Lincoln Navigator: Rear End Sheet Metal Repairs / Rear Wheelhouse. Removal and Installation

Special Tool(s) /

General Equipment

| 6.5 mm Drill Bit |

| Spherical Cutter |

| Self-Piercing Rivet (SPR) Remover/Installer |

| Belt Sander |

| Blind Rivet Gun |

| Air Body Saw |

| MIG/MAG Welding Equipment |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

Removal

NOTICE:

Bodyside sectioning is prohibited within 50 mm of door hinge, door striker and restraints anchoring points.

NOTE:

The wheelhouse outer panel may be sectioned for repair using

a backer plate, adhesive and blind rivets. The following steps assume

full component replacement. Adjust to meet repair needs.

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

LH side shown, RH side similar.

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

LH side shown, RH side shown.

-

Remove the liftgate.

Refer to: Liftgate (501-03 Body Closures, Removal and Installation).

-

Remove the C-pillar trim panel.

Refer to: C-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the loadspace interior trim.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the wheel and tire on the affected side.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

Remove the quarter panel.

Refer to: Quarter Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Remove the wheel opening splash shield.

-

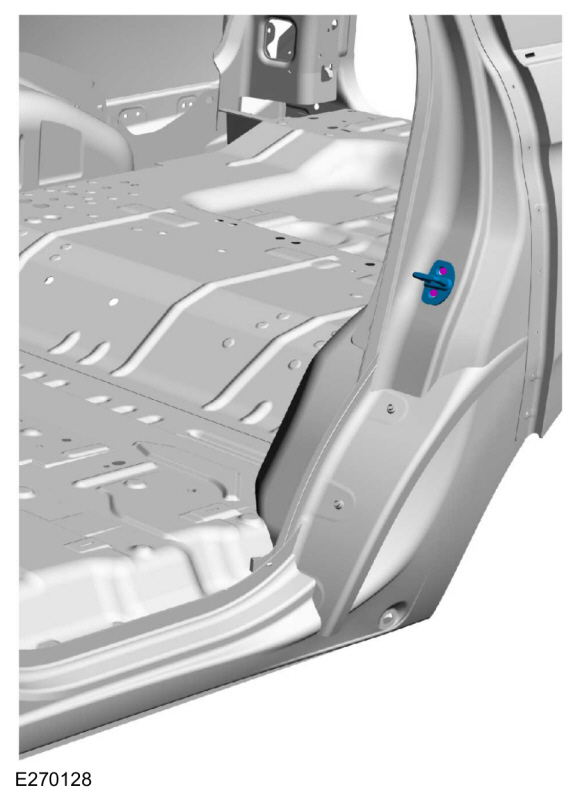

Remove the rear door striker.

