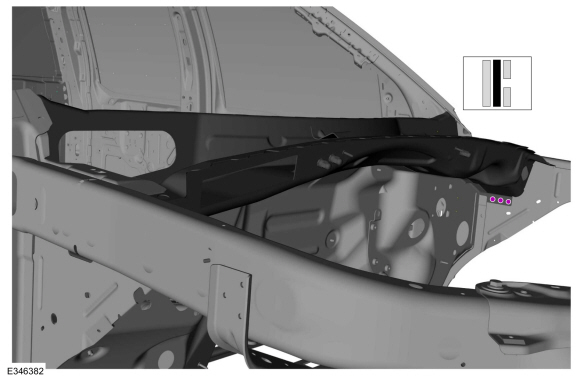

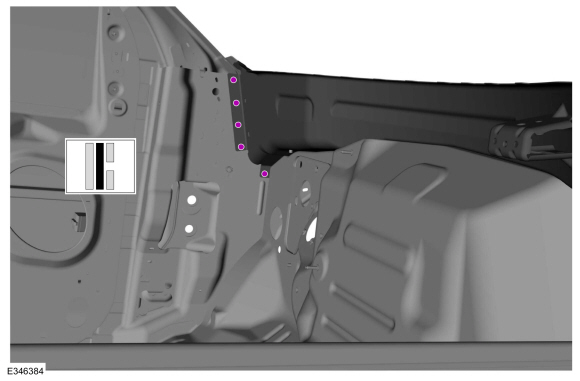

On Both Sides:

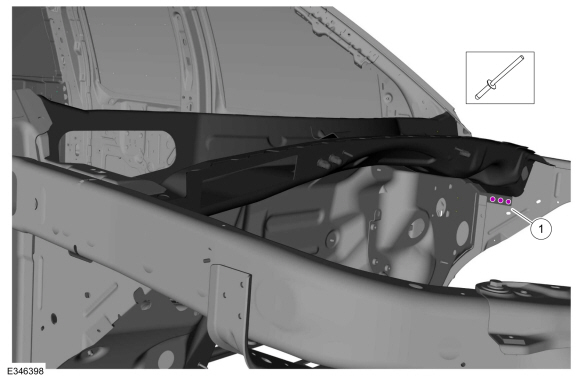

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

-

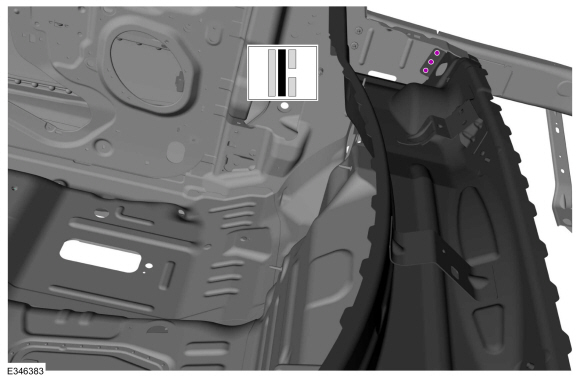

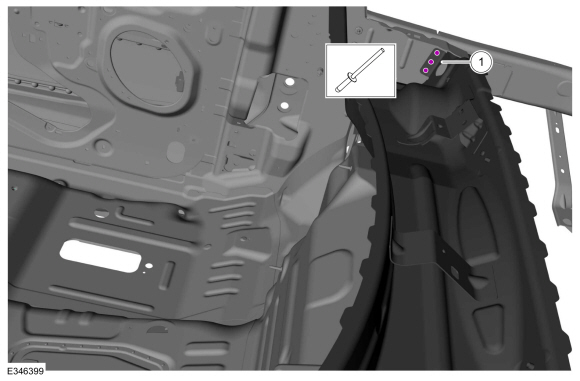

On Both Sides:

