Lincoln Navigator: Engine - 3.5L EcoBoost (272kW/370PS) / Engine Front Cover. Removal and Installation

Special Tool(s) /

General Equipment

|

205-142

(T80T-4000-J)

Installer, Differential Bearing Cone |

|

205-149

(T80T-4000-R)

Installer, Spindle Bearing |

|

205-150

(T80T-4000-S)

Installer, Spindle Bearing |

|

205-153

(T80T-4000-W)

Handle |

|

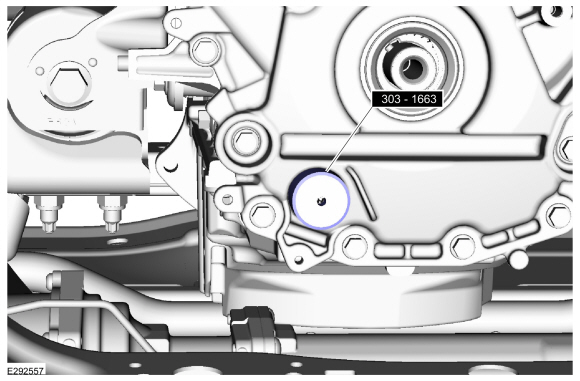

303-1663

Installer, VDOP Seal |

|

307-399

Alignment Pins, Transmission Fluid Pump

TKIT-2002N-DEW

TKIT-2000AP-FLM/LM |

| Oil Drain Equipment |

Materials

| Name |

Specification |

Motorcraft® High Performance Engine RTV Silicone

TA-357 |

WSE-M4G323-A6

|

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important. Any foreign material, including any material created while

cleaning gasket surfaces that enters the oil passages, coolant passages

or the oil pan, may cause engine failure.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

Release the fuel system pressure.

Refer to: Fuel System Pressure Release (310-00 Fuel System - General

Information - 3.5L EcoBoost (272kW/370PS), General Procedures).

-

Remove the following items:

-

Remove the undershields.

Refer to: Engine Front Undershield (501-02 Front End Body Panels, Removal and Installation).

Refer to: Engine Rear Undershield (501-02 Front End Body Panels, Removal and Installation).

-

Remove the charge air cooler outlet pipe.

Refer to: Charge Air Cooler (CAC) Outlet Pipe (303-12 Intake Air

Distribution and Filtering - 3.5L EcoBoost (272kW/370PS), Removal and

Installation).

-

Remove the LH valve cover.

Refer to: Valve Cover LH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the RH valve cover.

Refer to: Valve Cover RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the thermostat housing.

Refer to: Thermostat Housing (303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the coolant pump.

Refer to: Coolant Pump (303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the crankshaft front seal.

Refer to: Crankshaft Front Seal (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the A/C compressor.

Refer to: Air Conditioning (A/C) Compressor (412-00 Climate Control System - General Information, Removal and Installation).

-

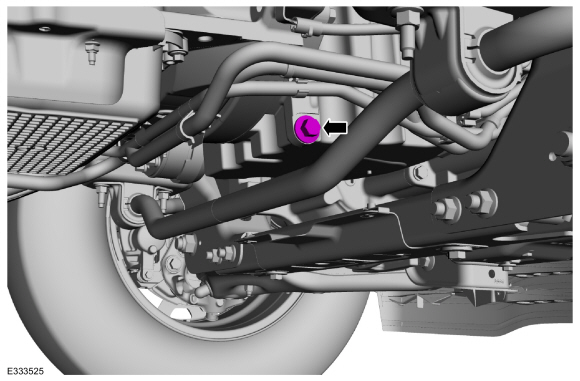

Remove the oil pan plug and drain the engine oil.

Use the General Equipment: Oil Drain Equipment

Torque:

20 lb.ft (27 Nm)

-

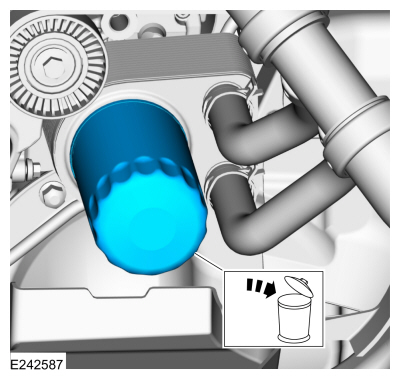

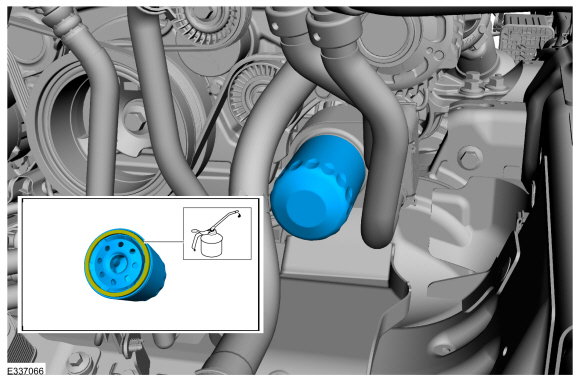

Remove and discard the engine oil filter.

