Lincoln Navigator: Front Suspension - LHD 4WD / Wheel Knuckle. Removal and Installation

Special Tool(s) / General Equipment

|

204-592 Separator, Lower Arm Ball Joint TKIT-2006C-FFMFLM TKIT-2006C-LM TKIT-2006C-ROW |

| Tie Rod End Remover | |

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

-

Remove the front wheel bearing and wheel hub.

Refer to: Front Wheel Bearing and Wheel Hub (204-01B Front Suspension - LHD 4WD, Removal and Installation).

-

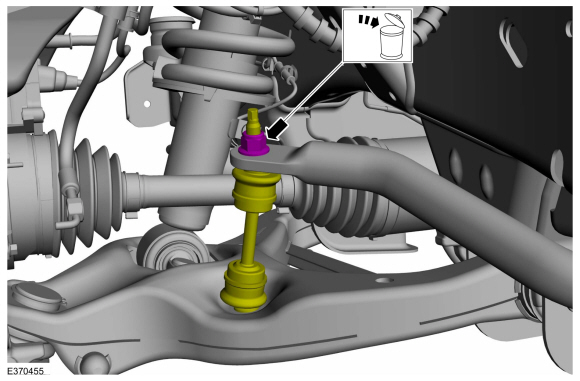

NOTICE: Do not use power tools to remove or install the stabilizer bar link nuts. Damage to the stabilizer bar link ball joints and boots may occur.

NOTE: The stabilizer bar links are designed with low friction ball joints that have a low breakaway torque.

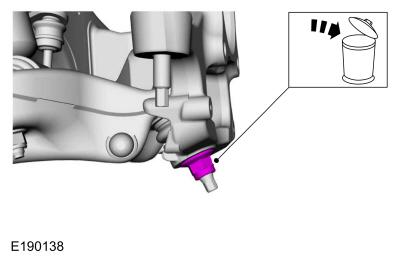

Use the hex-holding feature to prevent the ball stud from turning while removing or installing the stabilizer bar link nut. Remove and discard the front stabilizer bar link upper nut.

|

-

Disconnect the battery ground cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

-

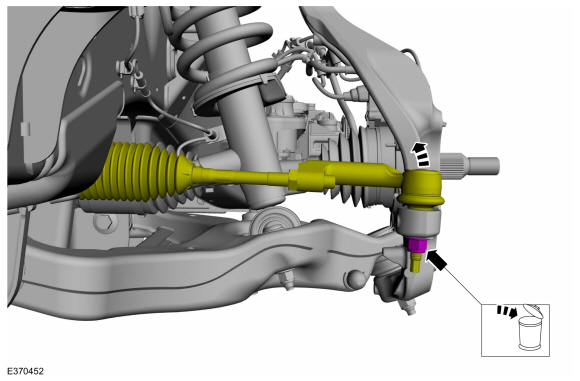

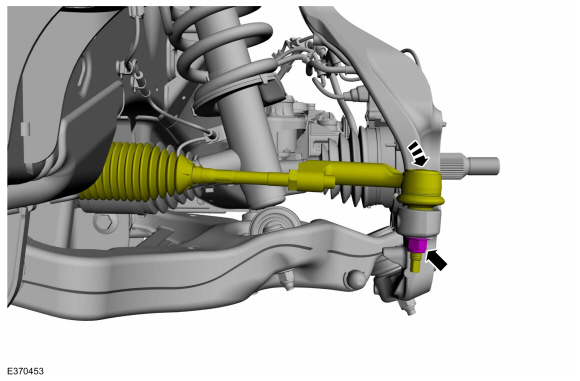

NOTICE: Do not use a hammer to separate the outer tie-rod end from the wheel knuckle or damage to the wheel knuckle may result.

NOTICE: Use care when installing the tie rod separator or damage to the outer tie-rod end boot may occur.

NOTE: Use the hex-holding feature to prevent the stud from turning while removing the nut.

Remove and discard the tie rod end nut and separate the tie rod end from the wheel knuckle.