-

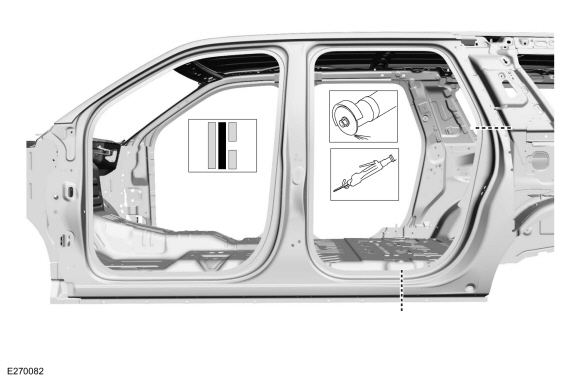

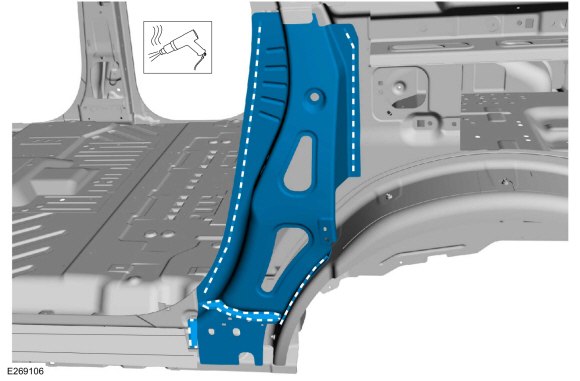

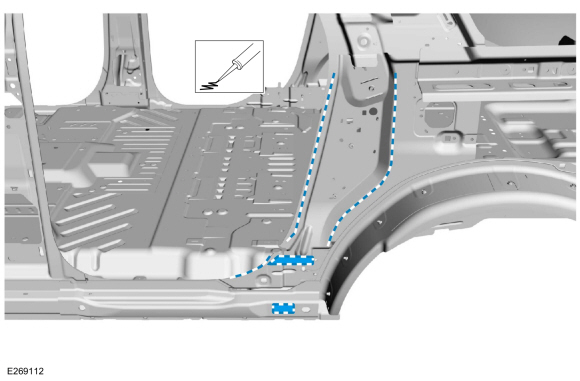

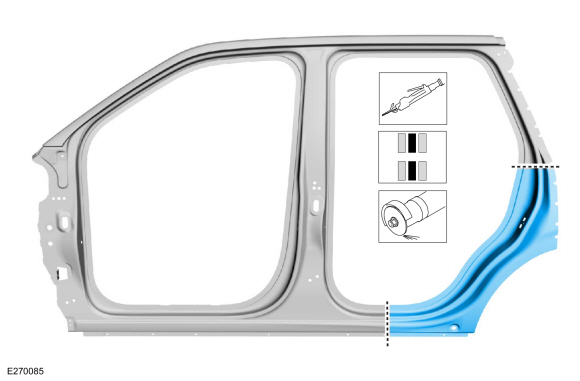

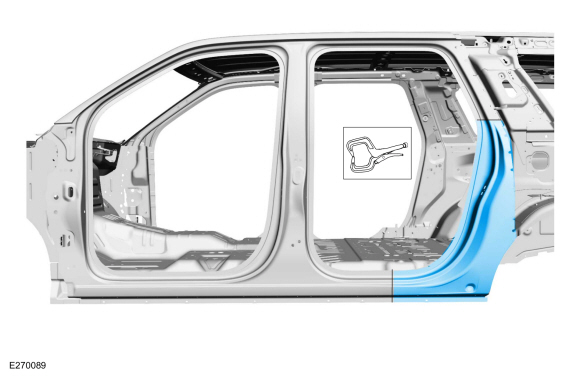

Cut section of the rear dear opening panel outer layer only as indicated.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

-

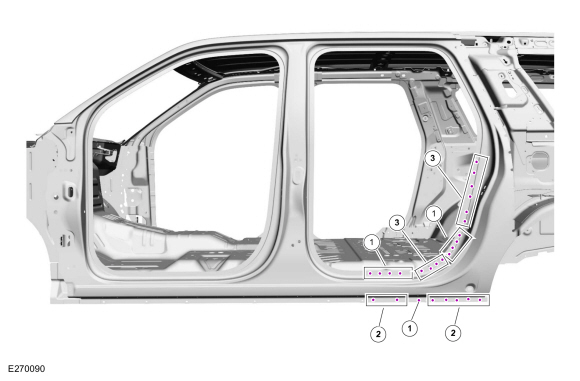

Remove the rivet fasteners from the rear door opening panel.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Break the adhesive bond, remove the wheel opening flange material and remove the door opening panel section.

Use the General Equipment: Spherical Cutter

-

Position aside the roof opening panel water drain tube, if equipped.

