Lincoln Navigator: Engine - 3.5L EcoBoost (272kW/370PS) / Cylinder Head LH. Removal and Installation

Special Tool(s) / General Equipment

| Long Nose Pliers |

Materials

| Name | Specification |

|---|---|

| Motorcraft® Silicone Gasket Remover ZC-30-A, AZC-30-C |

- |

| Motorcraft® Metal Surface Prep Wipes ZC-31-B |

- |

Removal

NOTICE: During engine repair procedures, cleanliness is extremely important. Any foreign material, including any material created while cleaning gasket surfaces that enters the oil passages, coolant passages or the oil pan, can cause engine failure.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

Release the fuel system pressure.

Refer to: Fuel System Pressure Release (310-00 Fuel System - General Information - 3.5L EcoBoost (272kW/370PS), General Procedures).

-

Disconnect the battery ground cable.

Refer to: Battery Cables (414-01 Battery, Mounting and Cables, Removal and Installation).

-

Remove the LH turbocharger.

Refer to: Turbocharger LH (303-04B Fuel Charging and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the LH camshaft.

Refer to: Camshaft LH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the port injection fuel rail.

Refer to: Port Injection Fuel Rail (303-04A Fuel Charging and Controls - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

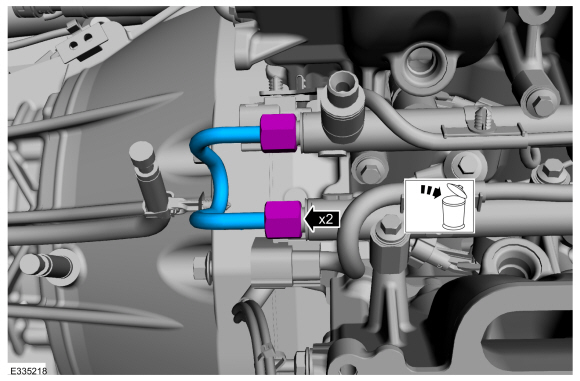

Remove and discard the fuel rail-to-fuel rail high-pressure tube.

|

-

-

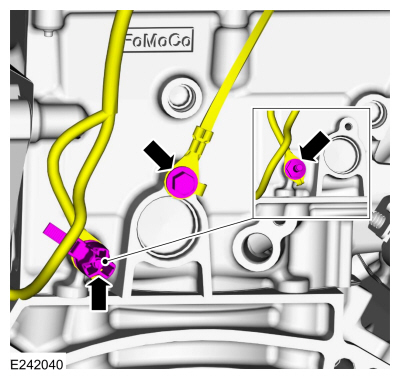

Position aside wire harness retainer. Remove the stud bolt and the ground wire.

-

Remove the bolt and position aside the body ground strap.

-

Position aside wire harness retainer. Remove the stud bolt and the ground wire.

|

-

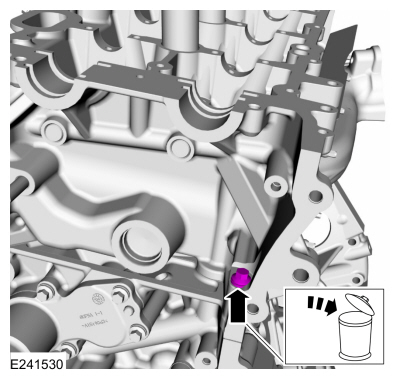

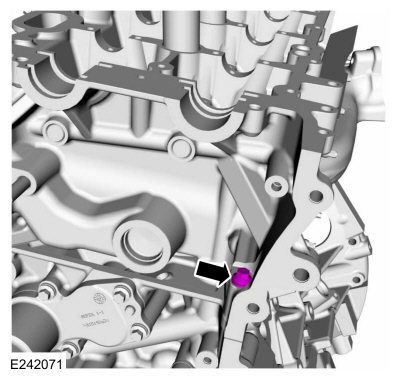

Remove and discard the LH M6 bolt.

|

-

NOTICE: Place clean shop towels over exposed engine cavities. Carefully remove the towels so foreign material is not dropped into the engine. Any foreign material (including any material created while cleaning gasket surfaces) that enters the oil passages or the oil pan, may cause engine failure.