Use the General Equipment: Tie Rod End Remover

|

-

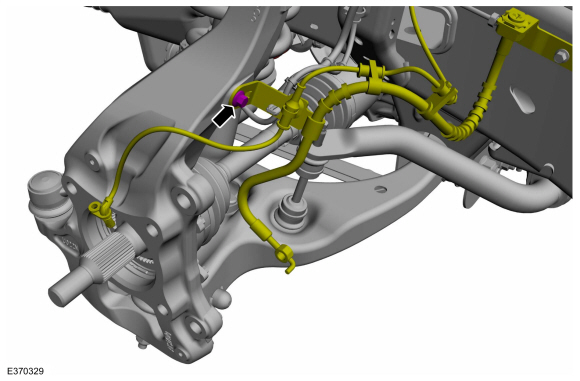

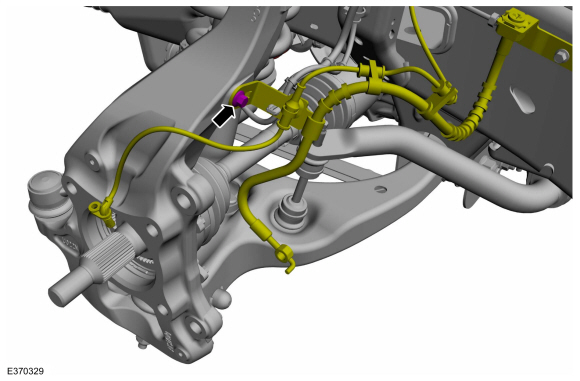

Remove the wheel speed sensor wire bracket bolt on the

wheel knuckle and position aside the wheel speed sensor wire.

|

-

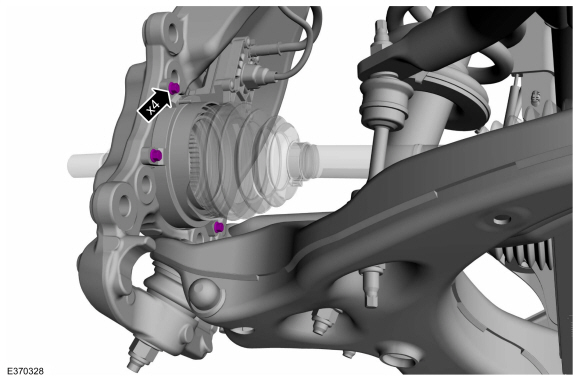

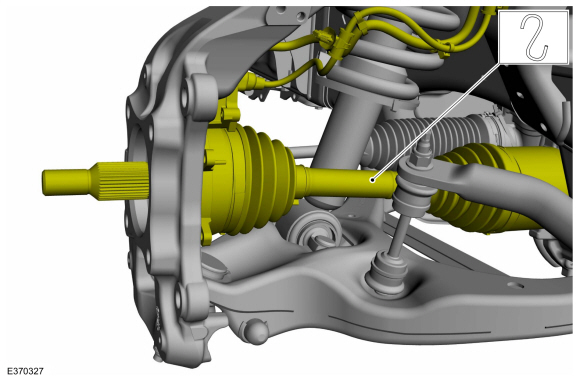

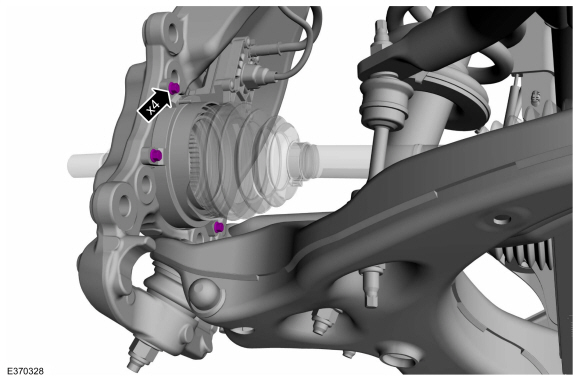

Remove the IWE bolts.

|

-

Position the IWE and halfshaft.

