Lincoln Navigator: Climate Control System - General Information / Condenser. Removal and Installation

Lincoln Navigator 2018-2026 Workshop Manual / Climate Control System / Climate Control System - General Information / Condenser. Removal and Installation

Removal

NOTICE: During the removal of components, cap, tape or otherwise appropriately protect all openings to prevent the ingress of dirt or other contamination. Remove protective materials prior to installation.

NOTE: Removal steps in this procedure may contain installation details.

NOTE: Expedition shown, Navigator similar.

-

Recover the refrigerant. Refer to the appropriate Recovery procedure in Group 412.

-

With the vehicle in N , position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

-

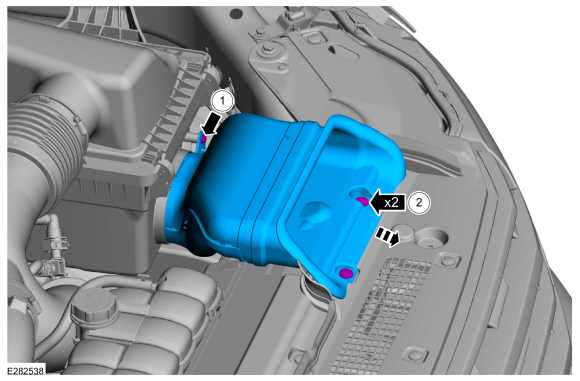

Remove the retainer.

-

Remove the push pin retainers and the air intake.

-

Remove the retainer.

|

-

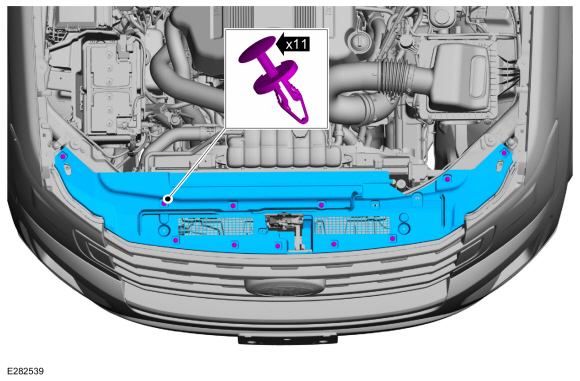

Remove the push pin retainers and the air deflector.

|

-

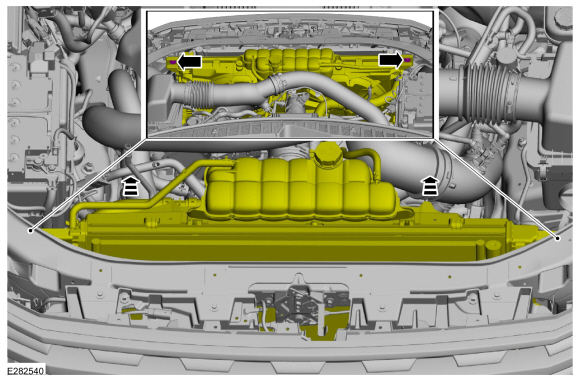

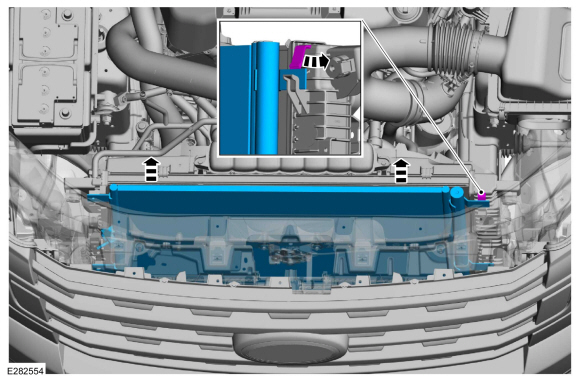

Remove the retainers and tilt the cooling module.

Torque: 133 lb.in (15 Nm)

|

-

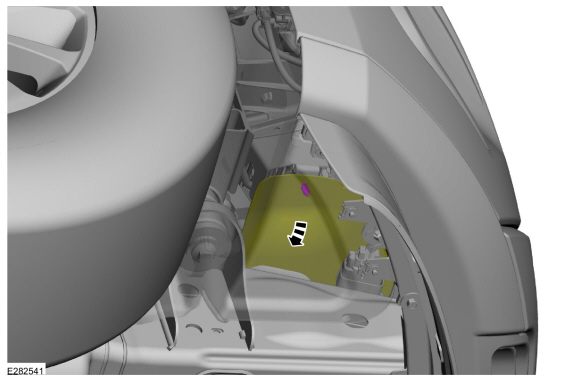

Position the lower air deflector aside.

|

-

-

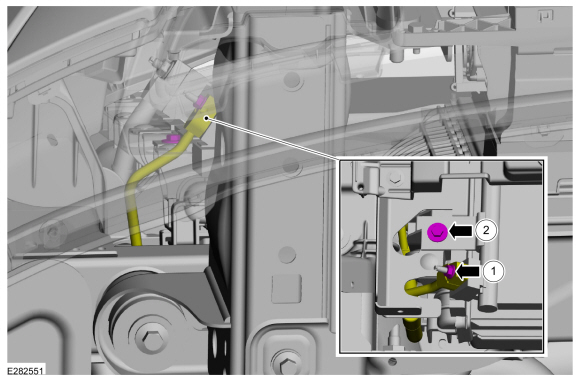

Remove the nut and disconnect the thermostatic expansion valve manifold and tube assembly.

