Lincoln Navigator: Front Suspension - LHD 4WD / Front Wheel Bearing and Wheel Hub. Removal and Installation

Special Tool(s) / General Equipment

| Puller |

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

-

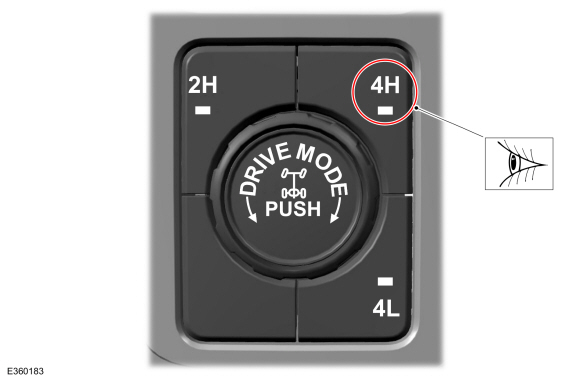

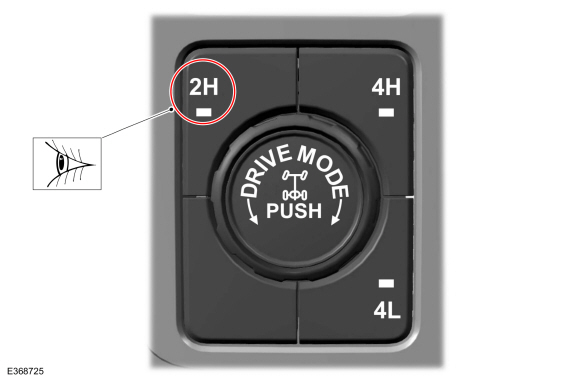

Select 4H on the ATCM .

|

-

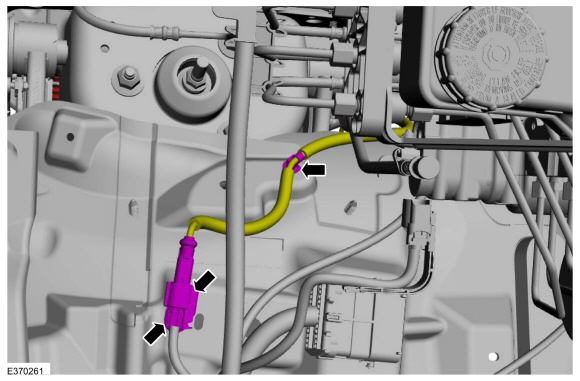

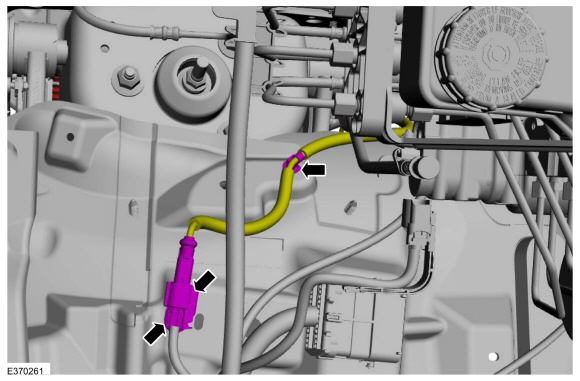

NOTE: The wheel speed sensor electrical connector is located in the engine compartment secured to the fender apron.

Disconnect the wheel speed sensor electrical connector and detach the harness retainer.

|

-

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

-

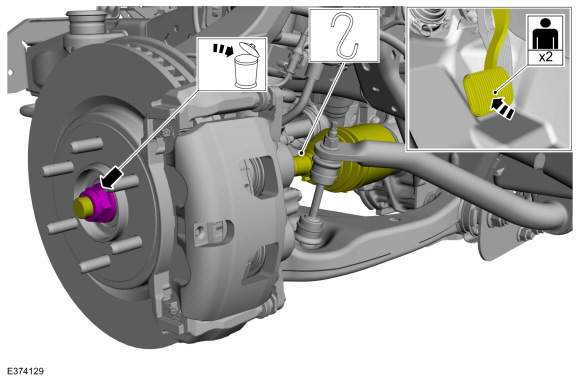

NOTE: This step requires the aid of another technician.