|

-

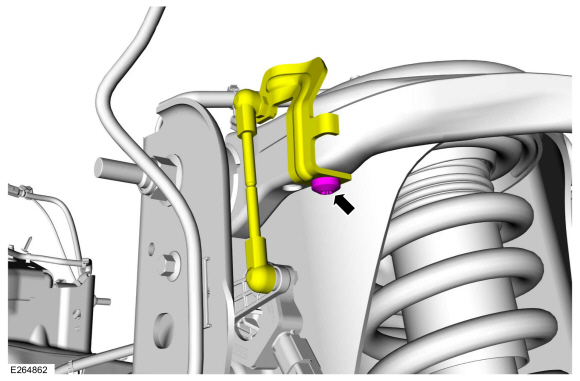

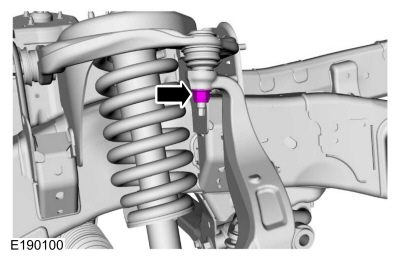

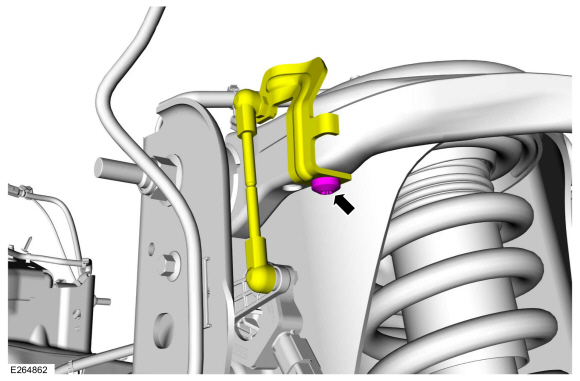

NOTICE: The suspension height sensors must be disconnected prior to servicing suspension components. Damage to the suspension height sensors and/or the vehicle dynamic suspension system may occur. The sensors will need to be recalibrated after reassembly.

NOTE: If equipped with dynamic suspension.

Remove the height sensor arm bracket screw and position aside the bracket.

|

-

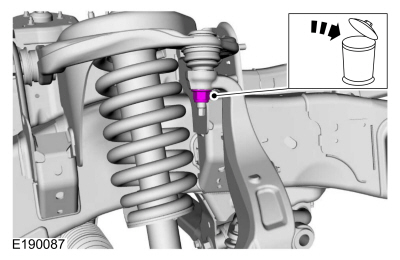

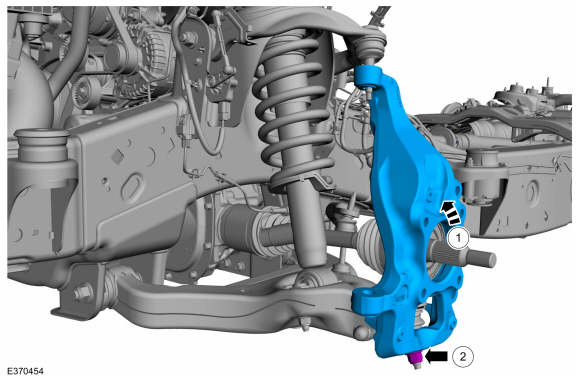

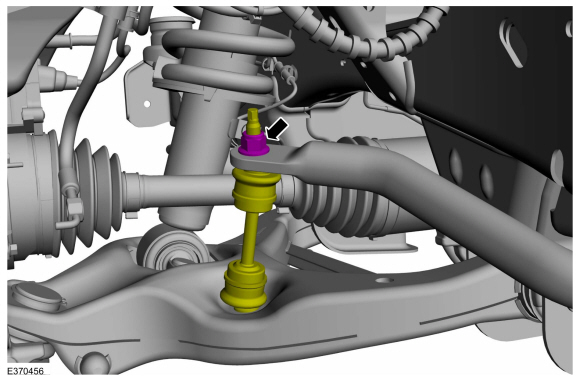

Remove and discard the upper ball joint nut.

|

-

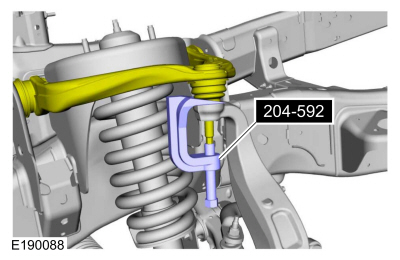

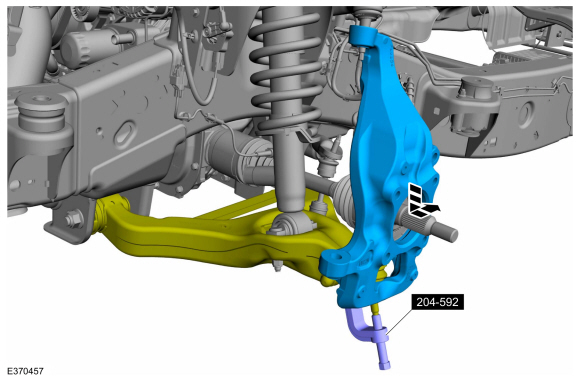

NOTE: Be sure not to damage the ball joint boot when installing the Ball Joint Separator.