Torque: 89 lb.in (10 Nm)

-

Remove the retainer.

Torque: 89 lb.in (10 Nm)

-

Make sure to cover any open ports to prevent debris from entering the system.

-

Remove the nut and disconnect the thermostatic expansion valve manifold and tube assembly.

|

-

-

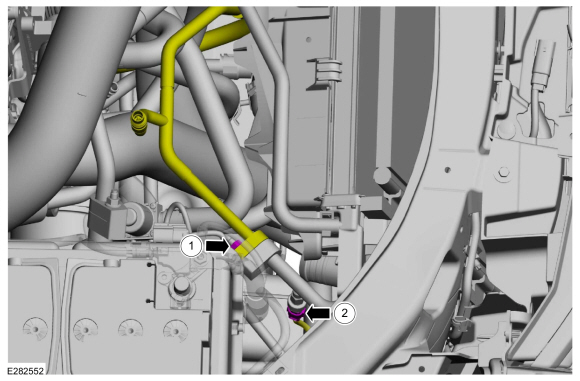

Remove the nut and disconnect the A/C fitting.

Torque: 159 lb.in (18 Nm)

-

Disconnect the electrical connector from the A/C pressure transducer.

-

Make sure to cover any open ports to prevent debris from entering the system.

-

Remove the nut and disconnect the A/C fitting.

|

-

-

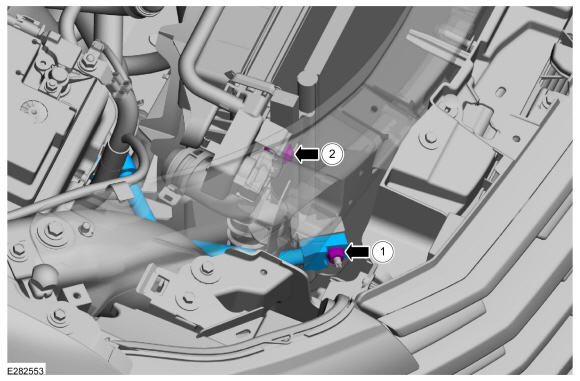

Remove the nut and the A/C compressor outlet line.

Torque: 159 lb.in (18 Nm)

-

Remove the retainer.

Torque: 89 lb.in (10 Nm)

-

Make sure to cover any open ports to prevent debris from entering the system.

-

Remove the nut and the A/C compressor outlet line.

|

-

Release the tab and remove the condenser.

|

Installation

-

To install, reverse the removal procedure.

-

NOTICE: Only use the specified material to lubricate the seals.

Install and lubricate new O-ring seals. Refer to the appropriate Specifications in Group 412.

-

Lubricate the refrigerant system with the correct amount

of clean PAG oil. Refer to the appropriate Refrigerant Oil Adding

procedure in Group 412.

Climate Control Housing. Removal and Installation

Climate Control Housing. Removal and Installation

Removal

NOTICE:

During the removal or installation of components, cap, tape

or otherwise appropriately protect all openings and tubes/fittings to

prevent the ingress of dirt or other contamination...

Desiccant Bag. Removal and Installation

Desiccant Bag. Removal and Installation

Removal

NOTICE:

During the removal or installation of components, cap, tape

or otherwise appropriately protect all openings and tubes/fittings to

prevent the ingress of dirt or other contamination...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Front Wheel Speed Sensor. Removal and Installation

Materials Name Specification Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C - Removal NOTE: Removal steps in this procedure may contain installation details. Remove the brake disc shield...

Lincoln Navigator 2018-2026 Workshop Manual: Passive Anti-Theft System (PATS) - System Operation and Component Description. Description and Operation

System Operation System Diagram Item Description 1 IPC 2 Passive Key 3 RTM 4 GWM 5 GWM 6 PCM 7 PATS Center Antenna 8 Keyless Entry Rear Antenna 9 Ignition Switch 10 PATS Enable 11 BCM Netwo..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Brake Service Mode Activation and Deactivation. General Procedures

- Identification Codes. Description and Operation

- Remote Function Actuator (RFA) Module. Removal and Installation

- Front Seat. Removal and Installation

- Front Bumper Cover. Removal and Installation

Front Driveshaft. Removal and Installation

Special Tool(s) / General Equipment

Crimping ToolMaterials

Name Specification Motorcraft® Premium Long-Life GreaseXG-1-E1 ESA-M1C75-B

Removal

With the vehicle in NEUTRAL, position the vehicle on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

Remove the bolts and the transmission shield.

Copyright © 2026 www.linavigator4.com