Lincoln Navigator: Front Drive Halfshafts / Front Drive Halfshafts. Diagnosis and Testing

Preliminary Inspection

-

Visually inspect the CV joints, housing, boots, and clamps for obvious signs of mechanical damage.

-

If an obvious cause for an observed or reported concern is

found, correct the cause (if possible) before proceeding to the next

step

-

If the cause is not visually evident, verify the symptom and REFER to Symptom Chart: NVH.

Symptom Chart(s)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart: NVH

Symptom Chart

| Condition | Actions |

|---|---|

| Axle howling or whine – front or rear axle | GO to Pinpoint Test A |

| Driveline clunk - loud clunk when shifting from REVERSE to DRIVE | GO to Pinpoint Test B |

| Driveline clunk (Front Wheel Drive (FWD) vehicles) — occurs during acceleration or from cruise to coast/deceleration | GO to Pinpoint Test C |

| Driveline clunk — occurs as the vehicle starts to move forward following a stop | GO to Pinpoint Test D |

| Clicking, popping or grinding - occurs while the vehicle is turning | GO to Pinpoint Test E |

| Grunting — normally associated with a shudder experienced during acceleration from a complete stop | GO to Pinpoint Test F |

| Driveline vibration - occurs at cruising speeds | GO to Pinpoint Test G |

PINPOINT TEST A: AXLE HOWLING OR WHINE – FRONT OR REAR AXLE

PINPOINT TEST A: AXLE HOWLING OR WHINE – FRONT OR REAR AXLE |

Normal Operation and Fault Conditions Halfshafts transmit rotary motion through constant velocity joints in a uniform manner. The outer CV joints use balls, have no length compensation and engage in the wheel hubs. The intermediate shaft (right side) is correctly positioned and secured in the differential by the intermediate shaft center bearing. The left CV joint is locked in the differential by a snap-ring. Possible Sources

|

||||

| A1 INSPECT WHEEL HUB BEARINGS | ||||

Was any wheel hub bearing play or damage found?

|

PINPOINT TEST B: DRIVELINE CLUNK- LOUD CLUNK WHEN SHIFTING FROM REVERSE TO DRIVE

PINPOINT TEST B: DRIVELINE CLUNK- LOUD CLUNK WHEN SHIFTING FROM REVERSE TO DRIVE|

Normal Operation and Fault Conditions Halfshafts transmit rotary motion through constant velocity joints in a uniform manner. The outer CV joints use balls, have no length compensation and engage in the wheel hubs. The intermediate shaft (right side) is correctly positioned and secured in the differential by the intermediate shaft center bearing. The left CV joint is locked in the differential by a snap-ring. Possible Sources

|

||||

| B1 CHECK THE HUB NUT TORQUE | ||||

Is the hub nut loose?

|

||||

| B2 CHECK THE CONSTANT VELOCITY (CV) BOOTS AND JOINTS FOR WEAR OR DAMAGE | ||||

Was damage found?

|

||||

| B3 CHECK THE TORQUE ON SUSPENSION AND STEERING SYSTEM FASTENERS | ||||

Is the any of the suspension and steering fastener loose?

|

PINPOINT

TEST C: DRIVELINE CLUNK (FRONT WHEEL DRIVE (FWD) VEHICLES) — OCCURS

DURING ACCELERATION OR FROM CRUISE TO COAST/DECELERATION

PINPOINT

TEST C: DRIVELINE CLUNK (FRONT WHEEL DRIVE (FWD) VEHICLES) — OCCURS

DURING ACCELERATION OR FROM CRUISE TO COAST/DECELERATION |

Normal Operation and Fault Conditions Halfshafts transmit rotary motion through constant velocity joints in a uniform manner. The outer CV joints use balls, have no length compensation and engage in the wheel hubs. The intermediate shaft (right side) is correctly positioned and secured in the differential by the intermediate shaft center bearing. The left CV joint is locked in the differential by a snap-ring. Possible Sources

|

||||

| C1 CHECK THE HUB NUT TORQUE | ||||

Is the hub nut loose?

|

||||

| C2 CHECK THE CONSTANT VELOCITY (CV) BOOTS AND JOINTS FOR WEAR OR DAMAGE | ||||

Was damage found?

|

||||

| C3 CHECK THE TORQUE ON SUSPENSION AND STEERING SYSTEM FASTENERS | ||||

Is the any of the suspension and steering fastener loose?

|

PINPOINT TEST D: DRIVELINE CLUNK — OCCURS AS THE VEHICLE STARTS TO MOVE FORWARD FOLLOWING A STOP

PINPOINT TEST D: DRIVELINE CLUNK — OCCURS AS THE VEHICLE STARTS TO MOVE FORWARD FOLLOWING A STOP |

Normal Operation and Fault Conditions Halfshafts transmit rotary motion through constant velocity joints in a uniform manner. The outer CV joints use balls, have no length compensation and engage in the wheel hubs. The intermediate shaft (right side) is correctly positioned and secured in the differential by the intermediate shaft center bearing. The left CV joint is locked in the differential by a snap-ring. Possible Sources

|

||||

| D1 CHECK FOR LOOSE HUB NUT | ||||

Are any hub nuts loose?

|

||||

| D2 CHECK THE TORQUE ON SUSPENSION AND STEERING SYSTEM FASTENERS | ||||

Is the any of the suspension and steering fastener loose?

