Lincoln Navigator: Fuel Charging and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS) / Turbocharger LH. Removal and Installation

Materials

| Name |

Specification |

Motorcraft® High Temperature Nickel Anti-Seize Lubricant

XL-2 |

-

|

Motorcraft® Metal Brake Parts Cleaner

PM-4-A, PM-4-B, APM-4-C |

-

|

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system. Failure to

do so may result in damage to the turbocharger.

NOTICE:

Special attention needs to be given to the sealing ports for

the oil feed, the oil drain, and the coolant tubes, on turbocharged

engines. The sealing ports must be totally clean and free from O-ring

residue, have no damage to the sealing surface and the tubes to ensure

that there are no leaks or repeat repairs.

-

Drain the cooling system.

Refer to: Engine Cooling System Draining, Vacuum Filling and Bleeding

(303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), General

Procedures).

-

Remove the engine rear undershield.

-

Remove the left front fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Remove the charge air cooler intake pipe - left side.

Refer to: Charge Air Cooler (CAC) Intake Pipe (303-12 Intake Air

Distribution and Filtering - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

-

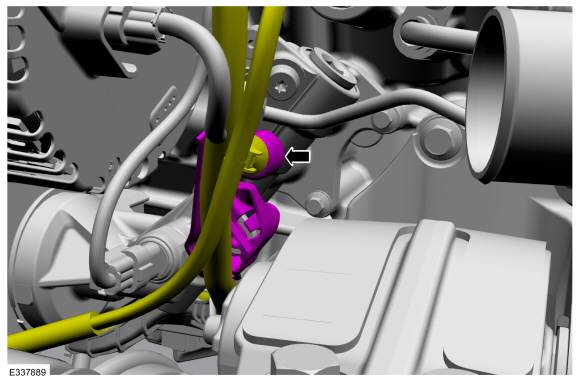

Detach the harness retainer, then move the harness out of the way.

-

NOTE:

The left turbocharger oil supply tube does not have a turbocharger oil supply filter.

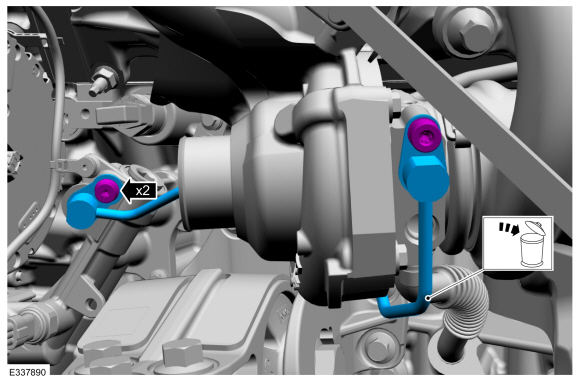

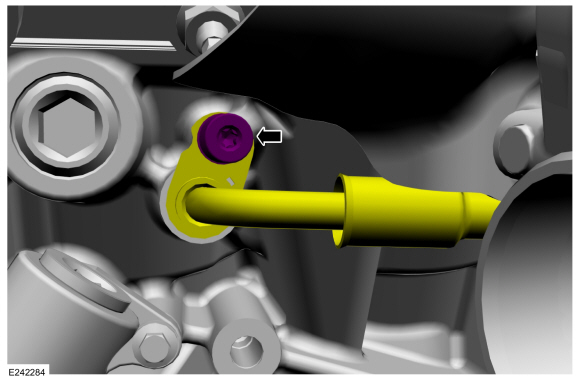

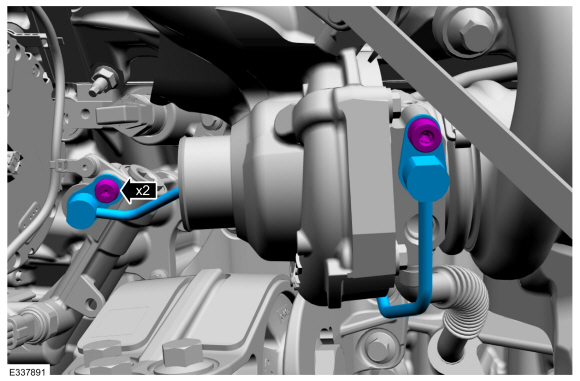

Remove the turbocharger oil supply tube bolts, then remove and discard the turbocharger oil supply tube.

