Lincoln Navigator: Rear End Sheet Metal Repairs / Rear Lamp Mounting Panel. Removal and Installation

Special Tool(s) /

General Equipment

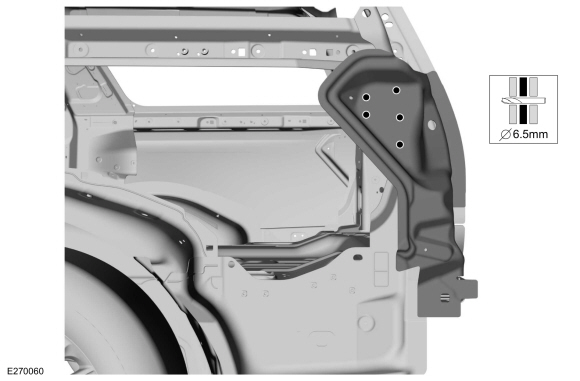

| 6.5 mm Drill Bit |

| Polydrive Bit Socket |

| Self-Piercing Rivet (SPR) Remover/Installer |

| Belt Sander |

| Blind Rivet Gun |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

Removal

NOTE:

Pay particular attention to location of NVH sealers and adhesives during removal to aid in installation.

NOTE:

Aluminum body panels are highly receptive to heat transfer.

With the extensive use of structural adhesives and non-structural

sealers used in vehicle construction, the potential of heat transfer

could impact adhesives and sealers in non-associated panels during the

repair process. Many repairs areas that utilize structural adhesive may

be separated after fastener removal by using a panel chisel along the

joint/flange. Using heat not exceeding 425° F to loosen a bonded panel

should only be done when all panels in the joint will be replaced and

new adhesive applied.

NOTE:

