Lincoln Navigator: Full Frame and Body Mounting / Frame Members-Rear Frame Section. Removal and Installation

Special Tool(s) / General Equipment

| Grinder | |

| MIG/MAG Welding Equipment |

Removal

-

Restore the vehicle to manufacturer's dimensions.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

-

As equipped.

Refer to: Muffler and Tailpipe (309-00 Exhaust System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

As equipped.

Refer to: Fuel Tank Filler Pipe (310-01 Fuel Tank and Lines - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Refer to: Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation).

-

Remove the spare wheel.

Refer to: Frame and Body Mounting (502-02 Full Frame and Body Mounting, Description and Operation).

-

Unbolt the Front End Sheet Metal (FESM) body mount bolts and raise or remove the body if required.

Refer to: Frame and Body Mounting (502-02 Full Frame and Body Mounting, Description and Operation).

-

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

-

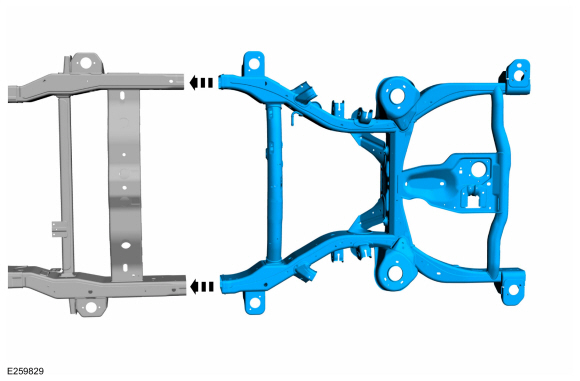

Rear frame section overview.

|

-

Position the vehicle on a frame rack and anchor per manufacturer's instructions.

-

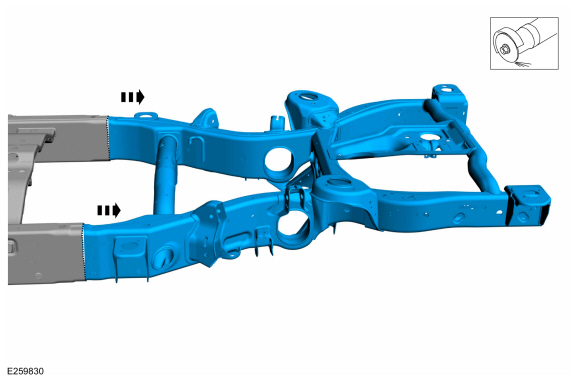

NOTICE: Do not cut directly along the center of the weld line. Leave enough material on the front side of the weld centerline to allow the remaining weld and frame material to be ground back to the front edge of the front mid rail. This is necessary to make sure of correct fit between the frame and the replacement frame section.

NOTE: Use caution not cut into the mid rear side rail as it will be reused.

Using a plasma cutter, reciprocating saw or die-grinder, remove the damaged rear frame section.

-

Separate the ground area of the joints using an air

chisel or similar tool and remove the complete rear frame section.

Use the General Equipment: Grinder

-

Separate the ground area of the joints using an air

chisel or similar tool and remove the complete rear frame section.

|

-

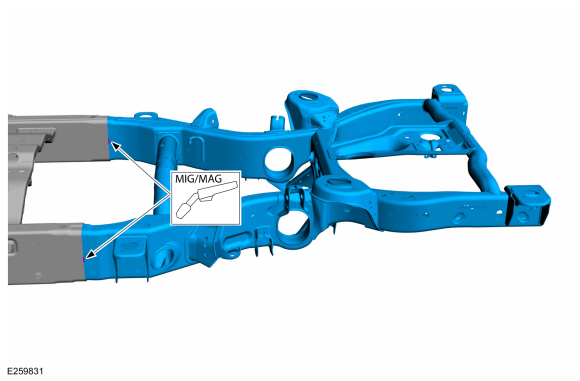

NOTICE: Do not thin out the frame rail. The material must maintain a minimum thickness of 3.1 mm (0.12 in) after grinding. This is required to maintain correct energy management in the event of a collision.