Separate the upper ball joint from the wheel knuckle.

Use Special Service Tool: 204-592 Separator, Lower Arm Ball Joint.

|

-

Remove and discard the lower ball joint nut.

|

-

NOTICE: Do not use a prying device or separator fork between the ball joint and the wheel knuckle. Damage to the ball joint or ball joint seal may result.

NOTICE: Use care when releasing the lower arm and wheel knuckle into the resting position or damage to the ball joint seal may occur.

Separate the wheel knuckle from the lower ball joint and remove the wheel knuckle.

Use Special Service Tool: 204-592 Separator, Lower Arm Ball Joint.

|

Installation

-

-

Install the wheel knuckle.

-

Install the new lower ball joint nut.

Torque: 76 lb.ft (103 Nm)

-

Install the wheel knuckle.

|

-

Install the new upper ball joint nut.

Torque: 46 lb.ft (63 Nm)

|

-

NOTICE: The suspension height sensors must be disconnected prior to servicing suspension components. Damage to the suspension height sensors and/or the vehicle dynamic suspension system may occur. The sensors will need to be recalibrated after reassembly.

NOTE: If equipped with dynamic suspension.

Position the height sensor arm bracket and install the height sensor arm bracket screw.

Torque: 177 lb.in (20 Nm)

|

-

Install the IWE bolts.

Torque: 106 lb.in (12 Nm)

|

-

Position the wheel speed sensor wire and install the wheel speed sensor wire bracket bolt on the wheel knuckle.

Torque: 18 lb.ft (25 Nm)

|

-

NOTICE: Do not use a hammer to separate the outer tie-rod end from the wheel knuckle or damage to the wheel knuckle may result.

NOTICE: Use care when installing the tie rod separator or damage to the outer tie-rod end boot may occur.

NOTE: Use the hex-holding feature to prevent the stud from turning while installing the nut.

Position the tie rod end and install the new tie rod end nut.

Torque: 76 lb.ft (103 Nm)

|

-

Connect the battery ground cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

-

NOTICE: Do not use power tools to remove the stabilizer bar link nut. Damage to the stabilizer bar link ball joint or boot may occur.

NOTE: The stabilizer bar links are designed with low friction ball joints that have a low breakaway torque.

Use the hex-holding feature to prevent the ball stud from turning while removing or installing the stabilizer bar link nut. Position the front stabilizer bar link and install the new front stabilizer bar link upper nut.

Torque: 59 lb.ft (80 Nm)

|

-

Install the front wheel bearing and wheel hub.

Refer to: Front Wheel Bearing and Wheel Hub (204-01B Front Suspension - LHD 4WD, Removal and Installation).

- If equipped with dynamic suspension, calibrate the suspension height sensor. Connect the scan tool and carry out the Ride Height Calibration routine. Follow the scan tool directions.

Upper Arm. Removal and Installation

Upper Arm. Removal and Installation

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems. Failure of these fasteners

may result in major service expense...

Wheel Studs. Removal and Installation

Wheel Studs. Removal and Installation

Special Tool(s) /

General Equipment

211-023

(T74P-3044-A1)

C-Frame and Screw

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Brake System. Diagnosis and Testing

Global Customer Symptom Code (GCSC) Chart Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Symptom Action Stop/Steer/Ride > Stopping > Performance/Effectiveness > Sticks/Binds GO to Pinpoint Test G Stop/Ste..

Lincoln Navigator 2018-2026 Workshop Manual: Front Seat Backrest. Removal and Installation

Removal WARNING: The following procedure describes critical repair steps required for correct seat component installation. Follow all notes and steps carefully. Do not place any objects between the seat components and the body of the vehicle, nor any objects within a joint internal to the seat structure. Failure to follow step instructions may result in incorrect operatio..

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Remote Function Actuator (RFA) Module. Removal and Installation

- Front Seat. Removal and Installation

- SYNC Module [APIM]. Removal and Installation

- Body and Paint

- Rear Bumper. Removal and Installation

Front Driveshaft. Removal and Installation

Special Tool(s) / General Equipment

Crimping ToolMaterials

Name Specification Motorcraft® Premium Long-Life GreaseXG-1-E1 ESA-M1C75-B

Removal

With the vehicle in NEUTRAL, position the vehicle on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

Remove the bolts and the transmission shield.