-

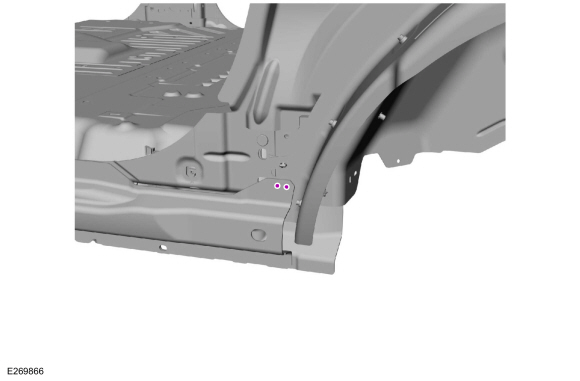

Remove the C-pillar lower reinforcement fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

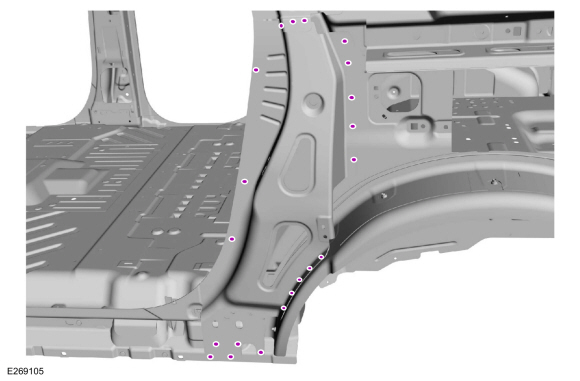

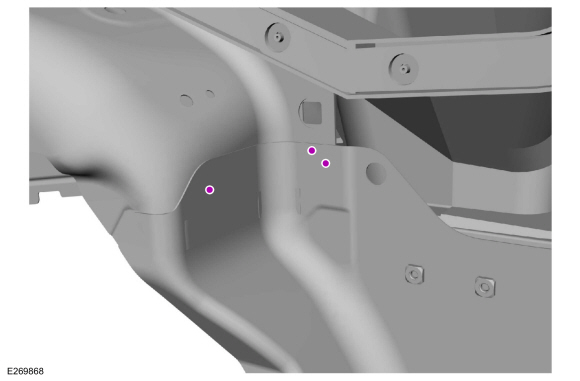

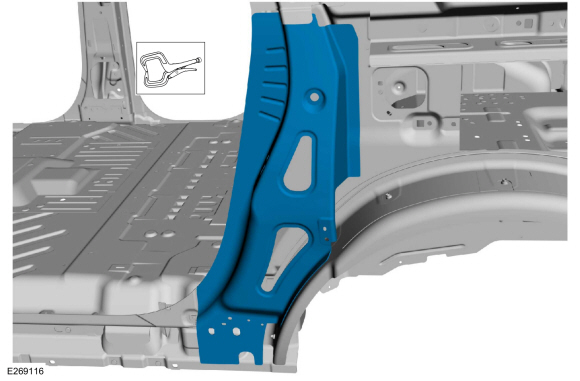

NOTE:

Long wheelbase (LWB) shown, short wheelbase (SWB) similar.

Note NVH foam locations when removing panel.

Break the adhesive bond and remove the C-pillar lower reinforcement.

