Lincoln Navigator: Engine - 3.5L EcoBoost (272kW/370PS) / Cylinder Head RH. Removal and Installation

Special Tool(s) /

General Equipment

Materials

| Name |

Specification |

Motorcraft® Silicone Gasket Remover

ZC-30-A, AZC-30-C |

-

|

Motorcraft® Metal Surface Prep Wipes

ZC-31-B |

-

|

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important. Any foreign material, including any material created while

cleaning gasket surfaces that enters the oil passages, coolant passages

or the oil pan, can cause engine failure.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

Release the fuel system pressure.

Refer to: Fuel System Pressure Release (310-00 Fuel System - General

Information - 3.5L EcoBoost (272kW/370PS), General Procedures).

-

Disconnect the battery ground cable.

Refer to: Battery Cables (414-01 Battery, Mounting and Cables, Removal and Installation).

-

Remove the EGR cooler.

Refer to: Exhaust Gas Recirculation (EGR) Cooler (303-08 Engine

Emission Control - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

-

-

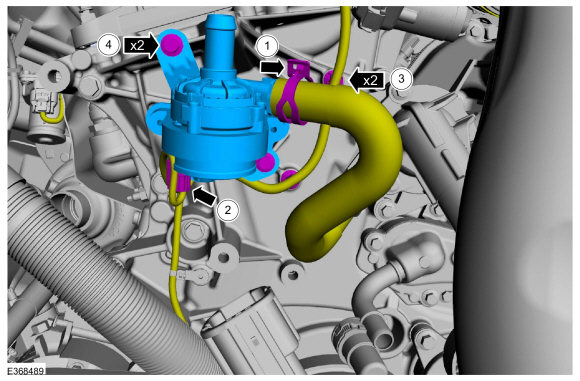

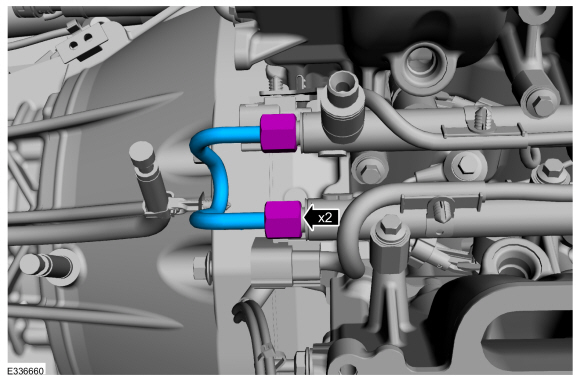

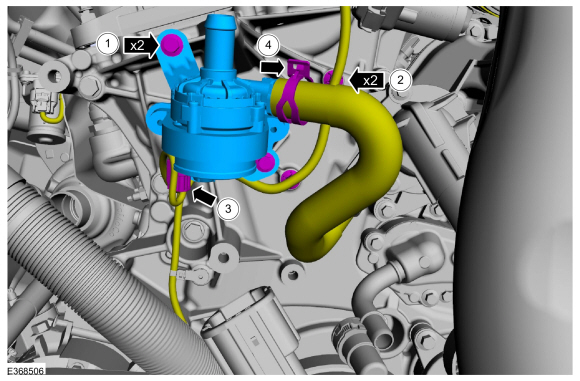

Disconnect the heater hose.

-

Disconnect the electrical connector.

-

Disconnect the pin-type retainer.

-

Remove the bolts and the cabin heater pump.

-

Remove the RH turbocharger.

Refer to: Turbocharger RH (303-04B Fuel Charging and Controls -

Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the RH camshaft.

Refer to: Camshaft RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

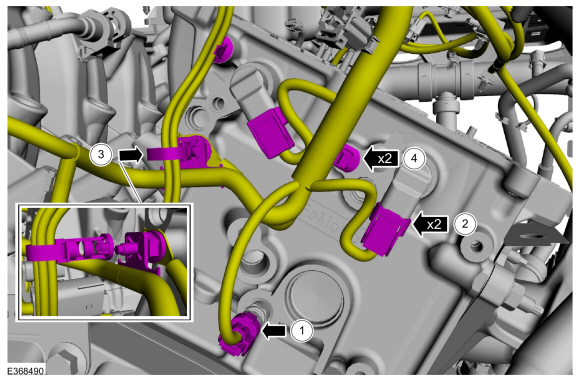

Remove the port injection fuel rail.