|

PINPOINT TEST E: CLICKING, POPPING OR GRINDING - OCCURS WHILE THE VEHICLE IS TURNING

PINPOINT TEST E: CLICKING, POPPING OR GRINDING - OCCURS WHILE THE VEHICLE IS TURNING |

Normal Operation and Fault Conditions Halfshafts transmit rotary motion through constant velocity joints in a uniform manner. The outer CV joints use balls, have no length compensation and engage in the wheel hubs. The intermediate shaft (right side) is correctly positioned and secured in the differential by the intermediate shaft center bearing. The left CV joint is locked in the differential by a snap-ring. Possible Sources

|

||||

| E1 CHECK THE CONSTANT VELOCITY (CV) BOOTS AND JOINTS FOR WEAR OR DAMAGE | ||||

Was wear or damage found?

|

||||

| E2 CHECK THE HALFSHAFTS FOR CONTACT WITH ANOTHER COMPONENT | ||||

Is there contact between other components with the halfshaft?

|

||||

| E3 INSPECT THE HALFSHAFT OR HALFSHAFT CIRCLIP | ||||

Was any damage found?

|

PINPOINT TEST F: GRUNTING — NORMALLY ASSOCIATED WITH A SHUDDER EXPERIENCED DURING ACCELERATION FROM A COMPLETE STOP

PINPOINT TEST F: GRUNTING — NORMALLY ASSOCIATED WITH A SHUDDER EXPERIENCED DURING ACCELERATION FROM A COMPLETE STOP |

Normal Operation and Fault Conditions Halfshafts transmit rotary motion through constant velocity joints in a uniform manner. The outer CV joints use balls, have no length compensation and engage in the wheel hubs. The intermediate shaft (right side) is correctly positioned and secured in the differential by the intermediate shaft center bearing. The left CV joint is locked in the differential by a snap-ring. Possible Sources

|

||||

| F1 CHECK THE OUTER CONSTANT VELOCITY (CV) JOINT FOR CORRECT SEATING INTO THE HUB | ||||

Is the outer Constant Velocity (CV) joint seated correctly into the hub?

|

PINPOINT TEST G: DRIVELINE VIBRATION - OCCURS AT CRUISING SPEEDS

PINPOINT TEST G: DRIVELINE VIBRATION - OCCURS AT CRUISING SPEEDS |

Normal Operation and Fault Conditions Halfshafts transmit rotary motion through constant velocity joints in a uniform manner. The outer CV joints use balls, have no length compensation and engage in the wheel hubs. The intermediate shaft (right side) is correctly positioned and secured in the differential by the intermediate shaft center bearing. The left CV joint is locked in the differential by a snap-ring. Possible Sources

|

||||

| G1 CHECK THE OUTER CONSTANT VELOCITY (CV) JOINT FOR CORRECT SEATING INTO THE HUB | ||||

Is the outer Constant Velocity (CV) joint seated correctly into the hub?

|

Halfshaft. Removal and Installation

Halfshaft. Removal and Installation

Special Tool(s) /

General Equipment

204-592Separator, Lower Arm Ball JointTKIT-2006C-FFMFLMTKIT-2006C-LMTKIT-2006C-ROW

Tie Rod End Remover

Tire Lever

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Variable Camshaft Timing (VCT) Unit. Removal and Installation

Removal NOTICE: During engine repair procedures, cleanliness is extremely important. Any foreign material, including any material created while cleaning gasket surfaces, that enters the oil passages, coolant passages or the oil pan, can cause engine failure...

Lincoln Navigator 2018-2026 Workshop Manual: Passive Anti-Theft System (PATS) - Overview. Description and Operation

Overview PATS uses the following main components: BCM Keyless entry rear antenna/PATS antenna Passive key PATS front antenna PCM RTM Start/Stop Switch When the START/STOP button is pressed, the key data is read by a PATS antenna...

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Brake Service Mode Activation and Deactivation. General Procedures

- Rear Bumper. Removal and Installation

- Windshield Washer Pump. Removal and Installation

- Vehicle Dynamics Control Module (VDM). Removal and Installation

- Remote Function Actuator (RFA) Module. Removal and Installation

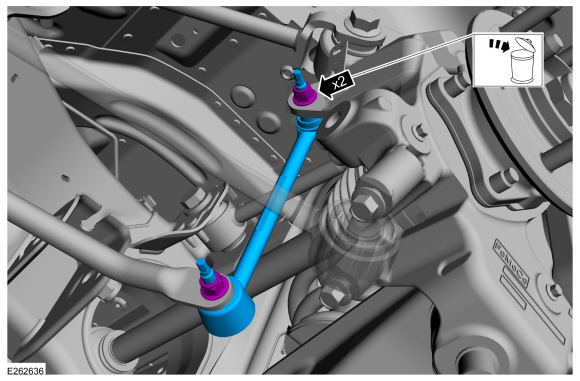

Rear Stabilizer Bar Link. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

With the vehicle in NEUTRAL, position it on a hoist.Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

NOTE: Use the hex-holding feature to prevent the stud from turning while removing the nut.

Remove and discard the 2 rear stabilizer bar link nuts and remove the rear stabilizer bar link.Torque: 46 lb.ft (63 Nm)