Lincoln Navigator: Electronic Engine Controls - 3.5L EcoBoost (272kW/370PS) / Powertrain Control Module (PCM). Removal and Installation

Lincoln Navigator 2018-2026 Workshop Manual / Engine / Electronic Engine Controls - 3.5L EcoBoost (272kW/370PS) / Powertrain Control Module (PCM). Removal and Installation

Special Tool(s) / General Equipment

| Ford Diagnostic Equipment |

Removal

-

NOTE: Removal steps in this procedure may contain installation details.

If installing a new PCM , connect a battery charger to the battery to make sure it is charged to maintain proper battery voltage.

Refer to: Battery Charging (414-01 Battery, Mounting and Cables, General Procedures).

-

NOTE: This step is only necessary when installing a new component.

Download the module information to the diagnostic tool using the Programmable Modules Installation routine.

Refer to: Module Configuration - System Operation and Component Description (418-01A Module Configuration, Description and Operation).

Use the General Equipment: Ford Diagnostic Equipment

-

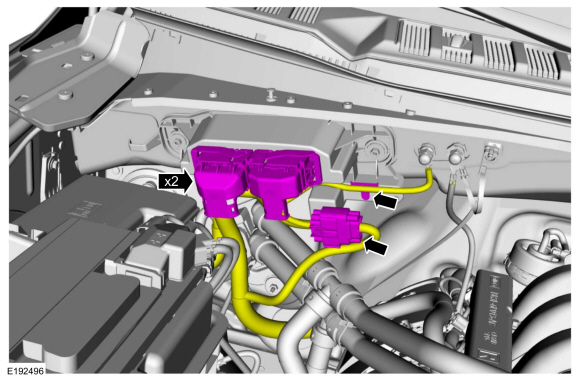

Disconnect the PCM electrical connectors, release the harness retainers to position aside wire harness.

|

-

-

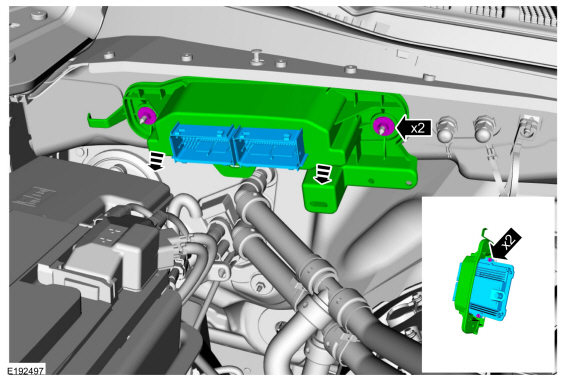

Remove the 2 retainers and the PCM .

Torque: 80 lb.in (9 Nm)

-

Remove the retainers and remove the PCM from the mounting frame.

Torque: 62 lb.in (7 Nm)

-

Remove the 2 retainers and the PCM .

|

Installation

-

To install, reverse the removal procedure.

-

NOTE: This step is only necessary when installing a new component.

Upload the module information from the diagnostic tool using the Programmable Modules Installation routine.

Refer to: Module Programming (418-01A Module Configuration, General Procedures).

-

NOTE: This step is only necessary when installing a new component.

Carry out the Parameter Reset procedure.

Refer to: Anti-Theft Key Programming - Scan Tool (419-01B Passive Anti-Theft System (PATS), General Procedures).

-

NOTE: This step is only necessary when installing a new component.

Using the scan tool, perform the Misfire Monitor Neutral Profile Correction procedure, following the on-screen instructions.

Oil Pressure Control Solenoid. Removal and Installation

Oil Pressure Control Solenoid. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the engine front cover.

Refer to: Engine Front Cover (303-01 Engine - 3...

Turbocharger Boost Pressure (TCBP) and Charger Air Cooler Temperature (CACT) Sensor. Removal and Installation

Turbocharger Boost Pressure (TCBP) and Charger Air Cooler Temperature (CACT) Sensor. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTE:

Lubricate the O ring with clean engine oil...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Body Control Module C (BCMC). Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: If the BCMC (body control module C) did not respond to the diagnostic scan tool, As-Built Data may need to be entered as part of the repair...

Lincoln Navigator 2018-2026 Workshop Manual: Rear Door Weatherstrip. Removal and Installation

Special Tool(s) / General Equipment Interior Trim Remover Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: LH side shown RH side similar. Open the rear door. Remove the check arm bolt...

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Telematics Control Unit (TCU) Module. Removal and Installation

- Transmission Fluid Level Check. General Procedures

- Body and Paint

- Windshield Washer Pump. Removal and Installation

- Rear Bumper. Removal and Installation

Axle Tube Bearing. Removal and Installation

Special Tool(s) / General Equipment

205-123

(T78P-1177-A)

205-123

(T78P-1177-A)

Installer, Axle Shaft Oil Seal

308-047

(T77F-1102-A)

308-047

(T77F-1102-A)

Remover, Bearing Cup Slide Hammer

Copyright © 2026 www.linavigator4.com