-

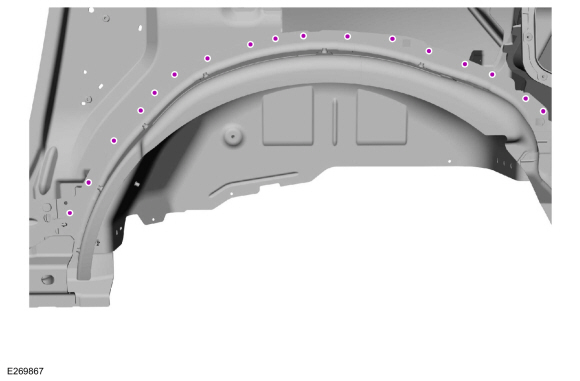

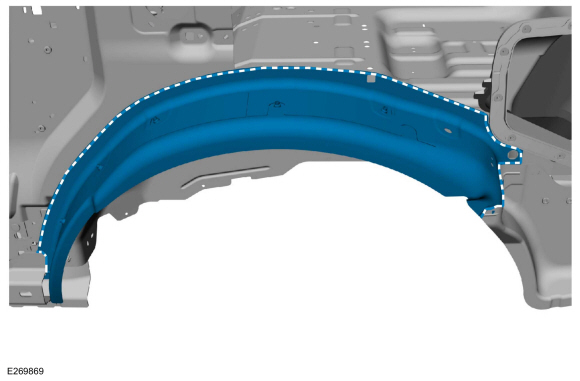

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

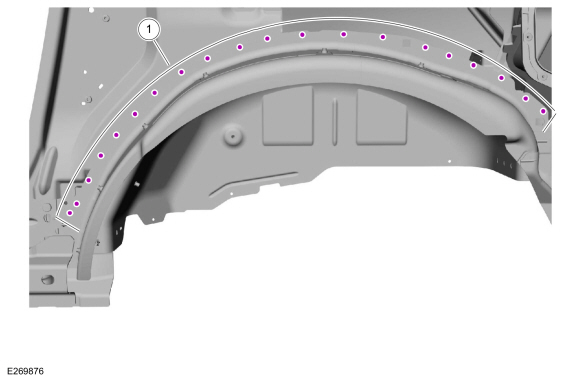

Remove the upper flange fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Break the adhesive and sealer bond and remove the outer wheelhouse panel.

Installation

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

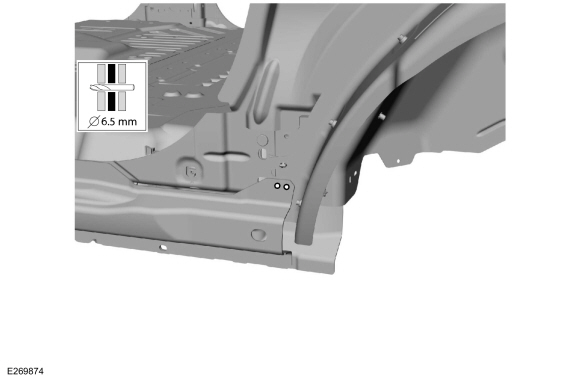

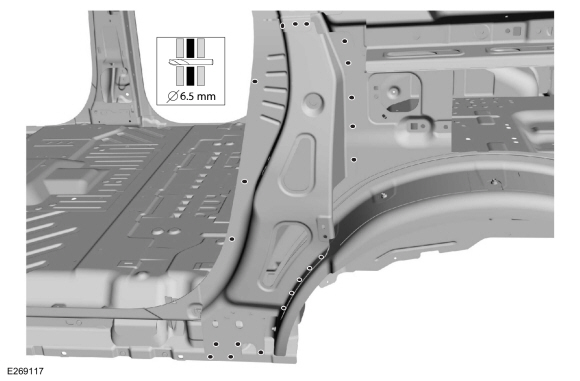

Blind or solid rivet fasteners may be used in place of SPR fasteners after enlarging holes to 6.5 mm.