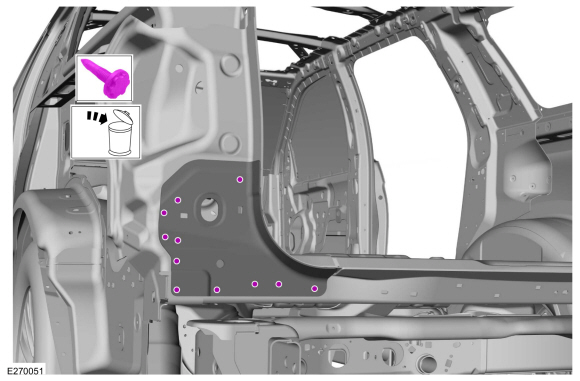

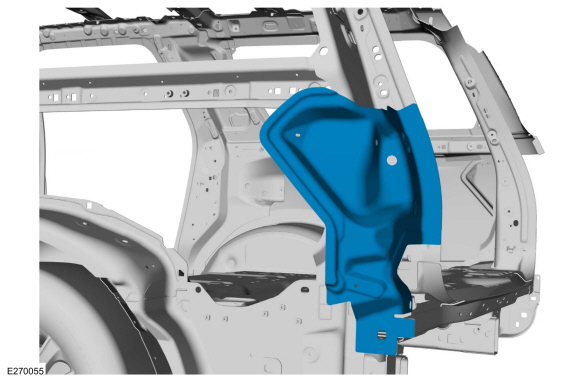

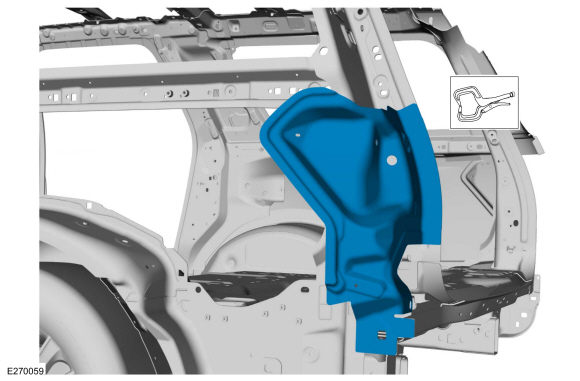

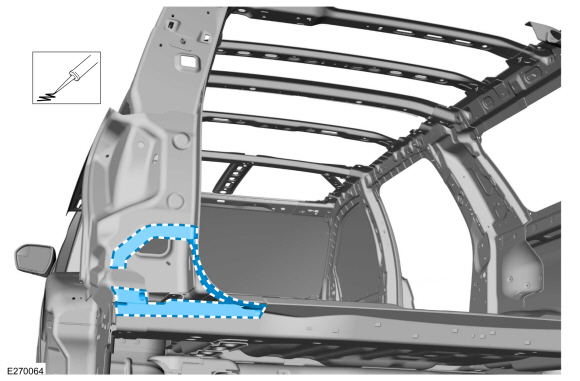

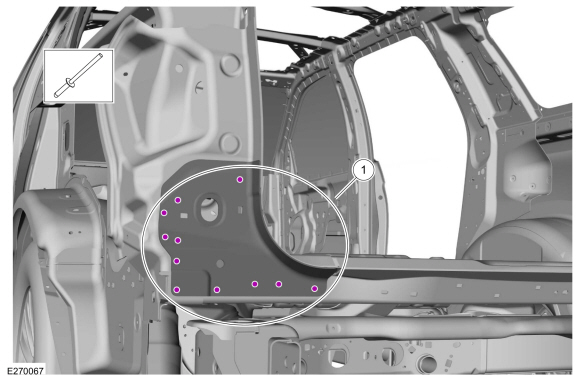

LH side shown, RH side similar.

-

Remove the drain panel.

Refer to: Water Drain Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

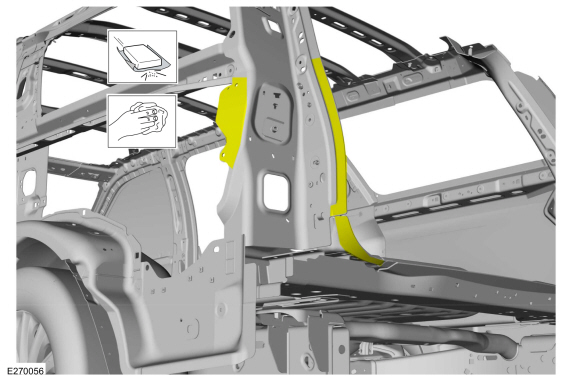

Remove and discard the FDS fasteners.

Use the General Equipment: Polydrive Bit Socket

-

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Remove the closeout panel.

-

Remove the fasteners.

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Belt Sander

-

Remove the lamp panel.

Installation

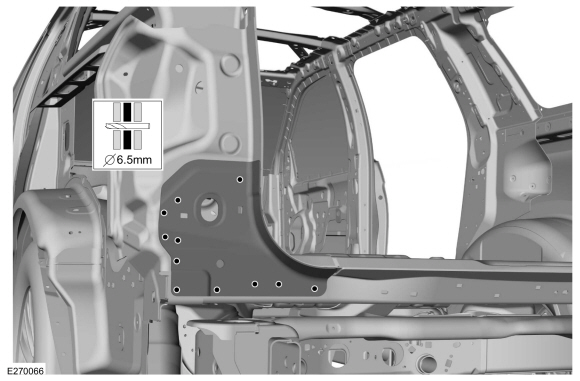

NOTE:

SPR fasteners may not be placed directly over original SPR location.

They must be placed adjacent to original location matching original

quantity.

NOTE:

Blind or solid rivet fasteners may be used in place of SPR fasteners

after enlarging holes to 6.5 mm. Blind or sold rivets must equal

original fasteners in both location and quantity.

