Lincoln Navigator: Full Frame and Body Mounting / Driveshaft Center Bearing Bracket. Removal and Installation

Lincoln Navigator 2018-2026 Workshop Manual / Frame and Mounting / Full Frame and Body Mounting / Driveshaft Center Bearing Bracket. Removal and Installation

Special Tool(s) / General Equipment

| Grinder | |

| MIG/MAG Welding Equipment | |

| Locking Pliers |

Removal

NOTE: The following applies to left hand (LH) drive/rear wheel drive (RWD) vehicles only.

-

Restore the vehicle to manufacturer's dimensions.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Remove the rear driveshaft.

Refer to: Rear Driveshaft (205-01 Driveshaft, Removal and Installation).

-

Remove the fuel tank.

Refer to: Fuel Tank (310-01 Fuel Tank and Lines - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the muffler.

Refer to: Muffler (309-00 Exhaust System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Remove the rear driveshaft.

-

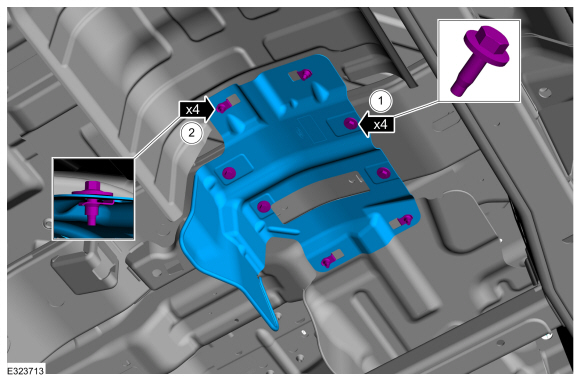

Remove the bolts and the heat shield.

|

- Anchor the vehicle to a frame rack following the equipment manufacturer's instructions.

-

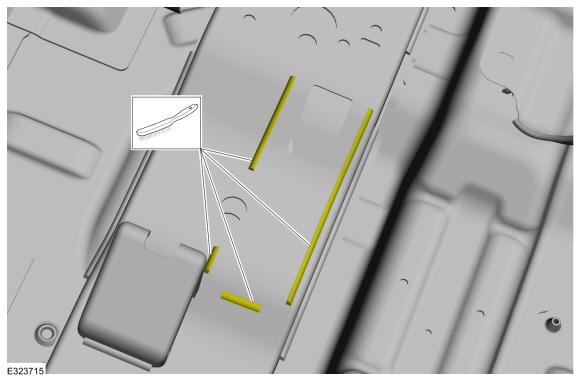

NOTE: Be careful not to cut into the frame cross member, it will be reused.

Grind the welds holding the driveshaft center bearing bracket to the frame and remove the driveshaft center bearing bracket.

Use the General Equipment: Grinder

|

-

Clean the areas of the frame where the welds were ground.

|

Installation

-

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

-

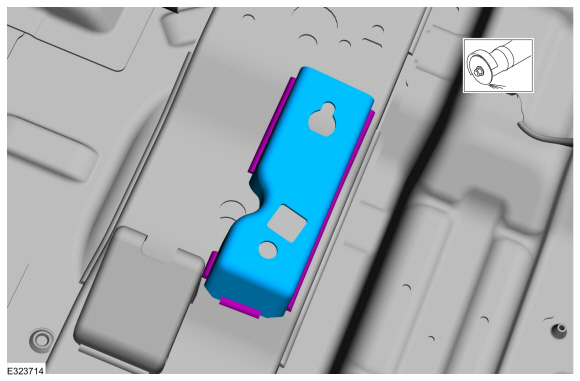

Loosely clamp the replacement bracket in a preliminary

position. Perform measurements to verify proper placement of the new

driveshaft center bearing bracket, then clamp firmly into position.

-

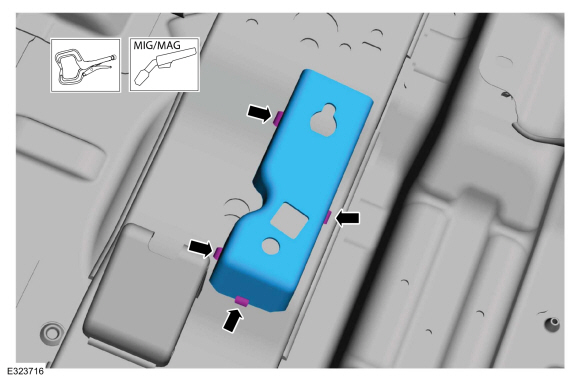

With all measurements verified and the new

driveshaft center bearing bracket in proper position, tack-weld the new

driveshaft center bearing bracket in place to the frame crossmember.

