Lincoln Navigator: Roof Sheet Metal Repairs / Roof Rear Frame. Removal and Installation

Special Tool(s) / General Equipment

| 6.5 mm Drill Bit | |

| Self-Piercing Rivet (SPR) Remover/Installer | |

| Belt Sander | |

| Blind Rivet Gun | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: Aluminum body panels are highly receptive to heat transfer. With the extensive use of structural adhesives and non-structural sealers used in vehicle construction, the potential of heat transfer could impact adhesives and sealers in non-associated panels during the repair process. Many repairs areas that utilize structural adhesive may be separated after fastener removal by using a panel chisel along the joint/flange. Using heat not exceeding 425° F to loosen a bonded panel should only be done when all panels in the joint will be replaced and new adhesive applied.

-

Remove the roof outer panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

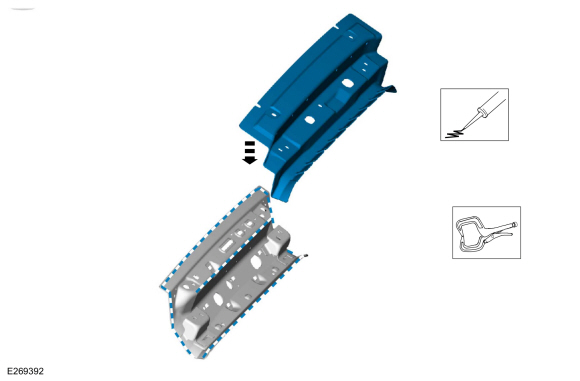

NOTE: Roof rear frame reinforcement is provided as 2 service parts (upper and lower), the following steps assume all components are to be replaced. Adjust to meet repair needs.

Assembly of the upper and lower rear frame is required when replacing entire component.-

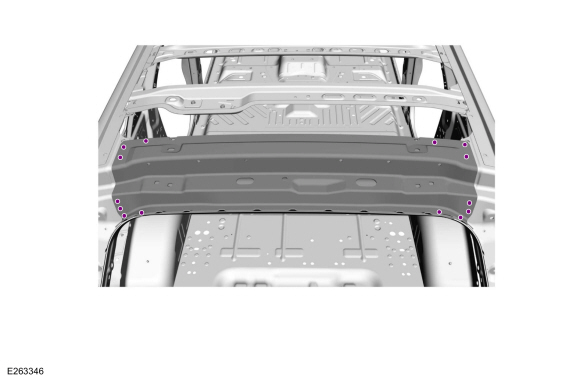

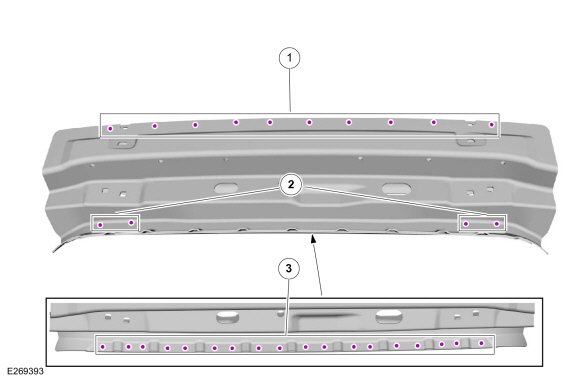

Remove the SPR fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

|

-

Remove the SPR fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

|

-

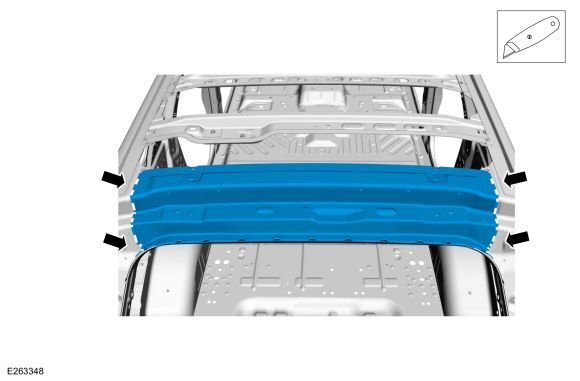

Break the adhesive bond and remove the roof rear frame.

