Lincoln Navigator: Ethernet Module Communications Network / Ethernet Module Communications Network. Diagnosis and Testing

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Module | DTC | Description | Action |

|---|---|---|---|

| APIM | U2400:81 | Ethernet Failure With Gateway Module A (GWM): Invalid Serial Data Received | GO to Pinpoint Test A |

| APIM | U2400:92 | Ethernet Failure With Gateway Module A (GWM): Performance Or Incorrect Operation | GO to Pinpoint Test A |

| GWM | U2120:00 | Ethernet Learning Incomplete: No Sub Type Information | GO to Pinpoint Test C |

| GWM | U2401:00 | Ethernet Failure With Accessory Protocol Interface Module (APIM): No Sub Type Information | GO to Pinpoint Test B |

| GWM | U2401:81 | Ethernet Failure With Accessory Protocol Interface Module (APIM): Invalid Serial Data Received | GO to Pinpoint Test A |

| GWM | U2401:92 | Ethernet Failure With Accessory Protocol Interface Module (APIM): Performance Or Incorrect Operation | GO to Pinpoint Test A |

| GWM | U2402:00 | Ethernet Failure With Telematic Control Unit Module (TCU): No Sub Type Information | GO to Pinpoint Test B |

| GWM | U2402:81 | Ethernet Failure With Telematic Control Unit Module (TCU): Invalid Serial Data Received | GO to Pinpoint Test A |

| GWM | U2402:92 | Ethernet Failure With Telematic Control Unit Module (TCU): Performance Or Incorrect Operation | GO to Pinpoint Test A |

| GWM | U2403:81 | Ethernet Failure With Instrument Panel Cluster Control Module (IPC): Invalid Serial Data Received | GO to Pinpoint Test A |

| GWM | U2403:92 | Ethernet Failure With Instrument Panel Cluster Control Module (IPC): Performance Or Incorrect Operation | GO to Pinpoint Test A |

| GWM | U2404:81 | Ethernet Failure With Image Processing Module 'A' (IPMA): Invalid Serial Data Received | GO to Pinpoint Test A |

| GWM | U2404:92 | Ethernet Failure With Image Processing Module 'A' (IPMA): Performance Or Incorrect Operation | GO to Pinpoint Test A |

| IPMA | U2400:00 | Ethernet Failure With Gateway Module A (GWM): No Sub Type Information | GO to Pinpoint Test A |

Pinpoint Tests

PINPOINT TEST A: ETHERNET NETWORK FAILURE - MULTIPLE DIAGNOSTIC TROUBLE CODES

PINPOINT TEST A: ETHERNET NETWORK FAILURE - MULTIPLE DIAGNOSTIC TROUBLE CODES |

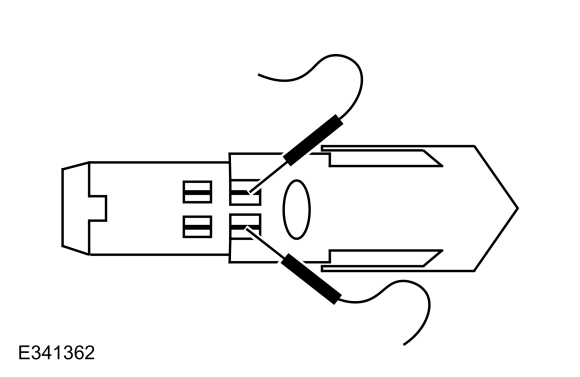

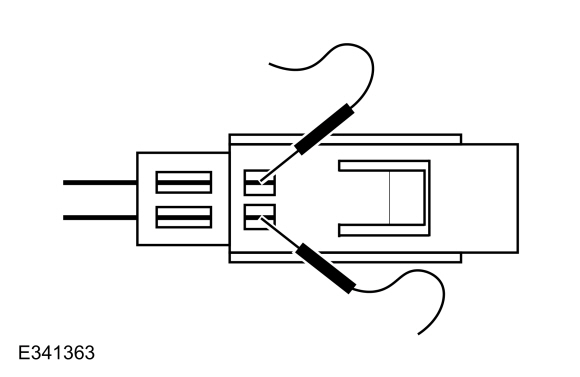

Refer to Wiring Diagrams Cell 14 for schematic and connector information. Normal Operation and Fault Conditions Ethernet Cable Testing At Cable End