-

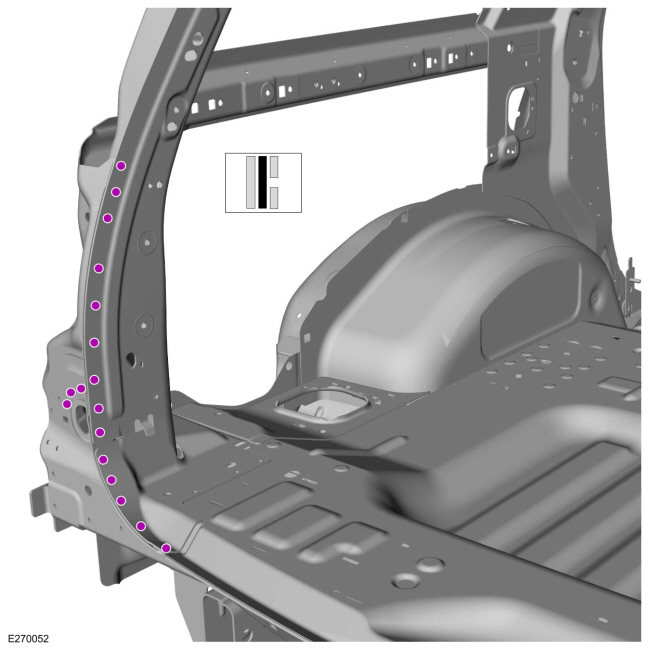

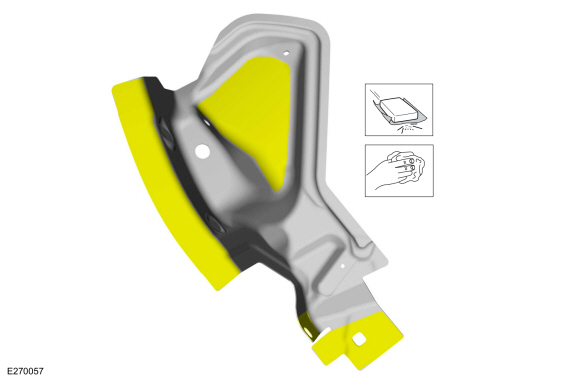

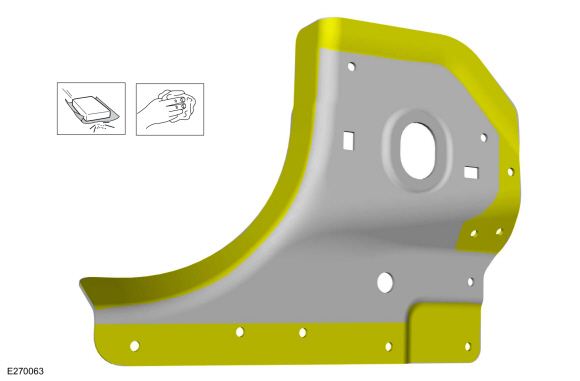

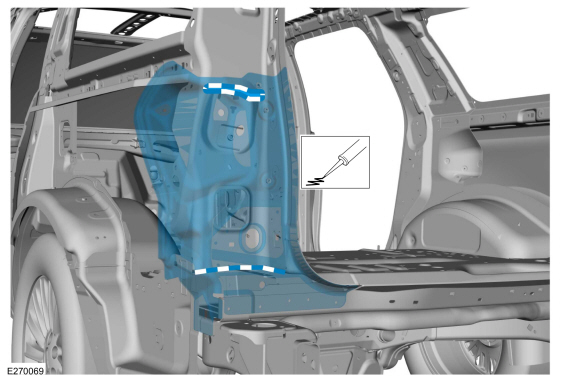

80-120 grit sandpaper.

Sand to remove old adhesive and sealer and clean.

-

80-120 grit sandpaper.

Sand to remove e-coat and clean.