Grind off the excess welding material that remains in rear of the weld line on the frame mid-rail.

Installation

-

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

-

NOTE: Verify dimensional accuracy before performing any welding operations.

Install the new rear frame section into the mid rear section of the frame and tack weld the frame rails.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

|

-

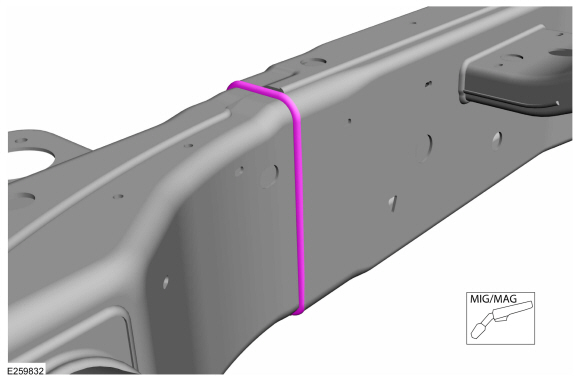

Perform a final measurement, then final weld the new

rear section to the mid rear section on all overlap joints on both

sides.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Metal finish the joint area typical metal finishing techniques.

-

Metal finish the joint area typical metal finishing techniques.

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

NOTICE: To avoid damage to the spare tire winch when installing the spare tire, DO NOT exceed 200 RPM if using power tool equipment.

Install the following items:-

As equipped.

Refer to: Fuel Tank Filler Pipe (310-01 Fuel Tank and Lines - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

As equipped.

Refer to: Muffler and Tailpipe (309-00 Exhaust System - 3.5L EcoBoost (272kW/370PS), Removal and Installation).

-

Refer to: Shock Absorber and Spring Assembly (204-02 Rear Suspension, Removal and Installation).

-

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

-

As equipped.

Frame Members-Front Frame Section. Removal and Installation

Frame Members-Front Frame Section. Removal and Installation

Special Tool(s) /

General Equipment

Grinder

Plasma Cutter

MIG/MAG Welding Equipment

Locking Pliers

Removal

NOTE:

The following procedure provides steps to replace the front

frame short section at the first frame crossmember or the frame section

at the center rail joint depending on the extent of vehicle damage...

Front Bumper Bracket. Removal and Installation

Front Bumper Bracket. Removal and Installation

Special Tool(s) /

General Equipment

Grinder

MIG/MAG Welding Equipment

Locking Pliers

Removal

WARNING:

Frame rail crush zones absorb crash energy during a

collision and must be replaced if damaged...

Other information:

Lincoln Navigator 2018-2026 Workshop Manual: Front Door Lock Control Switch. Removal and Installation

Removal NOTE: LH side shown, RH side similar. Remove the front door trim panel. Refer to: Front Door Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation). Remove the front door lock control switch...

Lincoln Navigator 2018-2026 Workshop Manual: Exhaust Gas Recirculation (EGR) Outlet Tube. Removal and Installation

Removal Remove the engine appearance cover retainers, release the engine appearance cover from the rear retainers and then remove the engine appearance cover. Remove the RH side air cleaner outlet pipe...

Categories

- Manuals Home

- 4th Gen Lincoln Navigator Service Manual (2018 - 2026)

- Identification Codes. Description and Operation

- Rear Bumper. Removal and Installation

- SYNC Module [APIM]. Removal and Installation

- Front Bumper Cover. Removal and Installation

- Remote Function Actuator (RFA) Module. Removal and Installation

Wheel to Hub Runout Minimization. General Procedures

Check

NOTE: Wheel-to-hub optimization is important. Clearance between the wheel and hub can be used to offset or neutralize the Road Force® or run-out of the wheel and tire assembly. For every 0.001 inch of wheel-to-hub clearance, the Road Force® can be affected between 1 and 3 pounds depending on the tire stiffness.

NOTE: The example below illustrates how the clearance between the wheel and the hub can be used to offset the high spot of radial run-out or Road Force®. Following the procedure will make sure of the best optimization.

Position the wheel and tire assembly on the vehicle so that the high spot location of radial run-out or Road Force® is at the 6 o'clock position and