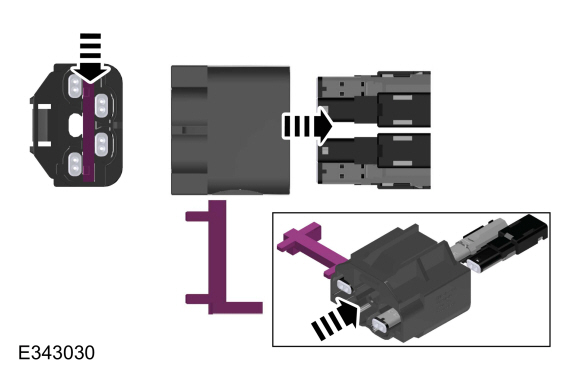

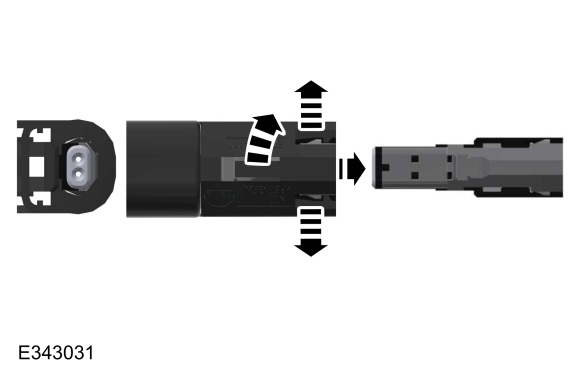

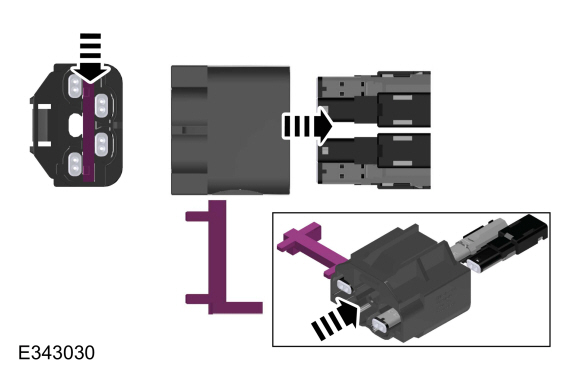

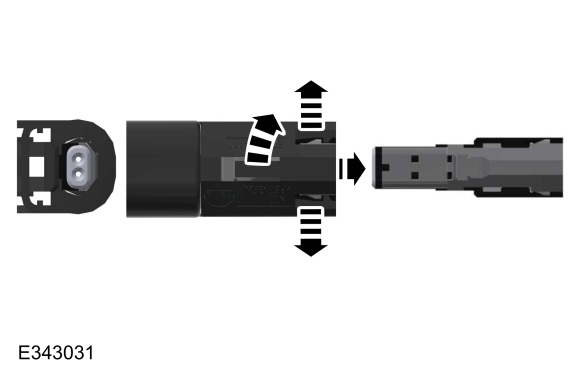

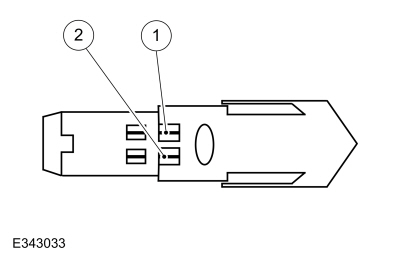

To test the Ethernet cable in question at the GWM , the cable must be removed from the GWM master connector to gain access to the connector pins where probing can take place (refer to the illustration above). The Ethernet cable connector end identification

color can be used to identify the module the Ethernet cable is connected

to. Refer to the chart in the Description and Operation section for the

color assignment. REFER to: Ethernet Module Communications Network -

System Operation and Component Description (418-00B Ethernet Module

Communications Network, Description and Operation).