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

-

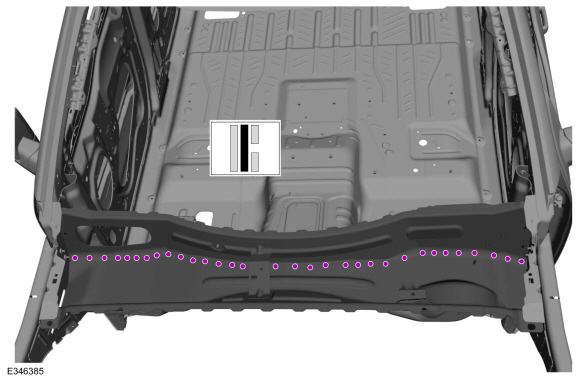

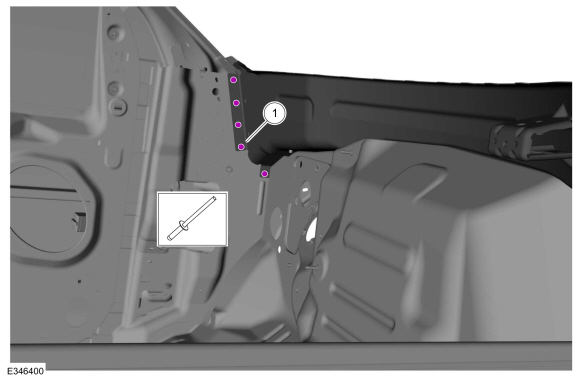

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

-

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

Use the General Equipment: Polydrive Bit Socket

-

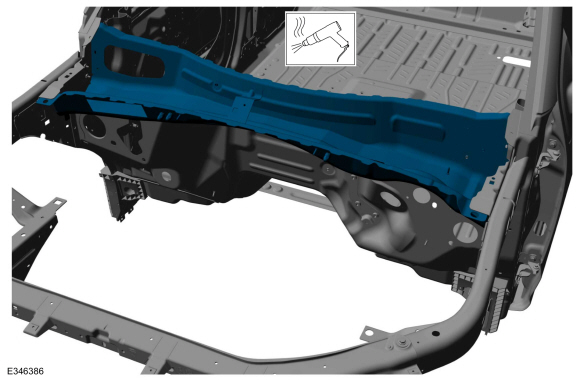

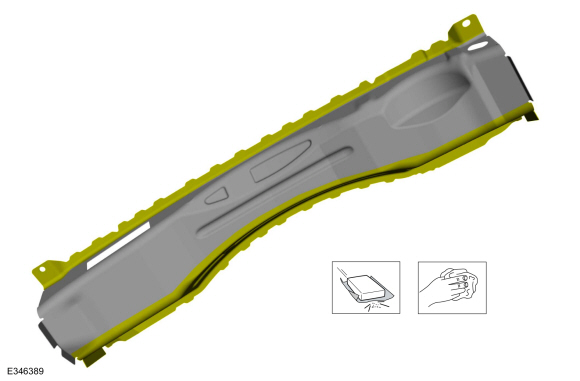

NOTE:

Pay particular attention to the location of adhesives or sealers to aid in installation.

Remove the inner cowl panel.

Use the General Equipment: Hot Air Gun

Installation

NOTE:

The cowl panel is available as a top panel, inner panel and

side panels. The following assumes full component replacement of the top

and inner panels. Adjust to meet repair needs.

NOTE:

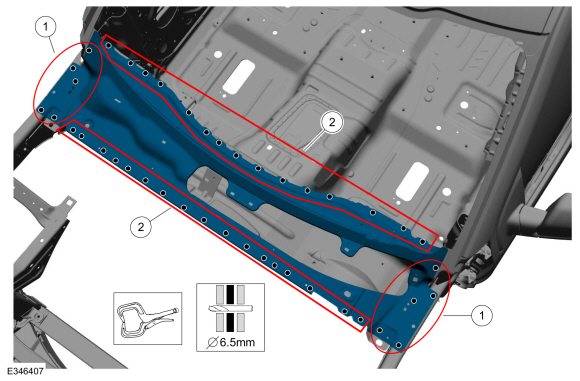

Self-Piercing Rivet (SPR) fasteners may not be placed

directly over original self-piercing rivet (SPR) fastener location. They

must be placed adjacent to original location matching original

quantity.