Use the General Equipment: Oil Drain Equipment

-

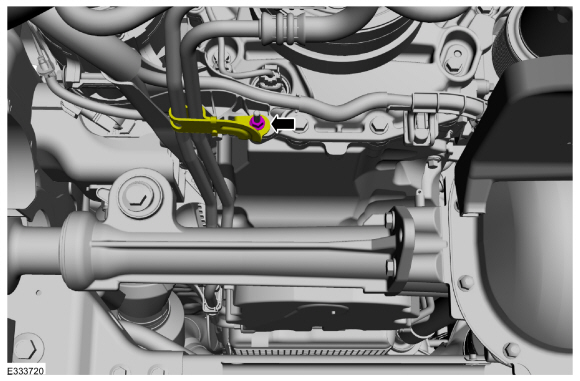

Remove the fasteners and position the wiring harness aside.

-

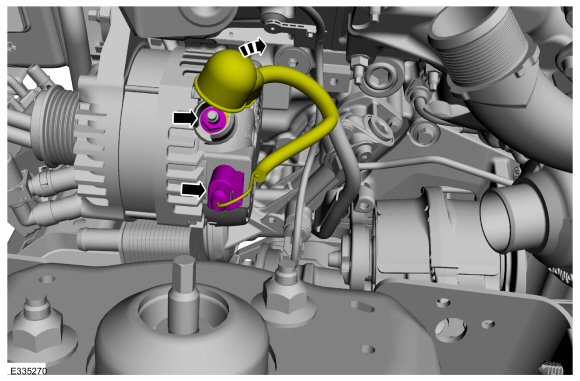

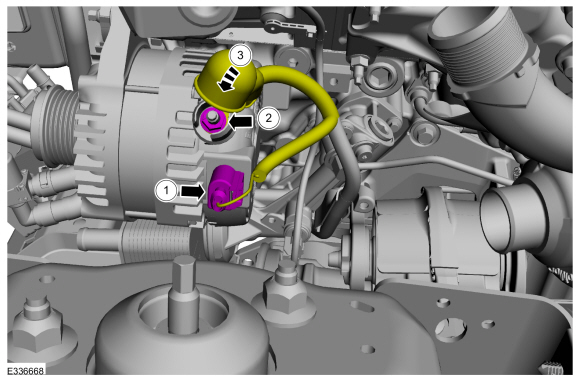

Disconnect the generator electrical connector, position

the B+ wire protective cover and remove the nut and the B+ wire.

-

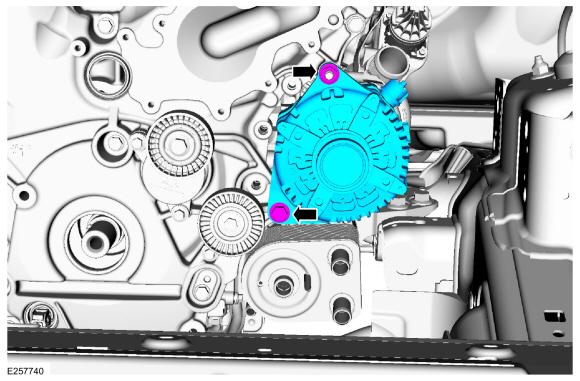

Remove the nut, bolt and the generator.

-

Remove the generator stud.

-

-

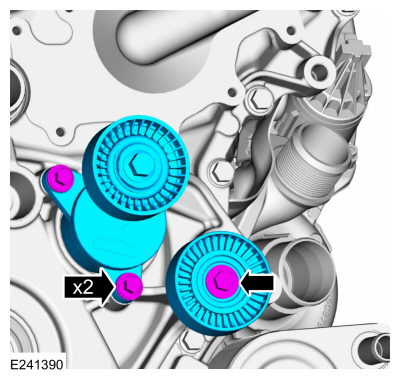

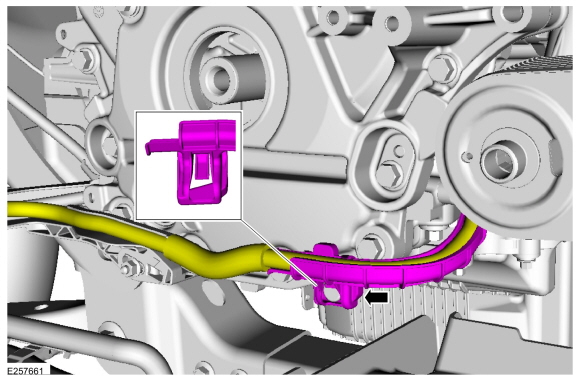

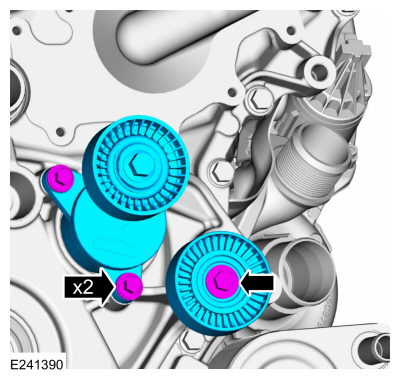

Remove the bolts and the accessory drive belt tensioner.

-

Remove the bolt and the accessory drive belt idler pulley.