Use the General Equipment: Locking Pliers

Use the General Equipment: MIG/MAG Welding Equipment

-

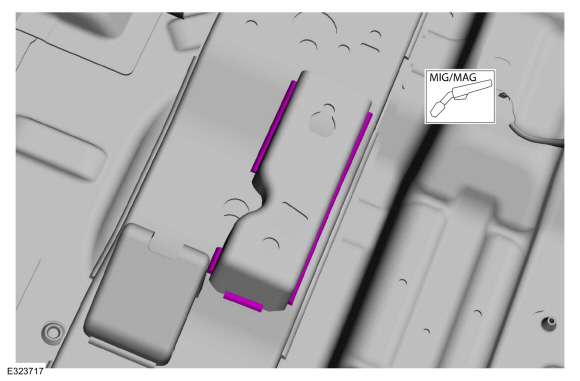

With all measurements verified and the new

driveshaft center bearing bracket in proper position, tack-weld the new

driveshaft center bearing bracket in place to the frame crossmember.

|

-

Re-check measurements, then solid weld the driveshaft center bearing bracket to the frame crossmember.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Metal finish the repair area using typical metal finishing techniques.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

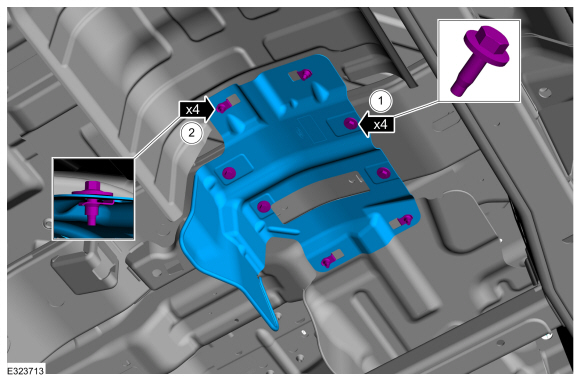

Install the bolts and the heat shield.

Torque:

1: 177 lb.in (20 Nm)

2: 177 lb.in (20 Nm)

|

-

Install the muffler.

Refer to: Muffler (309-00 Exhaust System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the fuel tank.

Refer to: Fuel Tank (310-01 Fuel Tank and Lines - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Install the rear driveshaft.

Refer to: Rear Driveshaft (205-01 Driveshaft, Removal and Installation).

Drilling Precautions. General Procedures

Drilling Precautions. General Procedures

Activation

If a hole must be drilled in the frame the following requirements must be followed:

The hole is at least the specified distance from the edge of the nearest hole...

Frame Members-Front Frame Section. Removal and Installation

Frame Members-Front Frame Section. Removal and Installation

Special Tool(s) /

General Equipment

Grinder

Plasma Cutter

MIG/MAG Welding Equipment

Locking Pliers

Removal

NOTE:

The following procedure provides steps to replace the front

frame short section at the first frame crossmember or the frame section

at the center rail joint depending on the extent of vehicle damage...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Bearing Inspection. General Procedures

Inspection Cratering - fatigue failure Spot glazing - incorrect seating Scratching - dirty engine oil Base exposed - poor lubrication Both edges worn - journal damaged One edge worn - journal tapered or bearing not seated ..

Lincoln Navigator 2018-2026 Workshop Manual: Oil Pump. Removal and Installation

Special Tool(s) / General Equipment 303-1655Tool, Camshaft Holding Vehicle/Axle Stands Materials Name Specification Motorcraft® High Performance Engine RTV SiliconeTA-357 WSE-M4G323-A6 Removal NOTICE: During engine repair procedures, cleanliness is extremely important. Any foreign material, including any material created ..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Telematics Control Unit (TCU) Module. Removal and Installation

- Front Bumper Cover. Removal and Installation

- Brake Service Mode Activation and Deactivation. General Procedures

- Transmission Fluid Level Check. General Procedures

- Body Control Module (BCM). Removal and Installation

Front Stabilizer Bar Link. Removal and Installation

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

NOTE: Removal steps in this procedure may contain installation details.

With the vehicle in NEUTRAL, position it on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

NOTICE: Do not use power tools to remove or install the stabilizer bar

Copyright © 2026 www.linavigator4.com