-

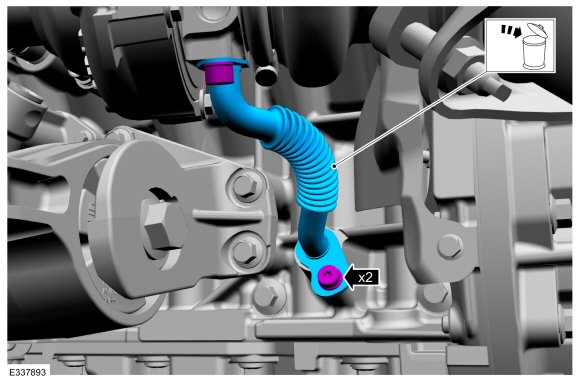

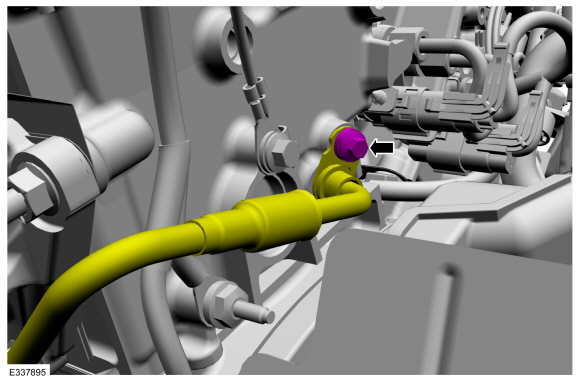

Remove the turbocharger oil return tube bolts, then remove and discard the turbocharger oil return tube.

-

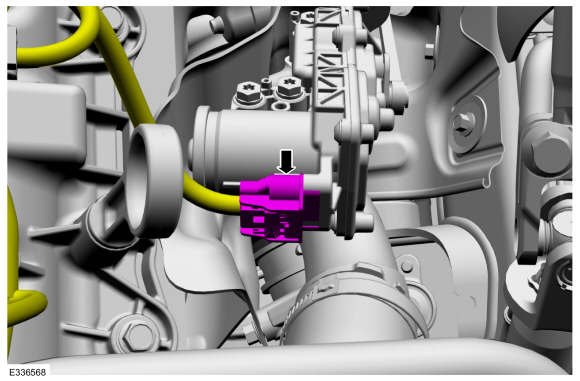

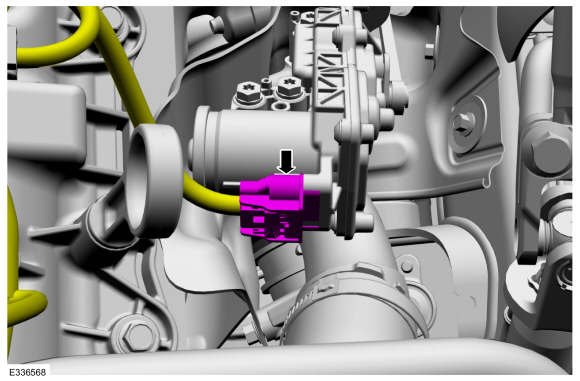

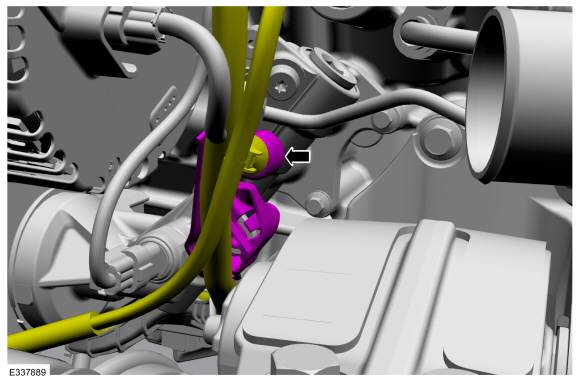

Disconnect the wastegate control actuator electrical connector.