NOTE:

Blind or solid rivets may be used in place of self-piercing

rivet (SPR) fasteners in the original self-piercing rivet (SPR)

fasteners location after enlarging hole to 6.5 mm.

NOTE:

Adequately protect all adjacent areas against cutting and grinding procedures.

-

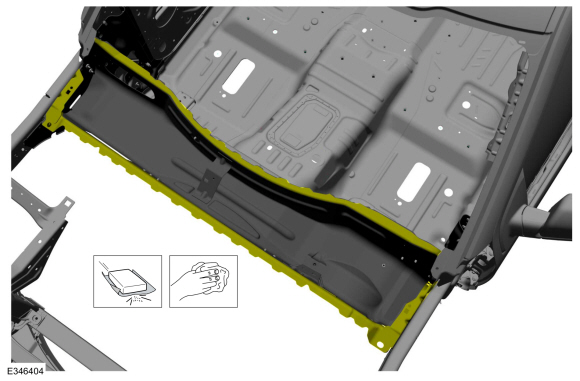

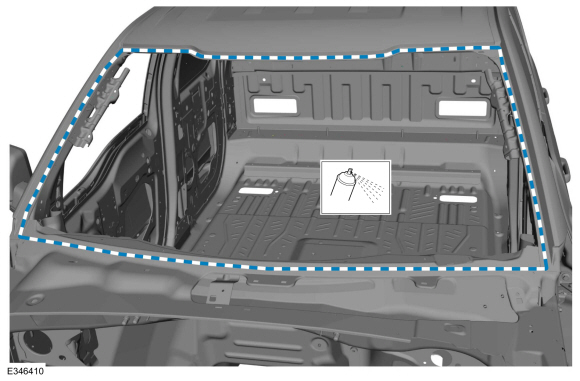

On Both Sides: Using 80-120 grit sand paper, sand to remove old adhesive and clean.

-

Using 80-120 grit sand paper, sand to remove old adhesive and clean.

-

Using 80-120 grit sand paper, sand to remove e-coat and clean.

-

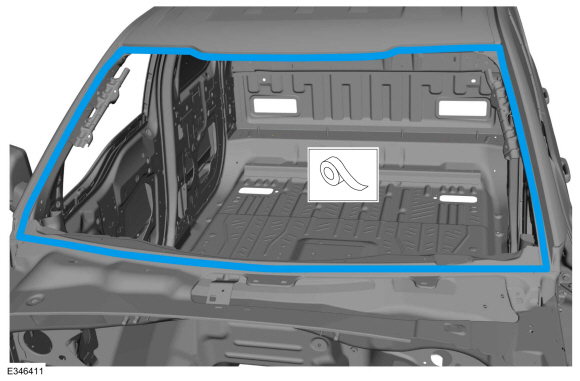

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

On Both Sides:

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

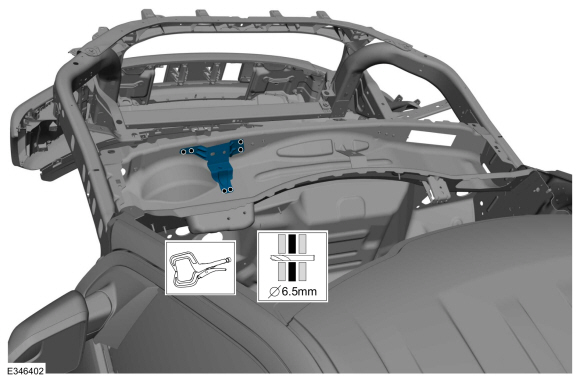

Install, properly position and clamp the inner cowl panel.

