Lincoln Navigator: Four-Wheel Drive Systems / Transfer Case Shift Motor. Removal and Installation

Lincoln Navigator 2018-2026 Workshop Manual / Automatic Transmission / Four-Wheel Drive Systems / Transfer Case Shift Motor. Removal and Installation

Removal

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02) .

-

-

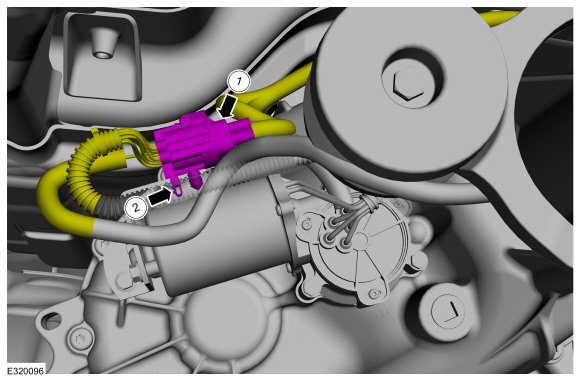

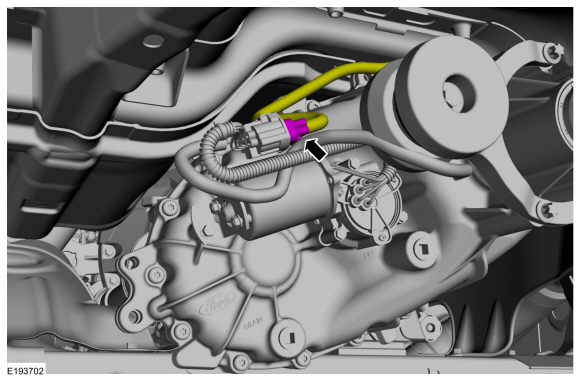

Disconnect the wiring harness connector.

-

Detach wiring harness retainers.

-

Disconnect the wiring harness connector.

|

-

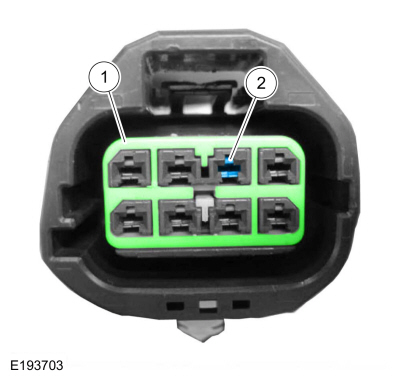

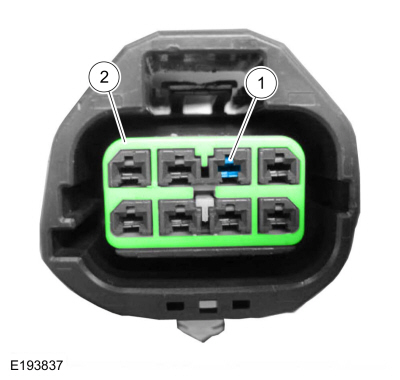

Remove the coil wire pin from the electrical connector.

-

Remove the inner retainer from the wire connector.

-

Press the release tab and remove the coil wire pin.

-

Remove the inner retainer from the wire connector.

|

-

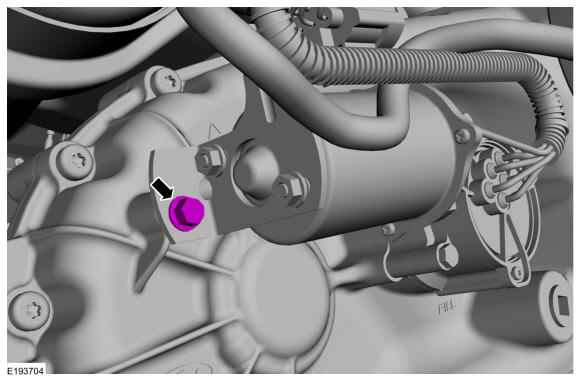

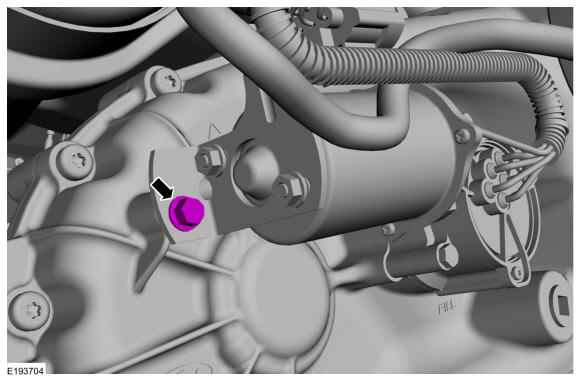

Remove the transfer case shift motor bracket bolt.

