Lincoln Navigator: Engine Ignition - 3.5L EcoBoost (272kW/370PS) / Engine Ignition - Component Location. Description and Operation

Lincoln Navigator 2018-2026 Workshop Manual / Engine / Engine Ignition - 3.5L EcoBoost (272kW/370PS) / Engine Ignition - Component Location. Description and Operation

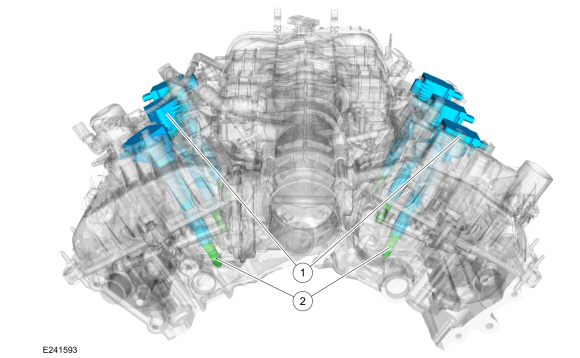

3.5L EcoBoost

| Item | Description |

|---|---|

| 1 | Ignition coil-on-plug(s) |

| 2 | Spark plug(s) |

Specifications

Specifications

General Specifications

Item

Specification

Spark plug

12405

Spark plug gap

0...

Engine Ignition - System Operation and Component Description. Description and Operation

Engine Ignition - System Operation and Component Description. Description and Operation

System Operation

Cold Start Emission Reduction Monitor

The

cold start emission reduction monitor is an on board strategy designed

for vehicles that meet the low emissions vehicle-II (LEV-II) emissions

standards...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Air Conditioning (A/C) System Leak Test Using Forming Gas. General Procedures

Special Tool(s) / General Equipment Forming Gas Pressure Gauge and Leak Detector Materials Name Specification Forming Gas - Leak detection All vehicles NOTE: Use a Rotunda-approved Forming Gas A/C System Dealership Leak Detection Service Kit that meets SAE J2790...

Lincoln Navigator 2018-2026 Workshop Manual: Specifications

Coolant Capacity: Vehicles Built Up To: 08-July-2018 Name Fill Capacity Material: Motorcraft® Orange Concentrated Antifreeze/Coolant / VC-3-B (WSS-M97B44-D) Base radiator — 18...

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Vehicle Dynamics Control Module (VDM). Removal and Installation

- Rear Bumper. Removal and Installation

- Power Running Board (PRB). Diagnosis and Testing

- SYNC Module [APIM]. Removal and Installation

- Body Control Module (BCM). Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position andCopyright © 2026 www.linavigator4.com