-

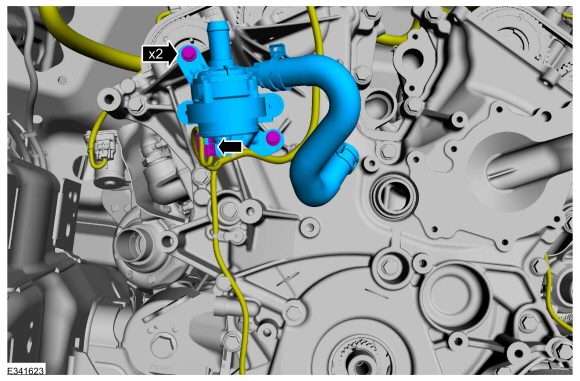

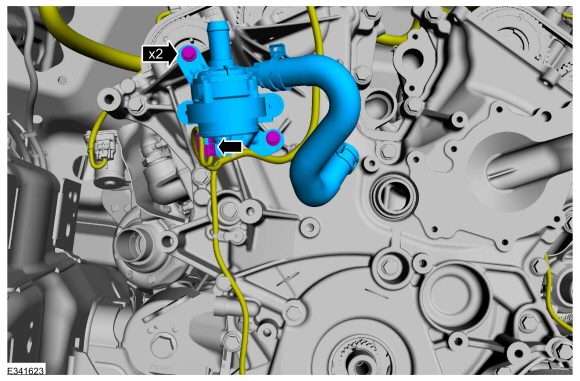

Disconnect the electrical connector, remove the bolts and position cabin heater coolant pump aside.

-

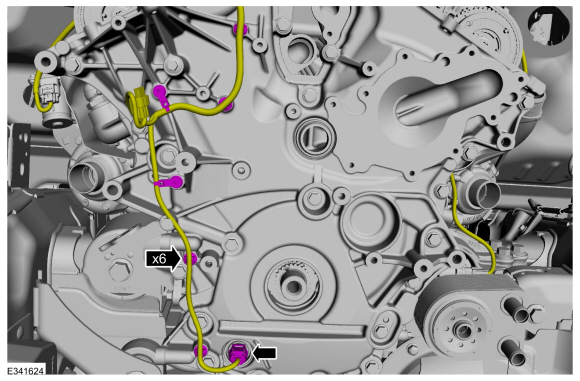

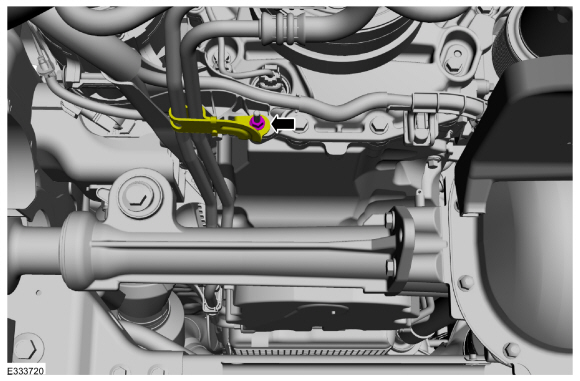

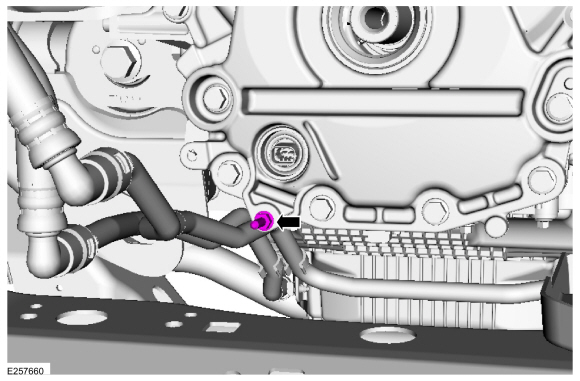

Disconnect the oil pump electrical connector, detach the pin-type retainers and position the wire harness aside.

-

Disconnect the generator wiring from the engine front cover.

-

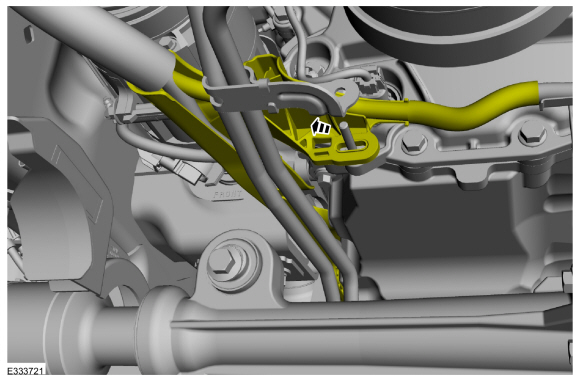

Remove the nut and position out the transmission cooler tube bracket.

-

Position out the engine wiring harness.