|

Installation

-

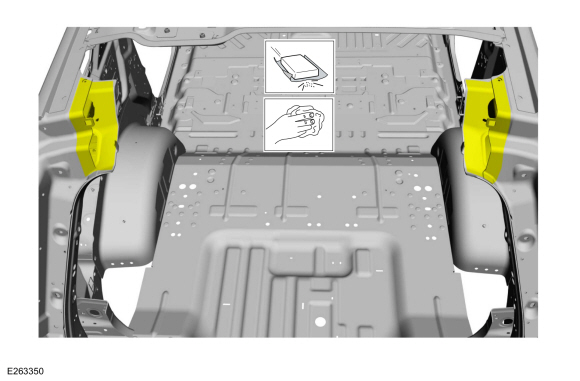

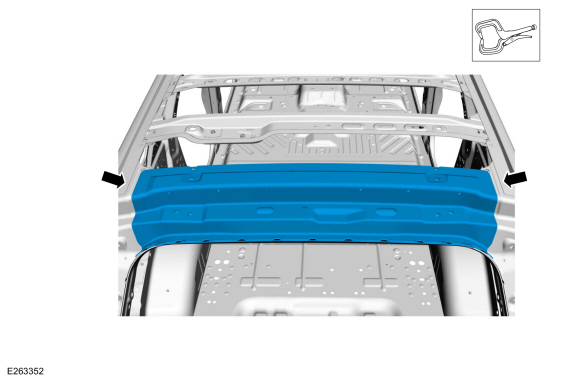

Apply adhesive to the mating surface, assemble and clamp the assembly.

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

Use the General Equipment: Locking Pliers

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

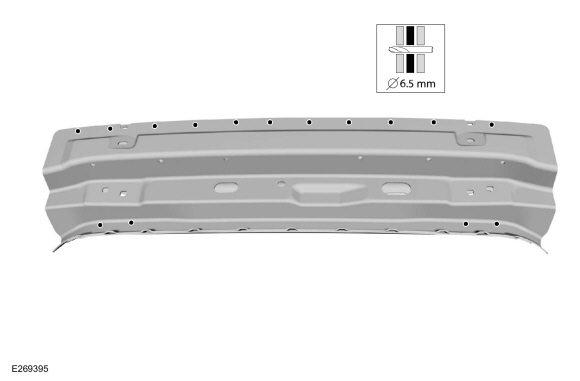

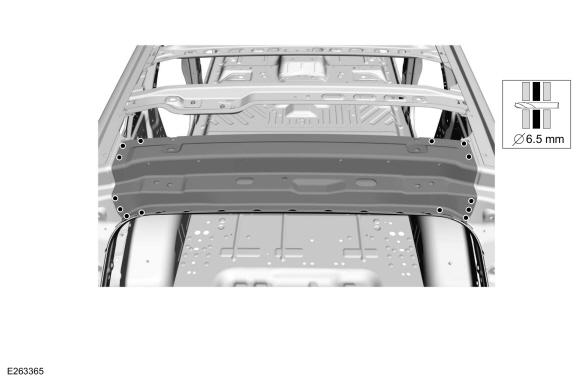

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

|

-

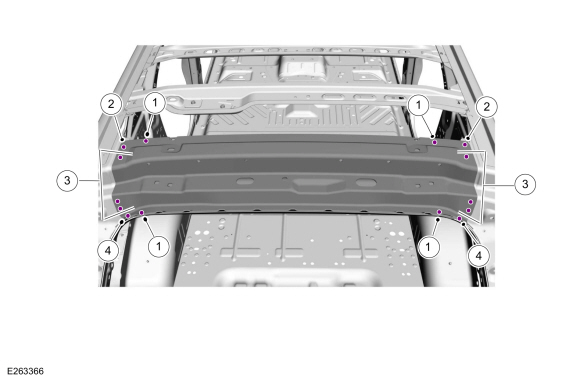

NOTE: SPR fasteners may not be placed directly over original SPR location. They must be placed adjacent to original location matching original quantity.

NOTE: Blind or solid rivets may be used in place of SPR in the original SPR location after enlarging hole to 6.5 mm.

Install fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/InstallerItem SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 - - - - W708777-S900C - - 2 W717182-S900 QE DG11-200/H SA-0400/SA-0402 - - - 3 W717186-S900 EN DG11-220/H SA-0400/SA-0402 - - -