Refer to: Port Injection Fuel Rail (303-04A Fuel Charging and Controls -

3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

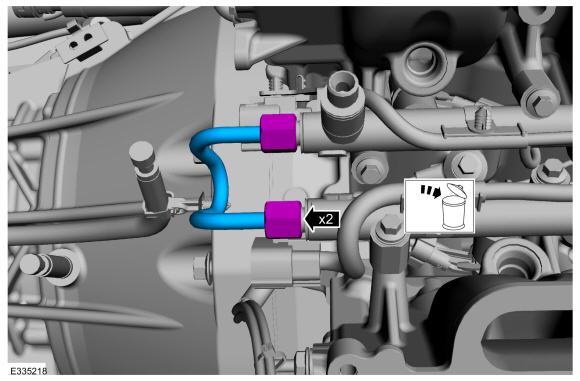

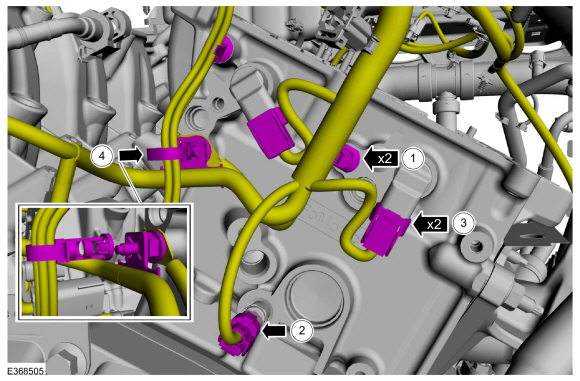

Remove and discard the fuel rail-to-fuel rail high-pressure tube.

-

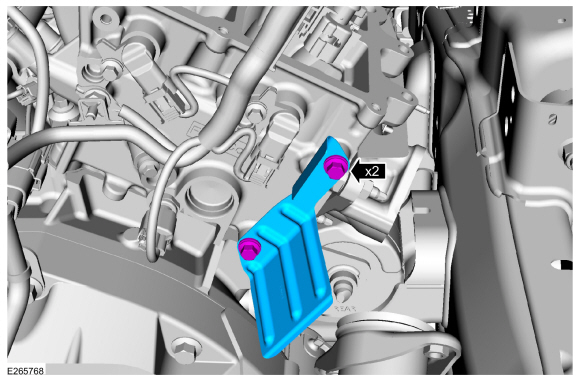

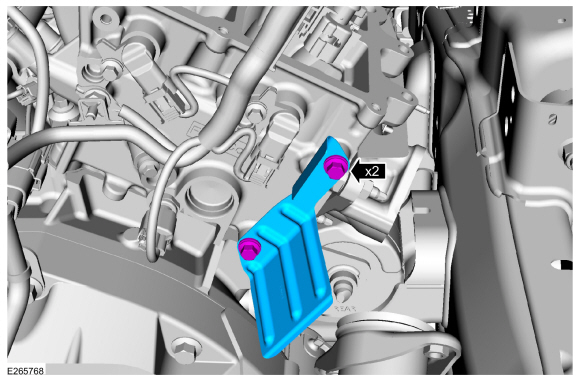

Remove the retainers and the heat shield.

-

-

Disconnect the CHT sensor electrical connector.

-

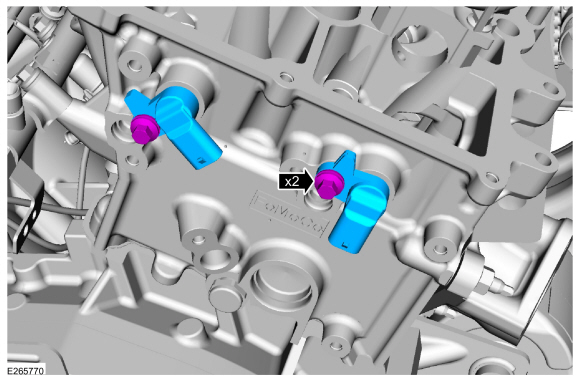

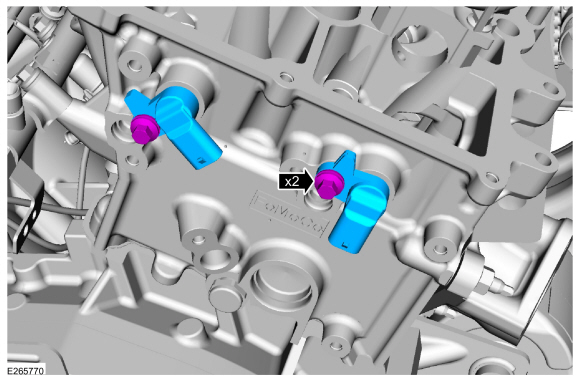

Disconnect the CMP sensor electrical connectors.

-

Position aside wire retainer. Remove the studbolt and the ground wire.

-

Disconnect the pin-type retainer.