-

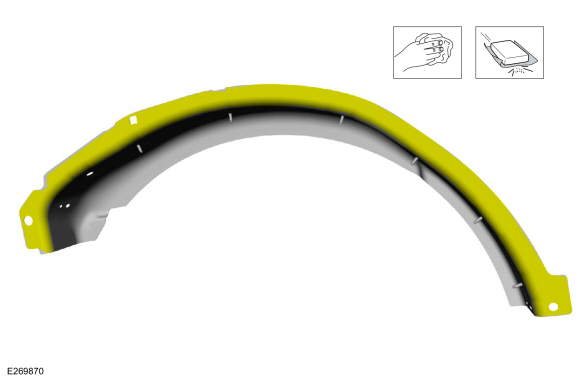

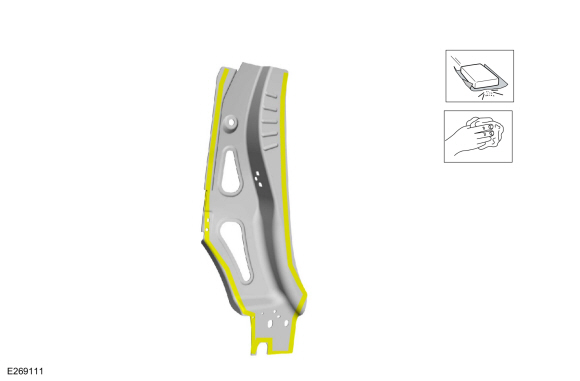

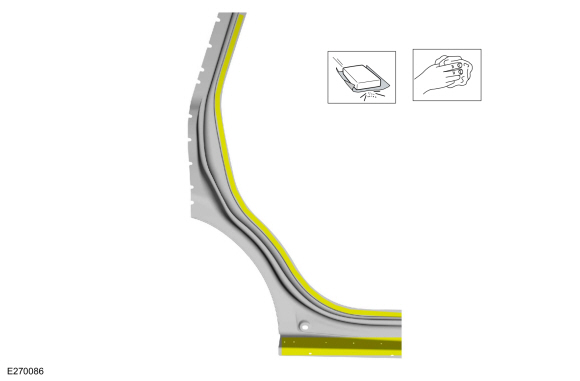

Sand to remove e-coating using 80-120 grit sandpaper on the replacement panel.

-

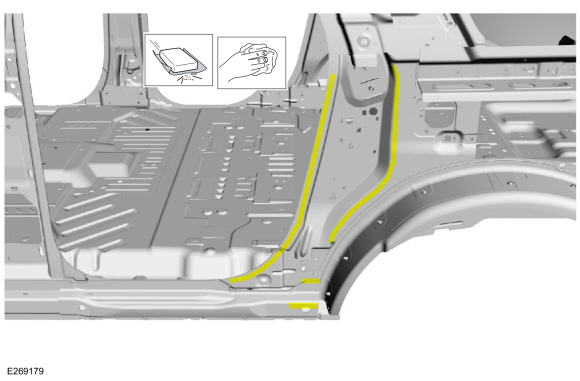

Sand inner wheelhouse mating surface using 80-120 grit sandpaper.