-

Remove the catalytic converter LH.

Refer to: Catalytic Converter LH (309-00 Exhaust System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

NOTICE:

If the 2 piece turbocharger cooling tubes are

separated or the rubber gasket is leaking, then the rubber gasket must

be replaced.

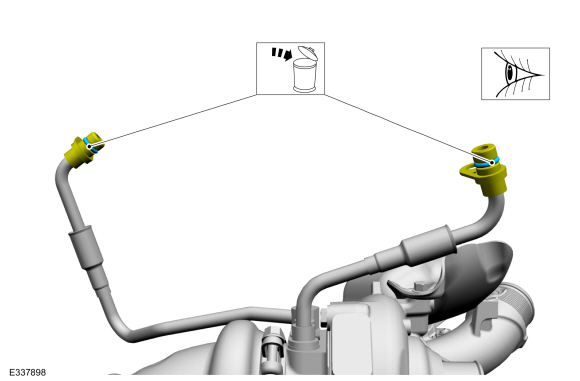

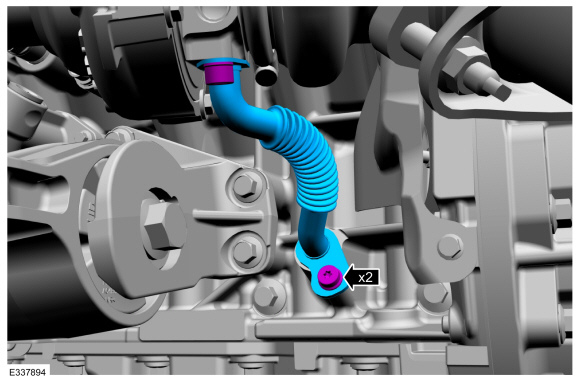

Remove the turbocharger coolant supply tube bolt, then

disconnect the turbocharger coolant supply tube from the engine.

-

NOTICE:

If the 2 piece turbocharger cooling tubes are

separated or the rubber gasket is leaking, then the rubber gasket must

be replaced.

Remove the turbocharger coolant return tube bolt, then

disconnect the turbocharger coolant return tube from the engine.

-

NOTE:

Remove the coolant tubes with the turbocharger. If

the 2 piece turbocharger cooling tubes are separated, then the rubber

gasket must be replaced.

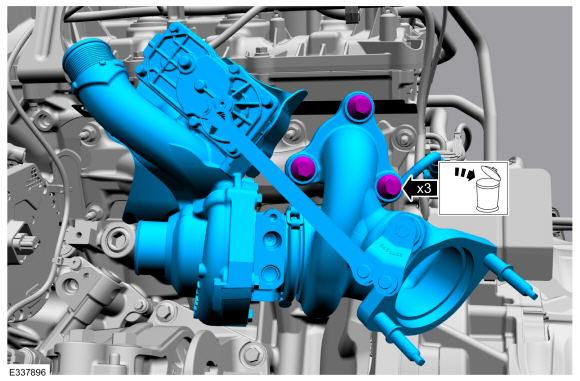

Remove and discard the turbocharger retainers, then remove the turbocharger.