Use the General Equipment: Locking Pliers

-

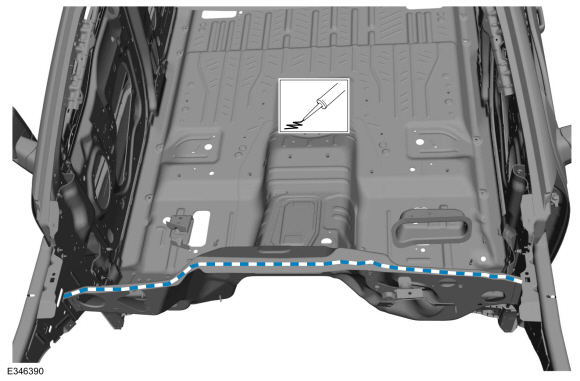

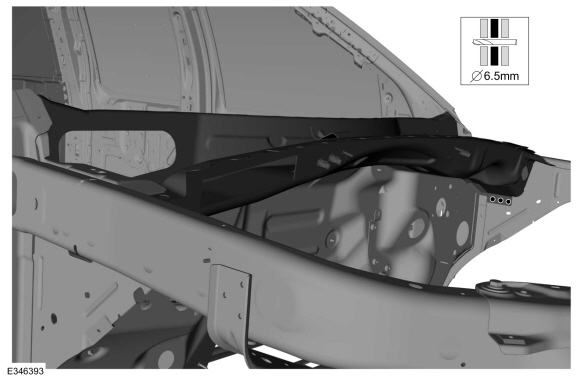

On Both Sides:

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

On Both Sides:

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

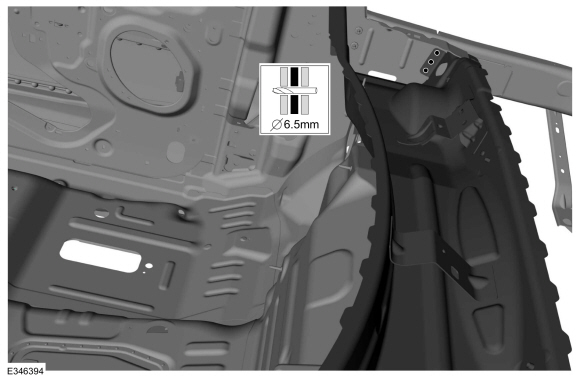

-

On Both Sides:

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

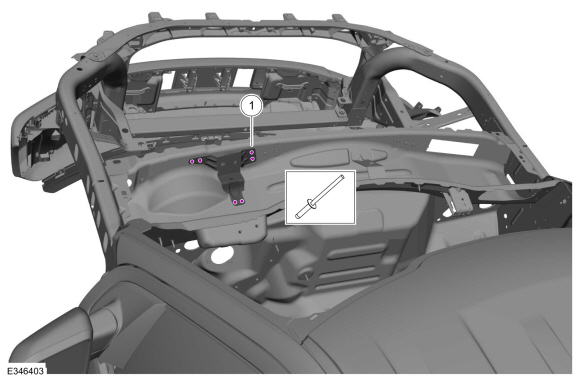

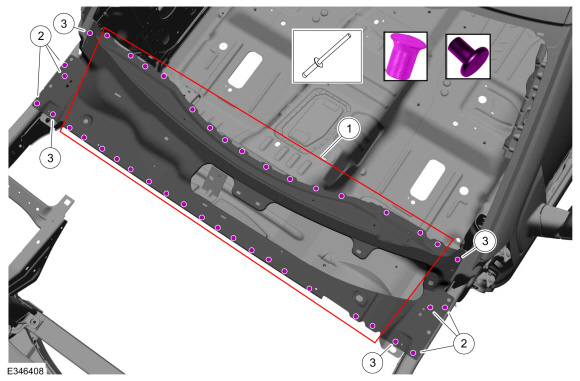

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

On Both Sides:

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

On Both Sides:

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

On Both Sides:

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

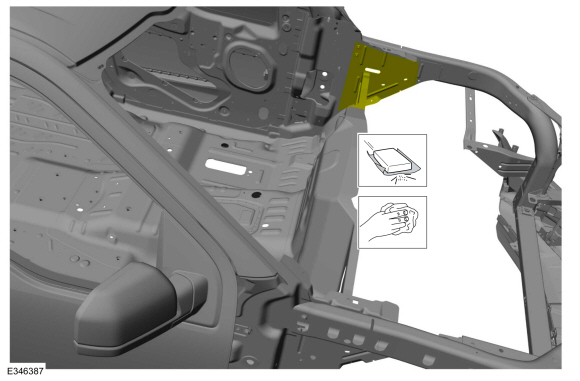

Install, properly position, clamp the reinforcement and drill for blind rivet fasteners.