-

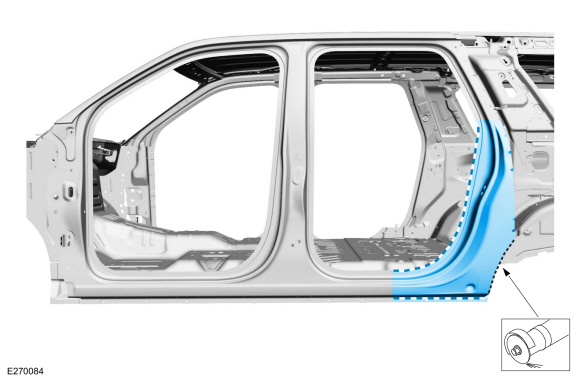

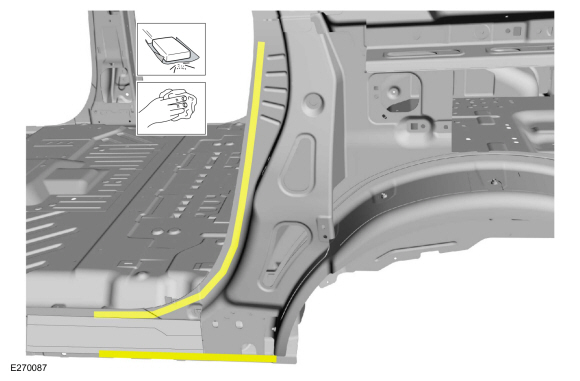

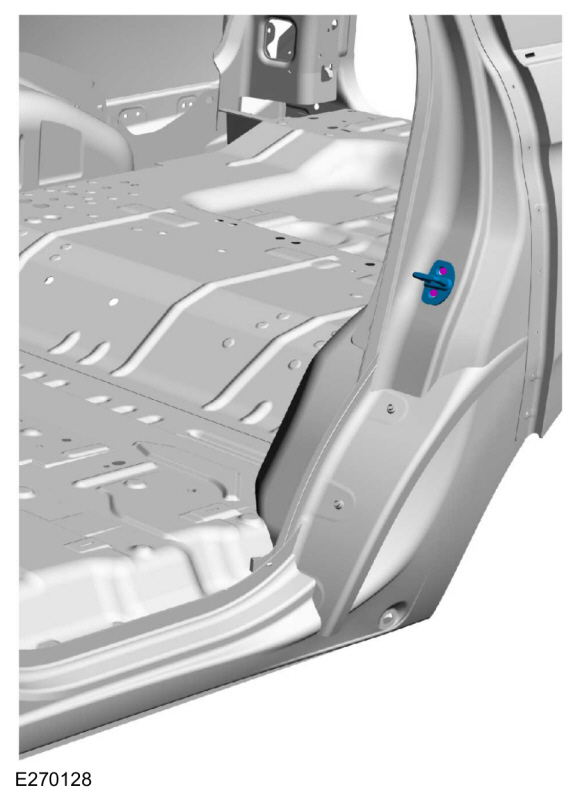

Apply adhesive and NVH foam as indicated.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

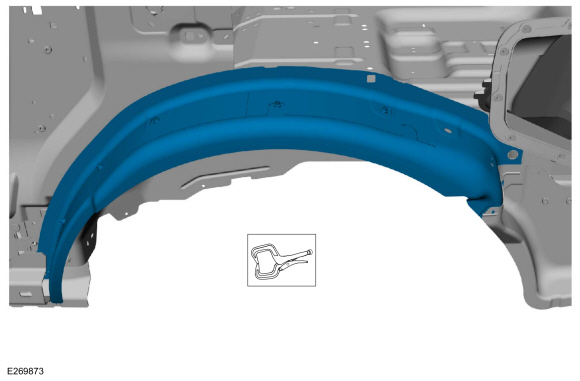

Install and clamp the wheelhouse panel in position.

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

Use the General Equipment: Locking Pliers

-

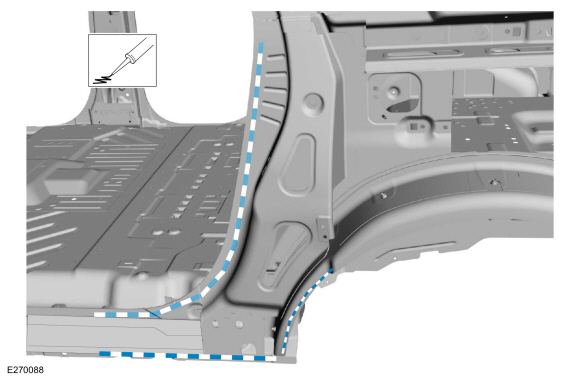

Drill for rivets.

Use the General Equipment: 6.5 mm Drill Bit

-

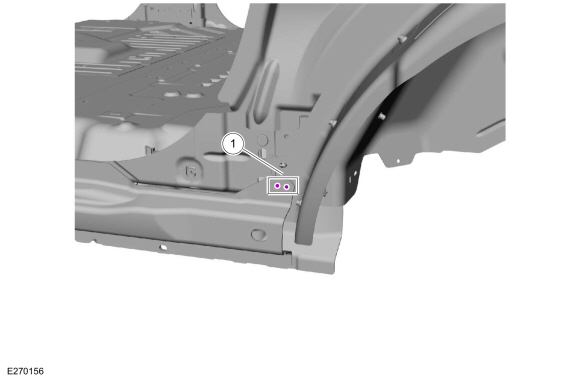

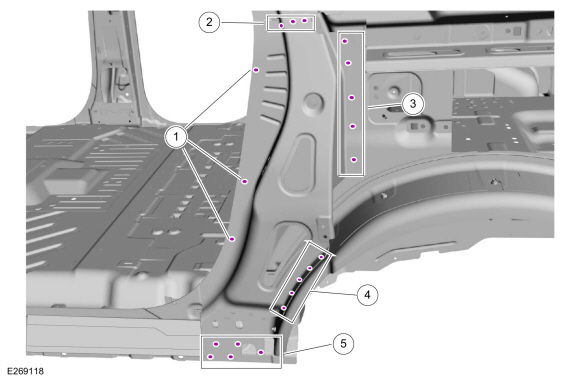

Install blind rivet fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Install rivet fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W702554-S900C