-

-

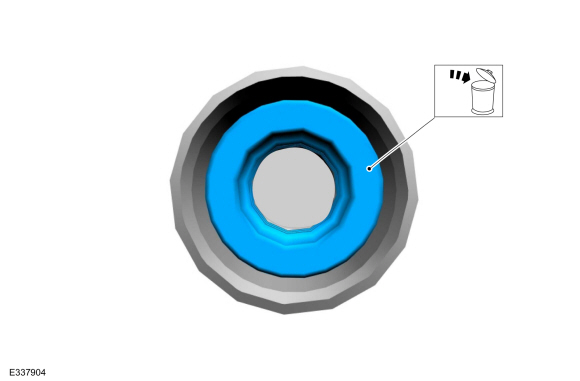

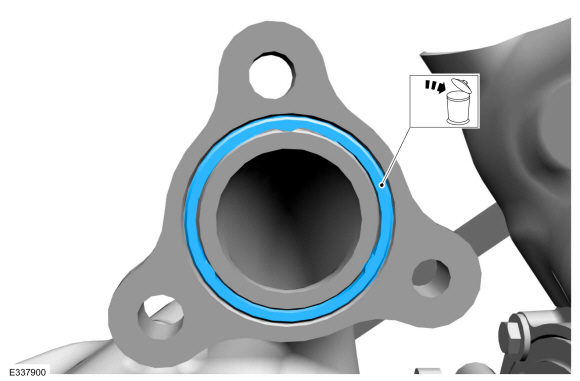

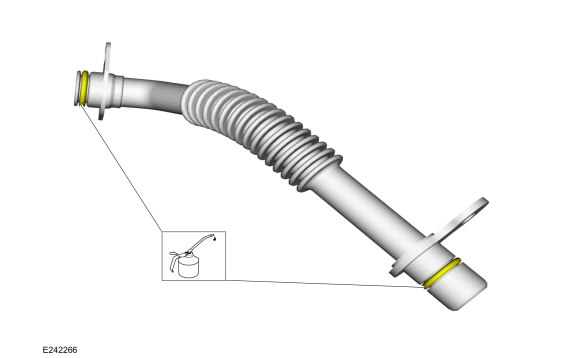

Remove and discard the turbocharger coolant tube O-ring seals.

-

NOTICE:

Do not use a metal brush, damage to sealing area will result in leaks.

Use brake cleaner and a nylon brush to clean. Clean

the turbocharger coolant tube sealing surfaces. Inspect the sealing

surfaces for debris or damage and make sure the retaining bracket is not

bent, check for squareness of the O-ring area. Install new components

if necessary.

-

NOTICE:

If the 2 piece turbocharger cooling tubes were

separated or the rubber gasket is leaking, then the rubber gasket must

be replaced.

If needed, then remove and discard the rubber gasket.

-

NOTICE:

Do not use a metal brush, damage to sealing area will result in leaks.

If needed, inspect and clean the turbocharger cooling

tube sealing surfaces, using brake cleaner and a nylon brush to clean.

Install new components if necessary.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B, APM-4-C

-

If needed, remove the turbocharger coolant tubes from the turbocharger.

Refer to: Turbocharger Coolant Return Tube LH (303-04B Fuel Charging

and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

Refer to: Turbocharger Coolant Supply Tube LH (303-04B Fuel Charging

and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

-

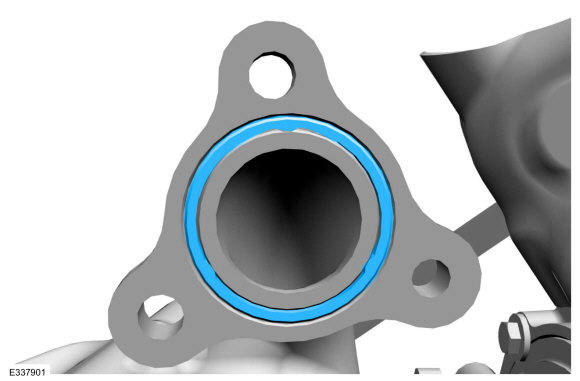

Remove and discard the turbocharger gasket.

-

If needed, remove the studbolts.

Installation

-

Make sure that the mating faces are clean and free of foreign material.

-

If removed, apply high temperature nickel anti-seize

lubricant to the studbolt threads, then install and tighten the

studbolts.

Material: Motorcraft® High Temperature Nickel Anti-Seize Lubricant

/ XL-2

Torque:

30 lb.ft (40 Nm)

-

Install the new turbocharger gasket by pressing the

gasket into the turbocharger flange groove evenly until at least 50% of

the gasket is within the groove.