-

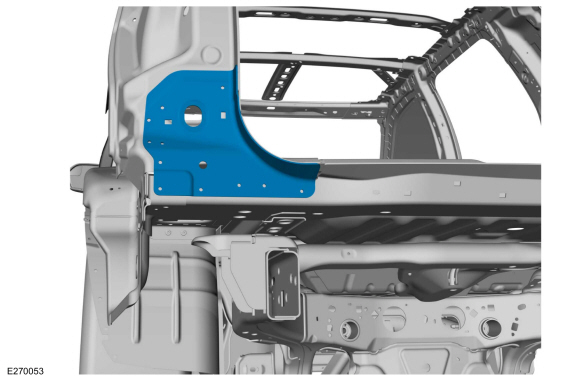

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

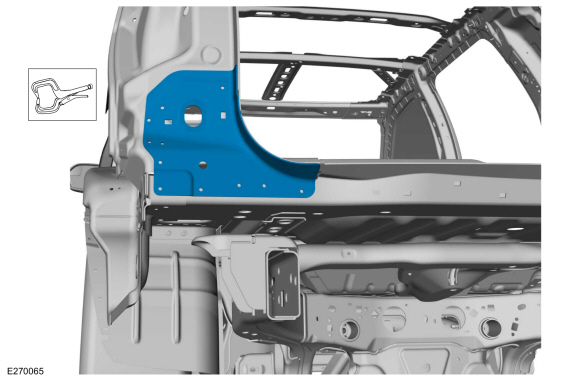

Install, properly position and clamp.

Use the General Equipment: Locking Pliers

-

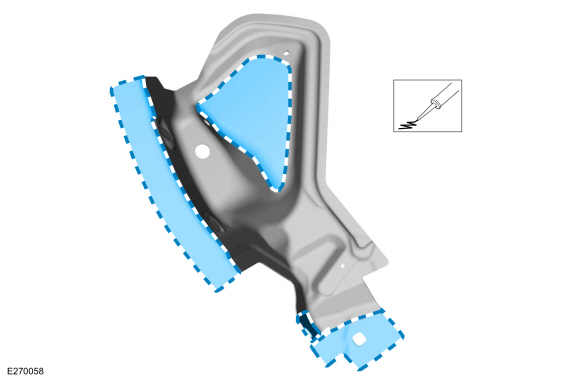

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

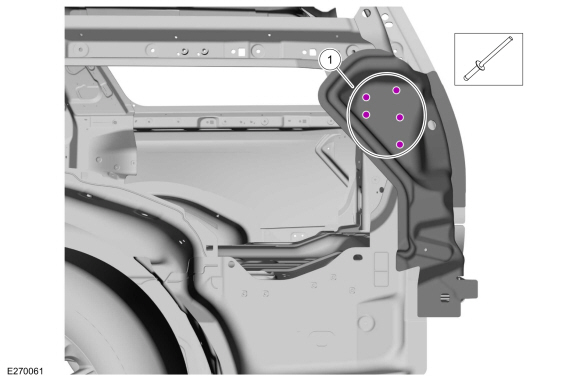

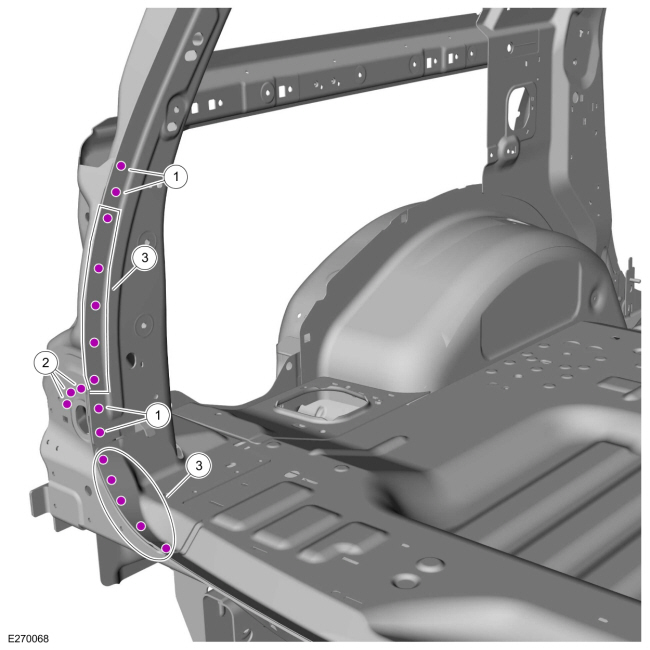

Install fasteners.

|

Item

|

SPR Number

|

SPR code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

80-120 grit sandpaper.