-

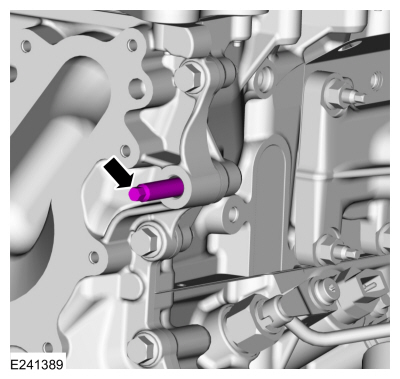

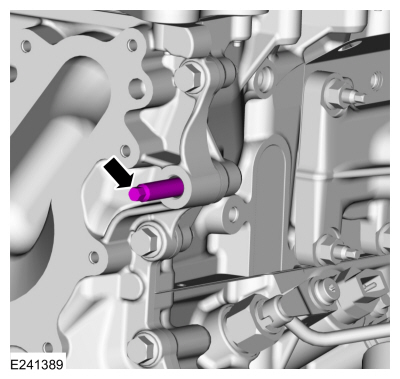

Remove the transmission cooler bracket stud.

-

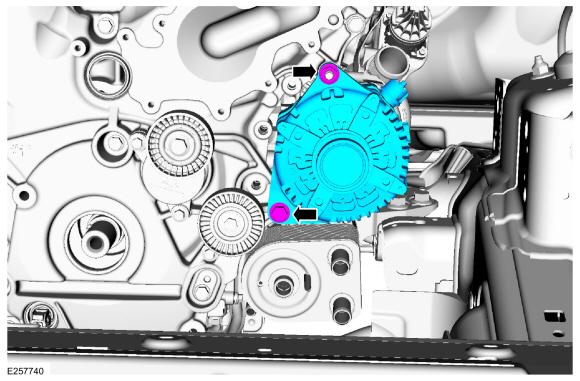

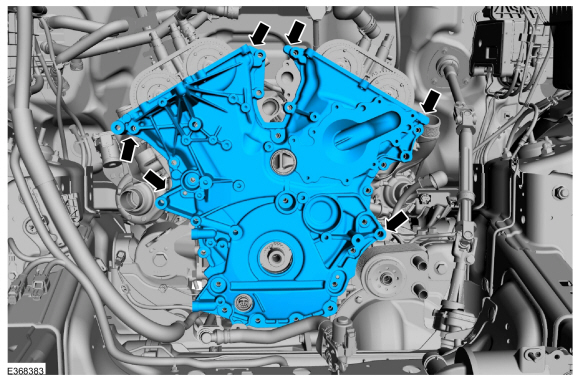

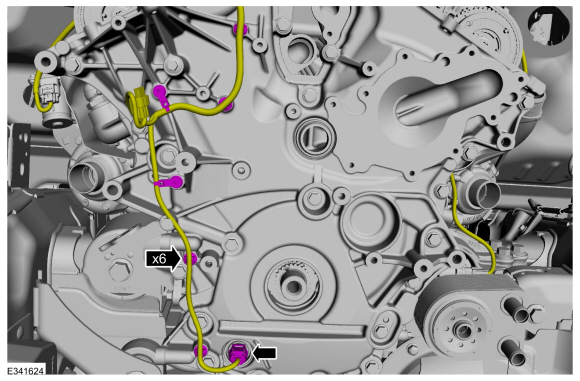

Remove the engine front cover bolts.

-

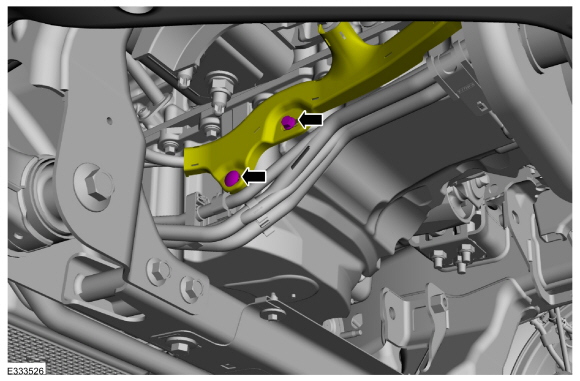

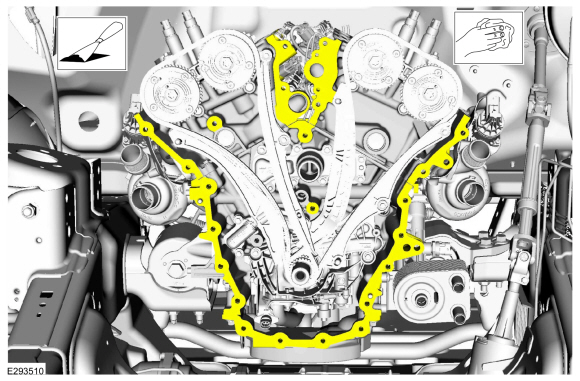

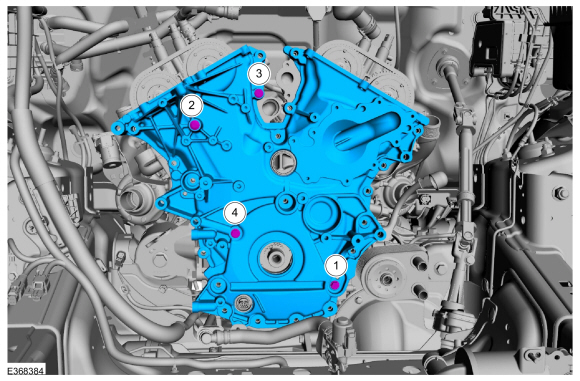

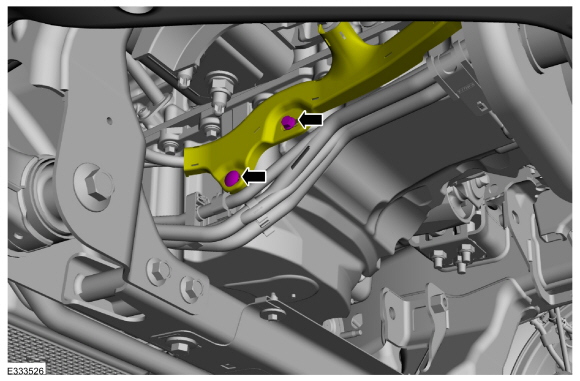

Using a pry tool on the pry pads shown, remove the engine front cover.