-

If removed, install the turbocharger coolant supply tubes.

Refer to: Turbocharger Coolant Return Tube LH (303-04B Fuel Charging

and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

Refer to: Turbocharger Coolant Supply Tube LH (303-04B Fuel Charging

and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

-

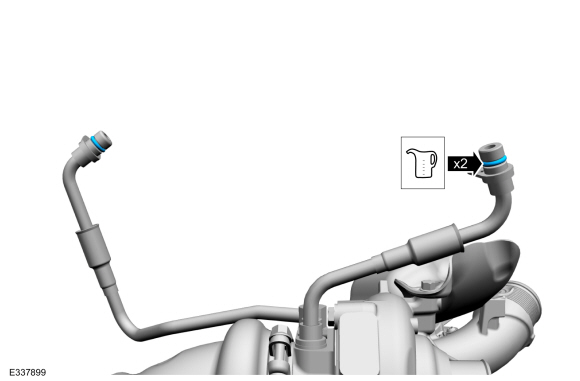

-

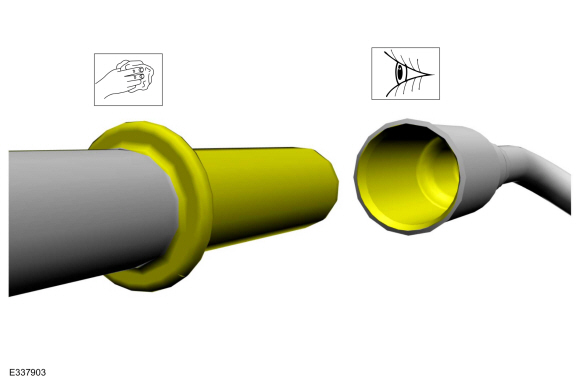

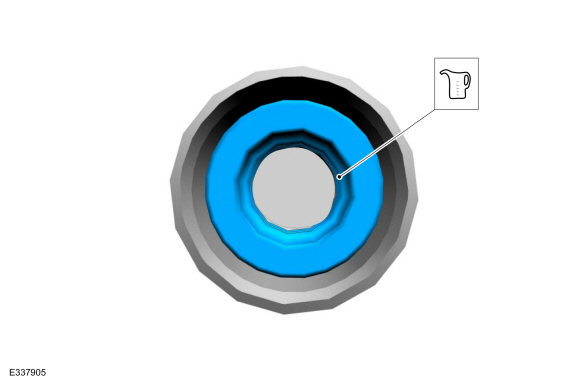

If needed, then install the turbocharger cooling

tube rubber gasket. After installing the new rubber gasket, lubricate

with clean engine coolant.

Refer to: Specifications (303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), Specifications).

-

Install the new turbocharger coolant tube O-ring seals Lubricate the new O-ring seal with clean engine coolant.

Refer to: Specifications (303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), Specifications).

-

NOTE:

Install the coolant tubes to the engine with the turbocharger.

-

NOTICE:

Do not use a metal brush damage to sealing area will result in leaks.

Carefully use a nylon brush to remove the old O-ring

residue, use brake cleaner to rinse the O-ring residue out of the

turbocharger tube to engine O-ring bores. Inspect the area for deep

scratches and gouges. Install new components if necessary.