To test the Ethernet cable in question at the all other applicable modules, the cable must be removed from the connector housing to gain access to the connector pins where probing can take place. (refer to the illustration above) Ethernet Cable Testing At Cable In-line Connection

To test the Ethernet cable in question at the in-line connection, the cable must be removed from the connector housing to gain access to the connector pins where probing can take place (refer to the illustration above).

REFER to: Ethernet Module Communications Network - System Operation and

Component Description (418-00B Ethernet Module Communications Network,

Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||||||||||||||||||||||

| A1 CHECK THE NETWORK COMMUNICATION | ||||||||||||||||||||||||||||||||||||

Does the module in question (APIM , TCU , IPC , IPMA ) pass the network test?

|

||||||||||||||||||||||||||||||||||||

| A2 CHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||||||||||||||||||||||||||||

Are any non-Ethernet related Diagnostic Trouble Codes (DTCs) present?

|

||||||||||||||||||||||||||||||||||||

| A3 CHECK THE ETHERNET CIRCUIT FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||

| A4 CHECK THE ETHERNET CIRCUIT FOR A SHORT TOGETHER | ||||||||||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||

| A5 CHECK THE ETHERNET CIRCUIT FOR A SHORT TO POWER | ||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

||||||||||||||||||||||||||||||||||||

| A6 CHECK THE ETHERNET CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||

| A7 RECHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||||||||||||||||||||||||||||

Is the DTC still present?

|

||||||||||||||||||||||||||||||||||||

| A8 CHECK FOR CORRECT APIM (SYNC MODULE) OPERATION | ||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||||||||||

| A9 CHECK FOR CORRECT TCU (TELEMATIC CONTROL UNIT MODULE) OPERATION | ||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||||||||||

| A10 CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER) OPERATION | ||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||||||||||

| A11 CHECK FOR CORRECT IPMA (IMAGE PROCESSING MODULE A) OPERATION | ||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST B: U2401:00, U2402:00

PINPOINT TEST B: U2401:00, U2402:00|

Refer to Wiring Diagrams Cell 14 for schematic and connector information. Normal Operation and Fault Conditions Ethernet Cable Testing At Cable End

To test the Ethernet cable in question at the GWM , the cable must be removed from the GWM master connector to gain access to the connector pins where probing can take place (refer to the illustration above). The Ethernet cable connector end identification

color can be used to identify the module the Ethernet cable is connected

to. Refer to the chart in the Description and Operation section for the

color assignment. REFER to: Ethernet Module Communications Network -

System Operation and Component Description (418-00B Ethernet Module

Communications Network, Description and Operation).

To test the Ethernet cable in question at the all other applicable modules, the cable must be removed from the connector housing to gain access to the connector pins where probing can take place. (refer to the illustrations above) Ethernet Cable Testing At Cable In-line Connection

To test the Ethernet cable in question at the in-line connection, the cable must be removed from the connector housing to gain access to the connector pins where probing can take place (refer to the illustrations above).

REFER to: Ethernet Module Communications Network - System Operation and

Component Description (418-00B Ethernet Module Communications Network,

Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||

| B1 CHECK THE NETWORK COMMUNICATION | |||||||||||||

Does the module in question (APIM , TCU ) pass the network test?

|

|||||||||||||

| B2 CHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

|||||||||||||

| B3 RESET THE MODULE IN QUESTION (APIM, TCU) | |||||||||||||

Does the authorization state PID still indicate Unprovisioned?

|

|||||||||||||

| B4 RECHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||

Is DTC U2401:00 or U2402:00 still present?

|

|||||||||||||

| B5 CHECK THE ETHERNET CIRCUIT FOR AN OPEN | |||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||

| B6 CHECK THE ETHERNET CIRCUIT FOR A SHORT TO GROUND | |||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||

| B7 CHECK THE ETHERNET CIRCUIT FOR A SHORT TOGETHER | |||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||

| B8 CHECK THE ETHERNET CIRCUIT FOR A SHORT TO POWER | |||||||||||||

Is any voltage present?

|

|||||||||||||

| B9 CHECK FOR CORRECT APIM (SYNC MODULE) OPERATION | |||||||||||||

Is the concern still present?

|

|||||||||||||

| B10 CHECK FOR CORRECT TCU (TELEMATIC CONTROL UNIT MODULE) OPERATION | |||||||||||||

Is the concern still present?

|

PINPOINT TEST C: U2120:00

PINPOINT TEST C: U2120:00 |

Refer to Wiring Diagrams Cell 14 for schematic and connector information. Normal Operation and Fault Conditions All Ethernet connected modules are learned through the Ethernet

learning mode at key on. If all modules are not learned thisDTC is set.