|

-

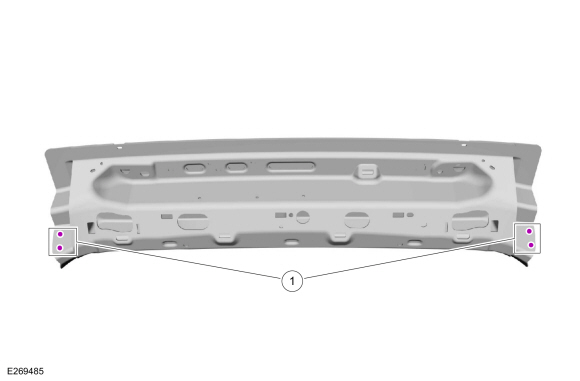

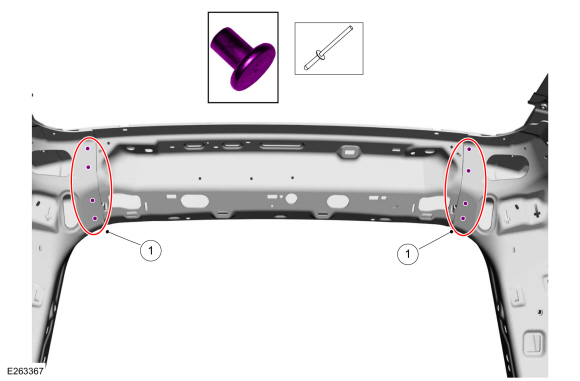

Install fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/InstallerItem SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 W717186-S900 EN DG11-220/H SA-0400/SA-0402 - W790377-S900 -

|

-

Sand using 80-120 grit sandpaper to remove all adhesive and clean.

|

-

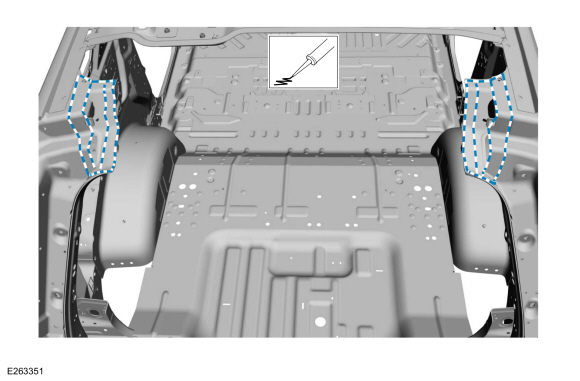

Sand the roof rear frame mating surfaces using 80 grit sandpaper to remove e-coat and clean.

|

-

Apply adhesive.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

Install the rear roof frame and clamp in position.

Use the General Equipment: Locking Pliers

|

-

Drill holes for fasteners as indicated

Use the General Equipment: 6.5 mm Drill Bit

|

-

Drill holes for fasteners as indicated

Use the General Equipment: 6.5 mm Drill Bit

|

-

NOTE: SPR fasteners may not be placed directly over original SPR location. They must be placed adjacent to original location matching original quantity.

NOTE: Blind or solid rivets may be used in place of SPR in the original SPR location after enlarging hole to 6.5 mm.

Install fasteners

Use the General Equipment: Blind Rivet GunItem SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 - - - - W708777-S900C - - 2 - - - - W708778-S900C - - 3 - - - - W708777-S900C - - 4 W717183-S900 QE DG11-200H - - - -

|

-

NOTE: SPR fasteners may not be placed directly over original SPR location. They must be placed adjacent to original location matching original quantity.

NOTE: Blind or solid rivets may be used in place of SPR in the original SPR location after enlarging hole to 6.5 mm.

Install fasteners

Use the General Equipment: Blind Rivet GunItem SPR Number SPR Code Henrob® Mandrel Pro-Spot® Mandrel Blind Rivet Solid Rivet Rivnut® 1 - - - - W708777-S900C W790377-S900 -

|

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Sand and prime the entire repair area with a Ford approved paint system.

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the roof outer panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Roof Reinforcement. Removal and Installation

Roof Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Blind Rivet Gun

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Removal

NOTE:

The following procedure details re..

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: DTC Chart and Pinpoint Tests - 3.5L EcoBoost (272kW/370PS). Diagnosis and Testing

Diagnostic Trouble Code (DTC) Chart Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Module DTC Description Action PCM P0218:00 Transmission Fluid Temperature Sensor 'A' Over Temperature Condition: No Sub Type Information ..

Lincoln Navigator 2018-2026 Workshop Manual: Defrost Vent Trim Panel. Removal and Installation

Removal Remove the A-pillar trim panels. Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation). Release the clips and remove the defroster vent trim panel. Installation To install, reverse the removal procedure. ..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Rear View Mirrors - System Operation and Component Description. Description and Operation

- Liftgate Trim Panel. Removal and Installation

- Front Bumper Cover. Removal and Installation

- Second Row Seat. Removal and Installation

- SYNC Module [APIM]. Removal and Installation

Differential Case Runout Check. General Procedures

Special Tool(s) / General Equipment

205-1016

205-1016Installer, Differential Bearing

TKIT-2014D-ROW2

TKIT-2014D-FL_ROW

205-153

(T80T-4000-W)

205-153

(T80T-4000-W)

Handle

205-D061

(D83T-4205-C2)

205-D061

(D83T-4205-C2)

Step Plate Dial Indicator Three Leg Puller Punch