-

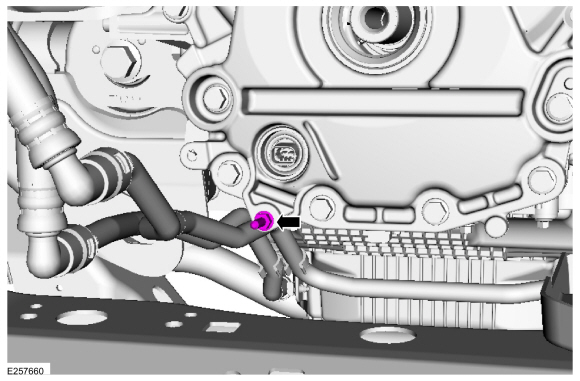

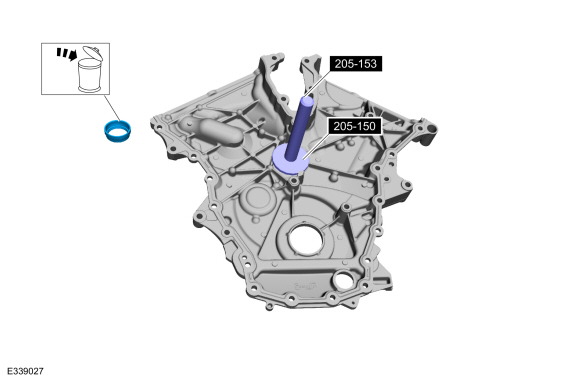

Using the special tools, remove the engine front cover to coolant pipe seal and discard.

Use Special Service Tool: 205-150

(T80T-4000-S)

Installer, Spindle Bearing.

, 205-153

(T80T-4000-W)

Handle.

-

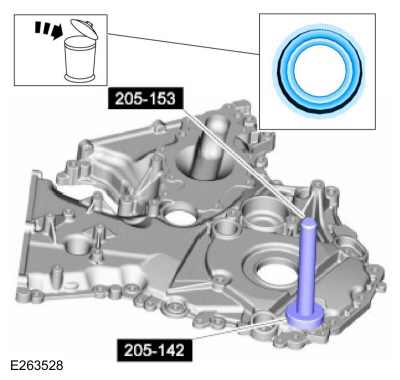

Using the special tools, remove and discard the oil pump electrical connector seal and discard.

Use Special Service Tool: 205-153

(T80T-4000-W)

Handle.

Install Special Service Tool: 205-142

(T80T-4000-J)

Installer, Differential Bearing Cone.

Installation

-

-

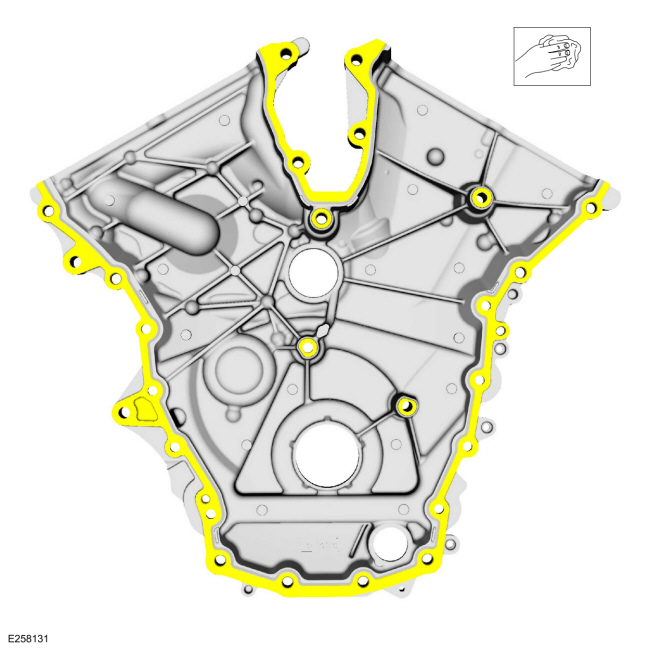

Clean and prepare the RTV sealing surface.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

-

Clean and prepare the RTV sealing surface.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

-

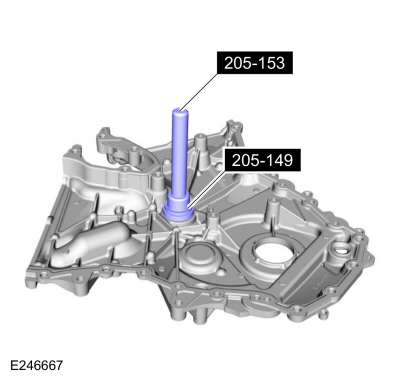

Using the special tools, install the new engine front cover to coolant pipe seal.