If the Ethernet module is learned at a subsequent key on event, the DTC

is cleared. REFER to: Ethernet Module Communications Network - System

Operation and Component Description (418-00B Ethernet Module

Communications Network, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||

| C1 CHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||

Is DTC U2120:00 the only DTC present?

|

||||||

| C2 RE-CHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||

Is DTC U2120:00 still present?

|

||||||

| C3 CHECK THE NETWORK COMMUNICATION | ||||||

Do the APIM , IPC , IPMA and TCU pass the network test?

|

||||||

| C4 CHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||||

| C5 CHECK FOR CORRECT GWM (GATEWAY MODULE A) OPERATION | ||||||

Is the concern still present?

|

Ethernet Module Communications Network - System Operation and Component Description. Description and Operation

Ethernet Module Communications Network - System Operation and Component Description. Description and Operation

System Operation

System Diagram

NOTE:

The system diagrams include all component options. Some components may not be equipped on the vehicle.

Ethernet Communication Network

*...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Parking, Rear and License Plate Lamps. Diagnosis and Testing

Diagnostic Trouble Code (DTC) Chart Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Module DTC Description Action BCM B10F3:11 Left front position light: Circuit Short To Ground GO to Pinpoint Test D BCM B10F3:..

Lincoln Navigator 2018-2026 Workshop Manual: Turbocharger LH. Removal and Installation

Materials Name Specification Motorcraft® High Temperature Nickel Anti-Seize LubricantXL-2 - Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C - Removal NOTICE: The turbocharger compressor vanes can be damaged by even the smallest particles. When removing any turbocharger or engine air intake system component, ensure t..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Rear Bumper. Removal and Installation

- All Terrain Control Module (ATCM). Removal and Installation

- Liftgate Trim Panel. Removal and Installation

- Identification Codes. Description and Operation

- Body Control Module (BCM). Removal and Installation

Front Driveshaft. Removal and Installation

Special Tool(s) / General Equipment

Crimping ToolMaterials

Name Specification Motorcraft® Premium Long-Life GreaseXG-1-E1 ESA-M1C75-B

Removal

With the vehicle in NEUTRAL, position the vehicle on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

Remove the bolts and the transmission shield.

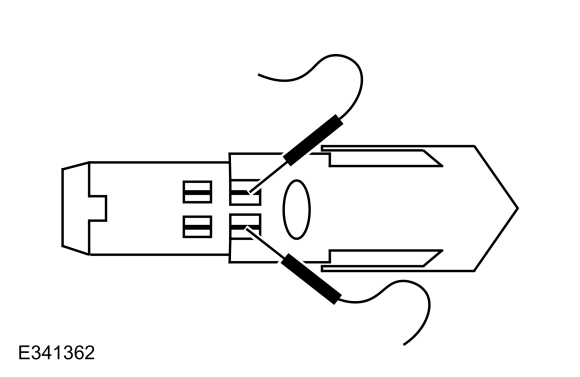

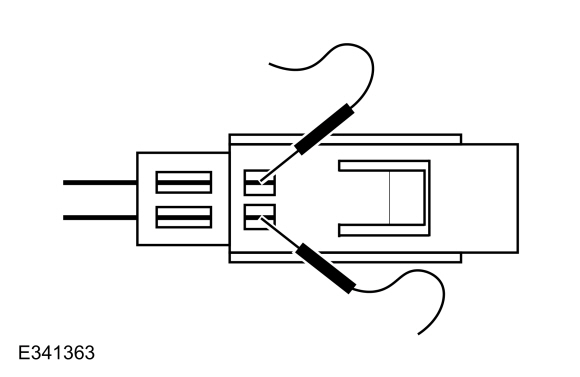

Ethernet cable , pin 1

Ethernet cable , pin 1