Refer to Wiring Diagrams Cell 20 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to: Starting System - System Operation and Component Description

(303-06 Starting System - 3.5L EcoBoost (272kW/370PS), Description and

Operation).

DTC Fault Trigger Conditions

| DTC |

Description |

Fault Trigger Condition |

| PCM P06E9:00 |

Engine Starter Performance: No Sub Type Information |

The PCM sets this DTC when no engine rotation is detected during a crank event.

|

| PCM P2535:00 |

Ignition Switch On/Start Position Circuit High: No Sub Type Information |

This DTC sets when the PCM detects voltage on the crank detect circuit while the engine is running.

|

Possible Sources

- Battery

- Battery cables

-

IPC

- Starter motor

-

BJB starter relay

Visual Inspection and Pre-checks

- Inspect the run/start relay.

- Inspect the high current BJB connections.

- Verify the BJB fuse 36 (30A).

- Inspect the passive key.

- Inspect the CPP switch.

|

| B1 PERFORM INSPECTION AND VERIFICATION |

-

Perform Inspection and Verification procedure in this section.

Was an obvious cause for an observed or reported concern found?

| Yes |

Correct the cause as necessary.

|

|

| B2 CHECK FOR NO KEY DETECTED MESSAGE IN THE MESSAGE CENTER |

-

NOTE:

There are certain areas inside the vehicle where

the IA key may not be detected and the message center displays NO KEY

DETECTED. If the IA key is in the far outside edges of the interior

(like in a door map pocket or above a sun visor) it might not be

detected. Move the IA key to a different location and try to start the

vehicle again.

Check the message displayed in the message center while pressing the ignition switch - push button start.

Is NO KEY DETECTED displayed?

| Yes |

Diagnose the NO KEY DETECTED concern.

REFER to: Perimeter Anti-Theft Alarm (419-01A Perimeter Anti-Theft Alarm, Diagnosis and Testing).

|

|

| B3 VERIFY THE BCM (BODY CONTROL MODULE)

AND PCM (POWERTRAIN CONTROL MODULE)

PASS THE NETWORK TEST |

-

Using a diagnostic scan tool, perform the Network Test.

Did the BCM and PCM pass the Network Test?

| No |

REFER to: Controller Area Network (CAN) Module Communications

Network (418-00A Controller Area Network (CAN) Module Communications

Network, Diagnosis and Testing).

|

|

| B4 RETRIEVE DIAGNOSTIC TROUBLE CODES (DTCS) |

-

Using a diagnostic scan tool, perform BCM and PCM self-tests.

Are any Diagnostic Trouble Codes (DTCs) present?

| Yes |

For all BCM Diagnostic Trouble Codes (DTCs), refer to the BCM DTC Chart in this section.

For PCM

DTC P06E9 GO to B5

For all other PCM

Diagnostic Trouble Codes (DTCs),

REFER to: Electronic Engine Controls (303-14 Electronic Engine Controls - 3.5L EcoBoost (272kW/370PS), Diagnosis and Testing).

|

|

| B5 CHECK THE OPERATION OF THE STOPLAMPS |

-

While observing the stoplamps, apply the brake pedal.

Do the stoplamps illuminate?

| No |

Diagnose All the Stoplamps are inoperative.

REFER to: Stoplamps (417-01 Exterior Lighting, Diagnosis and Testing).

|

|

| B6 CHECK THE BRAKE PEDAL POSITION (BOO1) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view PCM Parameter Identifications (PIDs)

-

Monitor the PCM B001 PID while applying the brake pedal.

Does the PID read On?

|

| B7 CHECK THE BPP (BRAKE PEDAL POSITION)

SWITCH CIRCUIT FOR VOLTAGE AT THE PCM (POWERTRAIN CONTROL MODULE)

|

-

While applying the brake pedal, measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C175B-87

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| B8 CHECK BCM (BODY CONTROL MODULE)

IGN_SW_STATE PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view the BCM Parameter Identifications (PIDs).

-

Make sure the transmission is in PARK or NEUTRAL.

-

Monitor the BCM

PID IGN_SW_STATE while pressing the ignition switch - push button start and the brake pedal.

Does the PID change from Off to Start when the ignition switch - push button start and the brake pedal are pressed?

| No |

DIAGNOSE No power in ON.

REFER to: Steering Wheel and Column

Electrical Components (211-05 Steering Wheel and Column Electrical

Components, Diagnosis and Testing).

|

|

| B9 CHECK THE TRANSMISSION RANGE INPUT ALLOWING ENGINE START (TR_CRANK) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view the TCM Parameter Identifications (PIDs).