|

-

|

-

|

-

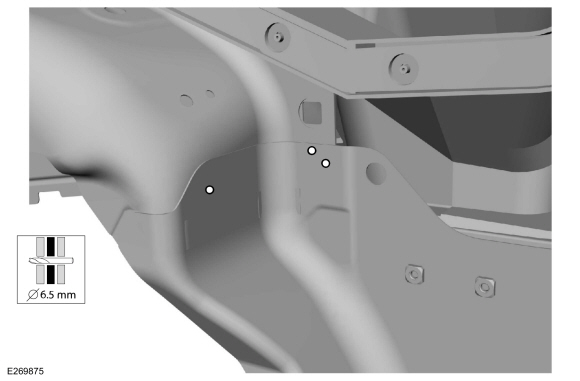

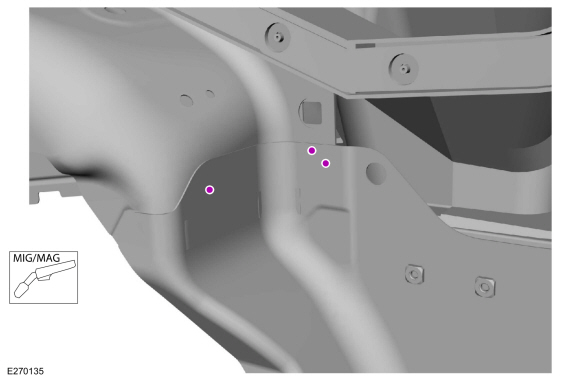

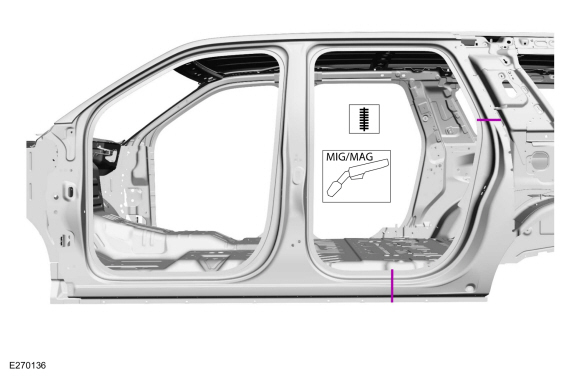

Drill for MIG plug welds.

Use the General Equipment: 6.5 mm Drill Bit

-

Install MIG plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

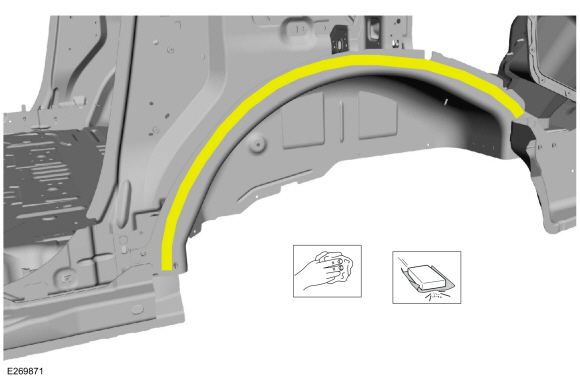

Sand and clean the mating surface using 80-120 grit sandpaper.

-

Sand and clean the mating surface using 80-120 grit sandpaper.

-

Apply adhesive and NVH foam as indicated.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install and clamp the C-pillar lower reinforcement panel.

Use the General Equipment: Locking Pliers

-

Drill for blind rivet fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

NOTE:

SPR fasteners may be replaced with solid rivets or blind rivet fasteners after enlarging hole to 6.5 mm.

NOTE:

SPR

fasteners may not be placed directly over original location. They must

equal original quantity and be placed adjacent to original location.