NOTE: Apply the brake to prevent the halfshaft from rotating while loosening the wheel hub nut.

Remove and discard the wheel hub nut.

-

Using a general equipment, push the halfshaft into the wheel hub.

Use the General Equipment: Puller

-

Support the halfshaft assembly using mechanic's wire.

-

|

-

Remove the brake disc shield.

Refer to: Brake Disc Shield (206-03 Front Disc Brake, Removal and Installation).

-

-

Remove the wheel speed sensor wire bracket bolt.

-

Remove the wheel speed sensor wire bracket bolt on

the wheel knuckle and position aside the wheel speed sensor wire.

-

Remove the wheel speed sensor wire bracket bolt.

|

-

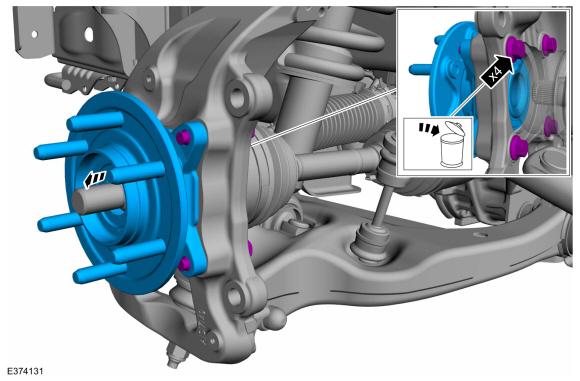

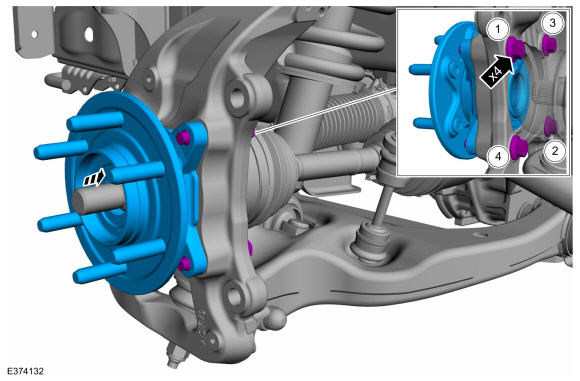

Remove and discard the 4 front wheel bearing and wheel

hub bolts and remove the front wheel bearing and wheel hub.

|

Installation

NOTICE: Tighten the suspension fasteners with the weight of the vehicle on the wheels and tires or use a suitable jack to raise the suspension to curb height or damage to the bushings may occur.

-

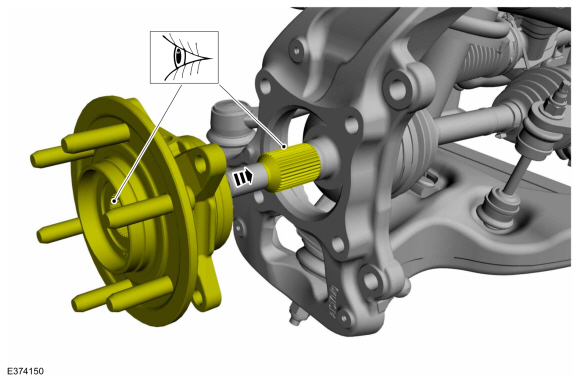

Align the wheel hub splines to the front halfshaft splines to verify spline engagement.

|

-

NOTICE: If the original wheel bearing and wheel hub is being installed, install a new wheel hub O-ring seal or damage to the wheel bearing may occur.

NOTE: Tighten the bolts in a cross pattern.

Position the front wheel bearing and wheel hub and install the 4 new front wheel bearing and wheel hub bolts.