-

Monitor the TCM

PID TR_CRANK, while placing the gear selector in PARK and then NEUTRAL.

Does the PID read Yes in both positions?

| No |

REFER to: DTC Chart and Pinpoint Tests - 3.5L EcoBoost

(272kW/370PS) (307-01 Automatic Transmission - 10-Speed Automatic

Transmission – 10R80, Diagnosis and Testing).

|

|

| B10 CHECK THE PCM (POWERTRAIN CONTROL MODULE)

ENGINE CRANKING (ENG_CRANK) PID (PARAMETER IDENTIFICATION)

|

-

Make sure the transmission is in PARK or NEUTRAL.

-

Using a diagnostic scan tool, view the PCM Parameter Identifications (PIDs).

-

Monitor the PCM

PID ENG_CRANK while pressing the ignition switch - push button start and the brake pedal.

Does the PID change from Inactive to Active?

|

| B11 CHECK THE BJB (BATTERY JUNCTION BOX)

STARTER RELAY FUSE |

-

Verify the BJB fuse 11 (30A).

Was the fuse OK?

| No |

REPAIR the circuit for a short to ground.

|

|

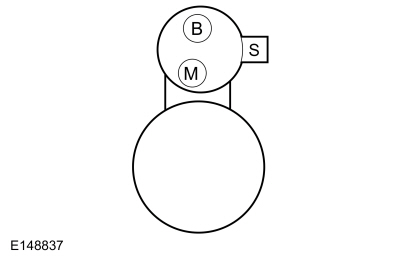

| B12 CHECK FOR START REQUEST AT THE STARTER |

-

Disconnect Starter solenoid C1716B

.

-

While holding the key in the START position, measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1716B-1 ("S" terminal)

|

|

Ground

|

Is the voltage greater than 11 volts?

| No |

Connect Starter solenoid C1716B and GO to B13

|

|

| B13 CHECK THE STARTER MOTOR CONTROL OPERATION |

-

Disconnect

BJB Relay Module C1035C

.

-

Connect a remote starter switch:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1035C-3

|

Remote Starter Switch

|

|

-

Momentarily engage the remote starter switch.

Does the engine crank?

| No |

REPAIR circuit for open.

|

|

| B14 CHECK THE PCM (POWERTRAIN CONTROL MODULE)

STARTER RELAY CONTROL CIRCUITS FOR A SHORT TO VOLTAGE |

-

Connect

BJB Relay Module C1035C

.

-

Measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C175B-60

|

|

Ground

|

|

C175B-11

|

|

Ground

|

Is any voltage present?

| Yes |

REPAIR the affected circuit.

|

|

| B15 CHECK THE PCM (POWERTRAIN CONTROL MODULE)

STARTER RELAY CONTROL CIRCUITS FOR A SHORT TO GROUND |

-

Disconnect

BJB Relay Module C1035C

.

-

Measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C175B-60

|

|

Ground

|

|

C175B-11

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

| No |

REPAIR the affected circuit.

|

|

| B16 CHECK THE PCM (POWERTRAIN CONTROL MODULE)

STARTER RELAY CONTROL CIRCUITS FOR AN OPEN |

-

Measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C175B-60

|

|

C1035C-23

|

|

C175B-11

|

|

C1035C-25

|

Are the resistances less than 3 ohms?

| Yes |

INSTALL a new BJB relay module.

|

| No |

REPAIR the affected circuit. CHECK the system for proper operation. If engine will still not crank, GO to B22

|

|

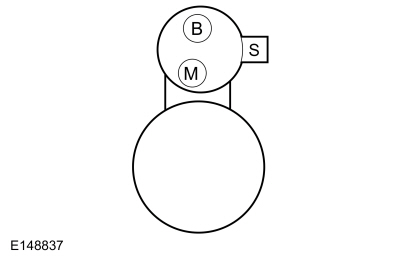

| B17 CHECK THE STARTER MOTOR FOR CORRECT OPERATION |

-

Perform Starter Motor - Positive Circuit Test.

REFER to: Starter Amperage Draw Test (303-06 Starting System - 3.5L EcoBoost (272kW/370PS), General Procedures).