NOTICE: Aluminum surfaces are soft and can be scratched easily. Never place the cylinder head gasket surface, unprotected, on a bench surface

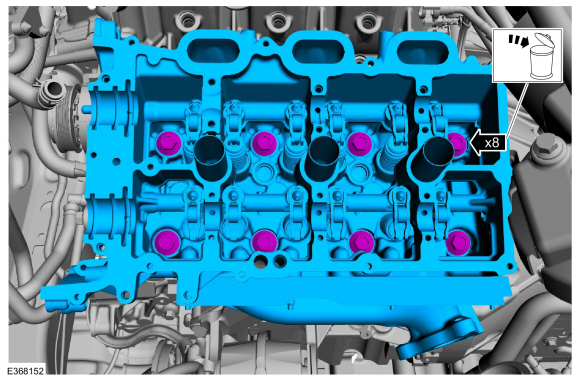

NOTE: The cylinder head bolts must be discarded and new bolts must be installed. They are tighten-to-yield designed and cannot be reused.

-

Remove and discard the bolts from the LH cylinder head.

-

Remove the cylinder head.

-

Remove and discard the bolts from the LH cylinder head.

|

-

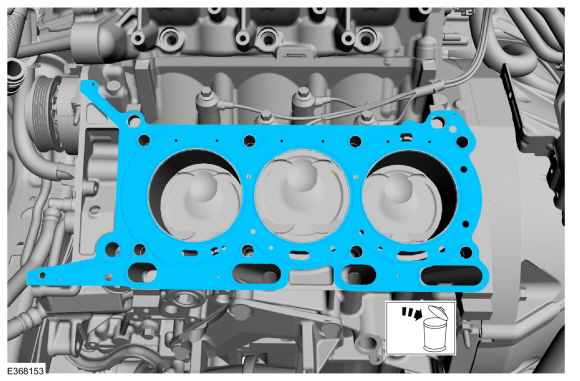

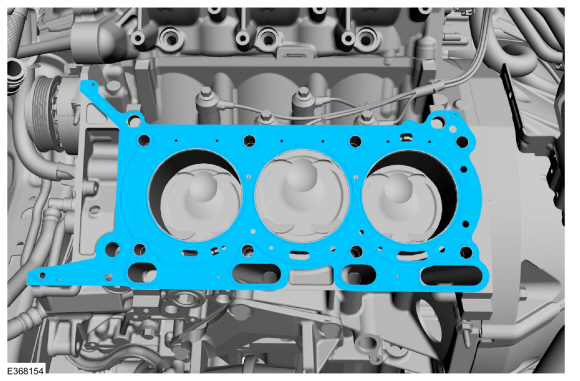

Remove and discard the LH cylinder head gasket.

|

-

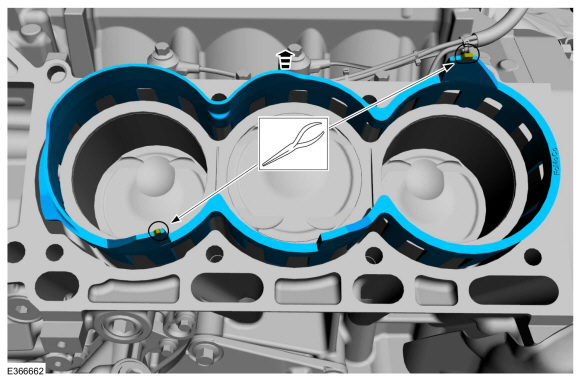

Remove the LH water jacket spacer.