Use Special Service Tool: 205-149

(T80T-4000-R)

Installer, Spindle Bearing.

, 205-153

(T80T-4000-W)

Handle.

-

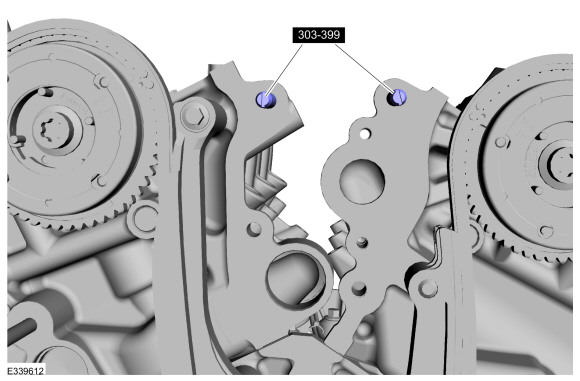

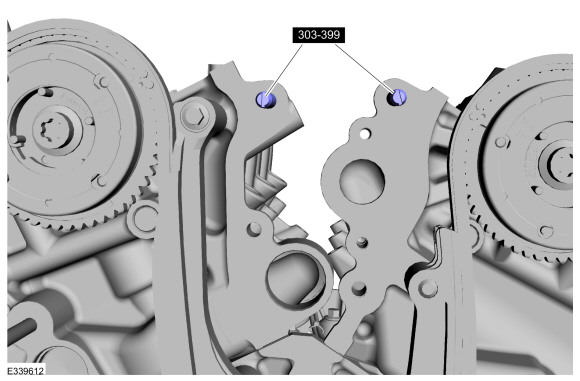

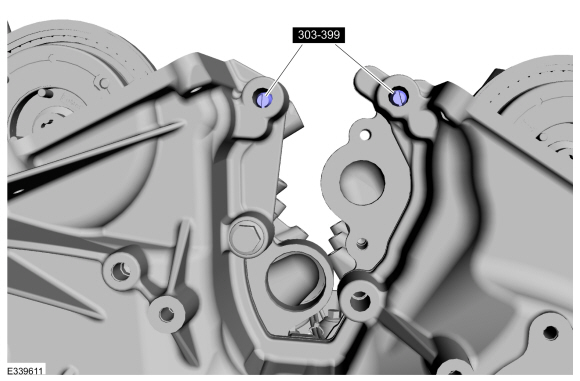

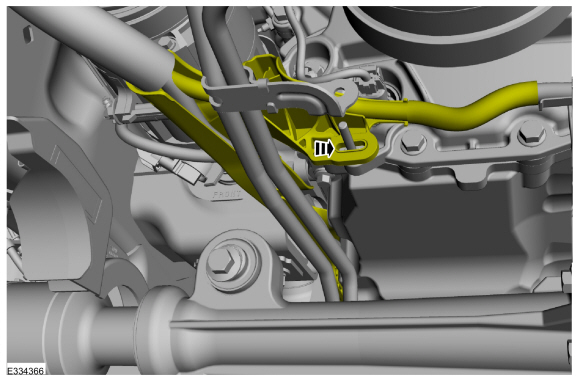

Install Special Service Tool: 307-399

Alignment Pins, Transmission Fluid Pump.

|

|

-

-

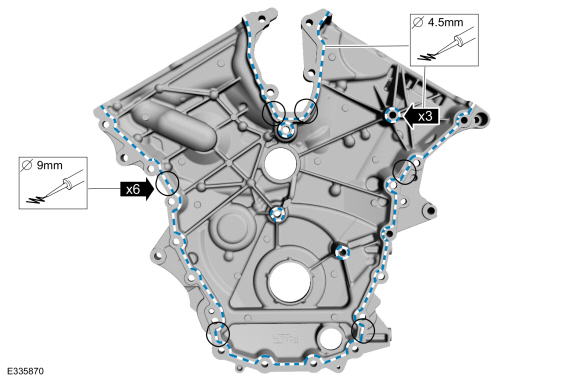

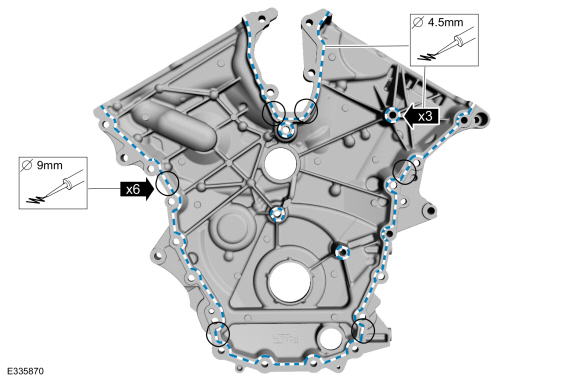

NOTICE:

Failure to use Motorcraft® High Performance

Engine RTV Silicone may cause the engine oil to foam excessively and

result in serious engine damage.