Sand to remove old adhesive and e-coat and clean.

-

80-120 grit sandpaper.

Sand to remove e-coat and clean.

-

Apply adhesive.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Install, properly position and clamp.

Use the General Equipment: Locking Pliers

-

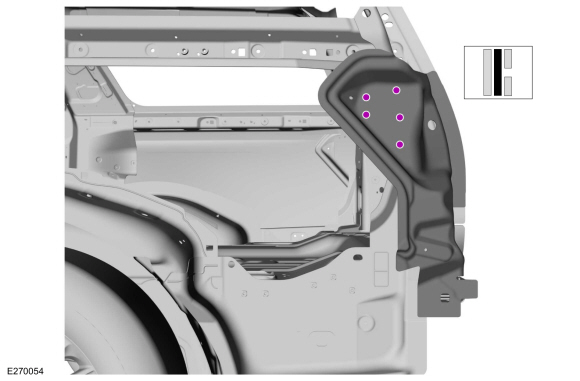

Drill for fasteners.

Use the General Equipment: 6.5 mm Drill Bit

-

Install fasteners.

|

Item

|

SPR Number

|

SPR Code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

Use the General Equipment: Blind Rivet Gun

-

Install fasteners.

|

Item

|

SPR Number

|

SPR code

|

Henrob®, Car-O-Liner ®, CMO®, Chief®, Spanesi®, Wielander and Schill® Mandrel

|

Pro-Spot® Mandrel

|

Blind Rivet

|

Solid Rivet

|

Rivnut®

|

|

1

|

W717182-S900

|

QC

|

DP10-200/H

|

SA-0400/SA-0402

|

-

|

W708777-S900

|

-

|

|

2

|

-

|

-

|

-

|

-

|

W708777-S900C

|

-

|

-

|

|

3

|

W712218-S900

|

DB

|

DP09-025/H

|

SA-0400/SA-0401

|

-

|

W708776-S900

|

-

|

Use the General Equipment: Self-Piercing Rivet (SPR) Remover/Installer

Use the General Equipment: Blind Rivet Gun

-

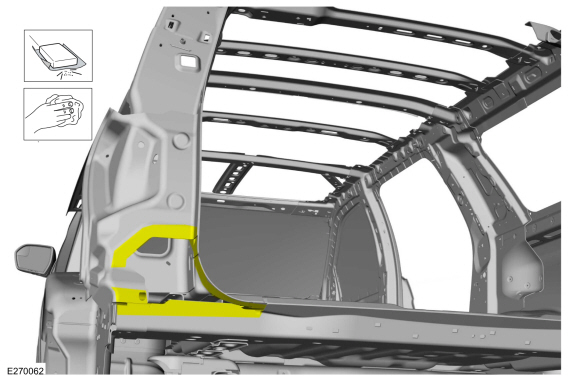

Install NVH foam in areas noted during removal.

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install the drain panel.

Refer to: Water Drain Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Spherical Cutter

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Blind Rivet Gun

Air Body Saw

MIG/MAG Welding Equipment

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5..

Other information:

Special Tool(s) /

General Equipment

6.5 mm Drill Bit

Polydrive Bit Socket

Rivet Gun

Self-Piercing Rivet (SPR) Remover/Installer

Belt Sander

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, 3M™ 08308, ..

Special Tool(s) /

General Equipment

204-594Forcing screw

307-549Installer, Shift Shaft Fluid SealTKIT-2005D1-F1

307-648Remover/Installer, Rear BearingTKIT-2009C-FTKIT-2009C-ROW

307-738Installer, R2 Bearing

307-739Installer, R3 Bearing

307-740Installer, Dog Bone

307-745Installer, Park Sleeve Roll Pin

..

Rear Wheelhouse. Removal and Installation

Rear Wheelhouse. Removal and Installation