Use the General Equipment: Long Nose Pliers

|

-

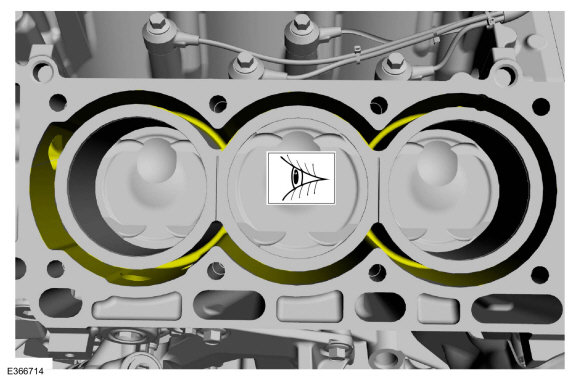

NOTICE: Do not use metal scrapers, wire brushes, power abrasive discs or other abrasive means to clean the sealing surfaces. These tools cause scratches and gouges that make leak paths. Use a plastic scraping tool to remove all traces of the head gasket.

NOTE: Observe all warnings or cautions and follow all application directions contained on the packaging.

Make sure that the mating faces are clean and free of foreign material.

Material: Motorcraft® Silicone Gasket Remover / ZC-30-A, AZC-30-C

Material: Motorcraft® Metal Surface Prep Wipes / ZC-31-B

-

Support the cylinder head on a bench with the head

gasket side up. Check the cylinder head distortion and the cylinder

block distortion.

Refer to: Cylinder Head Distortion (303-00 Engine System - General Information, General Procedures).

Installation

-

Inspect for any debri before installing the LH water jacket.

|

-

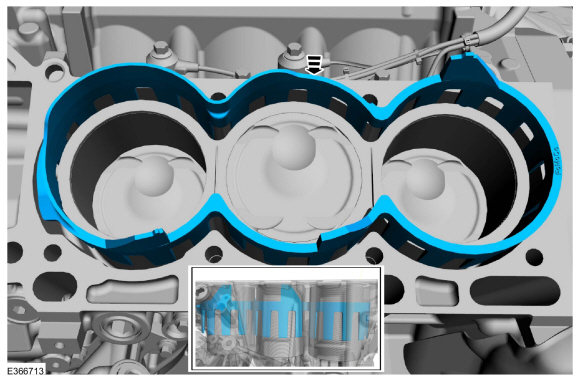

Install the LH water jacket flush with the bottom of the block.

|

-

Install the LH cylinder head gasket.

|

-

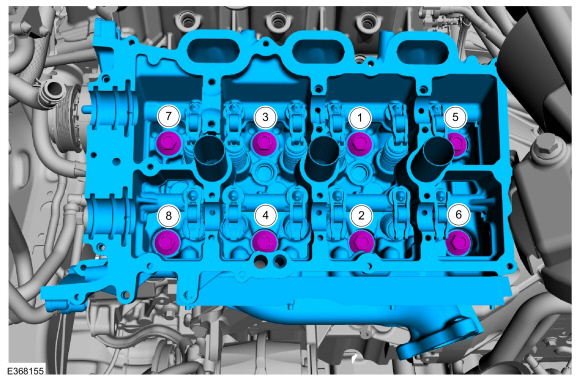

NOTE: Install new cylinder head bolts.

Install the LH cylinder head and the new bolts. Tighten in the sequence shown in 5 stages.

Torque:

Stage 1: 177 lb.in (20 Nm)

Stage 2: 33 lb.ft (45 Nm)

Stage 3: 90°

Stage 4: 90°

Stage 5: 90°

|

-

Install the LH M6 bolt.

Torque: 89 lb.in (10 Nm)

|

-

-

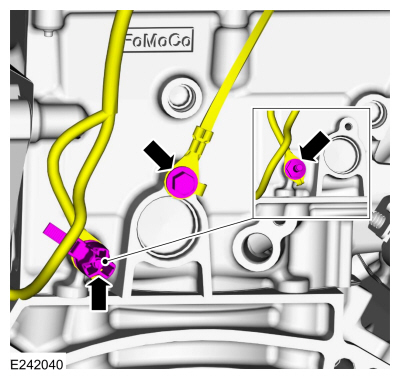

Install the ground strap & the stud bolt. Connect the wire retainer.