NOTE:

The engine front cover and the 6 bolts must be

installed within 4 minutes of the initial sealant application. The

remainder of the engine front cover bolts must be installed and

tightened within 35 minutes of the initial sealant application. If the

time limits are exceeded, the sealant must be removed, the sealing area

cleaned and sealant reapplied. To clean the sealing area, use silicone

gasket remover and metal surface prep. Failure to follow this procedure

can cause future oil leakage.

Apply a 4.5 mm (0.18 in) bead of Motorcraft® High

Performance Engine RTV Silicone to the engine front cover sealing

surfaces including the inner bolt bosses.

Material: Motorcraft® High Performance Engine RTV Silicone

/ TA-357

(WSE-M4G323-A6)

-

Apply a 9.0 mm (0.35 in) bead of Motorcraft® High

Performance Engine RTV Silicone to the oil pan-to-cylinder block joint

and the cylinder head-to-cylinder block joint areas of the engine front

cover in places as indicated.

Material: Motorcraft® High Performance Engine RTV Silicone

/ TA-357

(WSE-M4G323-A6)

|

|

-

NOTE:

Make sure the 2 locating dowel pins are seated correctly in the cylinder block.

Install the engine front cover and the bolts.

Torque:

27 lb.in (3 Nm)

-

Remove Special Service Tool: 307-399

Alignment Pins, Transmission Fluid Pump.

-

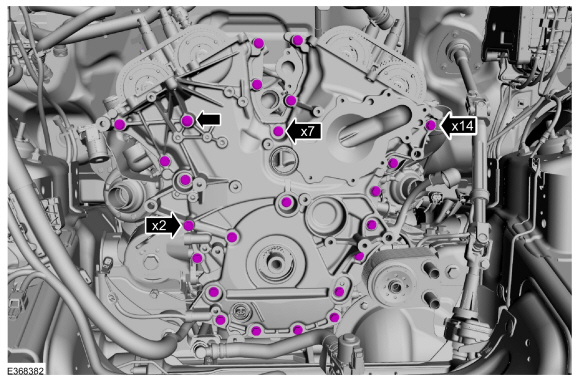

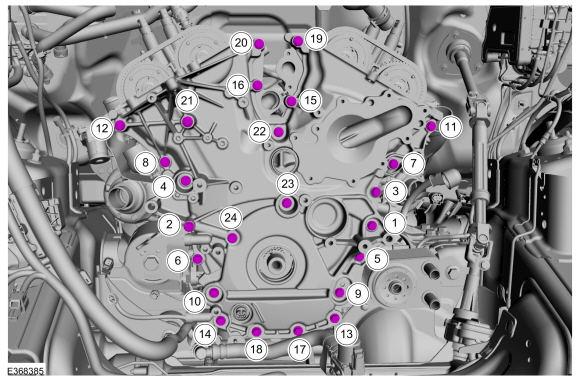

Install the engine front cover bolts. Tighten in the sequence shown in 2 stages.

Torque:

Stage 1:

Tighten bolts 1 thru 24 to:

177 lb.in (20 Nm)

Stage 2:

Tighten bolt 1 thru 24 an additional:

45°

-

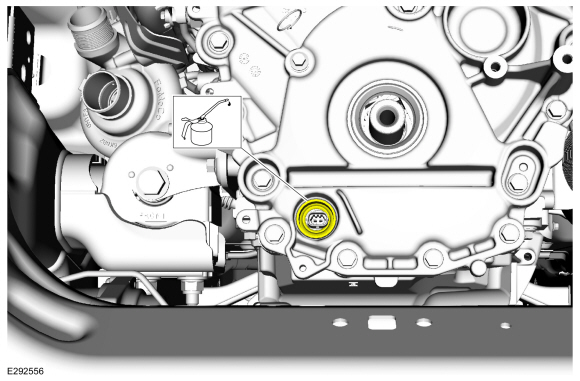

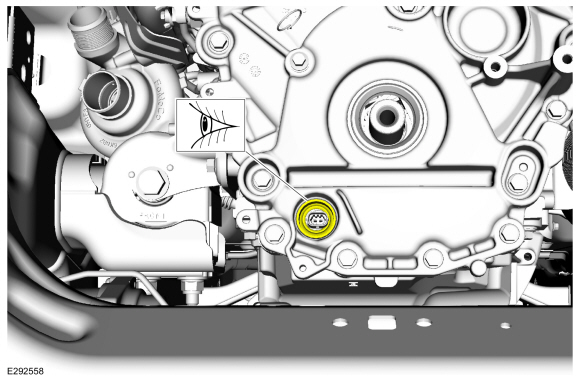

With clean oil, lubricate and position the new oil pump electrical connector seal.

Refer to: Specifications (303-01)

.

-

NOTICE:

If the oil pump electrical connector seal is not properly installed, it may result in oil leakage.

Using the special tool, install the oil pump electrical connector seal.

Install Special Service Tool: 303-1663

Installer, VDOP Seal.

-

NOTE:

The front surface of the oil pump electrical

connector seal will be level with the engine front cover recess.

Inspect the oil pump electrical connector seal for proper installation.

-

Install the transmission cooler bracket stud.

-

Position back the engine wiring harness.

-

Position back the engine wiring harness. Position back the transmission cooler tube bracket and install the nut.