Torque: 129 lb.ft (175 Nm)

|

-

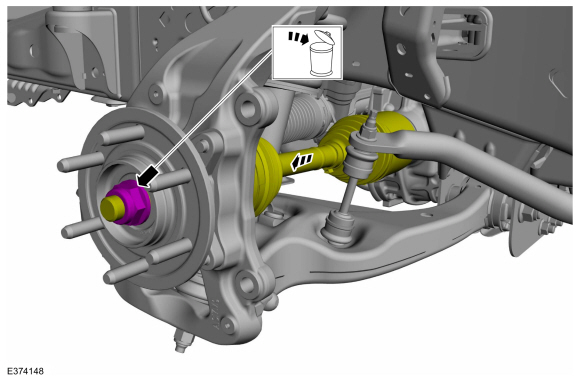

With old hub nut pull the halfshaft into the hub.

|

-

-

Position the wheel speed sensor wire and install the wheel speed sensor wire bracket bolt.

Torque: 106 lb.in (12 Nm)

-

Install the wheel speed sensor wire bracket bolt on the wheel knuckle.

Torque: 18 lb.ft (25 Nm)

-

Position the wheel speed sensor wire and install the wheel speed sensor wire bracket bolt.

|

-

Install the brake disc shield.

Refer to: Brake Disc Shield (206-03 Front Disc Brake, Removal and Installation).

-

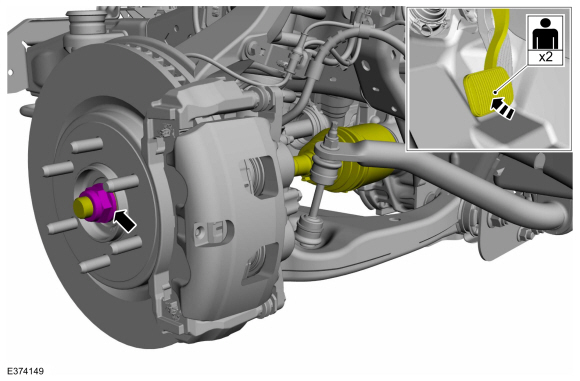

NOTICE: Install and tighten the new wheel hub nut to specification in a continuous rotation. Always install a new wheel hub nut after loosening or when not tightened to specification in a continuous rotation or damage to the components may occur.

NOTE: Apply the brake to keep the halfshaft from rotating.

While an assistant applies the brake, install the new wheel hub nut.

Torque: 184 lb.ft (250 Nm)

|

-

Install the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

NOTE: The wheel speed sensor electrical connector is located in the engine compartment secured to the fender apron.

Connect the wheel speed sensor electrical connector and the harness retainer.

|

-

Select 2H on the ATCM .

|

Front Stabilizer Bar Link. Removal and Installation

Front Stabilizer Bar Link. Removal and Installation

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems. Failure of these fasteners

may result in major service expense...

Lower Arm. Removal and Installation

Lower Arm. Removal and Installation

Special Tool(s) /

General Equipment

204-592Separator, Lower Arm Ball JointTKIT-2006C-FFMFLMTKIT-2006C-LMTKIT-2006C-ROW

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Rocker Arm. Removal and Installation

Special Tool(s) / General Equipment 303-1633Remover, Roller Rocker FollowerTKIT-2014D-ROW3TKIT-2014D-FL_ROW 303-1633-01Remover, Roller Rocker Follower Removal NOTE: This procedure should be used when removing and replacing the clipped roller finger follower or hydraulic lash adjuster and the camshafts are not removed...

Lincoln Navigator 2018-2026 Workshop Manual: Diagnosis By Symptom. Diagnosis and Testing

Global Customer Symptom Code (GCSC) Chart Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Symptom Action Start/Run/Move > Moving > Shift Lever (Manual) > Sticks/Binds GO to Pinpoint Test N Start/Run/Move &g..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Body and Paint

- Vehicle Dynamics Control Module (VDM). Removal and Installation

- Transmission Fluid Drain and Refill. General Procedures

- Transmission Fluid Level Check. General Procedures

- Second Row Seat. Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and