-

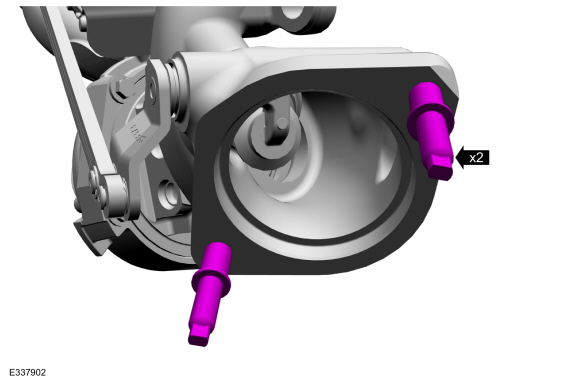

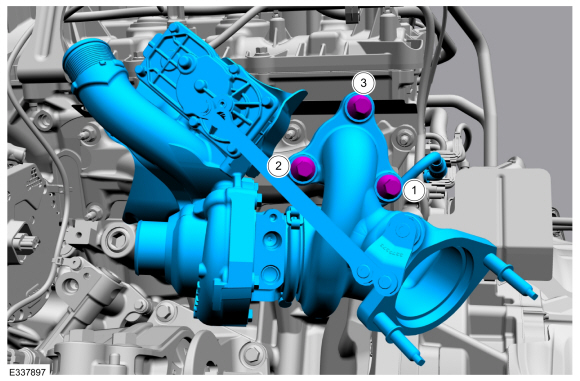

Install the turbocharger, then install and tighten

the new turbocharger retainers as indicated in the following 3 stages.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B, APM-4-C

Torque:

Stage 1:

Tighten 1-3 in the sequence shown to :

18 lb.in (2 Nm)

Stage 2:

Tighten 1-3 in the sequence shown to :

38 lb.ft (51 Nm)

Stage 3:

Re-tighten 1 to :

38 lb.ft (51 Nm)

-

Install and tighten the turbocharger coolant return tube bolt.

Torque:

Stage 1:

Tighten to. :

89 lb.in (10 Nm)

Stage 2:

Tighten an additional 30 degrees or tighten to 16 Nm, whichever comes first. :

30°

-

Install and tighten the turbocharger coolant supply tube bolt.

Torque:

Stage 1:

Tighten to :

89 lb.in (10 Nm)

Stage 2:

Tighten an additional :

30°

-

Install the catalytic converter LH.

Refer to: Catalytic Converter LH (309-00 Exhaust System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Connect the wastegate control actuator electrical connector.

-

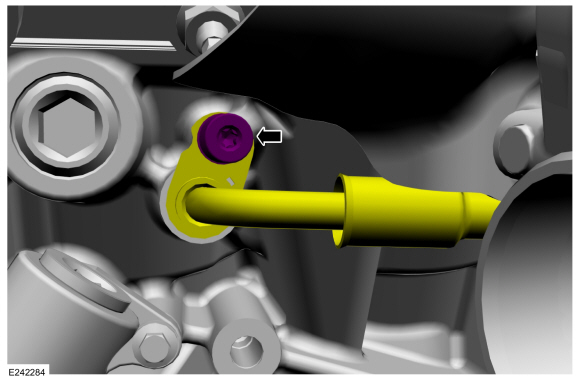

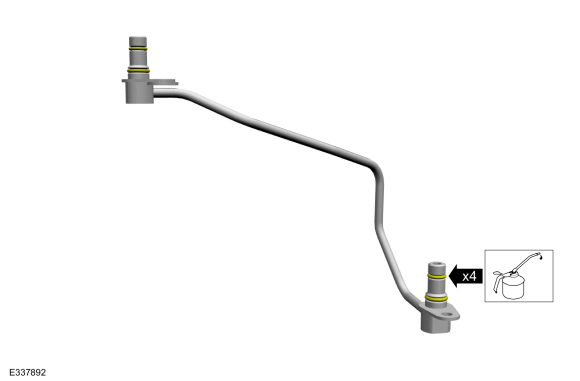

Lubricate the new turbocharger oil return tube O-ring seals with clean engine oil.

Refer to: Specifications (303-01 Engine - 3.5L V6 PowerBoost (CN))

.

-

-

NOTICE:

Do not use a metal brush, damage to the sealing area will result in leaks.

Carefully use a nylon brush to remove the old O-ring

residue, use brake cleaner to rinse the O-ring residue out of the

turbocharger and engine O-ring bores. Inspect the area for deep

scratches and gouges. Install new components if necessary.