-

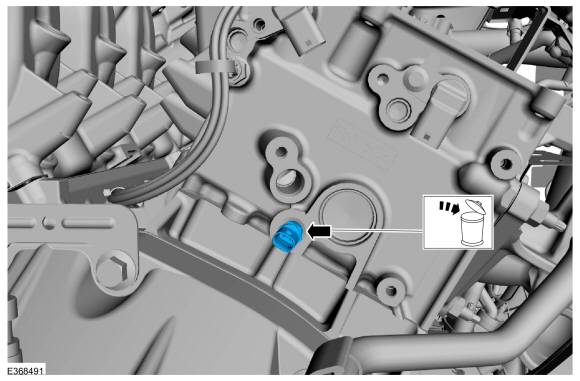

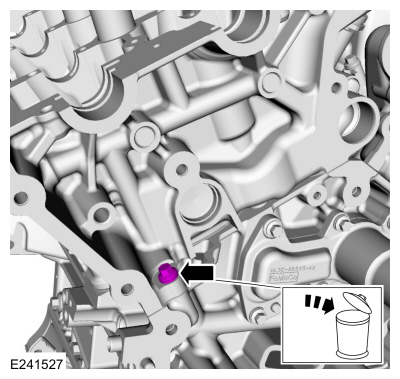

Remove and discard the CHT sensor.

-

Remove the bolts and the CMP sensors.

-

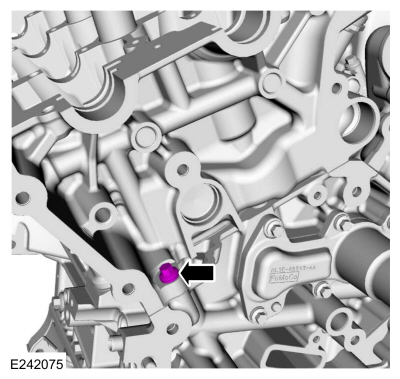

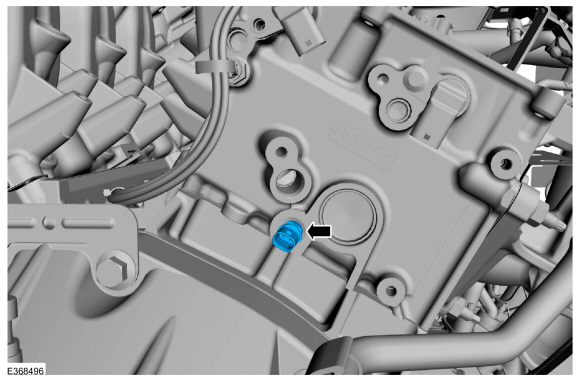

Remove and discard the RH M6 bolt.

-

NOTICE:

Place clean shop towels over exposed engine

cavities. Carefully remove the towels so foreign material is not dropped

into the engine. Any foreign material (including any material created

while cleaning gasket surfaces) that enters the oil passages or the oil

pan, may cause engine failure.

NOTICE:

Aluminum surfaces are soft and can be scratched

easily. Never place the cylinder head gasket surface, unprotected, on a

bench surface

NOTE:

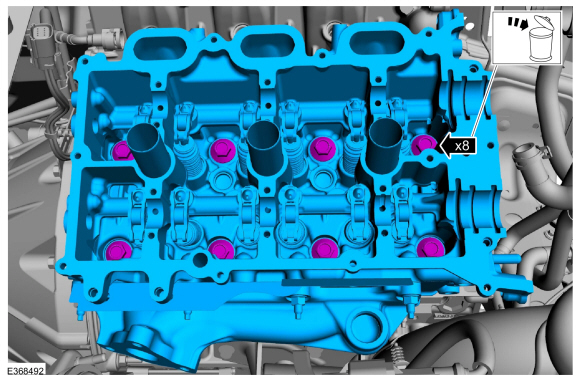

The cylinder head bolts must be discarded and new

bolts must be installed. They are tighten-to-yield designed and cannot

be reused.

-

Remove and discard the bolts from the RH cylinder head.

-

Remove the cylinder head.