Torque:

106 lb.in (12 Nm)

-

Connect the generator wiring to the engine front cover.

-

Install the pin-type retainers and connect the oil pump electrical connector.

-

Install the cabin heater coolant pump and bolts. Connect the electrical connector.

Torque:

89 lb.in (10 Nm)

-

-

Install the accessory drive belt tensioner and bolts.

Torque:

18 lb.ft (25 Nm)

-

Install the accessory drive belt idler pulley and bolt.

Torque:

18 lb.ft (25 Nm)

-

Install the generator stud.

Torque:

71 lb.in (8 Nm)

-

Position back the generator. Install the nut and the bolt.

Torque:

35 lb.ft (48 Nm)

-

NOTICE:

When installing the B+ terminal nut to the

generator, finger-start the nut before tightening or component damage

may occur.

-

Connect the electrical connector.

-

Install the generator nut.

Torque:

150 lb.in (17 Nm)

-

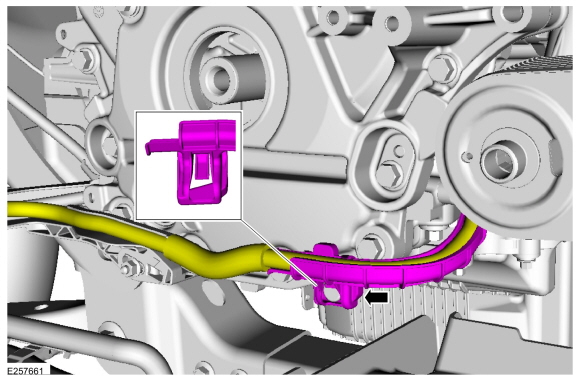

Attach the starter motor wiring harness and retainer to the oil pan.

-

Install the following items:

-

Install the crankshaft front seal.

Refer to: Crankshaft Front Seal (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the coolant pump.

Refer to: Coolant Pump (303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the thermostat housing.

Refer to: Thermostat Housing (303-03 Engine Cooling - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the RH valve cover.

Refer to: Valve Cover RH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the LH valve cover.

Refer to: Valve Cover LH (303-01 Engine - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the charge air cooler outlet pipe.

Refer to: Air Cleaner Outlet Pipe (303-12 Intake Air Distribution and

Filtering - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Lubricate the oil filter seal with clean oil and install the new oil filter.

Refer to: Specifications (303-01)

.

Torque:

Stage 1:

44 lb.in (5 Nm)

Stage 2:

180°

-

Install the undershields.

Refer to: Engine Front Undershield (501-02 Front End Body Panels, Removal and Installation).

Refer to: Engine Rear Undershield (501-02 Front End Body Panels, Removal and Installation).

-

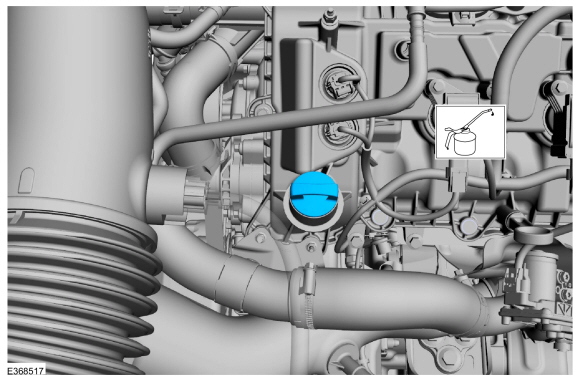

Fill the engine with clean engine oil.

Refer to: Specifications (303-01)

.

-

Pressurize the fuel system.

Refer to: Fuel System Pressure Release (310-00 Fuel System - General

Information - 3.5L EcoBoost (272kW/370PS), General Procedures).

-

After completing the repairs, perform the Misfire

Monitor Neutral Profile Correction procedure using a diagnostic scan

tool.

-

Road test the vehicle.

Special Tool(s) /

General Equipment

Long Nose Pliers

Materials

Name

Specification

Motorcraft® Silicone Gasket RemoverZC-30-A, AZC-30-C

-

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Special Tool(s) /

General Equipment

303-1246Engine Spreader BarTKIT-2006UF-FLMTKIT-2006UF-ROW

303-1654Lift Eyes

303-F070Support Bar, EngineTKIT-1999A-F/LTTKIT-1999A-FM/FLM

Vehicle/Axle Stands

Removal

NOTICE:

Use care when positioning the front axle housing or the

vacuum lines to the axle solenoid may become disconnected or damaged...

Other information:

Special Tool(s) /

General Equipment

Flat Headed Screw Driver

Boot Clamp Pliers

Removal

Remove the inner CV joint boot.

Refer to: Inner Constant Velocity (CV) Joint Boot (205-04 Front Drive Halfshafts, Removal and Installation)...

Low One Way Clutch

For low one way clutch operation, REFER to: Low One-Way Clutch

Assembly (307-01 Automatic Transmission - 10-Speed Automatic

Transmission – 10R80, Description and Operation).

NOTICE:

Do not clean with water or with water-based solvents...

Cylinder Head RH. Removal and Installation

Cylinder Head RH. Removal and Installation Engine Mount LH. Removal and Installation

Engine Mount LH. Removal and Installation