|

-

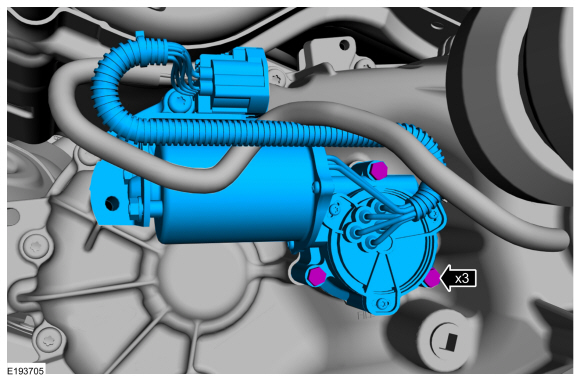

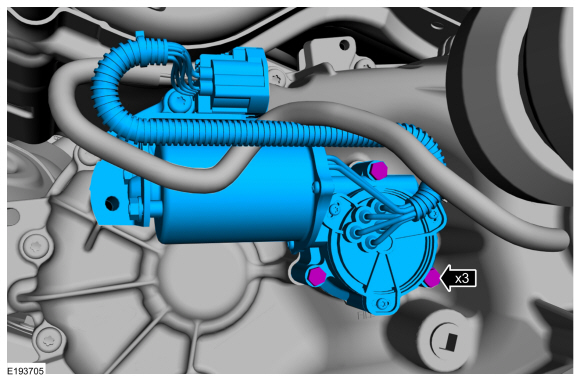

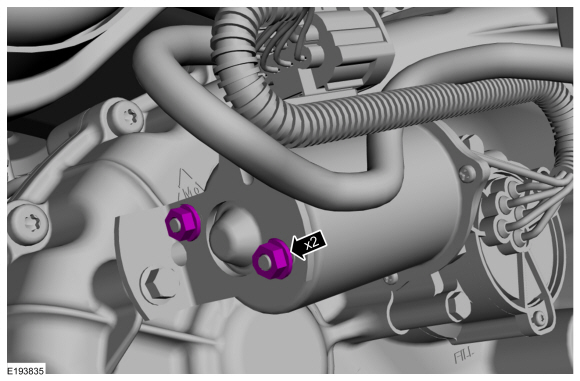

Remove the mounting bolts and the transfer case shift motor.

|

-

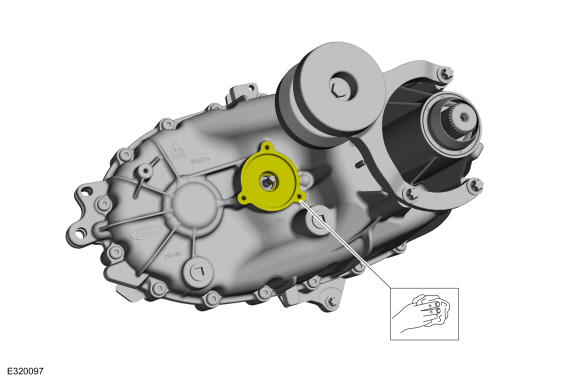

Clean the transfer case shift motor mating surface.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

|

Installation

-

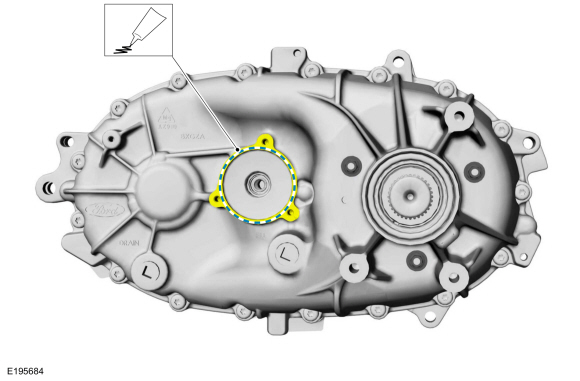

Apply a small bead of silicone sealant to the transfer case shift motor mating surface.

|

-

NOTICE: New shift motor bracket nuts are loose and are tightened last. Failure to follow the steps in the correct order may result in damage to the component.

Install the transfer case shift motor and bolts.

Torque: 89 lb.in (10 Nm)

|

-

Install the transfer case shift motor bracket bolt.

Torque: 89 lb.in (10 Nm)

|

-

Secure the transfer case shift motor bracket nuts.

Torque: 27 lb.in (3 Nm)

|

-

NOTE: After the wire is inserted into the connector, gently pull the wire back to verify the pin is locked inside the connector.

Install the coil wire pin in the electrical connector.

-

Insert the coil wire pin in the electrical connector.

-

Install the inner connector retainer.

-

Insert the coil wire pin in the electrical connector.

|

-

Connect the harness connector.

|

Transfer Case Control Module (TCCM). Removal and Installation

Transfer Case Control Module (TCCM). Removal and Installation

Removal

Remove the CJB cover.

Remove and disconnect the lower access panel.

NOTE:

The TCCM has slotted mounting holes...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Roof Side Rail. Removal and Installation

Special Tool(s) / General Equipment 6.5 mm Drill Bit Polydrive Bit Socket Self-Piercing Rivet (SPR) Remover/Installer Belt Sander Blind Rivet Gun Locking Pliers Materials Name Specification Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 - Seam SealerTA-2-B, 3M™ 0..

Lincoln Navigator 2018-2026 Workshop Manual: Welding Precautions. General Procedures

Check WARNING: Invisible ultraviolet and infrared rays emitted in welding can injure unprotected eyes and skin. Always use protection such as a welder's helmet with dark-colored filter lenses of the correct density. Electric welding will produce intense radiation, therefore, filter plate lenses of the deepest shade providing adequate visibility are recommended. It is stro..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Telematics Control Unit (TCU) Module. Removal and Installation

- Front Bumper Cover. Removal and Installation

- Vehicle Dynamics Control Module (VDM). Removal and Installation

- Remote Function Actuator (RFA) Module. Removal and Installation

- Transmission Fluid Drain and Refill. General Procedures

Front Driveshaft. Removal and Installation

Special Tool(s) / General Equipment

Crimping ToolMaterials

Name Specification Motorcraft® Premium Long-Life GreaseXG-1-E1 ESA-M1C75-B

Removal

With the vehicle in NEUTRAL, position the vehicle on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

Remove the bolts and the transmission shield.

Copyright © 2026 www.linavigator4.com