Was an obvious cause found?

| Yes |

Correct the cause as necessary.

|

|

| B18 CHECK THE BATTERY GROUND CABLES |

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

|

Ground G105

|

|

|

Ground G106

|

|

|

Ground G107

|

Are the voltages greater than 11 volts?

| No |

CLEAN or INSTALL anew negative battery cable as necessary.

REFER to: Battery Cables (414-01 Battery, Mounting and Cables, Removal and Installation).

|

|

| B19 CHECK THE STARTER MOTOR GROUND |

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

|

Starter motor case

Starter motor case

|

Is the voltage greater than 11 volts?

| No |

CLEAN the starter motor mounting flange and MAKE

SURE the starter motor is correctly mounted.

REFER to: Starter Motor (303-06 Starting System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

|

|

| B20 CHECK THE VOLTAGE TO THE STARTER MOTOR |

-

Measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1716A-1 ("B" terminal)

|

|

Ground

|

Is the voltage greater than 11 volts?

| Yes |

INSTALL a new starter motor.

REFER to: Starter Motor (303-06 Starting System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

|

| No |

INSTALL a new positive battery cable.

REFER to: Battery Cables (414-01 Battery, Mounting and Cables, Removal and Installation).

|

|

| B21 CHECK PCM (POWERTRAIN CONTROL MODULE)

FOR CRANK REQUEST |

-

While holding the key in the START position, measure:

Click to display connectors

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C175B-1 ("S" terminal)

|

|

Ground

|

Is the voltage greater than 11 volts?

| No |

REPAIR circuit for open.

|

|

| B22 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE)

OPERATION |

-

Disconnect and inspect all PCM connectors.

-

Repair:

-

corrosion (install new connectors or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the PCM connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes |

CHECK OASIS for any applicable Technical Service Bulletins (TSBs). If a

TSB exists for this concern, DISCONTINUE this test and FOLLOW the TSB

instructions. If no Technical Service Bulletins (TSBs) address this

concern,

Click here to access Guided Routine (PCM).

Click here to access Guided Routine (PCM).

|

| No |

The system is operating correctly at this time. The

concern may have been caused by module connections. ADDRESS the root

cause of any connector or pin issues.

|

|

PINPOINT TEST A: ENGINE DOES NOT CRANK - WITHOUT PUSH-BUTTON START

PINPOINT TEST A: ENGINE DOES NOT CRANK - WITHOUT PUSH-BUTTON START

PINPOINT TEST B: ENGINE DOES NOT CRANK - WITH PUSH-BUTTON START

PINPOINT TEST B: ENGINE DOES NOT CRANK - WITH PUSH-BUTTON START

PINPOINT TEST C: UNUSUAL STARTER NOISE

PINPOINT TEST C: UNUSUAL STARTER NOISE

PINPOINT TEST D: C113A:11, C113A:15

PINPOINT TEST D: C113A:11, C113A:15

PINPOINT TEST E: DTC P06E4

PINPOINT TEST E: DTC P06E4

PINPOINT TEST F: DTC P162F

PINPOINT TEST F: DTC P162F

PINPOINT TEST G: B15DB:09

PINPOINT TEST G: B15DB:09

PINPOINT TEST H: THE ENGINE CRANKS SLOWLY

PINPOINT TEST H: THE ENGINE CRANKS SLOWLY

PINPOINT TEST I: THE STARTER SPINS BUT THE ENGINE DOES NOT CRANK

PINPOINT TEST I: THE STARTER SPINS BUT THE ENGINE DOES NOT CRANK

PINPOINT TEST J: THE STARTER DOES NOT DISENGAGE FROM THE FLEXPLATE

PINPOINT TEST J: THE STARTER DOES NOT DISENGAGE FROM THE FLEXPLATE

PINPOINT TEST K: AUTO-START-STOP SYSTEM IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY

PINPOINT TEST K: AUTO-START-STOP SYSTEM IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY

PINPOINT TEST L: AUTO-START-STOP SYSTEM CANNOT BE DISABLED BY DRIVER

PINPOINT TEST L: AUTO-START-STOP SYSTEM CANNOT BE DISABLED BY DRIVER

PINPOINT TEST M: THE ENGINE CRANKS BUT WILL NOT START

PINPOINT TEST M: THE ENGINE CRANKS BUT WILL NOT START  Starter Amperage Draw Test. General Procedures

Starter Amperage Draw Test. General Procedures 205-123

(T78P-1177-A)

205-123

(T78P-1177-A)

308-047

(T77F-1102-A)

308-047

(T77F-1102-A)

Starter motor case

Starter motor case