-

Fully seat the turbocharger oil return tube into the

turbocharger and engine bore holes flush to 2.5 mm off of the mounting

surface prior to tightening the bolts. Install the new turbocharger oil

return tube, then install and tighten the turbocharger oil return tube

bolts.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B, APM-4-C

Torque:

Stage 1:

Tighten to :

89 lb.in (10 Nm)

Stage 2:

Tighten an additional :

30°

-

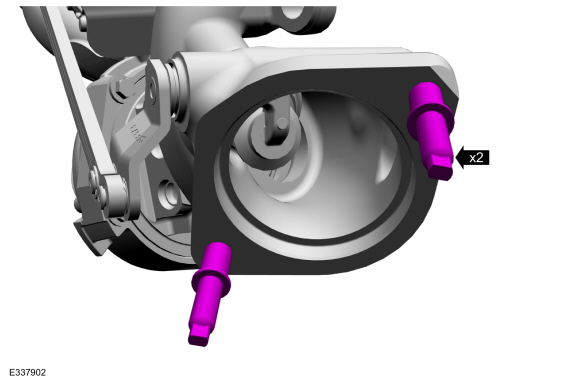

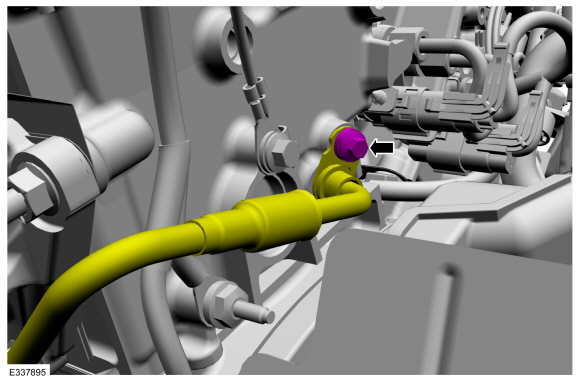

Lubricate the new O-ring seals with clean engine oil.

Refer to: Specifications (303-01 Engine - 3.5L V6 PowerBoost (CN))

.

-

-

NOTICE:

Do not use any brushes, damage to sealing area

will result in leaks and possible internal turbo bearing damage.

Use brake cleaner on a lint free rag to remove the

O-ring residue out of the turbocharger and the engine oil filter adapter

O-ring bores. Inspect the area for deep scratches and gouges. Install

new components if necessary.

-

Install the oil supply tube and the bolts, by

simultaneously fully seating the oil supply tube into the turbocharger

bore hole and the engine oil filter adapter bore hole flush to 2.5 mm

off the mounting surface prior to tightening the bolts, then tighten the

bolts in the following 2 stages.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B, APM-4-C

Torque:

Stage 1:

Tighten to :

89 lb.in (10 Nm)

Stage 2:

Tighten an additional :

30°

-

Attach the harness retainer.

-

Install the charge air cooler intake pipe - left side.

Refer to: Charge Air Cooler (CAC) Intake Pipe (303-12 Intake Air

Distribution and Filtering - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

-

Install the left front fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Install the engine rear undershield.

-

Check and top off the engine oil level as needed.

Refer to: Specifications (303-01 Engine - 3.5L V6 PowerBoost (CN))

.

-

Fill the cooling system.

Refer to: Engine Cooling System Draining, Vacuum Filling and Bleeding

(303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), General

Procedures).

-

Road test the vehicle.

Materials

Name

Specification

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C

-

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Materials

Name

Specification

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C

-

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Other information:

Removal

NOTE:

DSM (driver front seat module) shown, SCMB (front passenger seat control module) is similar.

NOTE:

Removal steps in this procedure may contain installation details.

All vehicles

NOTE:

This step is only necessary when installing a new component...

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTE:

Do not allow the steering column to rotate while the

steering column shaft is disconnected or damage to the steering column

internal sensor may result...

Turbocharger Coolant Supply Tube RH. Removal and Installation

Turbocharger Coolant Supply Tube RH. Removal and Installation Turbocharger Oil Return Tube LH. Removal and Installation

Turbocharger Oil Return Tube LH. Removal and Installation