-

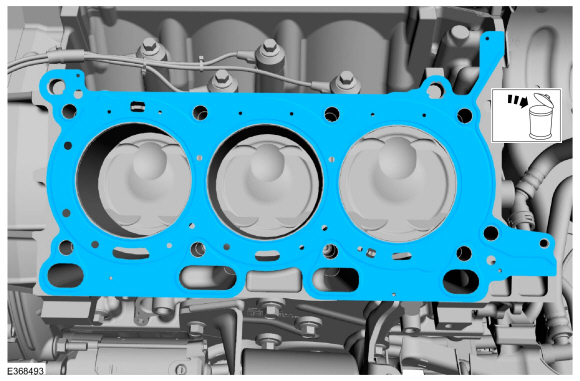

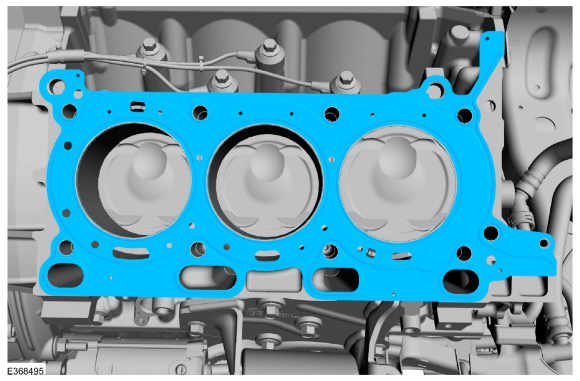

Remove and discard the RH cylinder head gasket.

-

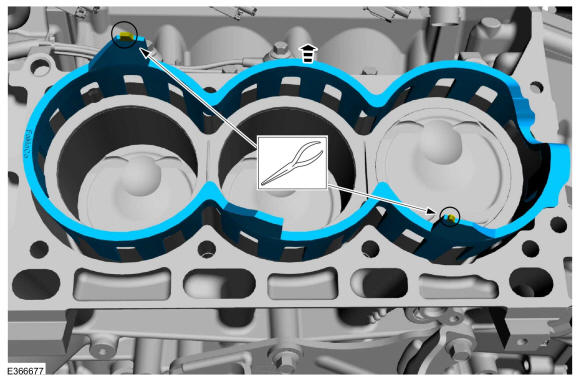

Remove the RH water jacket spacer.

Use the General Equipment: Long Nose Pliers

-

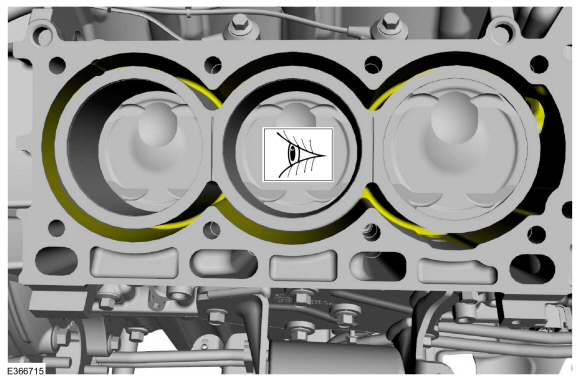

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges that make leak paths. Use a

plastic scraping tool to remove all traces of the head gasket.

NOTE:

Observe all warnings or cautions and follow all application directions contained on the packaging.

Make sure that the mating faces are clean and free of foreign material.

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A, AZC-30-C

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

-

Support the cylinder head on a bench with the head

gasket side up. Check the cylinder head distortion and the cylinder

block distortion.

Refer to: Cylinder Block Distortion (303-00 Engine System - General Information, General Procedures).

Installation

-

Inspect for any debri before installing the RH water jacket.

-

Install the RH water jacket flush with the bottom of the block.

-

Install the RH cylinder head gasket.

-

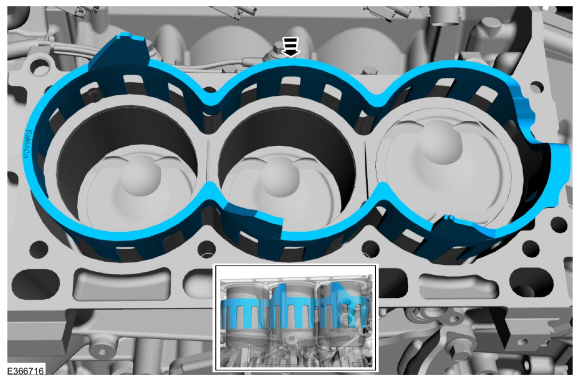

NOTE:

Install new cylinder head bolts.

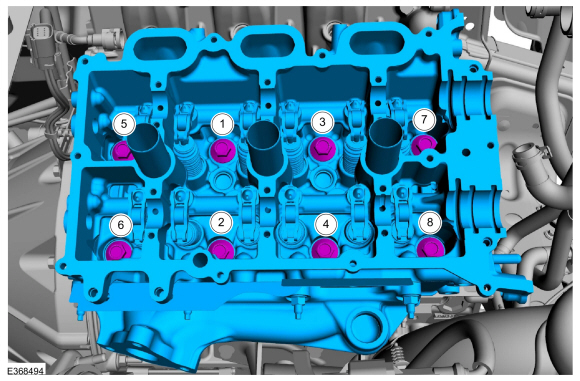

Install the RH cylinder head and the new bolts. Tighten in the sequence shown in 5 stages.