Use the General Equipment: Locking Pliers

Use the General Equipment: 6.5 mm Drill Bit

-

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

Use the General Equipment: Rivet Gun

-

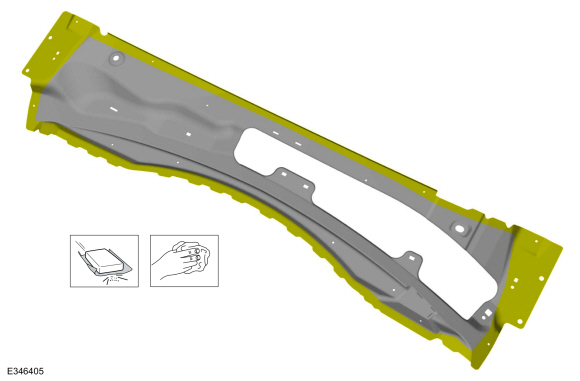

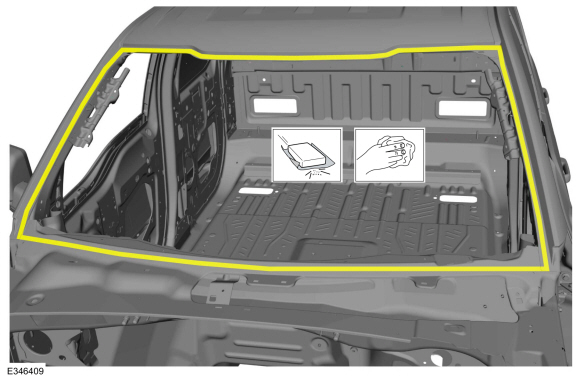

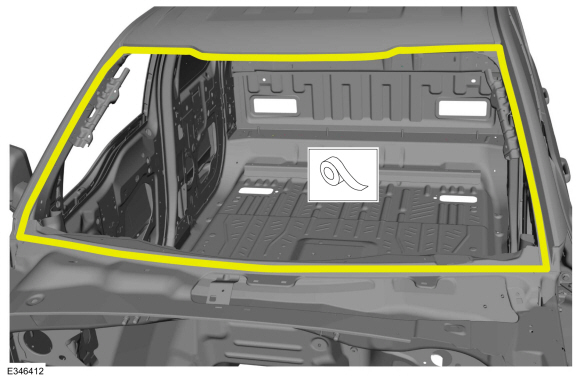

Using 80-120 grit sand paper, sand to remove old adhesive or e-coat and clean.

-

Using 80-120 grit sand paper, sand to remove e-coat and clean.

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

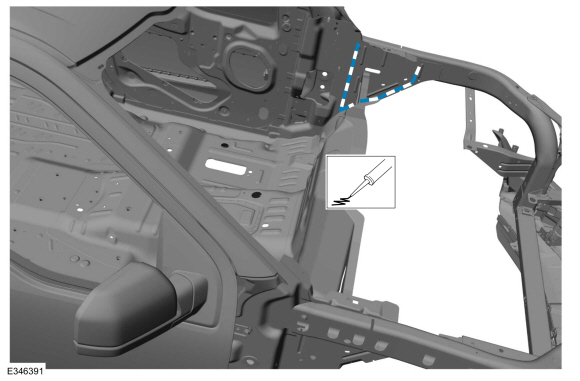

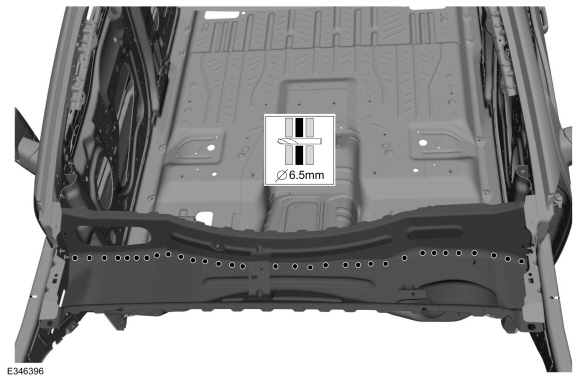

NOTE:

Item 2 should not be drilled if using self-piercing rivet (SPR) fasteners.

Install, properly position, clamp and drill the cowl top panel for fasteners installation.

Use the General Equipment: Locking Pliers

Use the General Equipment: 6.5 mm Drill Bit

|

|

-

NOTE:

Self-piercing rivet (SPR) fasteners may not be

placed directly over original self-piercing rivet (SPR) location. They

must be placed adjacent to original location matching original quantity.

NOTE:

Blind rivet or solid rivet fasteners may be used in

place of self-piercing rivet (SPR) fasteners after enlarging holes to

6.5 mm.

NOTE:

Blind rivet or solid rivet fasteners may be used in

place of self-piercing rivet (SPR) fasteners after enlarging holes to

6.5 mm.

Install the fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

W708713-S900

|

AS

|

DZ09-025/H

|

SA-0400/SA-0401

|

W702512-S900C

|

W790376-S900

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Rivet Gun

-

Sand to remove old adhesive, paint, e-coat and clean.

-

Apply a Ford approved epoxy-based primer and allow to dry.

-

Mask the windshield channel.

-

Refinish the entire repair using a Ford approved paint system.

-

Unmask the windshield channel.

-

Install a new VIN plate.

Refer to: Identification Codes (100-01 Identification Codes, Description and Operation).

-

Install the windshield glass.

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition all electrical modules, wiring harnesses and the carpet to original location.

-

Install the instrument panel and console.

Refer to: Instrument Panel (501-12 Instrument Panel and Console, Removal and Installation).

Refer to: Instrument Panel Upper Section (501-12 Instrument Panel and Console, Removal and Installation).

Refer to: Floor Console (501-12 Instrument Panel and Console, Removal and Installation).

-

Install the windshield wiper motor and associated linkage.

Refer to: Rear Window Wiper Motor (501-16 Wipers and Washers, Removal and Installation).

Refer to: Wiper Linkage Assembly (501-16 Wipers and Washers, Removal and Installation).

Refer to: Windshield Wiper Pivot Arm (501-16 Wipers and Washers, Removal and Installation).

-

On Both Sides:

Install the fender.

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

-

Install the cowl panel, cowl panel grille and hood.

Refer to: Cowl Panel (501-02 Front End Body Panels, Removal and Installation).

Refer to: Cowl Panel Grille (501-02 Front End Body Panels, Removal and Installation).

Refer to: Hood (501-02 Front End Body Panels, Removal and Installation).

-

Align the hood.

Refer to: Hood Alignment (501-03 Body Closures, General Procedures).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

11 mm Drill Bit

Rivet Gun

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Hot Air Gun

8 mm Drill Bit

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

..

Other information:

Overview

The HUD serves as a supplemental display for driver information and advanced driver assistance features. All HUD

information and warnings are displayed on the windshield and can be

turned on, off and setup to display individual features using the RH steering wheel switches.

NOTE:

Not all displays shown on the illustration will display at the same time.

HUD

..

Disposal

Disposal of Deployable Devices and Pyrotechnic Devices That Are Undeployed-Inoperative

NOTE:

All inoperative airbags, seatbelt pretensioners and

inflatable seatbelt inflators have been placed on the Mandatory Return

List. Treat all discolored or damaged airbags the same as any

inoperative live airbag being returned.

WARNING:

Before beginning..

Cowl Side Panel. Removal and Installation

Cowl Side Panel. Removal and Installation