Torque:

Stage 1: 89 lb.in (10 Nm)

Stage 2: 20°

-

Position back the body ground strap and install the bolt.

Torque: 97 lb.in (11 Nm)

-

Install the ground strap & the stud bolt. Connect the wire retainer.

|

-

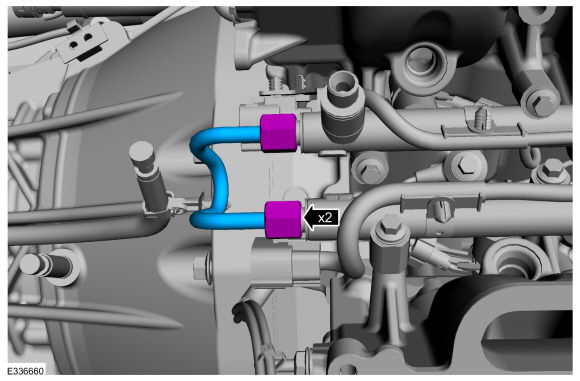

Position the flare nuts and connect the fuel rail-to-fuel rail high-pressure fuel tube.

Torque:

Stage 1: 89 lb.in (10 Nm)

Stage 2: 30°

|

-

Install the port injection fuel rail.

Refer to: Port Injection Fuel Rail (303-04A Fuel Charging and Controls - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the LH camshaft.

Refer to: Camshaft LH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the LH turbocharger.

Refer to: Turbocharger LH (303-04B Fuel Charging and Controls - Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Connect the battery ground cable.

Refer to: Battery Cables (414-01 Battery, Mounting and Cables, Removal and Installation).

-

Road test the vehicle.

Crankshaft Rear Seal. Removal and Installation

Crankshaft Rear Seal. Removal and Installation

Materials

Name

Specification

Motorcraft® High Performance Engine RTV SiliconeTA-357

WSE-M4G323-A6

Engine Oil - SAE 5W-30 - Synthetic Blend Motor OilXO-5W30-Q1SP

WSS-M2C946-B1

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Cylinder Head RH. Removal and Installation

Cylinder Head RH. Removal and Installation

Special Tool(s) /

General Equipment

Long Nose Pliers

Materials

Name

Specification

Motorcraft® Silicone Gasket RemoverZC-30-A, AZC-30-C

-

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Hydraulic Actuator. Removal and Installation

Special Tool(s) / General Equipment 205-1049Socket, 9.75 Plenum 4 pin 205-153 (T80T-4000-W) Handle 205-D044 (D81T-4221-A) Installer, Differential Carrier Bearing 205-D061 (D83T-4205-C2) Step Plate 205-D072 (D97L-4221-A) 2 Jaw Puller 307-003 (T57L-500-B) Holding Fixture, Transmission Cable Ties ..

Lincoln Navigator 2018-2026 Workshop Manual: Keyless Entry Keypad. Removal and Installation

Removal NOTE: The keyless entry keypad is serviced as an assembly with the front door upper moulding. Remove the front door upper moulding. Refer to: Front Door Upper Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation). Installation To install, reverse the removal procedure. Carry out the power door windo..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Transmission Fluid Level Check. General Procedures

- Power Running Board (PRB). Diagnosis and Testing

- Liftgate Trim Panel. Removal and Installation

- Windshield Washer Pump. Removal and Installation

- Rear View Mirrors - System Operation and Component Description. Description and Operation

Rear Drive Halfshafts. Diagnosis and Testing

Preliminary Inspection

Visually inspect the CV joints, housing, boots, and clamps for obvious signs of mechanical damage.If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step

If the cause is not visually evident, verify the symptom and REFER to Symptom Chart: NVH.