Torque:

Stage 1:

177 lb.in (20 Nm)

Stage 2:

33 lb.ft (45 Nm)

Stage 3:

90°

Stage 4:

90°

Stage 5:

90°

-

Install the RH M6 bolt.

Torque:

89 lb.in (10 Nm)

-

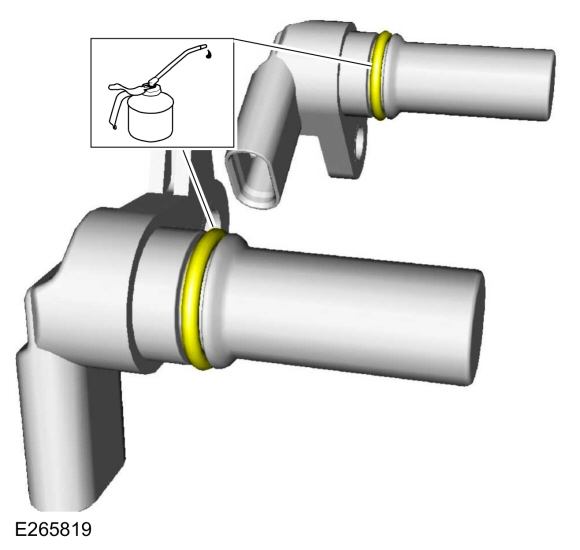

Lubricate the CMP sensor O-ring seal with clean engine oil.

Refer to: Specifications (303-01 Engine - 3.5L EcoBoost (272kW/370PS))

.

-

Install the bolts and the CMP sensors.

Torque:

71 lb.in (8 Nm)

-

Install the new CHT sensor.

Torque:

97 lb.in (11 Nm)

-

-

Connect the pin-type retainers.

-

Connect the CHT sensor electrical connector.

-

Connect the CMP sensor electrical connectors.

-

Install the wiring harness ground and the studbolt. Position back the wire retainer.

Torque:

Stage 1:

89 lb.in (10 Nm)

Stage 2:

20°

-

Install the heat shield and the retainers.

Torque:

89 lb.in (10 Nm)

-

Install the fuel rail-to-fuel rail high-pressure fuel tube and tighten the flare nuts.

Torque:

Stage 1:

89 lb.in (10 Nm)

Stage 2:

30 °

-

Install the port injection fuel rail.

Refer to: Port Injection Fuel Rail (303-04A Fuel Charging and Controls -

3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the RH camshaft.

Refer to: Camshaft RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

-

Install the cabin heater pump and bolts.

-

Connect the pin-type retainer.

-

Connect the electrical connector.

-

Install the EGR cooler.

Refer to: Exhaust Gas Recirculation (EGR) Cooler (303-08 Engine

Emission Control - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

-

Install the RH turbocharger.

Refer to: Turbocharger RH (303-04B Fuel Charging and Controls -

Turbocharger - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Connect the battery ground cable.

Refer to: Battery Cables (414-01 Battery, Mounting and Cables, Removal and Installation).

-

Road test the vehicle.

Special Tool(s) /

General Equipment

Long Nose Pliers

Materials

Name

Specification

Motorcraft® Silicone Gasket RemoverZC-30-A, AZC-30-C

-

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Special Tool(s) /

General Equipment

205-142

(T80T-4000-J)

Installer, Differential Bearing Cone

205-149

(T80T-4000-R)

Installer, Spindle Bearing

205-150

(T80T-4000-S)

Installer, Spindle Bearing

205-153

(T80T-4000-W)

Handle

303-1663Installer, VDOP Seal

307-399Alignment Pins, Transmission Fluid PumpTKIT-2002N-DEWTKIT-2..

Other information:

Repair

of aluminum vehicle components requires some specialized handling and

the proper isolation of the work area from steel repairs and dedicated

hand and power tools that will be used only for aluminum repair. The

following details some of these considerations.

Isolation of Work Area

Galvanic

corrosion is caused through dissimilar metals remaining in contact with

one another...

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the brake disc.

Refer to: Brake Disc (206-04 Rear Disc Brake, Removal and Installation).

Remove the 3 bolts and the brake disc shield.

Torque:

159 lb.in (18 Nm)

Installation

To install, reverse the removal pr..

Cylinder Head LH. Removal and Installation

Cylinder Head LH. Removal and Installation Engine Front Cover. Removal and Installation

Engine Front Cover. Removal and Installation