Install rivet fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

W712218-S900

|

DB

|

DZ09-025/H

|

SA-0400/SA-0401

|

W702512-S900C

|

W790376-S900

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

3

|

-

|

-

|

-

|

-

|

W702512-S900C

|

-

|

-

|

|

4

|

-

|

-

|

|

-

|

W707638-S900C

|

-

|

-

|

|

5

|

-

|

-

|

-

|

-

|

W08777-S900C

|

-

|

-

|

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

-

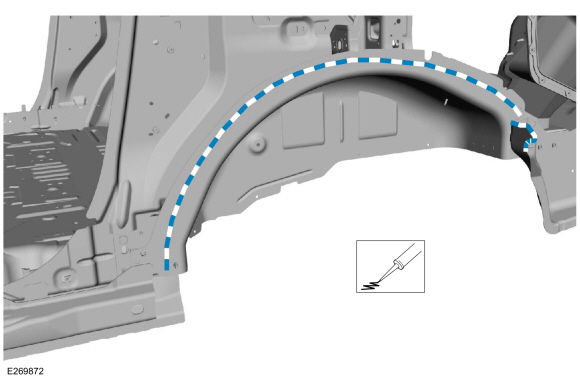

Cut section from the service panel to fit repair.

Use the General Equipment: Spherical Cutter

Use the General Equipment: Air Body Saw

-

Sand to remove e-coating on flanges of replacement section.

-

Sand to remove old adhesive on mating surfaces.

-

Apply adhesive and NVH foam to mating surfaces as indicated.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

NOTE:

The use of a backer plate when creating butt weld joints will produce a stronger and more uniform repair.

In butt-weld areas: Create a backer plate

from an unused portion of the old body panel or service replacement

panel and install on the vehicle at each sectioning joint.

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

-

Install and clamp the door opening panel section in position.

Use the General Equipment: Locking Pliers

-

NOTE:

SPR fasteners may be replaced with solid rivets or blind rivet fasteners after enlarging hole to 6.5 mm.

NOTE:

SPR

fasteners may not be placed directly over original location. They must

equal original quantity and be placed adjacent to original location.

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

W708713-S900

|

AS

|

DZ09-025/H

|

SA-0400/SA-0401

|

-

|

W790376-S900

|

-

|

|

2

|

W717184-S900

|

QA

|

DP10-200/H

|

SA-0400/SA-0402

|

-

|

W790377-S900

|

-

|

|

3

|

W717186-S900

|

EN

|

DP11-200/H

|

SA-0400/SA-0402

|

-

|

W790377-S900

|

-

|

-

Seam weld the sectioning joints.

Use the General Equipment: MIG/MAG Welding Equipment

-

Metal finish the repair using typical aluminum metal finishing techniques and a fiber-based body filler.

Refer to: Special Repair Considerations for Aluminum Repairs (501-25

Body Repairs - General Information, Description and Operation).

-

Seam Sealing:

All areas must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair area using a Ford approved paint system and typical refinishing techniques.

-

Install the quarter panel.

Refer to: Quarter Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Install the wheel opening splash shield.

-

Install the C-pillar trim panel.

Refer to: C-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Install the loadspace interior trim.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Install the wheel and tire on the affected side.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

Install the rear door striker.

Torque:

Striker :

18 lb.ft (25 Nm)

-

Install the rear door scuff plate and door opening weather strip.

-

Install the liftgate and align as necessary.

Refer to: Liftgate (501-03 Body Closures, Removal and Installation).

Refer to: Liftgate Alignment (501-03 Body Closures, General Procedures).

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Blind Rivet Gun

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-..

Other information:

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Module

DTC

Description

Action

PCM

P00FE:00

EVAP System Tank Vapor Line Restricted/Blocked: No Sub Type Information

GO to Pinpoint Test H..

Removal

NOTE:

Double seat shown, single seat similar.

Remove the third row seat.

Refer to: Third Row Seat (501-10C Third Row Seats, Removal and Installation).

Remove the child safety seat tether anchor bezels.

Release the third row double seat backrest cover the J-clip.

Unzip th..

Water Drain Panel. Removal and Installation

Water Drain Panel. Removal and Installation